Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (11): 3476-3484.doi: 10.13229/j.cnki.jdxbgxb.20240206

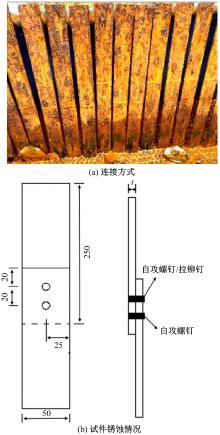

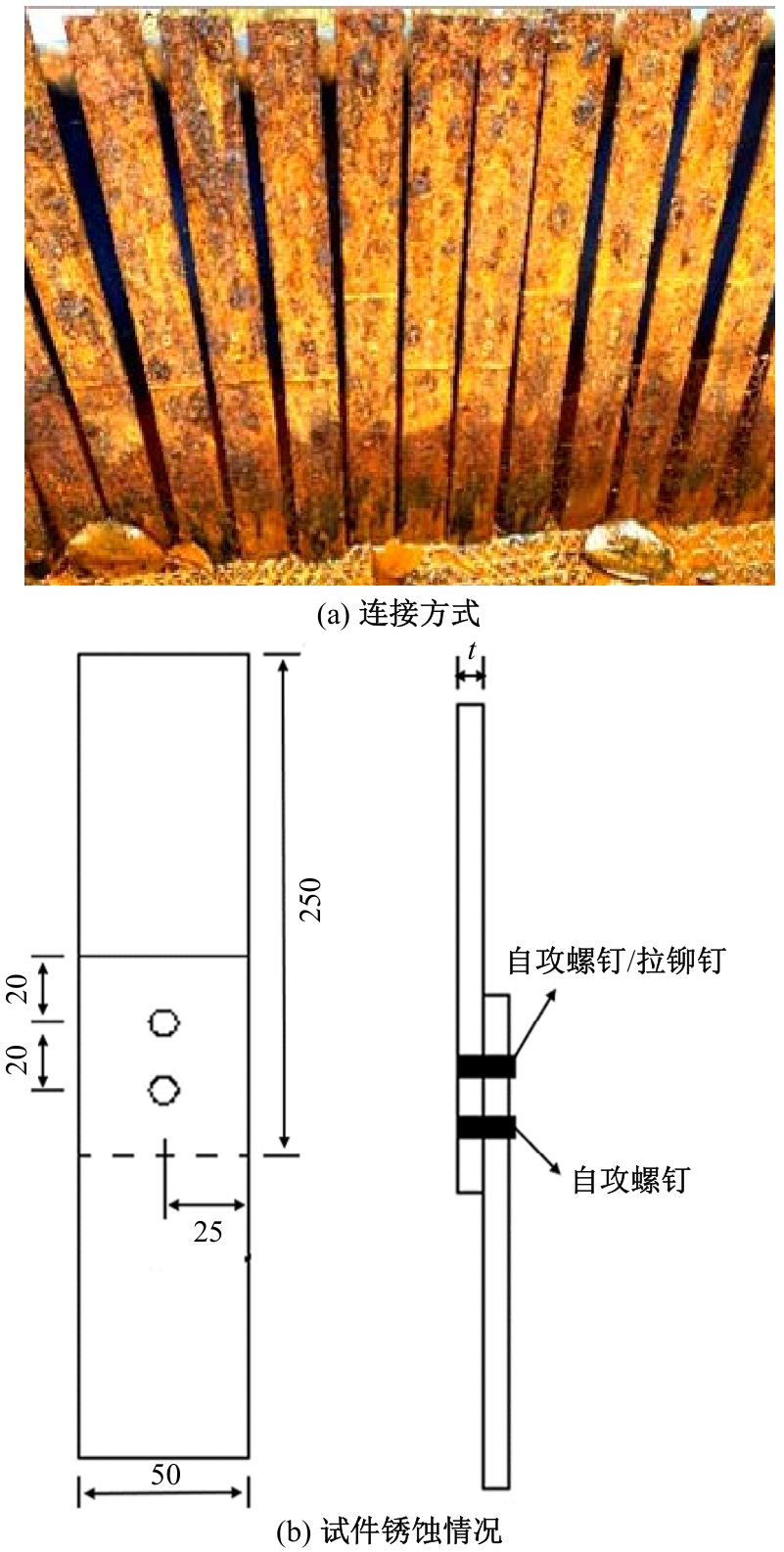

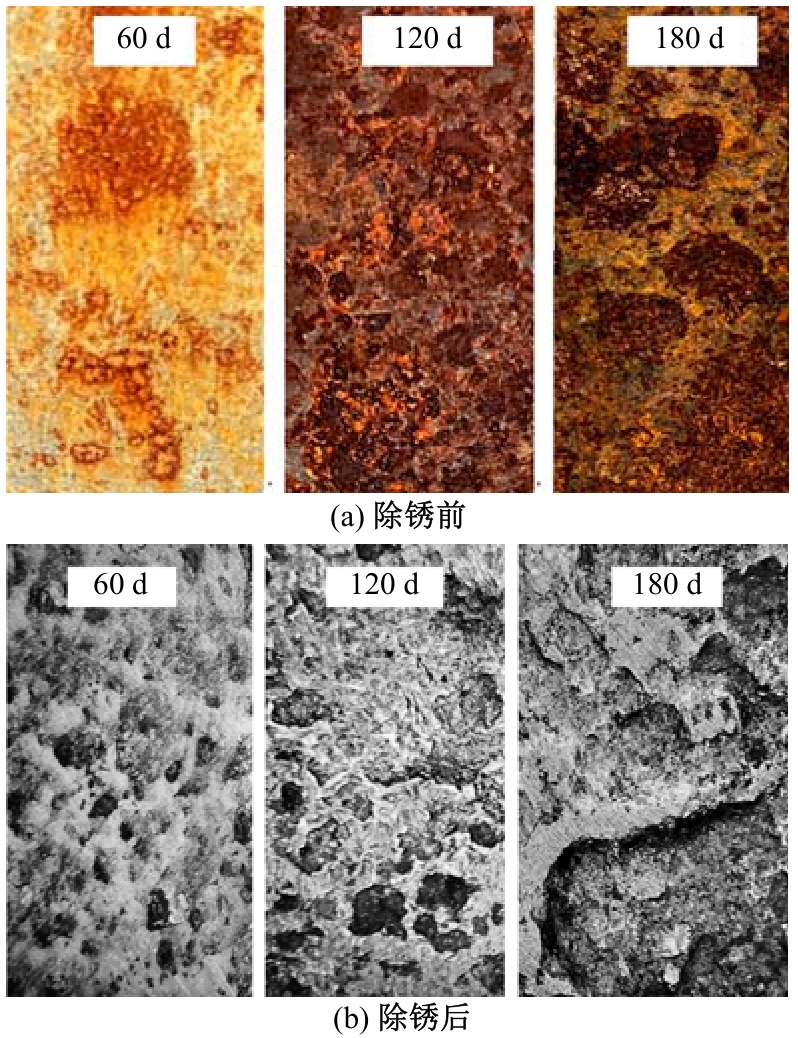

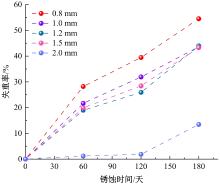

Shear performance test of corroded cold-formed thin-walled steel hybrid connection

Yun-peng CHU( ),Xue-qin CHEN,Ya-xin XIAO,Hui XIA

),Xue-qin CHEN,Ya-xin XIAO,Hui XIA

- College of Civil Engineering and Architecture,Southwest University of Science and Technology,Mianyang 621010,China

CLC Number:

- TU33

| [1] | 黄炳生, 顾彪,倪红. 冷弯薄壁型钢结构事故特点与处理[J].南京建筑工程学院学报: 自然科学版, 2001, 42(3): 76-79. |

| Huang Bing-sheng, Gu Biao, Ni Hong. Accident characteristics and treatment of cold-formed thin-walled steel structures[J]. Journal of Nanjing Institute of Building Engineering (Natural Science Edition), 2001, 42(3): 76-79. | |

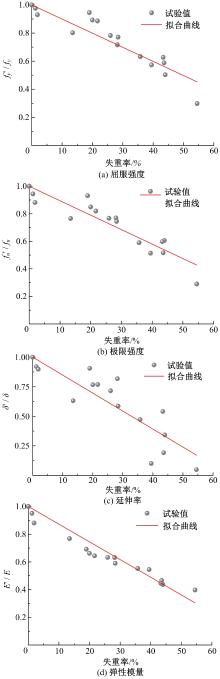

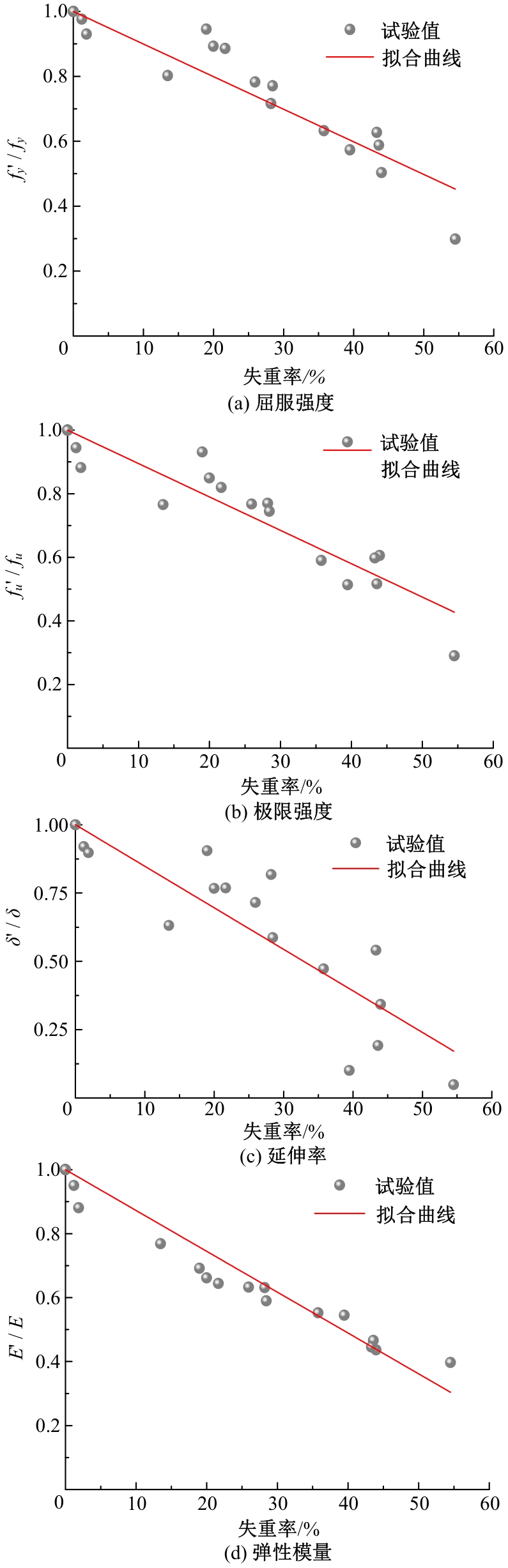

| [2] | Xu S H, Wang H, Su L. Degradation law of mechanical properties of Q235 steel plate in neutral salt spray corrosion environment [J]. Material Mechanical Engineering, 2016, 40(5): 86-91. |

| [3] | Wang Y, Xu S, Wang H, et al. Predicting the residual strength and deformability of corroded steel plate based on the corrosion morphology[J]. Construction and Building Materials, 2017, 152:777-793. |

| [4] | Xu S, Zhang Z, Li R, et al. Effect of cleaned corrosion surface topography on mechanical properties of cold-formed thin-walled steel[J]. Construction and Building Materials, 2019, 222: 1-14. |

| [5] | Nie B, Xu S, Zhang Z, et al. Experimental investigation on corroded cold-formed steel beam-columns under compression and major axis bending[J]. Journal of Constructional Steel Research, 2020, 169: 106026. |

| [6] | Zhang Z, Xu S, Li R. Comparative investigation of the effect of corrosion on the mechanical properties of different parts of thin-walled steel[J]. Thin-Walled Structures, 2020, 146: 106450. |

| [7] | Kong Z, Yang F, Jin Y, et al. Experimental study on bearing capacity of corroded high-strength bolt connections under shear force [J]. Construction and Building Materials, 2021, 309: 125117. |

| [8] | Liao Y X, Wang Y B, Qi H Z,et al. Mechanical degradation and failure behavior of Al/steel electromagnetic assisted clinched joint in chloride salt environment[J]. Thin-Walled Structures, 2023, 190: 110958. |

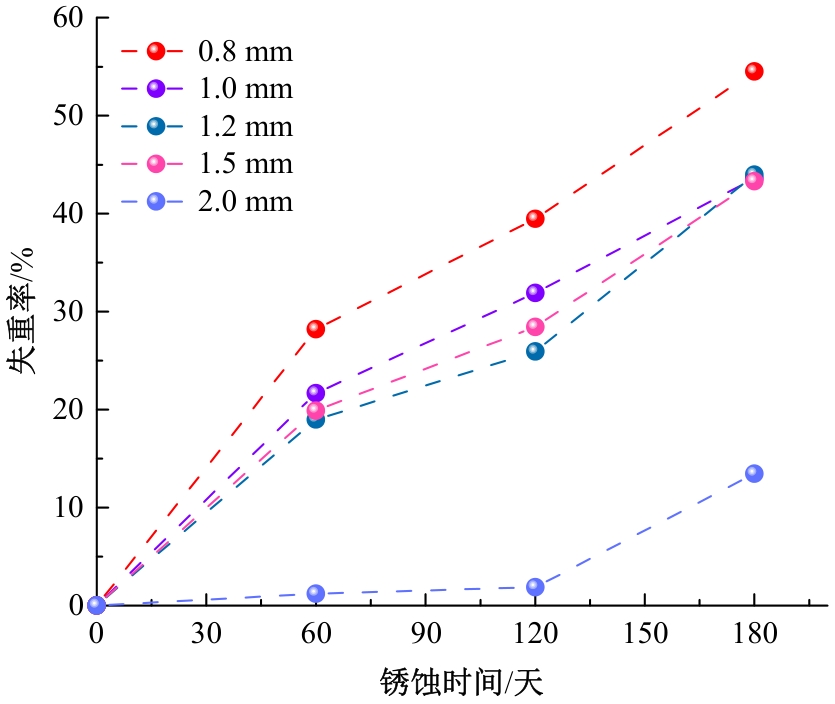

| [9] | 徐善华, 古仁俊, 聂彪, 等. 锈蚀冷弯薄壁型钢板材力学性能退化规律[J]. 哈尔滨工业大学学报, 2021, 53(4): 177-186. |

| Xu Shan-hua, Gu Ren-jun, Nie Biao, et al. Degradation law of mechanical properties of corroded cold-formed thin-walled steel sheet[J]. Journal of Harbin Institute of Technology, 2021, 53(4): 177-186. | |

| [10] | Roy K, Lau H H, Fang Z, et al. Effects of corrosion on the strength of self-drilling screw connections in cold-formed steel structures-experiments and finite element modeling[C]∥Structures,Amsterdam,Netherlands,2022: 1080-1096. |

| [11] | . 人造气氛腐蚀试验 盐雾试验 [S]. |

| [12] | . 金属材料拉伸试验 第1部分: 室温试验方法 [S]. |

| [13] | . 冷弯薄壁型钢结构技术规范 [S]. |

| [14] | . North American specification for the design of cold-formed steel structural members [S]. |

| [15] | PREN1999-1-4. Eurocode 9: design of aluminium structures, part: 1-4: supplementary rules for cold-formed sheeting [S]. |

| [16] | 伏金蓉. 采用混合连接的冷弯薄壁型钢双肢拼合构件受力性能研究[D].绵阳:西南科技大学土木工程与建筑学院,2023. |

| Fu Jin-rong. Study on the mechanical properties of cold-formed thin-walled steel double-limb composite members with hybrid connection[D]. Mianyang:school of Civil Engineering and Architecture, Southwest University of Science and Technology, 2023. |

| [1] | Hao ZHANG,Yi-yan CHEN,Jun-yu YE,Ju-can DONG,Qiu ZHAO. Experiment on bending-torsional performance of super- span box girders with corrugated steel webs [J]. Journal of Jilin University(Engineering and Technology Edition), 2026, 56(1): 209-218. |

| [2] | Hua-nan HE,Qi-ze WU,Xiao ZHANG,Song SUN,Bing LI,Xuan-yi ZHANG. Shear resistance of UHPC⁃NC planting bar interface [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(12): 3976-3985. |

| [3] | Huai-xin LI,Chang-gen YAN,Bin LIN,Yu-ling SHI. Strength and statistical damage model in whole process of clay-concrete combined body [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 245-255. |

| [4] | Guo-lin YANG,Yi-fan YANG,Hao-dong XU,Gui-jun LUO,Hong-bo XIAO. Calculation method and influencing factors of surface displacement during construction of curved shield tunnel [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1997-2008. |

| [5] | Li-hua LI,Zi-jian LI,Heng-lin XIAO,Wen-zhe CAO,Xin-long ZHOU,Shao-ping HUANG. Experiment on cyclic shear of geosynthetic reinforced construction waste soil [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1612-1623. |

| [6] | Han-hui HUANG,Kang-ming CHEN,Qing-xiong WU. Flexural behavior of composite continuous girders with concrete-filled steel tubular truss chords [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1665-1676. |

| [7] | Fang-cheng LIU,Jiang WANG,Meng-tao WU,Guo-bin BU,Jie HE. Stress⁃strain characteristics of geogrid reinforced rubber sand mixtures [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2542-2553. |

| [8] | Ya-chuan KUANG,Li-bin CHEN,Chao-ju LI,Yu-hao HE. Analysis of mechanical properties of stud shear connectors [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 538-546. |

| [9] | Deng-hui GAO,Yi-chuan XING,Min-xia GUO,Ai-jun ZHANG,Xian-tao WANG,Bao-hong MA. Modified hyperbola model of interface between unsaturated remolded loess and concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 156-164. |

| [10] | Yang WANG,Zhan⁃shuai SONG,Kong⁃hui GUO,Ye ZHUANG. Measurement of inertial parameters of rotating inertia rig [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1795-1801. |

| [11] |

SUN Xu-jie,PAN Jing-long,ZHENG Wen-zhong .

Anti-seismic behavior of composite GFRPconcrete small hollow block wall [J]. 吉林大学学报(工学版), 2008, 38(05): 1054-1059. |

|

||