Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (6): 1906-1914.doi: 10.13229/j.cnki.jdxbgxb.20230947

Previous Articles Next Articles

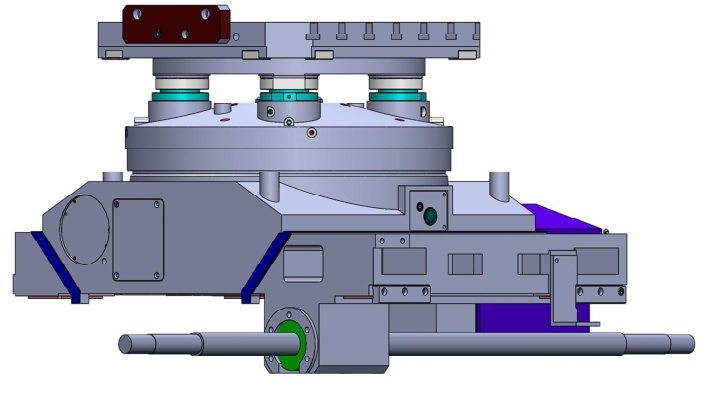

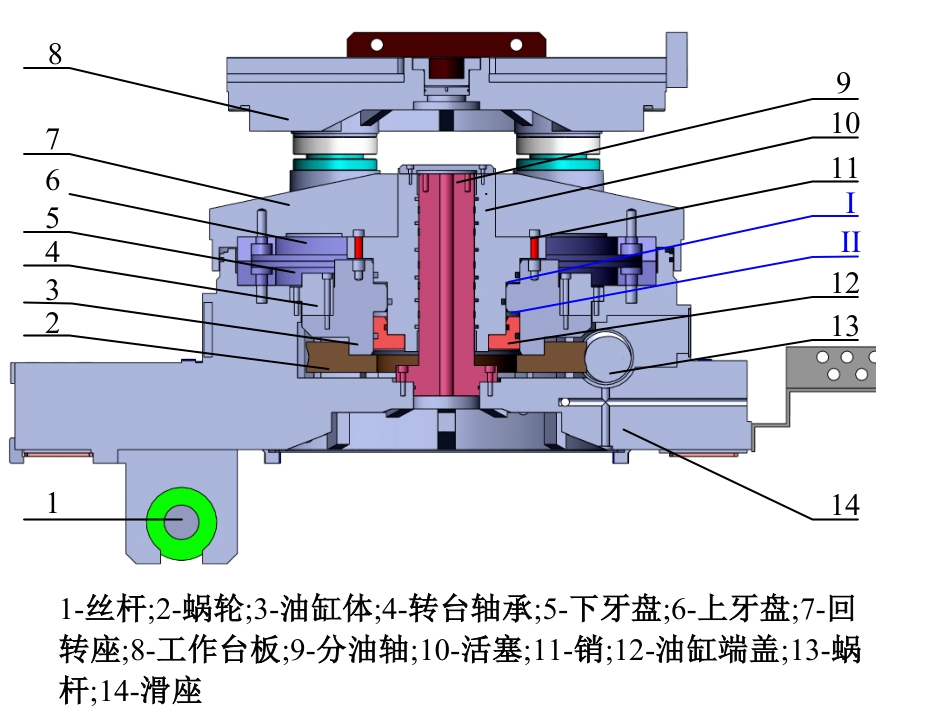

Global reliability sensitivity analysis of deformation for machine tool rotary table

Xian-zhen HUANG1,2( ),Ming-fei MA1,Chao LI1,Xu WANG1,Zhi-ming RONG3(

),Ming-fei MA1,Chao LI1,Xu WANG1,Zhi-ming RONG3( )

)

- 1.School of Mechanical Engineering and Automation,Northeastern University,Shenyang 110819,China

2.Key Laboratory of Vibration and Control of Aero-Propulsion Systems Ministry of Education of China,Northeastern University,Shenyang 110819,China

3.Apllied Technology College of Dalian Ocean University,Dalian 116399,China

CLC Number:

- TG659

| [1] | 周鸿斌, 张建民, 付红伟, 等. PRS-XY型混联数控机床工作台误差补偿技术[J]. 北京理工大学学报, 2007(2): 120-124. |

| Zhou Hong-bin, Zhang Jian-min, Fu Hong-wei, et al. Error calibration of the X-Y table of a PRS-XY type hybrid CNC machine tool[J]. Journal of Beijing Institute of Technology, 2007(2): 120-124. | |

| [2] | 梅雪松, 陶涛, 堤正臣, 等. 高速、高精度数控伺服工作台摩擦误差的研究[J]. 机械工程学报, 2001(6):76-81. |

| Mei Xue-song, Tao Tao, Di Zheng-chen, et al. Study on friction error of high-speed high - precision NC servo table[J]. Journal of Mechanical Engineering, 2001(6): 76-81. | |

| [3] | Winiarski Z, Kwaśny W, Jędrzejewski J,et al.Modelling thermal deformation of tilting rotary table with direct drive system[J]. Journal of Machine Engineering, 2010, 10(4): 26-40. |

| [4] | Bok H L, Han J O, Hwan C O,et al.Structural design optimization of the rotary table of a floor type boring machine for minimum weight and compliance by using GA[J]. Applied Mechanics and Materials, 2012, 271-272: 1421-1426. |

| [5] | Deng H X, Zhao L, Ma J F,et al.Structural bi-onic design for high-speed machine tool working table based on distribution rules of leaf veins[J].Science China Technological Sciences, 2012, 55(8): 2091-2098. |

| [6] | Gao Q D, Zhang F, Mao Y Z, et al.Application of honeycomb structure in machine tool table[J].Advanced Materials Research, 2011, 1377(308-310): 1233-1237. |

| [7] | Liu C, Zhao C Y, Wen B C. Investigation on coupled vibration of machine tool table system with position deviations[J].The International Journal of Advanced Manufacturing Technology, 2021, 114(7/8): 1-17. |

| [8] | Wang W, Li C Y, Zhou Y X,et al. Nonlinear dynamic analysis for machine tool table system mounted on linear guides[J]. Nonlinear Dynamics, 2018, 94(3): 2033-2045. |

| [9] | 谢里阳. 机械可靠性理论、方法及模型中若干问题评述[J]. 机械工程学报, 2014, 50(14): 27-35. |

| Xie Li-yang. Issues and commentary on mechanical reliability theories, methods and models[J]. Journal of Mechanical Engineering, 2014, 50(14): 27-35. | |

| [10] | Cheng Q, Kang Y B, Yang C B, et al. A new reliability allocation method for machine tools based on ITrFNs and AHP-GRA[J]. The International Journal of Advanced Manufacturing Technology, 2022, 124(11/12): 4019-4032. |

| [11] | Cheng Q, Wang C, Sun D Y, et al. A new reliability allocation method for machine tools using the intuitionistic trapezoidal fuzzy numbers and TOPSIS[J]. The International Journal of Advanced Manufacturing Technology, 2021, 124(11/12): 1-12. |

| [12] | Wang P J, Wang H J, Chen X M. Research on reliability comprehensive evaluation method of five-axis CNC machine tools based on AHP and extension theory[J]. The Journal of Engineering, 2019, 2019(23): 8599-8603. |

| [13] | Wang Z, Yang J, Wang G, et al. Application of three-parameter Weibull mixture model for reliability assessment of NC machine tools: a case study[J]. Proceedings of the Institution of Mechanical Engineers, 2011, 225(11): 2718-2726. |

| [14] | Kharoufeh P J, Cox M S, Oxley E M. Reliability of manufacturing equipment in complex environments[J]. Annals of Operations Research, 2013, 209(1): 231-254. |

| [15] | Theodor F, Jack S H. Impact of machining parameters on machine reliability and system productivity[J]. Journal of Manufacturing Science and Engineering, 2002, 124(2): 296-304. |

| [16] | Li Y L, Zhang X G, Zhang W,et al. Reliability and modal analysis of key meta-action unit for CNC machine tool[J]. IEEE Access, 2019, 7: 23640-23655. |

| [17] | Cheng Q, Zhao H W, Zhao Y S, et al. Machining accuracy reliability analysis of multi-axis machine tool based on Monte Carlo simulation[J]. Journal of Intelligent Manufacturing, 2018, 29(1): 191-209. |

| [18] | 闫明, 张义民, 孙志礼, 等. 机械零件相关失效可靠度及灵敏度计算的Monte Carlo方法[J].东北大学学报:自然科学版, 2011, 32(6): 834-837. |

| Yan Ming, Zhang Yi-min, Sun Zhi-li, et al. Monte Carlo method for computing of reliability and sensitivity of mechanical components with dependent failure modes[J]. Journal of Northeastern University (Natural Science), 2011, 32(6): 834-837. | |

| [19] | Chen J, Qiu H B, Gao L, et al. Real-time estimation error-guided active learning Kriging method for time-dependent reliability analysis[J]. Applied Mathematical Modelling, 2020, 77(1): 82-98. |

| [20] | Sun Z L, Wang J, Li R, et al. LIF: a new Kriging based learning function and its application to structural reliability analysis[J]. Reliability Engineering and System Safety, 2017, 157: 152-165. |

| [1] | Xue-zhong FU,Hou-bing HE,Xu-dong LIU,Jing-zhen LI. Tooth width design of helical face gear with non-orthogonal offset modification integration [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(4): 1207-1214. |

| [2] | Wen-jing WU,Chun-chun DENG,Hong-fei JIA,Shu-hang SUN. Evaluation of road network unblocked reliability and identification of critical sections under influence of flooding [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(4): 1250-1257. |

| [3] | Jian-feng SONG,Xin-lei HUANG,Si-ran WANG,Guang-yao XIE,Yong-gang DONG. Fatigue life prediction of brake treads for C80 trains with long downhill cycles [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 866-876. |

| [4] | Wan-feng WEI,Ling-yun KONG,Wei-an XUAN,Fan YANG,Peng GUO. Review of characteristics of asphalt foaming and moisture sensitivity of warm mix mixtures [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 20-35. |

| [5] | Shu-kun WANG,Yu-ze FENG,Jing-ran ZHANG,Xin-ming ZHANG,Long ZHENG. Analysis on decontamination performance of lower lip structure of imitation scavenger [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 392-400. |

| [6] | Xian-zhen HUANG,Rui YU,Hui-zhen LIU,Ji-wu TANG. Spindle vibration reliability analysis considering bearing nonlinear restoring force [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 116-124. |

| [7] | Kai MA,Jian-hang SUN,Sen-kang YAN,Yan TAO,Wen-tao WANG,Gui-kai GUO. Multi-objective optimization method of structural static displacement based on projection priority selection method [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 74-83. |

| [8] | Chang-jiang ZHENG,Tong-tong TAO,Zhi-chao CHEN. Cascading failure model based on adjustable redistribution of traffic flow [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2441-2450. |

| [9] | Xian-zhen HUANG,Bin GUO,Zhi-yuan JIANG,Ji-wu TANG. Vibration characteristics and precision reliability analysis of high-speed motorized spindle system [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2432-2440. |

| [10] | Chen WANG,Te LUO,Qian-qian HUI,Zhong-hao WANG,Fang-fang WANG. Design and verification of electromechanical system for docking and locking of modular flying vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2130-2140. |

| [11] | Yang LIU. Simulation and experiment of elastic roughing for rubber shoe [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2167-2173. |

| [12] | Xue-lian GUO,Wan-shui HAN,Tao WANG,Kai ZHOU,Xiu-shi ZHANG,Shu-ying ZHANG. Assessment method of resistant overturning stability safety factors of curved bridge under customized transport vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2229-2237. |

| [13] | Guo-lin YANG,Yi-fan YANG,Hao-dong XU,Gui-jun LUO,Hong-bo XIAO. Calculation method and influencing factors of surface displacement during construction of curved shield tunnel [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1997-2008. |

| [14] | Yang LIU,Tao JIANG. Interference calculation model of Hooke joint of 6-DOF platform considering installation angle [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1519-1527. |

| [15] | Lei WANG,Dong-xia LI,Song ZHOU,Li HUI,Zhen-xin SHEN. Fatigue crack propagation behavior and life prediction of 2024-O aluminum alloy FSW joints [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1563-1569. |

|