Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (9): 2460-2468.doi: 10.13229/j.cnki.jdxbgxb.20221503

Ground⁃based experiments of measuring flame speed for combustion science rack aboard china space station

Yu FANG1,2( ),De-qing MEI3,Hui-long ZHENG1,Xiao-fang YANG1,Hai-long WU4,Xiao-wu ZHANG1

),De-qing MEI3,Hui-long ZHENG1,Xiao-fang YANG1,Hai-long WU4,Xiao-wu ZHANG1

- 1.Institute of Engineering Thermophysics,Chinese Academy of Sciences,Beijing 100190,China

2.School of Engineering Science,University of Chinese Academy of Sciences,Beijing 100049,China

3.School of Automotive and Traffic Engineering,Jiangsu University,Zhenjiang 212013,China

4.School of Energy and Environment,Shenyang Aerospace University,Shengyang 110136,China

CLC Number:

- V419/TK16

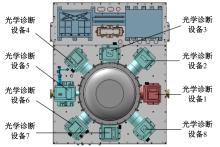

| 1 | 张晓武,郑会龙,王琨,等. 中国空间站燃烧科学实验系统燃烧室设计与分析[J]. 空间科学学报,2021,41(2):301-309. |

| Zhang Xiao-wu, Zheng Hui-long, Wang Kun, et al. Combustion chamber design and analysis of the space station combustion science experimental system[J]. Chinese Journal of Space Science, 2021, 41(2): 301-309. | |

| 2 | 商兰, 王宝瑞, 刘闯, 等. 微重力燃烧实验系统多功能支撑平板结构设计[J]. 空间科学学报,2018,38(4): 524-529. |

| Shang Lan, Wang Bao-rui, Liu Chuang, et al. Structure design of multifunctional supporting bench in the microgravity combustion science experimental system[J]. Chinese Journal of Space Science, 2018, 38(4): 524-529. | |

| 3 | Ando S, Wu Y, Nakaya S, et al. Droplet combustion behavior of oxidatively degraded methyl laurate and methyl oleate in microgravity[J]. Combustion and Flame, 2020, 214: 199-210. |

| 4 | Wu C, Sun P, Wang X, et al. Flame extinction of spherical PMMA in microgravity: effect of fuel diameter and conduction[J]. Microgravity Science and Technology, 2020, 32(6): 1065-1075. |

| 5 | Masato M, Kodai M, Yasuko Y, et al. Space-based microgravity experiments on flame spread over randomly distributed n-decane-droplet clouds: anomalous behavior in flame spread[J]. Proceedings of the Combustion Institute, 2020, 38(2): 3167-3174. |

| 6 | Ju Y, Reuter C, Yehia O, et al. Dynamics of cool flames[J]. Progress in Energy and Combustion Science, 2019, 75: 1-39. |

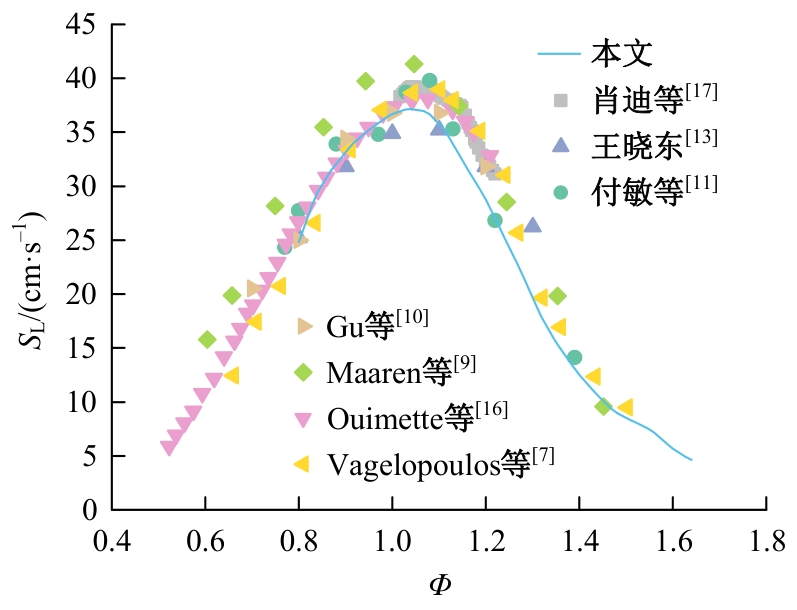

| 7 | Vagelopoulos C, Egolfopoulos F. Direct experimental determination of laminar flame speeds[J]. Symposium on Combustion, 1998, 27(1): 513-519. |

| 8 | 王峰. 富氧燃烧中CO2对烷烃C1-C3火焰传播速度的影响[D]. 武汉: 华中科技大学能源与动力工程学院, 2018: 5-6. |

| Wang Feng. The effects of CO2 on the laminar flame speed of C1-C3 alkanes in O2/CO2 atmospheres [D]. Wuhan: School of Energy and Power Engineering, Huazhong University of Science and Technology,2018: 5-6. | |

| 9 | Maaren V, Thung D, Goeyl D. Measurement of flame temperature and adiabatic burning velocity of methane/air mixtures[J]. Combustion Science and Technology, 1994, 96(4-6): 327-344. |

| 10 | Gu X, Haq M, Lawes M, et al. Laminar burning velocity and markstein lengths of methane-air mixtures[J]. Combustion and Flame, 2000, 121(1-2): 41-58. |

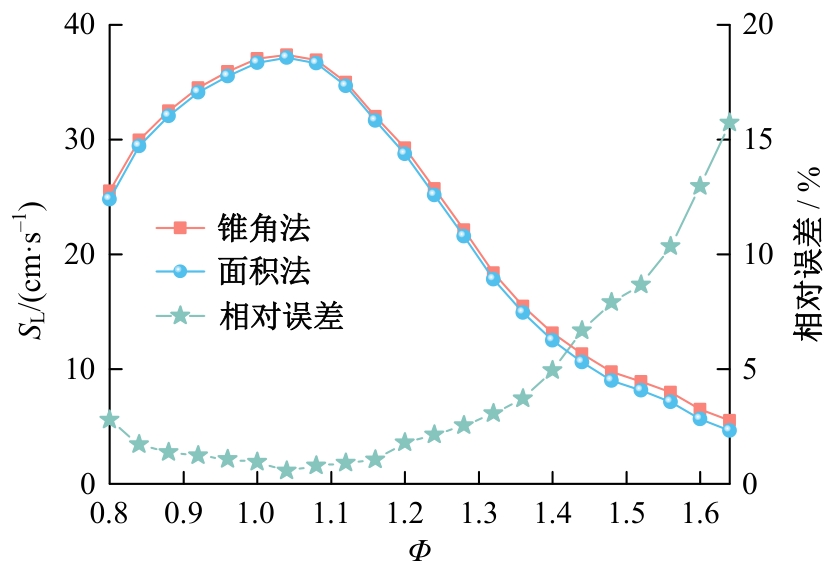

| 11 | 付敏, 王林, 任常兴. 基于MATLAB图像处理的层流火焰传播速度研究[J]. 安全与环境学报, 2017, 17(4): 1354-1359. |

| Fu Min, Wang Lin, Ren Chang-xing. Study on the laminar flame spreading speed based on the MATLAB image process ing technology[J]. Journal of Safety and Environmen, 2017, 17(4): 1354-1359. | |

| 12 | Law C. A Compilation of Experimental Data on Laminar Burning Velocities[M]. Berlin, Heidelberg: Springer, 1993. |

| 13 | 王晓东. 基于定容燃烧弹的甲烷-氧气-水蒸气混合气的层流火焰特性研究[D]. 合肥: 合肥工业大学汽车与交通工程学院, 2019: 35-38. |

| Wang Xiao-dong. Laminar flame characteristics research of methane-oxygen-water mixture based on constant volume combustion bomb[D]. Hefei: School of Automotive and Transportation Engineering, Hefei University of Technology,2019: 35-38. | |

| 14 | Andrews G, Bradley D. The burning velocity of methane-air mixtures[J]. Combustion and Flame, 1972, 19(2): 275-288. |

| 15 | Mohamad M, James C. Burning velocities of mixtures of air with methanol, isooctane, and indolene at high pressure and temperature[J]. Combustion and Flame, 1982, 48: 191-210. |

| 16 | Ouimette P, Seers P. Numerical comparison of premixed laminar flame velocity of methane and wood syngas[J]. Fuel, 2009, 88(3): 528-533. |

| 17 | 肖迪,廉静,纪少波,等. 臭氧对甲烷/空气层流火焰传播速度影响规律[J]. 山东大学学报: 工学版,2017,47(4):59-63. |

| Xiao Di, Lian Jing, Ji Shao-bo, et al. Influence of ozone addition on laminar flame speed in methane-air lean mixtures[J]. Journal of Shandong University (Engineering Science), 2017, 47(4): 59-63. | |

| 18 | 王岩,王宝瑞,王岳. 流预混火焰自由基特性研究[J]. 光谱学与光谱分析,2022,42(8):2403-2410. |

| Wang Yan, Wang Bao-rui, Wang Yue. Study on radical characteristics of methane laminar premixed flame based on hyperspectral technology[J]. Spectroscopy and Spectral Analysis, 2022, 42(8): 2403-2410. | |

| 19 | 秦静, 徐鹤, 裴毅强, 等. 初始温度和初始压力对甲烷-甲醇裂解气预混层流燃烧特性的影响[J]. 吉林大学学报: 工学版, 2018, 48(5): 1475-1482. |

| Qin Jing, Xu He, Pei Yi-qiang, et al. Influence of initial temperature and initial pressure on premixed laminar burning characteristics of methane-dissociated methanol flames[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(5): 1475-1482. |

| [1] | De-xing WANG,Kai GAO,Hong-chun YUAN,Yu-rui YANG,Yue WANG,Ling-dong KONG. Underwater image enhancement based on color correction and TransFormer detail sharpening [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(3): 785-796. |

| [2] | Guo-jun YANG,Ya-hui QI,Xiu-ming SHI. Review of bridge crack detection based on digital image technology [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 313-332. |

| [3] | Ming-yao XIAO,Xiong-fei LI,Rui ZHU. Medical image fusion based on pixel correlation analysis in NSST domain [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2640-2648. |

| [4] | Xiao-jun JIN,Yan-xia SUN,Jia-lin YU,Yong CHEN. Weed recognition in vegetable at seedling stage based on deep learning and image processing [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2421-2429. |

| [5] | Gui-sheng CHEN,Guo-yan LUO,Liang-xue LI,Zhen HUANG,Yi LI. Analysis of diesel particulate filter channel flow field and its noise characteristics in plateau environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 1892-1901. |

| [6] | Zhen-hai ZHANG,Kun JI,Jian-wu DANG. Crack identification method for bridge based on BCEM model [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1418-1426. |

| [7] | Xin RONG,Hong-hai LIU,Zuo-yao YIN,Hai-xiang LIN,Qing-hua BIAN. On-line detection method of aggregate gradation based on image processing [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(10): 2847-2855. |

| [8] | Huai-jiang YANG,Er-shuai WANG,Yong-xin SUI,Feng YAN,Yue ZHOU. Simplified residual structure and fast deep residual networks [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1413-1421. |

| [9] | Hai-yang JIA,Rui XIA,An-qi LYU,Ceng-xuan GUAN,Juan CHEN,Lei WANG. Panoramic mosaic approach of ultrasound medical images based on template fusion [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 916-924. |

| [10] | Yan ZHANG,Wei LIU,Shu-yong ZHANG,Yi-qiang PEI,Meng-meng DONG,Jing QIN. Optimization on thermal load of combustion chamber on two/four⁃stroke switchable diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 504-514. |

| [11] | Zhong-hua GU,Pei-gang YAN,Pan-hong LIU,Xiang-feng WANG. Applying data driven algorithm to promote prediction accuracy of separation boundary simulation with eddy viscosity model [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2532-2541. |

| [12] | Dong TANG,Yu-bin HAN,Lun HUA,Jin-chong PAN,Sheng LIU. Effect of lubricating oil ash on performance of gasoline particle filter in direct injection gasoline engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2501-2507. |

| [13] | Wen-bo ZHAO,Yu-jie LI,Jun DENG,Li-guang LI,Zhi-jun WU. Needle motion and its influence on in-nozzle flow and spray jet characteristics [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2234-2243. |

| [14] | Kang WANG,Meng YAO,Li-ben LI,Jian-qiao LI,Xiang-jin DENG,Meng ZOU,Long XUE. Mechanical performance identification for lunar soil in lunar surface sampling [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 1146-1152. |

| [15] | Jian LI,Kong-yu LIU,Xian-sheng REN,Qi XIONG,Xue-feng DOU. Application of canny algorithm based on adaptive threshold in MR Image edge detection [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 712-719. |

|

||