Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (9): 2044-2054.doi: 10.13229/j.cnki.jdxbgxb20220215

Matching,simulation and optimization for 2.5 ton fuel cell/battery hybrid forklift

Feng-xiang CHEN1( ),Qi WU1,Yuan-song LI2,Tian-de MO3,Yu LI3,Li-ping HUANG4,Jian-hong SU4,Wei-dong ZHANG5

),Qi WU1,Yuan-song LI2,Tian-de MO3,Yu LI3,Li-ping HUANG4,Jian-hong SU4,Wei-dong ZHANG5

- 1.College of Automotive Studies,Tongji University,Shanghai 201804,China

2.Technical Center,Zhejiang Hangcha Group Co. ,Ltd. ,Hangzhou 311305,China

3.Smart City Division,Hong Kong Productivity Council,Hong Kong 999077,China

4.Electric Forklift Research Institute,JAC Heavy-Duty Construction Machine Co. ,Ltd. ,Hefei 230051,China

5.School of Information and Communication Engineering,Hainan University,Haikou 570228,China

CLC Number:

- U469.72

| 1 | 温序晖, 杨海玉. 叉车用燃料电池概述[J]. 东方电气评论, 2020, 34(1): 6-11. |

| Wen Xu-hui, Yang Hai-yu. Review of fuel cell applied for forklift[J]. Dongfang Electric Review, 2020, 34(1): 6-11. | |

| 2 | 沈忱. 叉车用燃料电池混合动力系统集成及能量管理策略研究[D]. 杭州:浙江大学工程师学院, 2021. |

| Shen Chen. Fuel cell hybrid forklift system integration and research on energy management strategy[D]. Hangzhou: Polytechnic Institute, Zhejiang University, 2021. | |

| 3 | 任春龙. 叉车用PEMFC/蓄电池混合动力系统仿真研究[D]. 哈尔滨:东北林业大学工程技术学院, 2020. |

| Ren Chun-long. Research and Simulation of hybrid power system for fuel cell battery of forklift truck[D]. Harbin: College of Engineering and Technology, Northeast Forestry University, 2020. | |

| 4 | Chan E, Dawson F, Bekker H, et al. A software simulation program for a hybrid fuel cell-battery power supply for an electric forklift[C]∥Proceedings of the 12th European Conference on Power Electronics and Applications, Aalborg, Denmark, 2007: No. 9852408. |

| 5 | Keränen T M, Karimaki H, Viitakangas J, et al. Development of integrated fuel cell hybrid power source for electric forklift[J]. Journal of Power Sources, 2011, 196(21): 9058-9068. |

| 6 | 杨洁. 叉车质子交换膜燃料电池混合动力系统构建与仿真[D]. 哈尔滨:东北林业大学工程技术学院, 2019. |

| Yang Jie. Construction and simulation of hybrid power system for proton exchange membrane fuel cell of forklift[D]. Harbin: College of Engineering and Technology, Northeast Forestry University, 2019. | |

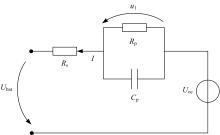

| 7 | Pacheco D S, Gonzalez L G, Espinoza J L, et al. Energy consumption of an electric forklift truck: alternative with fuel cell and supercapacitor[C]∥IEEE International Autumn Meeting on Power, Ixtapa, MEXICO: Electronics and Computing (ROPEC), 2019 :11-15. |

| 8 | Hosseinzadeh E, Rokni M, Advani S G, et al. Performance simulation and analysis of a fuel cell/battery hybrid forklift truck[J]. International Journal of Hydrogen Energy, 2013, 38(11): 4241-4249. |

| 9 | Zhang Z, Mortensen H H, Jensen J V, et al. Fuel cell and battery powered forklifts[C]∥The 9th IEEE Vehicle Power and Propulsion Conference (VPPC), Beijing, China, 2013: No.13917769. |

| 10 | 游志宇. PEMFC混合动力叉车能量管理策略及应用研究[D]. 成都:西南交通大学电气工程学院, 2015. |

| You Zhi-yu. Strategy and application study on energy management of proton exchange membrane fuel cell hybrid forklift[D]. Chengdu: School of Electrical Engineering, Southwest Jiaotong University, 2015. | |

| 11 | Radica G, Tolj I, Markota D, et al. Control strategy of a fuel-cell power module for electric forklift[J]. International Journal of Hydrogen Energy, 2021, 46(72): 35938-35948. |

| 12 | 徐煜超. 燃料电池混合动力叉车动力系统设计研究[D]. 青岛:青岛理工大学汽车与交通学院, 2018. |

| Xu Yu-chao. Design and study of fuel cell hybrid forklift power system[D]. Qingdao: School of Auto and Transportation, Qingdao University of Technology, 2018. | |

| 13 | 周静. 燃料电池混合动力叉车动力系统设计与仿真[D]. 西安:长安大学工程机械学院, 2019. |

| Zhou Jing. Design and simulation of fuel cell hybrid forklift power system[D]. Xi'an: School of Construction Machinery, Chang'an University, 2019. | |

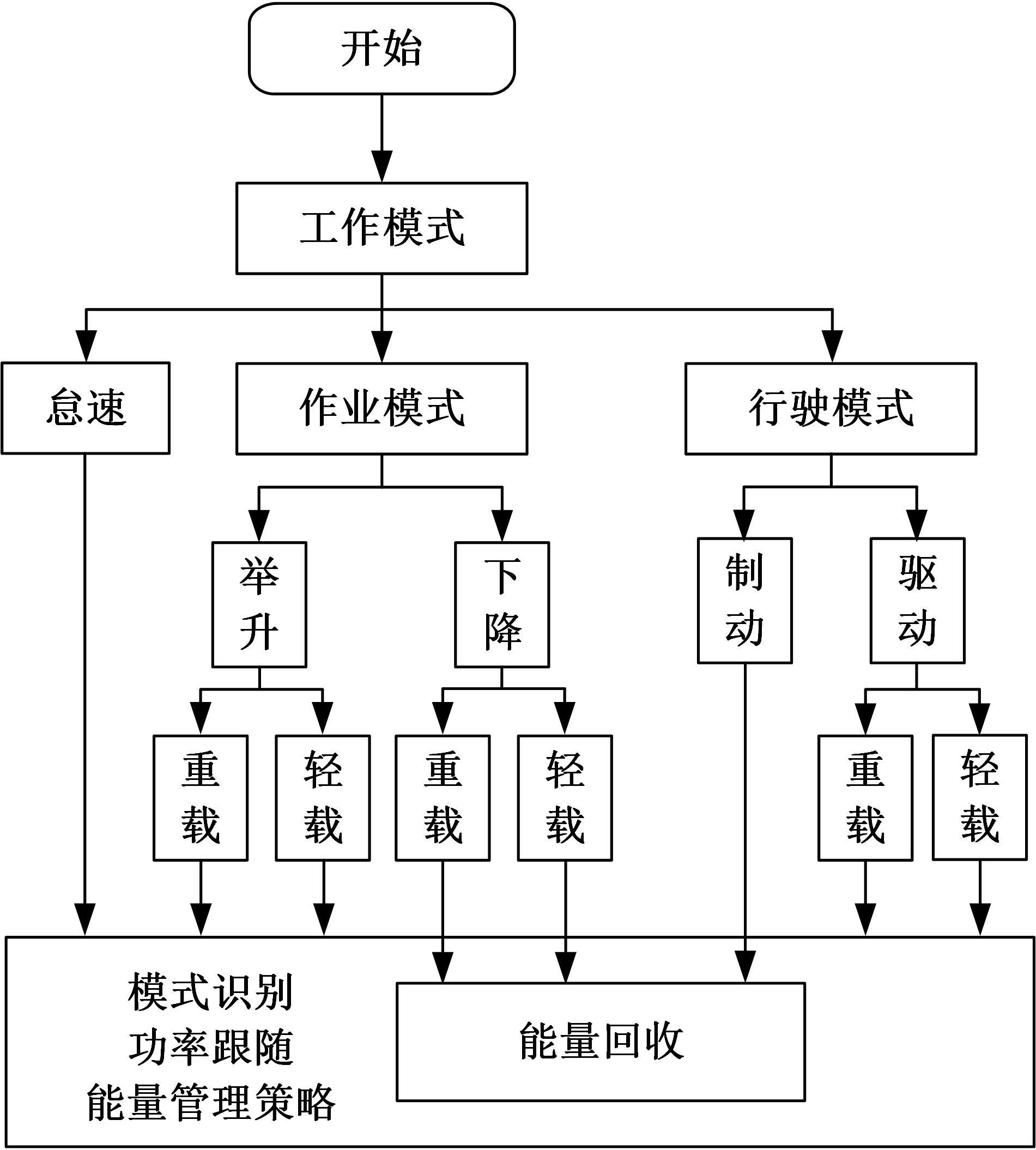

| 14 | 郭高易. 叉车用燃料电池混合动力系统能量管理策略研究[D]. 成都:西南交通大学电气工程学院, 2018. |

| Guo Gao-yi. Research and design of energy management strategy for fuel cell hybrid power system of forklift truck[D]. Chengdu: School of Electrical Engineering, Southwest Jiaotong University, 2018. | |

| 15 | 张德玉. 燃料电池/蓄电池混合动力叉车电源系统设计[D]. 成都:西南交通大学电气工程学院, 2015. |

| Zhang De-yu. Design for power system of fuel cell/battery hybrid forklift[D]. Chengdu: School of Electrical Engineering, Southwest Jiaotong University, 2015. | |

| 16 | 于远彬, 王庆年, 王伟华, 等. 应用复合电源的轻度混合动力汽车的参数匹配[J].吉林大学学报: 工学版, 2009, 39(2): 281-285. |

| Yu Yuan-bin, Wang Qing-nian, Wang Wei-hua, et al. Parameter matching of mild hybrid electric vehicle with compound power supply[J]. Journal of Jilin University(Engineering and Technology Edition), 2009, 39(2): 281-285. | |

| 17 | 余志生. 汽车理论[M]. 5版. 北京:机械工业出版社,2009. |

| 18 | Puranik S V, Keyhani A, Khorrami F. State-space modeling of proton exchange membrane fuel cell[J]. Ieee Transactions on Energy Conversion, 2010, 25(3): 804-813. |

| 19 | O'hayre R, Cha S-W, Colella W, et al. Fuel Cell Fundamentals[M]. Hoboken, US: John Wiley & Sons, 2016. |

| 20 | 王哲, 谢怡, 臧鹏飞, 等. 基于极小值原理的燃料电池客车能量管理策略[J]. 吉林大学学报: 工学版, 2020, 50(1): 36-43. |

| Wang Zhe, Xie Yi, Zang Peng-fei, et al. Energy management strategy of fuel cell bus based on Pontryagin's minimum principle[J]. Journal of Jilin University(Engineering and Technology Edition), 2020,50(1):36-43. | |

| 21 | Nemes R, Ciornei S, Ruba M, et al. Modeling and simulation of first-order Li-Ion battery cell with experimental validation[C]∥Proceedings of the 8th International Conference on Modern Power Systems(MPS), Cluj-Napoca, Romania, 2019: 21-23. |

| 22 | 匡累, 黄振华, 严杰, 等. 关于燃料电池电动汽车能耗计算方法的研究[J]. 现代车用动力, 2021, 46(3): 47-50. |

| Kuang Lei, Huang Zhen-hua, Yan Jie, et al. Research on calculation method of fuel cell electric vehicle power consumption[J]. Modern Vehicle Power, 2021, 46(3): 47-50. | |

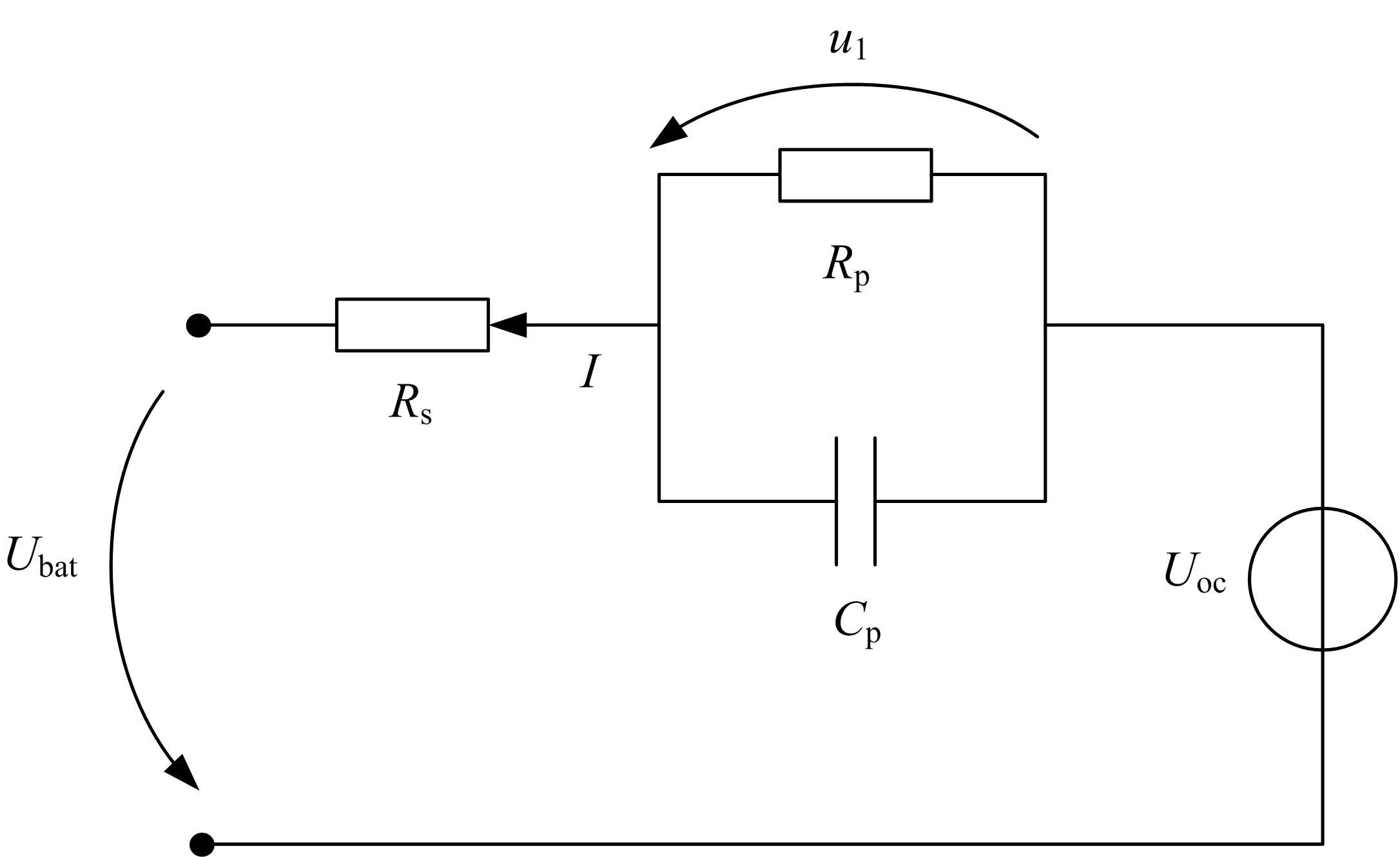

| 23 | 强维博. 叉车混合动力系统设计及控制策略研究 [D]. 长沙: 中南大学机电工程学院, 2013. |

| Qiang Wei-bo. Hybrid power-train system design and research on control strategy for forklift[D]. Changsha: College of Mechanical and Electrical Engineering, Central South University, 2013. | |

| 24 | . 平衡重式叉车整机试验方法 [S]. |

| 25 | 张涛, 宋珂, 章桐. 基于经济性的燃料电池汽车混合度对比研究[J]. 机电一体化, 2015, 21(7): 11-16. |

| Zhang Tao, Song Ke, Zhang Tong. Comparative study on degree of hybridization for fuel cell electric vehicle based on economy[J]. Mechatronics, 2015, 21(7): 11-16. |

| [1] | Pei ZHANG,Zhi-wei WANG,Chang-qing DU,Fu-wu YAN,Chi-hua LU. Oxygen excess ratio control method of proton exchange membrane fuel cell air system for vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 1996-2003. |

| [2] | Xun-cheng CHI,Zhong-jun HOU,Wei WEI,Zeng-gang XIA,Lin-lin ZHUANG,Rong GUO. Review of model⁃based anode gas concentration estimation techniques of proton exchange membrane fuel cell system [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 1957-1970. |

| [3] | Yao-wang PEI,Feng-xiang CHEN,Zhe HU,Shuang ZHAI,Feng-lai PEI,Wei-dong ZHANG,Jie-ran JIAO. Temperature control of proton exchange membrane fuel cell thermal management system based on adaptive LQR control [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2014-2024. |

| [4] | Kui-yang WANG,Ren HE. Recognition method of braking intention based on support vector machine [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1770-1776. |

| [5] | Qing GAO,Hao-dong WANG,Yu-bin LIU,Shi JIN,Yu CHEN. Experimental analysis on spray mode of power battery emergency cooling [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1733-1740. |

| [6] | Jun-cheng WANG,Lin-feng LYU,Jian-min LI,Jie-yu REN. Optimal sliding mode ABS control for electro⁃hydraulic composite braking of distributed driven electric vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1751-1758. |

| [7] | Han-wu LIU,Yu-long LEI,Xiao-feng YIN,Yao FU,Xing-zhong LI. Multi⁃point control strategy optimization for auxiliary power unit of range⁃extended electric vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1741-1750. |

| [8] | Hong-bo YANG,Wen-ku SHI,Zhi-yong CHEN,Nian-cheng GUO,Yan-yan ZHAO. Optimization of tooth surface modification based on a two-stage reduction gear system [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1541-1551. |

| [9] | Guang-ming NIE,Bo XIE,Yan-tao TIAN. Design of cooperative adaptive cruise control algorithm based on Frenet framework [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1687-1695. |

| [10] | Shuai HAO,Chuan-tai CHENG,Jun-nian WANG,Jun-yuan ZHANG,You YU. Ergonomic optimization and test evaluation of sports SUV cockpit layout design [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1477-1488. |

| [11] | Jia-xu ZHANG,Chong GUO,Chen WANG,Jian ZHAO,Xin-zhi WANG. Performance evaluation of automatic parking system based on hardware in the loop simulation platform [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1552-1560. |

| [12] | Chen HUA,Run-xin NIU,Biao YU. Methods and applications of ground vehicle mobility evaluation [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1229-1244. |

| [13] | Xiong LI,Feng-chong LAN,Ji-qing CHEN,Fang TONG. Comparison of injuries in front impact between Hybird III dummy model and CHUBM human biomechanical model [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1264-1272. |

| [14] | Ying-chao ZHANG,Yun-hang LI,Zi-yu GUO,Guo-hua WANG,Zhe ZHANG,Chang SU. Optimization of the aerodynamic drag reduction of a cab behind engine vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 745-753. |

| [15] | Wen-ku SHI,Shu-guang ZHANG,You-kun ZHANG,Zhi-yong CHEN,Yi-fei JIANG,Bin-bin LIN. Parameter identification of magnetorheological damper model with modified seagull optimization algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 764-772. |

|

||