Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (2): 333-345.doi: 10.13229/j.cnki.jdxbgxb.20221099

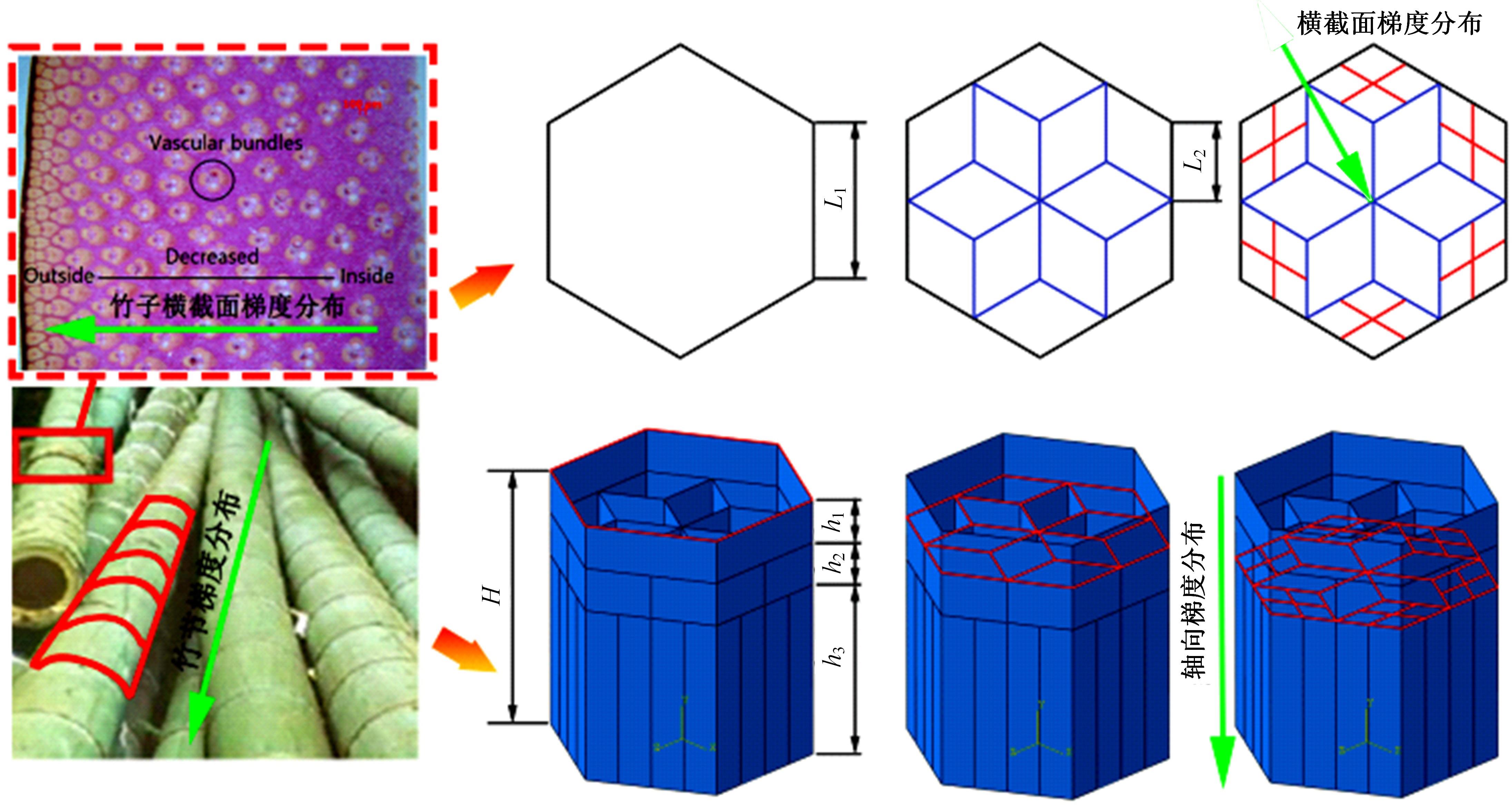

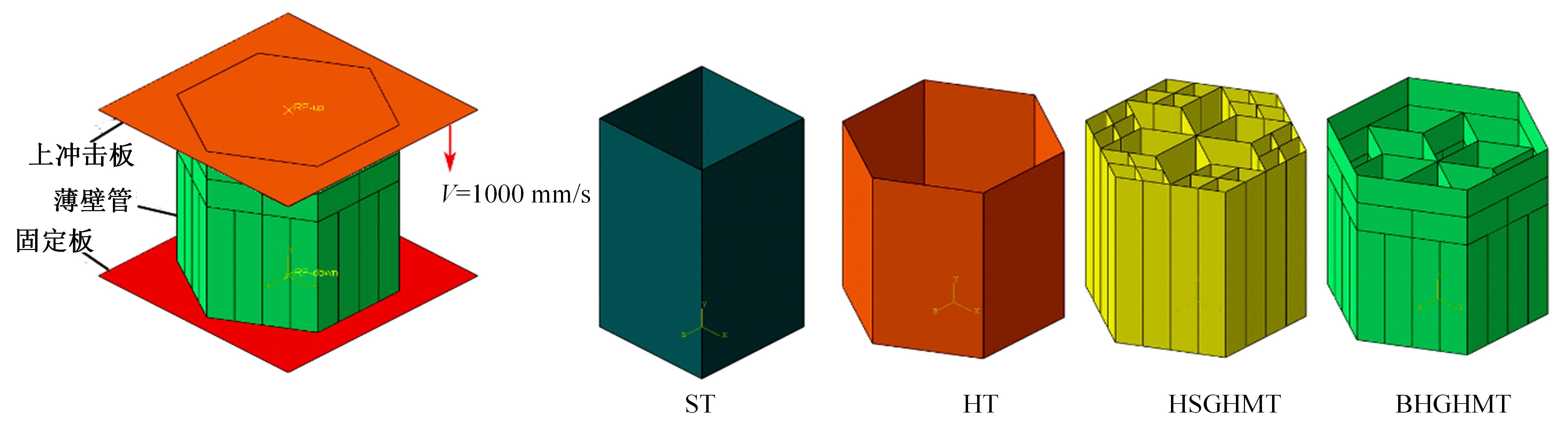

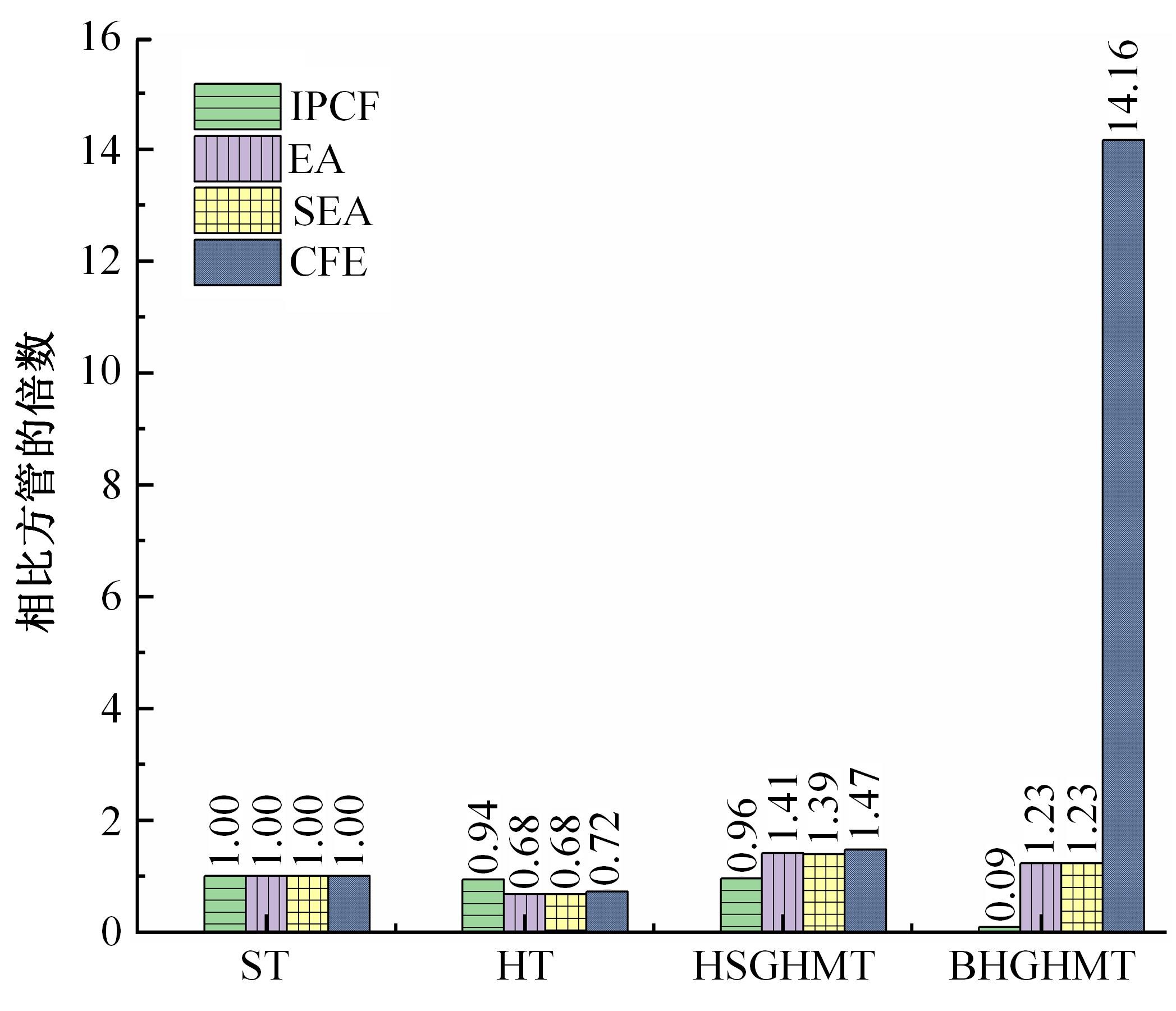

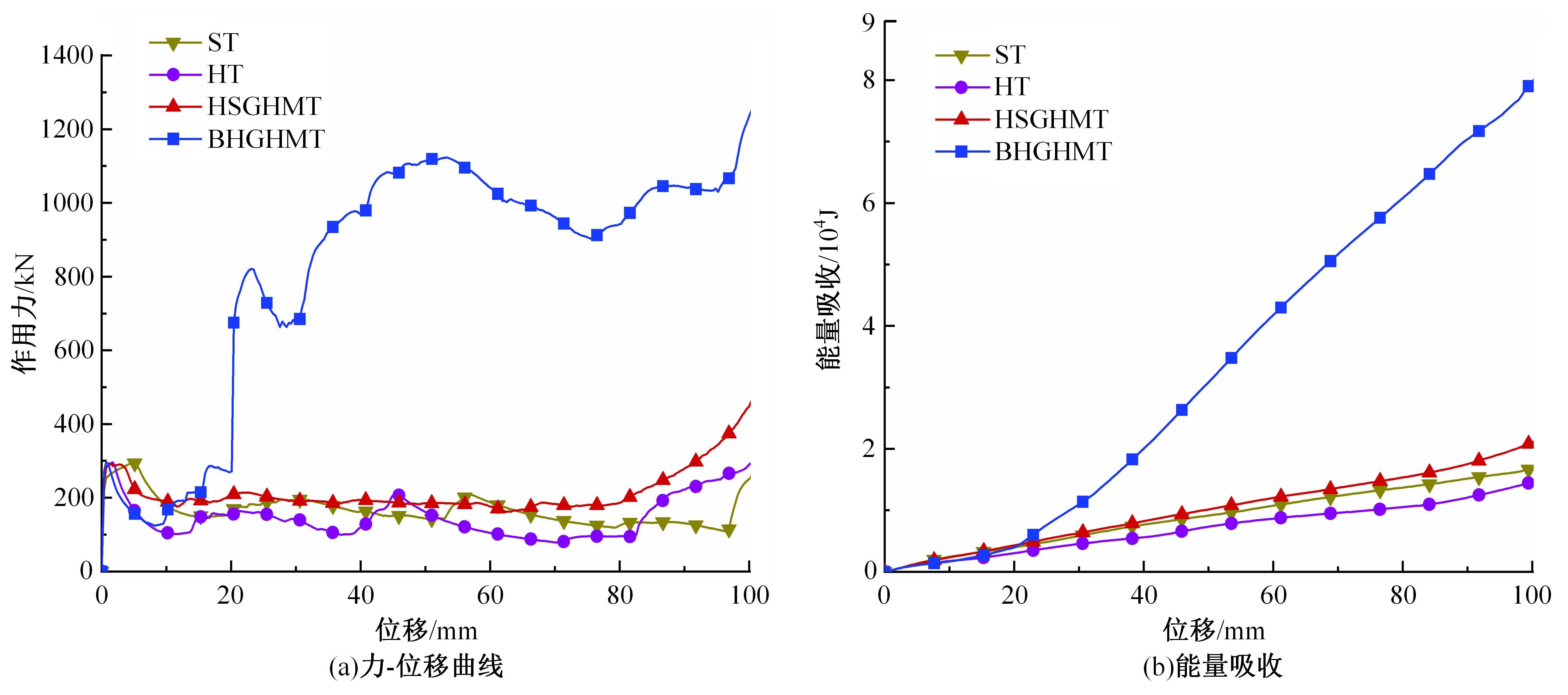

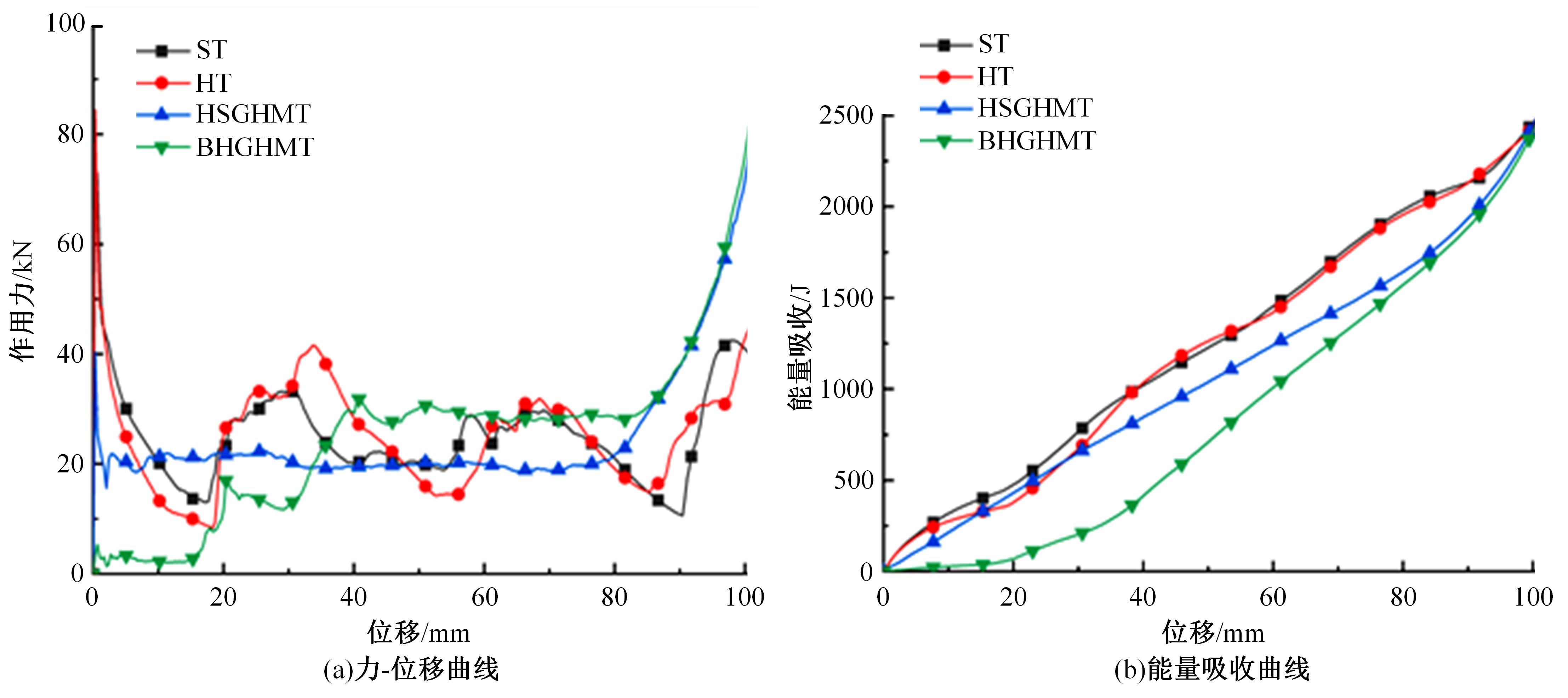

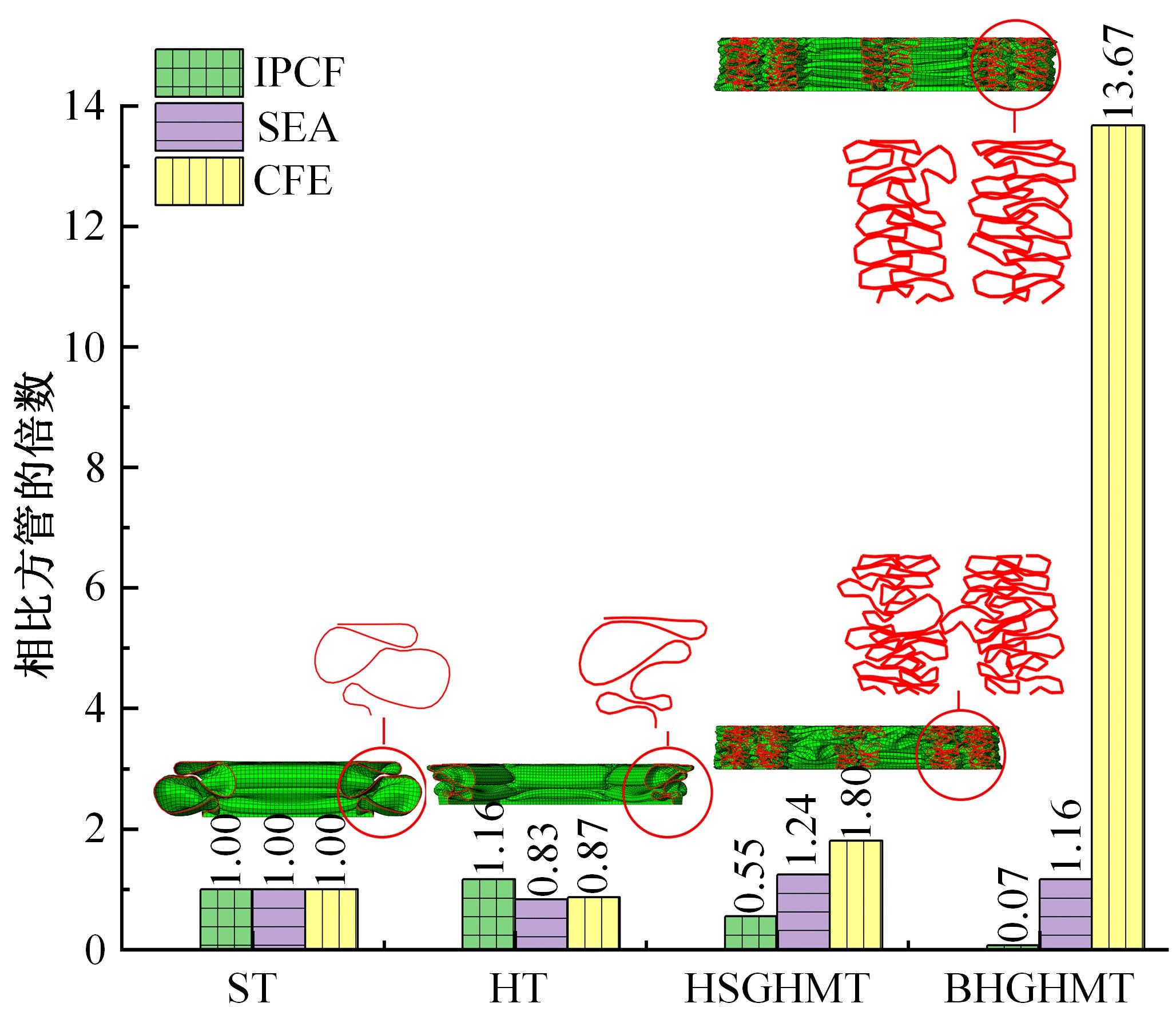

Comparative analysis on crashworthiness of a novel bamboo⁃like hexagonal gradient hierarchical multicellular tube

Xiao-lin DENG1( ),Fu-mo YANG2,Shan-gan QIN2

),Fu-mo YANG2,Shan-gan QIN2

- 1.School of Electronics and Information Engineering,Wuzhou University,Wuzhou 543002,China

2.School of Mechanical Engineering,Guangxi University,Nanning 530004,China

CLC Number:

- U463.8

| 1 | Patel V, Tiwari G, Dumpala R, et al. Review of the crushing response of collapsible tubular structures[J]. Frontiers of Mechanical Engineering, 2020, 15(3): 438-474. |

| 2 | Wang Z, Lei Z, Li Z, et al. Mechanical reinforcement mechanism of a hierarchical Kagome honeycomb[J]. Thin-Walled Structures, 2021, 167: 108235. |

| 3 | Tan H L, He Z C, Li K X, et al. In-plane crashworthiness of re-entrant hierarchical honeycombs with negative Poisson's ratio[J]. Composite Structures, 2019, 229: 111415. |

| 4 | Lu Q, Qi D, Li Y, et al. Impact energy absorption performances of ordinary and hierarchical chiral structures[J]. Thin-Walled Structures, 2019, 140: 495-505. |

| 5 | 邹猛, 于用军, 张荣荣, 等. 仿牛角结构薄壁管吸能特性仿真分析[J]. 吉林大学学报: 工学版, 2015, 45(6): 1863-1868. |

| Zou Meng, Yu Yong-jun, Zhang Rong-rong, et al. Simulation analysis of energy-absorption properties of thin-wall tube based on horn structure[J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45(6): 1863-1868. | |

| 6 | 黄晗, 闫庆昊, 向枳昕, 等. 基于虾螯的仿生多胞薄壁管耐撞性分析及优化[J]. 吉林大学学报: 工学版, 2022, 52(3): 716-724. |

| Huang Han, Yan Qing-hao, Xiang Zhi-xin, et al. Crashworthiness investigation and optimization of bionic multi-cell tube based on shrimp chela[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(3): 716-724. | |

| 7 | Xu S, Li W, Li L, et al. Crashworthiness design and multi-objective optimization for bio-inspired hierarchical thin-walled structures[J]. Computer Modeling in Engineering & Sciences, 2022, 131(2): 929-947. |

| 8 | Li W, Fan H. Crushing behavior of hierarchical hexagonal thin-walled steel tubes under oblique impact[J]. International Journal of Steel Structures, 2020, 21(1): 202-212. |

| 9 | Wang Z, Li Z, Shi C, et al. Mechanical performance of vertex-based hierarchical vs square thin-walled multi-cell structure[J]. Thin-Walled Structures, 2019, 134: 102-110. |

| 10 | Zhang S, Fan T. Impact behaviour of hexagonal hierarchical honeycombs[J]. Journal of Sandwich Structures & Materials, 2022, 24(3): 1597-1610. |

| 11 | Zhang X, Shen Z, Wu H, et al. In-plane dynamic crushing behaviors of joint-based hierarchical honeycombs with different topologies[J]. Journal of Sandwich Structures & Materials, 2021, 23(8): 4218-4251. |

| 12 | Huang W, Zhang Y, Xu Y, et al. Out-of-plane mechanical design of bi-directional hierarchical honeycombs[J]. Composites Part B: Engineering, 2021, 221: 109012. |

| 13 | Zhang D, Fei Q, Liu J, et al. Crushing of vertex-based hierarchical honeycombs with triangular substructures[J]. Thin-Walled Structures, 2020, 146: 106436. |

| 14 | Tao Y, Li W, Cheng T, et al. Out-of-plane dynamic crushing behavior of joint-based hierarchical honeycombs[J]. Journal of Sandwich Structures & Materials, 2020, 23(7): 2832-2855. |

| 15 | Ha N S, Pham T M, Hao H, et al. Energy absorption characteristics of bio-inspired hierarchical multi-cell square tubes under axial crushing[J]. International Journal of Mechanical Sciences, 2021, 201: 106464. |

| 16 | Ha N S, Pham T M, Chen W, et al. Crashworthiness analysis of bio-inspired fractal tree-like multi-cell circular tubes under axial crushing[J]. Thin-Walled Structures, 2021, 169: 108315. |

| 17 | Wu J, Zhang Y, Zhang F, et al. A bionic tree-liked fractal structure as energy absorber under axial loading[J]. Engineering Structures, 2021, 245: 112914. |

| 18 | He Q, Wang Y, Gu H, et al. The dynamic behavior of fractal-like tubes with Sierpinski hierarchy under axial loading[J]. Engineering with Computers, 2021(1): 012756. |

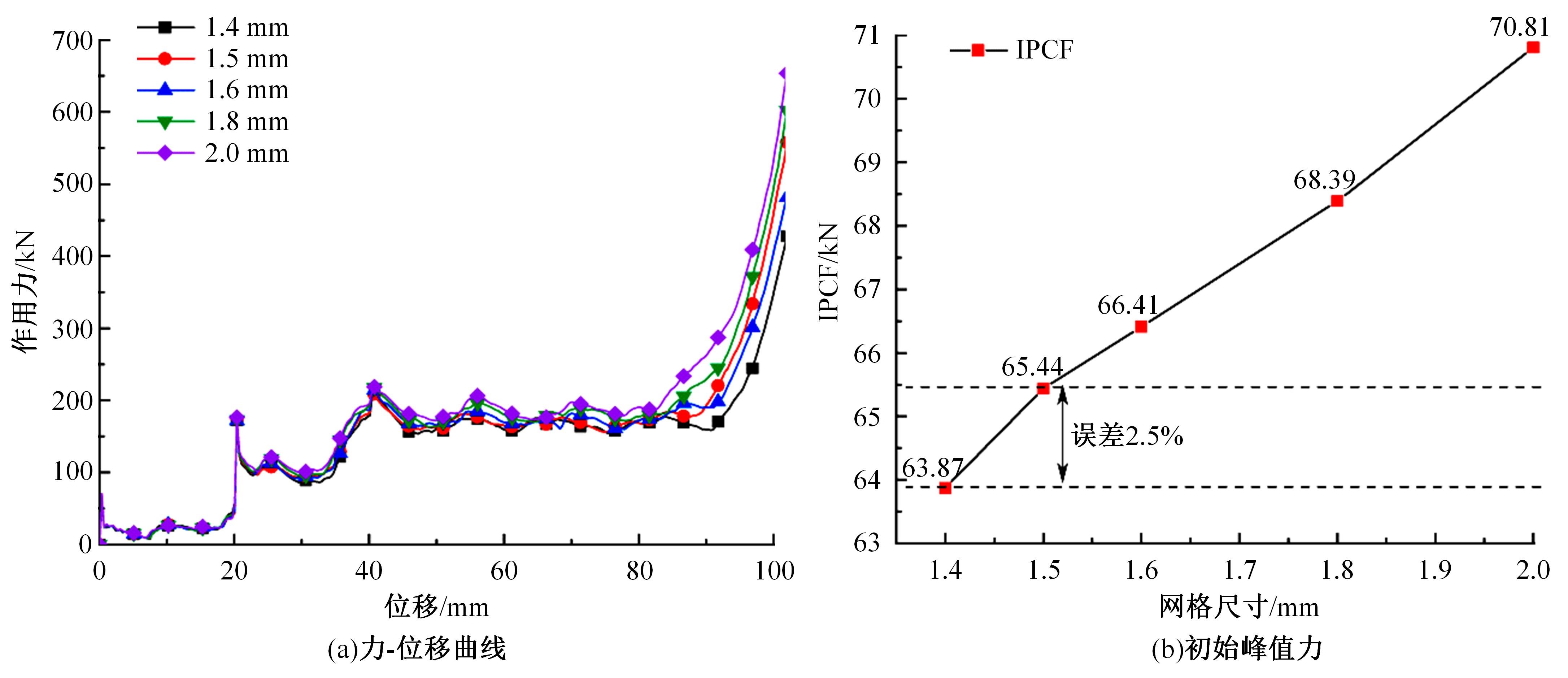

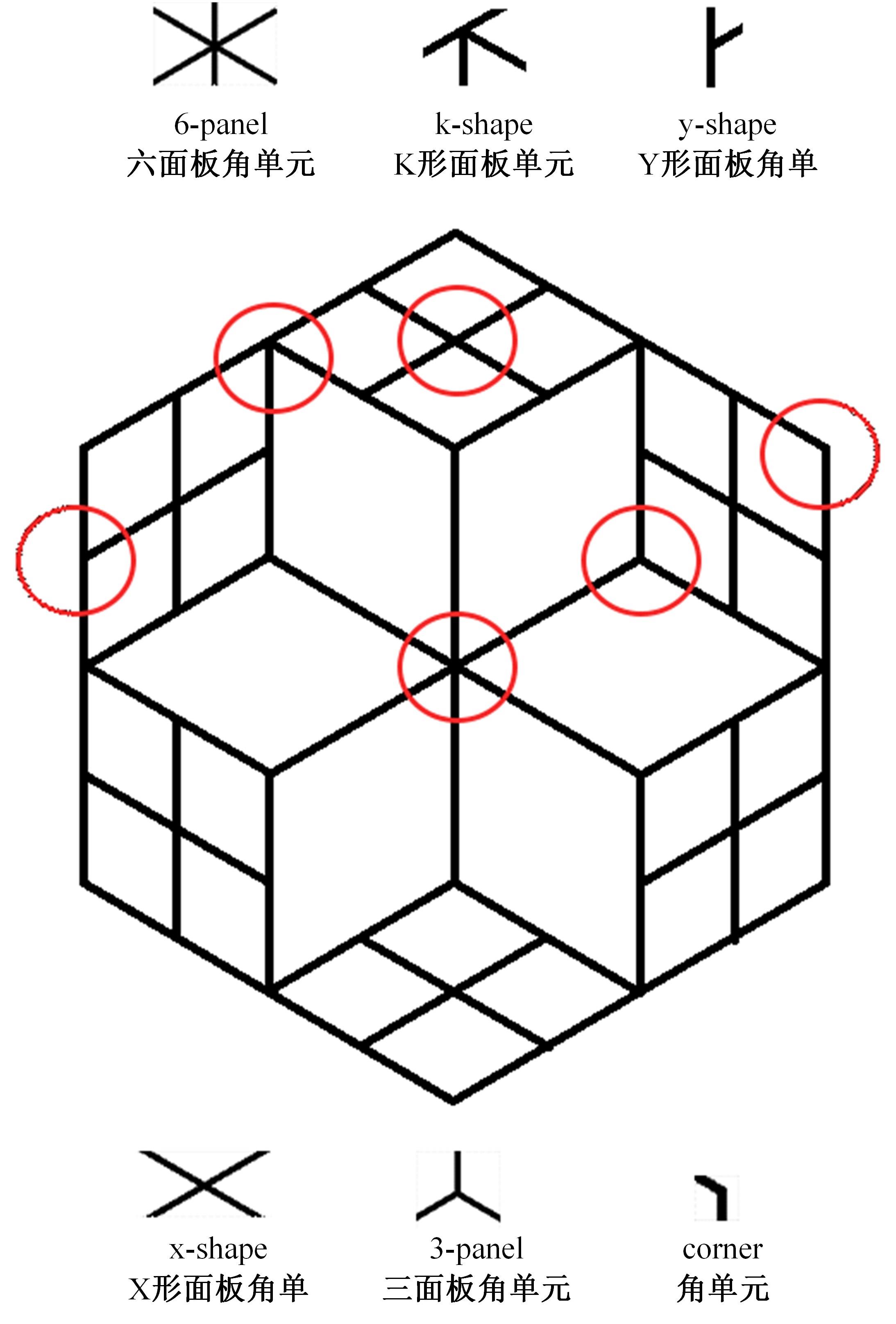

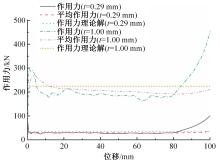

| 19 | Deng X, Qin S, Huang J. Crashworthiness analysis of gradient hierarchical multicellular columns evolved from the spatial folding[J]. Materials & Design, 2022, 215: 110435. |

| 20 | Deng X, Qin S, Huang J. Multiobjective optimization of axially varying thickness lateral corrugated tubes for energy absorption[J]. Mechanics of Advanced Materials and Structures, 2021(1): 1924901. |

| 21 | Zhou J, Qin R, Chen B. Energy absorption properties of multi-cell thin-walled tubes with a double surface gradient[J]. Thin-Walled Structures, 2019, 145: 106386. |

| 22 | Zheng J, Qin Q, Wang T J. Impact plastic crushing and design of density-graded cellular materials[J]. Mechanics of Materials, 2016, 94: 66-78. |

| 23 | Karagiozova D, Alves M. Propagation of compaction waves in cellular materials with continuously varying density[J]. International Journal of Solids and Structures, 2015, 71: 323-337. |

| 24 | Zou M, Xu S, Wei C, et al. A bionic method for the crashworthiness design of thin-walled structures inspired by bamboo[J]. Thin-Walled Structures, 2016, 101: 222-230. |

| 25 | Pirmohammad S, Saravani S A. Crashworthiness performance of stiffened foam-filled tapered structures under axial and oblique dynamic loads[J]. Latin American Journal of Solids and Structures, 2018, 15(5): 1-15. |

| 26 | Zhang Y, He N, Song X, et al. On impacting mechanical behaviors of side fractal structures[J]. Thin-Walled Structures, 2020, 146: 1-9. |

| 27 | Ha N S, Pham T M, Hao H, et al. Energy absorption characteristics of bio-inspired hierarchical multi-cell square tubes under axial crushing[J]. International Journal of Mechanical Sciences, 2021, 201: 17-25. |

| 28 | Zheng G, Wu S, Sun G, et al. Crushing analysis of foam-filled single and bitubal polygonal thin-walled tubes[J]. International Journal of Mechanical Sciences, 2014, 87: 226-240. |

| 29 | Zhang L, Bai Z, Bai F. Crashworthiness design for bio-inspired multi-cell tubes with quadrilateral, hexagonal and octagonal sections[J]. Thin-Walled Structures, 2018, 122: 42-51. |

| 30 | Zhang X, Cheng G, Zhang H. Theoretical prediction and numerical simulation of multi-cell square thin-walled structures[J]. Thin-Walled Structures, 2006, 44(11): 1185-1191. |

| [1] | Yong-zhong ZHANG,Yun-hai MA. New honeycomb multi-stage thin-walled structure with high efficiency energy absorption characteristics [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 259-267. |

| [2] | Tie WANG,Xu-dong LI,Cheng TIAN,Hong-wei ZHAO. Building biaxial fatigue damage model of wheel rims based on multi-axial loads projection theory [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 99-104. |

| [3] | Xu-dong LI,Xin-yu WANG,Cheng TIAN,Xin-feng ZHANG,Zhi-hui NIU,Zhi-qiang ZHAO. Compiling vehicle durability load spectrum based on customer usage correlation [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 66-75. |

| [4] | Zhao-wei CHEN,Qian-hua PU. Suppression characteristics of vehicle⁃bridge coupling vibration of long⁃span cable⁃stayed bridge with resilient wheels [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2519-2532. |

| [5] | Ping-yi LIU,Xiao-ting LI,Ruo-lin GAO,Hai-tao LI,Wen-jun WEI,Ya WANG. Design and experiment of tilt-driving mechanism for the vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2185-2192. |

| [6] | Xue-jin HUANG,Jin-xing ZHONG,Jing-yu LU,Ji ZHAO,Wei XIAO,Xin-mei YUAN. Electric vehicle charging load forecasting method based on user portrait [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2193-2200. |

| [7] | Shu-pei ZHANG,Ming-yue XIA,Wei ZHANG,Zhao CHEN,Yi-xiang CHEN. Impact dynamic modeling and simulation for ball joint with clearance considering nonlinear stiffness [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2227-2235. |

| [8] | Hui CHEN,Ya-jun SHAO. Measurement method of pavement surface spectrum with multi⁃sensor coupling based on inertial benchmark [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2254-2262. |

| [9] | Lei CHEN,Yang WANG,Zhi-sheng DONG,Ya-qi SONG. A vehicle agility control strategy based on steering intent [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1257-1263. |

| [10] | Xin CHEN,Guan-chen ZHANG,Kang-ming ZHAO,Jia-ning WANG,Li-fei YANG,De-rong SITU. Influence of lap welds on the lightweight design of welded aluminum structures [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1282-1288. |

| [11] | Yong ZHANG,Feng-zhao MAO,Shui-chang LIU,Qing-yu WANG,Shen-gong PAN,Guang-sheng ZENG. Optimization on distortion grid of vehicle external flow field based on Laplacian Algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1289-1296. |

| [12] | Shao-hua WANG,Kun CHU,De-hua SHI,Chun-fang YIN,Chun LI. Robust compound coordinated control of HEV based on finite⁃time extended state observation [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1272-1281. |

| [13] | Yan-li YIN,Xue-jiang HUANG,Xiao-liang PAN,Li-tuan WANG,Sen ZHAN,Xin-xin ZHANG. Hierarchical control of hybrid electric vehicle platooning based on PID and Q⁃Learning algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1481-1489. |

| [14] | Gui-shen YU,Xin CHEN,Zi-tao WU,Yi-xiong CHEN,Guan-chen ZHANG. Analysis of microstructure and mechanical properties of probeless friction stir spot welding joint in AA6061⁃T6 aluminum thin plate [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1338-1344. |

| [15] | Yan-tao TIAN,Xing HUANG,Hui-qiu LU,Kai-ge WANG,Fu-qiang XU. Multi⁃mode behavior trajectory prediction of surrounding vehicle based on attention and depth interaction [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1474-1480. |

|

||