Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (2): 375-384.doi: 10.13229/j.cnki.jdxbgxb.20220350

Adaptive vibration type flexible mechanical weeding test between rice plants

Xue-shen CHEN( ),Yue-song XIONG,Nan CHENG,Xu MA(

),Yue-song XIONG,Nan CHENG,Xu MA( ),Long QI

),Long QI

- College of Engineering,South China Agricultural University,Guangzhou 510642,China

CLC Number:

- S237

| 1 | 张帅. 我国主要农作物田杂草防控技术[J]. 杂草学报, 2020,38(2): 50-55. |

| Zhang Shuai. Weed control techniques in farmland of China[J]. Journal of Weeds, 2020, 38(2): 50-55. | |

| 2 | 金远明,王传惠,吴富梅,等. 化学除草组合用药对直播水稻田杂草的药效实验[J]. 湖北植保,2019(5): 14-15. |

| Jin Yuan-ming, Wang Chuan-hui, Wu Fu-mei, et al. Chemical herbicide combination drug effectiveness experiment on live rice field weeds[J]. Hubei Plant Protection, 2019(5): 14-15. | |

| 3 | 李杨,马智宏,李冰茹,等. 我国主要作物中除草剂登记情况及存在问题[J]. 食品安全质量检测学报,2018,9(17): 4483-4488. |

| Li Yang, Ma Zhi-hong, Li Bing-ru, et al. Registration status and existing problems of herbicides in the major crops in China[J]. Journal of Food Safety and Quality, 2018, 9(17): 4483-4488. | |

| 4 | 董立尧,高原,房加鹏,等. 我国水稻田杂草抗药性研究进展[J]. 植物保护,2018,44(5): 69-76. |

| Dong Li-yao, Gao Yuan, Fang Jia-peng, et al. Research progress on the herbicide-resistance of weeds in rice fields in China[J]. Journal of Plant protection, 2018, 44(5): 69-76. | |

| 5 | 齐月,李俊生,闫冰,等. 化学除草剂对农田生态系统野生植物多样性的影响[J]. 生物多样性,2016,24(2): 228-236. |

| Qi Yue, Li Jun-sheng, Yan Bing, et al. Impact of herbicides on wild plant diversity in agro-ecosystems[J]. Biodiversity Science, 2016, 24(2): 228-236. | |

| 6 | 崔思远,曹光乔,张文毅,等. 适宜机插株行距促进水稻生长提高产量[J]. 农业工程学报,2014,30(22): 37-43. |

| Cui Si-yuan, Cao Guang-qiao, Zhang Wen-yi, et al. Suitable mechanical transplanting spacing promoting rice growth and increasing rice yield[J]. Transactions of the Chinese Society of Agricultural Engineering, 2014, 30(22): 37-43. | |

| 7 | 胡雅杰,邢志鹏,龚金龙,等. 适宜机插株行距提高不同穗型粳稻产量[J]. 农业工程学报,2013,29(14): 33-44. |

| Hu Ya-jie, Xing Zhi-peng, Gong Jin-long, et al. Suitable spacing in and between rows of plants by machinery improves yield of different panicle type japonica rices[J]. Transactions of the Chinese Society of Agricultural Engineering, 2013, 29(14): 33-44. | |

| 8 | 齐龙,梁仲维,蒋郁,等. 轻型水田除草机的设计及试验[J]. 吉林大学学报: 工学版,2016,46(3): 1004-1012. |

| Qi Long, Liang Zhong-wei, Jiang Yu, et al. Design and field test of lightweight paddy weeder[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(3): 1004-1012. | |

| 9 | 齐龙,刘闯,蒋郁. 水稻机械除草技术装备研究现状及智能化发展趋势[J]. 华南农业大学学报,2020,41(6): 29-36. |

| Qi Long, Liu Chuang, Jiang Yu. Present status and intelligent development prospects of mechanical weeding technology and equipment for rice[J]. Journal of South China Agricultural University, 2020, 41(6): 29-36. | |

| 10 | 王金武,李超,李鑫,等. 铺膜插秧后水田3SCJ-1型除草机设计与试验[J]. 农业机械学报,2018,49(4): 102-109. |

| Wang Jin-wu, Li Chao, Li Xin, et al. Design and experiment of 3SCJ-1 type weeding machine for paddy field applied to film mulching and transplanting[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(4): 102-109. | |

| 11 | 马旭,齐龙,梁柏,等. 水稻田间机械除草装备与技术研究现状及发展趋势[J]. 农业工程学报,2011,27(6): 162-168. |

| Ma Xu, Qi Long, Liang Bo, et al. Present status and prospects of mechanical weeding equipment and technology in paddy field[J]. Transactions of the Chinese Society of Agricultural Engineering, 2011, 27(6): 162-168. | |

| 12 | Ishii H, Satho M. Three performance of paddy weeding machine and improvements in the performance[J]. The Crop Science Society of Japan, 2006, 21: 22-23. |

| 13 | 牛春亮,王金武,唐继武,等. 稻田株间除草弹齿齿形及安装方式分析与试验[J]. 农机化研究,2017,39(12): 176-179. |

| Niu Chun-liang, Wang Jin-wu, Tang Ji-wu, et al. Analysis and test on weed-tooth type and installation mode of inter-plant weeds in rice field[J]. Journal of Agricultural Mechanization Research, 2017, 39(12): 176-179. | |

| 14 | 牛春亮,王金武,马莉莎,等. 双弧形水稻株间除草部件设计及切土轨迹研究[J]. 农机化研究,2016,38(12): 122-126. |

| Niu Chun-liang, Wang Jin-wu, Ma Li-sha, et al. Double curved rice strains between analysis and design of key components weeding setsudo track[J]. Journal of Agricultural Mechanization Research, 2016, 38(12): 122-126. | |

| 15 | 三菱農機株式会社,株式会社キュウホー.除草機[P].2007105006,[2007-04-26]. |

| 16 | 周福君,王文明,李小利, 等. 凸轮摇杆式摆动型玉米株间除草装置设计与试验[J]. 农业机械学报,2018,49(1): 77-85. |

| Zhou Fu-jun, Wang Wen-ming, Li Xiao-li, et al. Design and experiment of cam rocker swing intra-row weeding device for Maize[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(1): 77-85. | |

| 17 | 吴崇友,张敏,金诚谦,等. 2BYS-6型水田中耕除草机设计与试验[J]. 农业机械学报,2009,40(7): 51-54. |

| Wu Chong-you, Zhang Min, Jin Cheng-qian, et al. Design and experiment of 2BYS6 type paddy weeding-cultivating machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(7): 51-54. | |

| 18 | 王金峰,高观保,闫东伟,等. 水田电动双行深施肥除草机设计与试验[J]. 农业机械学报,2018,49(7): 46-57. |

| Wang Jin-feng, Gao Guan-bao, Yan Dong-wei, et al. Design and experiment of electric control double row deep fertilizing weeder in paddy field[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(7): 46-57. | |

| 19 | 王金武,李超,李鑫,等. 铺膜插秧后水田3SCJ-1型除草机设计与试验[J]. 农业机械学报,2018,49(4): 102-109. |

| Wang Jin-wu, Li Chao, Li Xin, et al. Design and experiment of 3SCJ-1 type weeding machine for paddy field applied to film mulching and transplanting[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(4): 102-109. | |

| 20 | 王金峰,王金武,闫东伟,等. 3SCJ-2型水田行间除草机设计与试验[J]. 农业机械学报,2017,48(6): 71-78. |

| Wang Jin-feng, Wang Jin-wu, Yan Dong-wei, et al. Design and experiment of 3SCJ-2 type row weeding machine for paddy field[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(6): 71-78. | |

| 21 | 董春华,曾希柏,刘强,等. 有机无机肥配施对晚稻产量和杂草群落的影响[J]. 核农学报, 2016, 30(9): 1815-1823. |

| Dong Chun-hua, Zeng Xi-bai, Liu Qiang, et al. Effects of combined application of organic and inorganic fertilizer on weed community and late rice yield[J]. Journal of Nuclear Agriculture, 2016, 30(9): 1815-1823. | |

| 22 | 郭保卫,许轲,张洪程,等. 有序摆抛栽超高产栽培对水稻根系形态生理特征的影响[J]. 中国水稻科学,2016,30(6): 611-625. |

| Guo Bao-wei, Xu Ke, Zhang Hong-cheng, et al. Effect of ordered transplanting and optimized broadcasting on rice root system morphological and physiological characteristics under super high-yielding cultivation[J]. Journal of China Rice Science, 2016, 30(6): 611-625. | |

| 23 | 邱佩,崔远来,韩焕豪,等. 淹灌和间歇灌溉对晚稻田杂草群落多样性的影响[J]. 农业工程学报,2015,31(22): 115-121. |

| Qiu Pei, Cui Yuan-lai, Han Huan-hao, et al. Effect of flooding irrigation and intermittent irrigation patterns on weed community diversity in late rice fields[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(22): 115-121. | |

| 24 | 董春华,刘强,高菊生,等. 不同施肥模式下水稻生育期间杂草群落特征[J]. 草业学报,2013,22(3): 218-226. |

| Dong Chun-hua, Liu Qiang, Gao Ju-sheng, et al. Effects of different fertilization models on the characteristics of weed communities during the rice growing seasons[J]. Acta Prataculturae Sinica, 2013, 22(3): 218-226. | |

| 25 | 郑文汉,齐龙,曹聪,等. 分蘖期深施液体氮肥对水稻分蘖及产量影响[J]. 农机化研究,2020,42(7): 160-165. |

| Zheng Wen-han, Qi Long, Cao Cong, et al. Effects of deep placement liquid fertilizer in tillering stage on tillering dynamics and yield components[J]. Journal of Agricultural Mechanization Research, 2020, 42(7): 160-165. | |

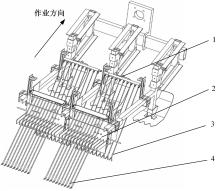

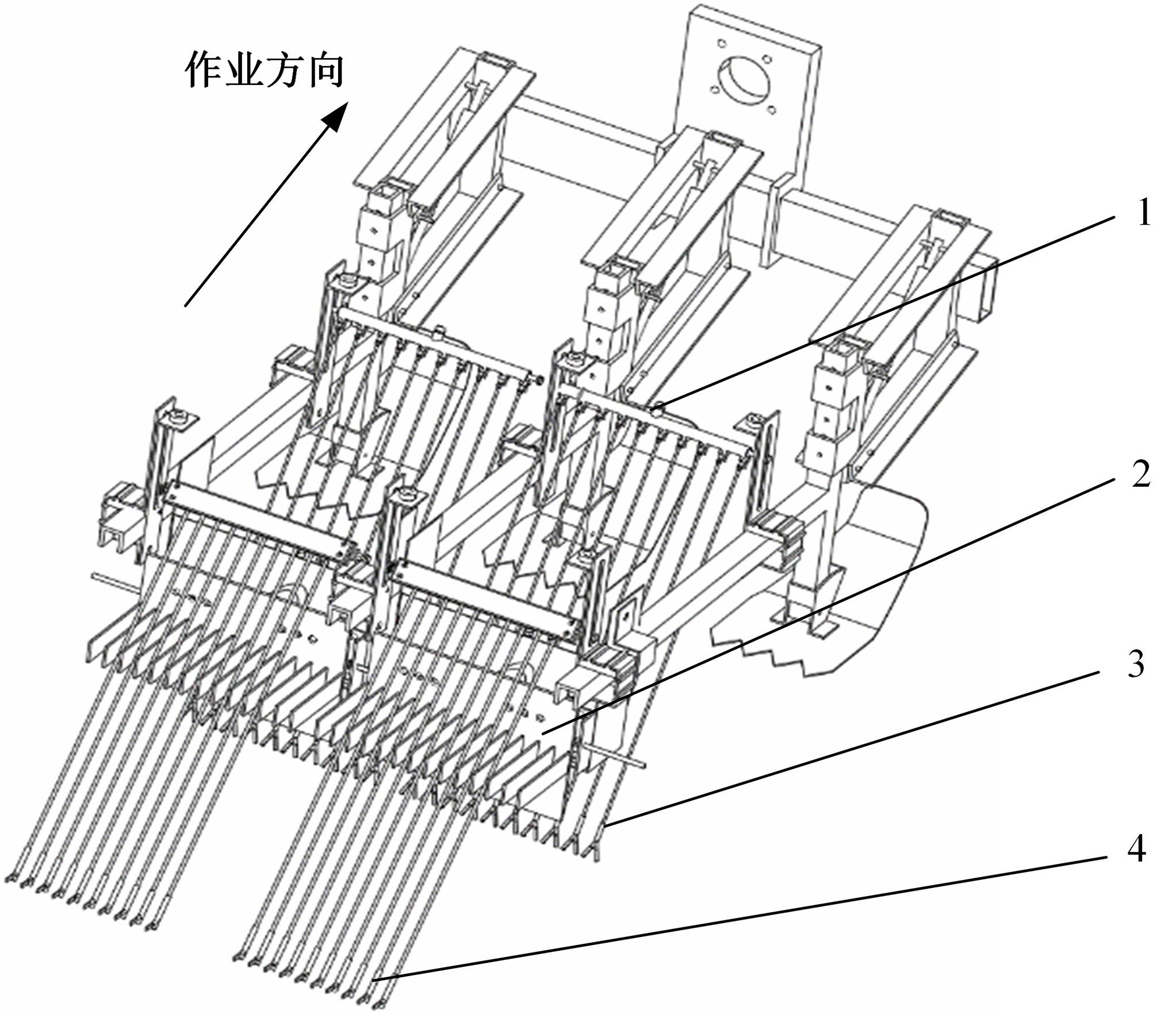

| 26 | 齐龙,赵柳霖,马旭,等. 3GY-1920型宽幅水田中耕除草机的设计与试验[J]. 农业工程学报,2017,33(8): 47-55. |

| Qi Long, Zhao Liu-lin, Ma Xu, et al. Design and test of 3GY-1920 wide-swath type weeding-cultivating machine for paddy[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(8): 47-55. | |

| 27 | 郭洁,陈祥献,黄海,等. 基于峰度的电力变压器铁芯松动故障在线监测方法[J]. 仪器仪表学报,2010,31(11): 2401-2407. |

| Guo Jie, Chen Xiang-xian, Huang Hai, et al. Application of kurtosisin online detection of transformer iron coreloosenes[J]. Chinese Journal of Scientific Instrument, 2010, 31(11): 2401-2407. | |

| 28 | 杨兆升,王媛,管青. 基于支持向量机方法的短时交通流量预测方法[J]. 吉林大学学报: 工学版, 2006, 36(6): 881-884. |

| Yang Zhao-sheng, Wang Yuan, Guan Qing. Short-time traffic prediction method based on SVM[J]. Journal of Jilin University (Engineering and Technology Edition), 2006, 36(6): 881-884. |

| [1] | Guo-jun YANG,Ya-hui QI,Xiu-ming SHI. Review of bridge crack detection based on digital image technology [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 313-332. |

| [2] | Hao YUE,Qi-yue ZHANG,Zi-yu YANG,Meng-jie REN,Xu ZHANG. Iterative weighted algorithms of static congestion traffic assignment considering spatial queuing [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 136-145. |

| [3] | Fu-zeng YANG,Jing-bin SUN,Ya-nan LI,Ya-zhou ZHANG,Zhi-jie LIU. Design and performance test of image transmission remote control mower in closed orchard [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 281-293. |

| [4] | Wei-jian LIU,Xi-wen LUO,Shan ZENG,Zhi-qiang WEN,Li ZENG. Field turning mechanism and performance test of crawler reclaimed rice harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2695-2705. |

| [5] | Peng-ju LIU. Design of automatic identification algorithm for Internet of Things security situation based on deep neural network [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2121-2126. |

| [6] | Ya-li ZHANG,Rui FU,Wei YUAN,Ying-shi GUO. Classification and recognition model of entering and leaving stops' driving style considering energy consumption [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2029-2042. |

| [7] | Chen JIN,Meng-yuan ZENG,Di-fei WU. Damage identification of concrete pavement joint using vibration transmissibility [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1736-1745. |

| [8] | Guo-jin TAN,Qing-wen KONG,Xin HE,Pan ZHANG,Run-chao YANG,Yang-jun CHAO,Zhong YANG. Bridge scour depth identification based on dynamic characteristics and improved particle swarm optimization algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1592-1600. |

| [9] | Yun-long ZHANG,Jia-yuan ZHANG,Xue-song QIAN,Pan ZHANG,Run-chao YANG. Spectrum⁃driven methods for modal parameter identification of bridge under environmental excitation [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1580-1591. |

| [10] | Qing-xia ZHANG,Ji-lin HOU,Xin-hao AN,Xiao-yang HU,Zhong-dong DUAN. Road roughness identification method based on vehicle impulse response [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1765-1772. |

| [11] | Lei CHEN,Yang WANG,Zhi-sheng DONG,Ya-qi SONG. A vehicle agility control strategy based on steering intent [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1257-1263. |

| [12] | Peng YU,Yan PIAO. New method for extracting person re-identification attributes based on multi-scale features [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1155-1162. |

| [13] | Guo WANG,Wen-kai GUO,Chang-chun WANG. Overview and prospect of distribution network topology identification [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 312-327. |

| [14] | Shan ZENG,Deng-pan HUANG,Wen-wu YANG,Wei-jian LIU,Zhi-qiang WEN,Li ZENG. Design and test of the chassis of triangular crawler reclaiming rice harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1943-1950. |

| [15] | Wei LI,Hai-sheng SONG,Hao-yu LU,Wen-ku SHI,Qiang WANG,Xiao-jun WANG. Linear identification method of hysteresis characteristic of composite leaf springs [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 829-836. |

|

||