Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (7): 1489-1498.doi: 10.13229/j.cnki.jdxbgxb20210111

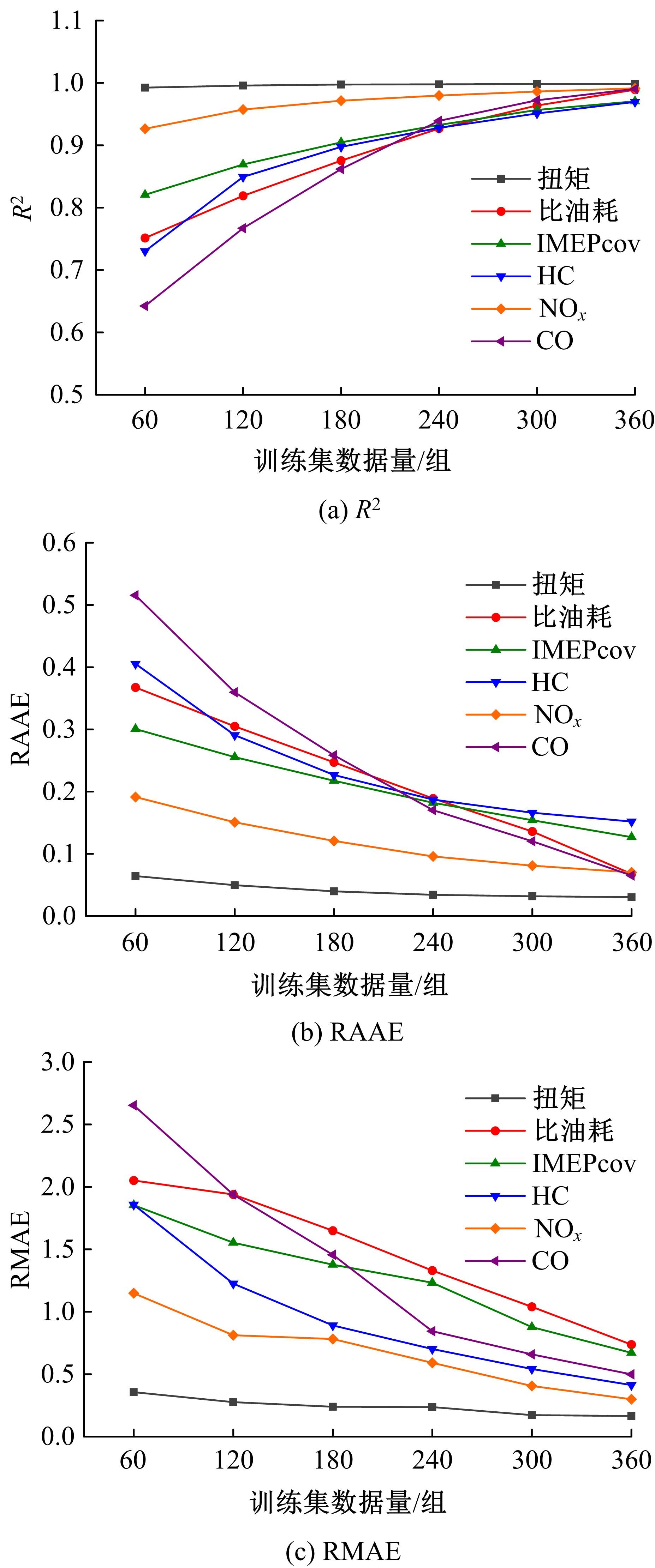

Prediction method of engine performance and emission based on PSO-GPR

Jing QIN1,2( ),De ZHENG1,2,Yi-qiang PEI2,Yong LYU3,Qing-peng SU2,3,Ying-bo WANG2

),De ZHENG1,2,Yi-qiang PEI2,Yong LYU3,Qing-peng SU2,3,Ying-bo WANG2

- 1.Internal Combustion Engine Research Institute,Tianjin University,Tianjin 300072,China

2.State Key Laboratory of Engines,Tianjin University,Tianjin 300072,China

3.GAC Automotive Research & Development Center,Guangzhou 511434,China

CLC Number:

- TK411

| 1 | 张文. 基于运行工况的发动机基本标定研究[D]. 上海:上海交通大学机械与动力工程学院, 2019. |

| Zhang Wen. Research on basic engine calibration based on operating conditions[D]. Shanghai:School of Mechanical Engineering, Shanghai Jiao Tong University, 2019. | |

| 2 | 李志辉. 基于模型的电控发动机标定技术[J]. 内燃机与配件, 2020(21): 71-72. |

| Li Zhi-hui. Model-based electronic-controlled engine calibration technology [J]. Internal Combustion Engine & Parts, 2020(21): 71-72. | |

| 3 | 杜乐. 基于模型的直喷汽油机标定技术研究[D]. 长春:吉林大学机械科学与工程学院, 2013. |

| Du Le. Research on model-based calibration of GDI engine[D]. Changchun: College of Mechanical Sciences and Engineering,Jilin University, 2013. | |

| 4 | Martínez M, Palacios H, Velázquez C. Modeling engine fuel consumption and NO x with RBF neural network and MOPSO algorithm[J]. International Journal of Automotive Technology, 2015, 16(6):1041-1049. |

| 5 | Francesco D N, Giovanni G, Alfredo G, et al. Volumetric efficiency estimation based on neural networks to reduce the experimental effort in engine base calibration[J]. Fuel, 2019, 244: 31-39. |

| 6 | Rask E, Sellnau M. Simulation-based engine calibration: tools, techniques, and applications[J]. SAE Transactions, 2004, 113:821-832. |

| 7 | Gao J, Shen T. Online calibration of spark advance for combustion phase control of gasoline SI engines[C]//Seventh International Conference on Intelligent Control and Information Processing (ICICIP), Dali, China, 2016. |

| 8 | Carvalho R, Machado G B, Colaço M, et al. Estimating gasoline performance in internal combustion engines with simulation metamodels[J]. Fuel, 2017, 193: 230-240. |

| 9 | Zutta E, Acosta D, Andrés D, et al. Development of simulation metamodels to predict the performance and exhaust emission parameters of a spark ignition engine[J]. International Journal on Interactive Design and Manufacturing (IJIDeM), 2020, 14(1):1-12. |

| 10 | 侯献军,高寒,席光维, 等. 基于BP神经网络的发动机最佳点火提前角MAP优化分析[J]. 武汉理工大学学报:交通科学与工程版, 2018, 42(3): 353-356. |

| Hou Xian-jun, Gao Han, Xi Guang-wei, et al. Optimization analysis of engine ignition advance angle MAP based on BP neural network [J]. Journal of Wuhan University of Technology (Traffic Science and Engineering Edition), 2018, 42(3): 353-356. | |

| 11 | 何志昆, 刘光斌, 赵曦晶, 等. 高斯过程回归方法综述[J]. 控制与决策, 2013(8): 1121-1129. |

| He Zhi-kun, Liu Guang-bin, Zhao Xi-jing, et al. A review of gaussian process regression methods[J]. Control and Decision, 2013, 28(8): 1121-1129. | |

| 12 | 王阳, 唐朝晖, 王紫勋, 等. 选用改进高斯过程回归模型的碳排放短期预测[J]. 计算机工程与应用, 2018, 54(23): 246-251, 258. |

| Wang Yang, Tang Chao-hui, Wang Zi-xun, et al. Short-term forecasting of carbon emission by using improved gaussian process regression[J]. Computer Engineering and Applications, 2018, 54(23): 246-251, 258. | |

| 13 | Keprate A, Chandima Ratnayake R M, Sankararaman S. Experimental validation of the adaptive gaussian process regression model used for prediction of stress intensity factor as an alternative to FEM[J]. Journal of Offshore Mechanics and Arctic Engineering, 2018, 141(2):1-11. |

| 14 | 钟美, 赵兵涛, 黄朔. 基于高斯过程回归的燃煤烟气汞排放预测[J]. 动力工程学报, 2016, 36(12): 987-992. |

| Zhong Mei, Zhao Bing-tao, Huang Shuo. Prediction of Mercury emission from coal-fired flue gas based on Gaussian process regression[J]. Chinese Journal of Power Engineering, 2016, 36(12): 987-992. | |

| 15 | 黄南天, 齐斌, 刘座铭, 等. 采用面积灰关联决策的高斯过程回归概率短期负荷预测[J]. 电力系统自动化, 2018, 42(23): 64-71. |

| Huang Nan-tian, Qi Bin, Liu Zuo-ming, et al. Gaussian process regression probability short-term load forecasting based on area grey relational decision[J]. Automation of Electric Power Systems, 2018, 42(23): 64-71. | |

| 16 | 任利强, 张立民, 王海鹏, 等. 基于IPSO-GPR的短期负荷区间预测[J]. 计算机工程与设计, 2019, 40(10): 3002-3008. |

| Ren Li-qiang, Zhang Li-min, Wang Hai-peng, et al. Short-term power load interval forecasting based on improved particle swarm optimization and Gaussian process regression[J]. Computer Engineering and Design, 2019, 40(10): 3002-3008. | |

| 17 | 杜常清, 曹锡良, 何彪, 等. 基于混合粒子群算法的双离合变速器参数优化设计[J]. 吉林大学学报: 工学版, 2020, 50(5): 1556-1564. |

| Du Chang-qing, Cao Xi-liang, He Biao, et al. Parameters optimization of dual clutch transmission based on hybrid particle swarm optimization[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(5): 1556-1564. | |

| 18 | 张静, 刘向东. 混沌粒子群算法优化最小二乘支持向量机的混凝土强度预测[J]. 吉林大学学报: 工学版, 2016, 46(4): 1097-1102. |

| Zhang Jing, Liu Xiang-dong. Prediction of concrete strength based on least square support vector machine optimized by chaotic particle swarm optimization[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(4): 1097-1102. | |

| 19 | 杨景明, 马明明, 车海军, 等. 多目标自适应混沌粒子群优化算法[J]. 控制与决策, 2015, 30(12): 2168-2174. |

| Yang Jing-ming, Ma Ming-ming, Che Hai-jun, et al. Multi-objective adaptive chaotic particle swarm optimization algorithm[J]. Control and Decision, 2015, 30(12): 2168-2174. | |

| 20 | 徐从东, 陈春. 一种自适应动态控制参数的粒子群优化算法[J]. 计算机工程, 2013, 39(10): 203-207. |

| Xu Cong-dong, Chen Chun. A particle swarm optimization algorithm of adaptive dynamic control parameter[J]. Computer Engineering, 2013, 39(10): 203-207. | |

| 21 | 李建平. 仿真元建模中的拟合方法及其应用研究[D]. 长沙:国防科学技术大学计算机学院, 2007. |

| Li Jian-ping. Study on fitting methods of simulation metamodelling and its application[D]. Changsha: College of Computer Science and Technology, National University of Defense Technology, 2007. | |

| 22 | Lee S, Chang J H. On Using Multivariate Polynomial Regression Model with Spectral Difference for Statistical Model-based Speech Enhancement[M]. London: Elsevier North-Holland, Inc., 2016. |

| 23 | 郭栋, 高松, 王晓原, 等. 轻型车微观排放模型的建立与比较分析[J]. 中南大学学报: 自然科学版, 2012, 43(10): 4123-4128. |

| Guo Dong, Gao Song, Wang Xiao-yuan, et al. Comparative analysis of light-duty vehicle emission model[J]. Journal of Central South University (Science and Technology), 2012, 43(10): 4123-4128. |

| [1] | Hai-yan XING,Chao LIU,Cheng XU,Yu-huan CHEN,Song-hong-ze WANG. Quantitative metal magnetic memory classification model of weld grades based on particle swarm optimization fuzzy C⁃means [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 525-532. |

| [2] | Wei LUO,Bo LU,Fei CHEN,Teng MA. Fault diagnosis method of NC turret based on PSO⁃SVM and time sequence [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 392-399. |

| [3] | Chang-qing DU,Xi-liang CAO,Biao HE,Wei-qun REN. Parameters optimization of dual clutch transmission based on hybrid particle swarm optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1556-1564. |

| [4] | Fang-wu MA,Li HAN,Liang WU,Jin-hang LI,Long-fan YANG. Damping optimization of heavy⁃loaded anti⁃vibration platform based on genetic algorithm and particle swarm algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1608-1616. |

| [5] | Xiang-jun YU,Yuan-hui HUAI,Xue-fei LI,De-wu WANG,An YU. Shoveling trajectory planning method for wheel loader based on kriging and particle swarm optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 437-444. |

| [6] | Shun-fu JIN,Xiu-chen QIE,Hai-xing WU,Zhan-qiang HUO. Clustered virtual machine allocation strategy in cloud computing based on new type of sleep-mode and performance optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 237-246. |

| [7] | Hong⁃zhi WANG,Fang⁃da JIANG,Ming⁃yue ZHOU. Power allocation of cognitive radio system based on genetic particle swarm optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1363-1368. |

| [8] | Yuan-ning LIU,Shuai LIU,Xiao-dong ZHU,Guang HUO,Tong DING,Kuo ZHANG,Xue JIANG,Shu-jun GUO,Qi-xian ZHANG. Iris secondary recognition based on decision particle swarm optimization and stable texture [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1329-1338. |

| [9] | Kai XU,Zhi⁃gang CHEN,Jing⁃hua ZHAO,Lu DAI,Feng LI. Layout design method of star sensor based on particle swarm optimization algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 972-978. |

| [10] | ZHAO Dong,SUN Ming-yu,ZHU Jin-long,YU Fan-hua,LIU Guang-jie,CHEN Hui-ling. Improved moth-flame optimization method based on combination of particle swarm optimization and simplex method [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1867-1872. |

| [11] | YANG Shuai, FENG Zhi-wei, ZHAO Zhi-guo, ZHOU Yi. 1-Dimensional simulation analysis about the influence of different Miller cycle strategies on diesel engine operating process [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1444-1454. |

| [12] | LIU Yuan-ning, LIU Shuai, ZHU Xiao-dong, CHEN Yi-hao, ZHENG Shao-ge, SHEN Chun-zhuang. LOG operator and adaptive optimization Gabor filtering for iris recognition [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1606-1613. |

| [13] | ZANG Guo-shuai, SUN Li-jun. Method based on inertial point for setting depth to rigid layer [J]. 吉林大学学报(工学版), 2018, 48(4): 1037-1044. |

| [14] | HUANG Hui, FENG Xi-an, WEI Yan, XU Chi, CHEN Hui-ling. An intelligent system based on enhanced kernel extreme learning machine for choosing the second major [J]. 吉林大学学报(工学版), 2018, 48(4): 1224-1230. |

| [15] | LIU Ying, ZHANG Kai, YU Xiang-jun. Multi-objective optimization of hydrostatic bearing of hollow shaft based on surrogate model [J]. 吉林大学学报(工学版), 2017, 47(4): 1130-1137. |

|

||