吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (1): 259-267.doi: 10.13229/j.cnki.jdxbgxb.20230802

• 农业工程·仿生工程 • 上一篇

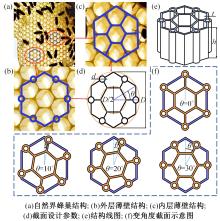

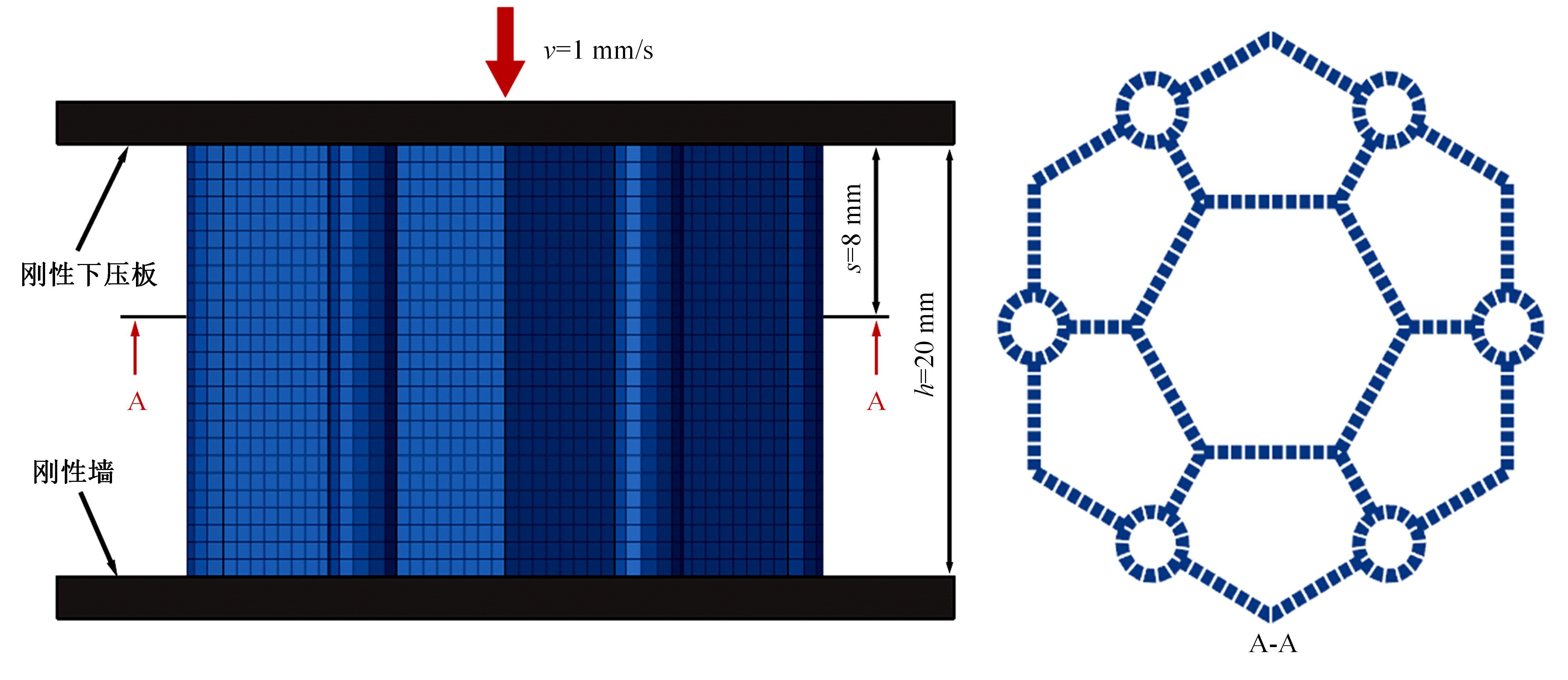

具有高效吸能特性的新型仿蜂窝多级薄壁结构

- 1.吉林大学 生物与农业工程学院,长春 130022

2.北京城市学院 智能电子制造研究中心,北京 101309

3.人工结构化材料技术研究所 辽宁材料实验室,沈阳 110167

New honeycomb multi-stage thin-walled structure with high efficiency energy absorption characteristics

Yong-zhong ZHANG1,2( ),Yun-hai MA1,3

),Yun-hai MA1,3

- 1.College of Biological and Agricultural Engineering,Jilin University,Changchun 130022,China

2.Intelligent Electronic Manufacturing Research Center,Beijing City University,Beijing 101309,China

3.Institute of Structured and Architected Materials,Liaoning Academy of Materials,Shenyang 110167,China

摘要:

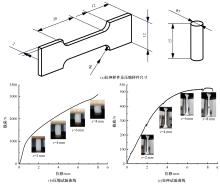

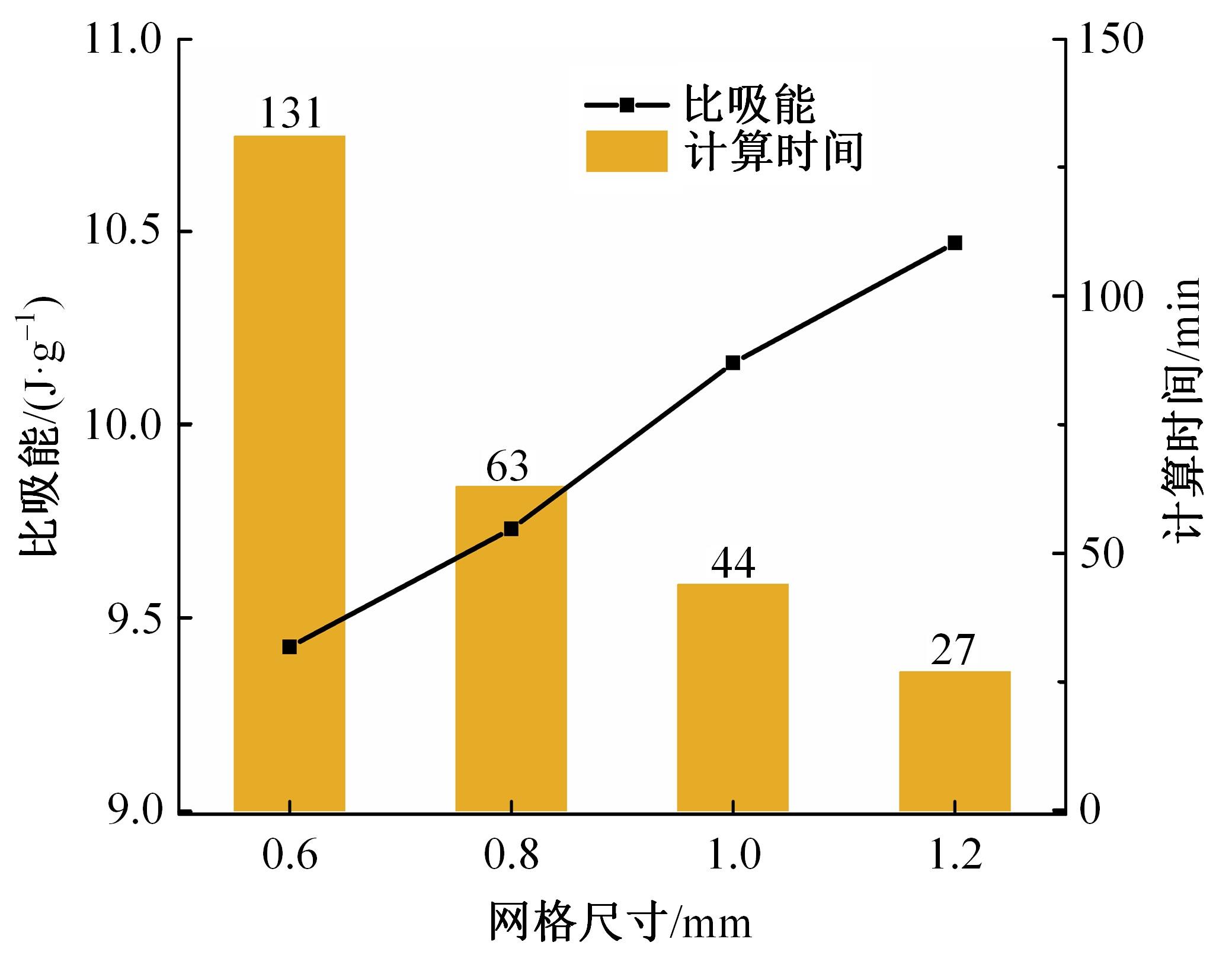

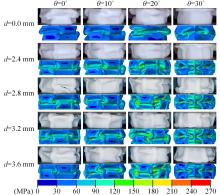

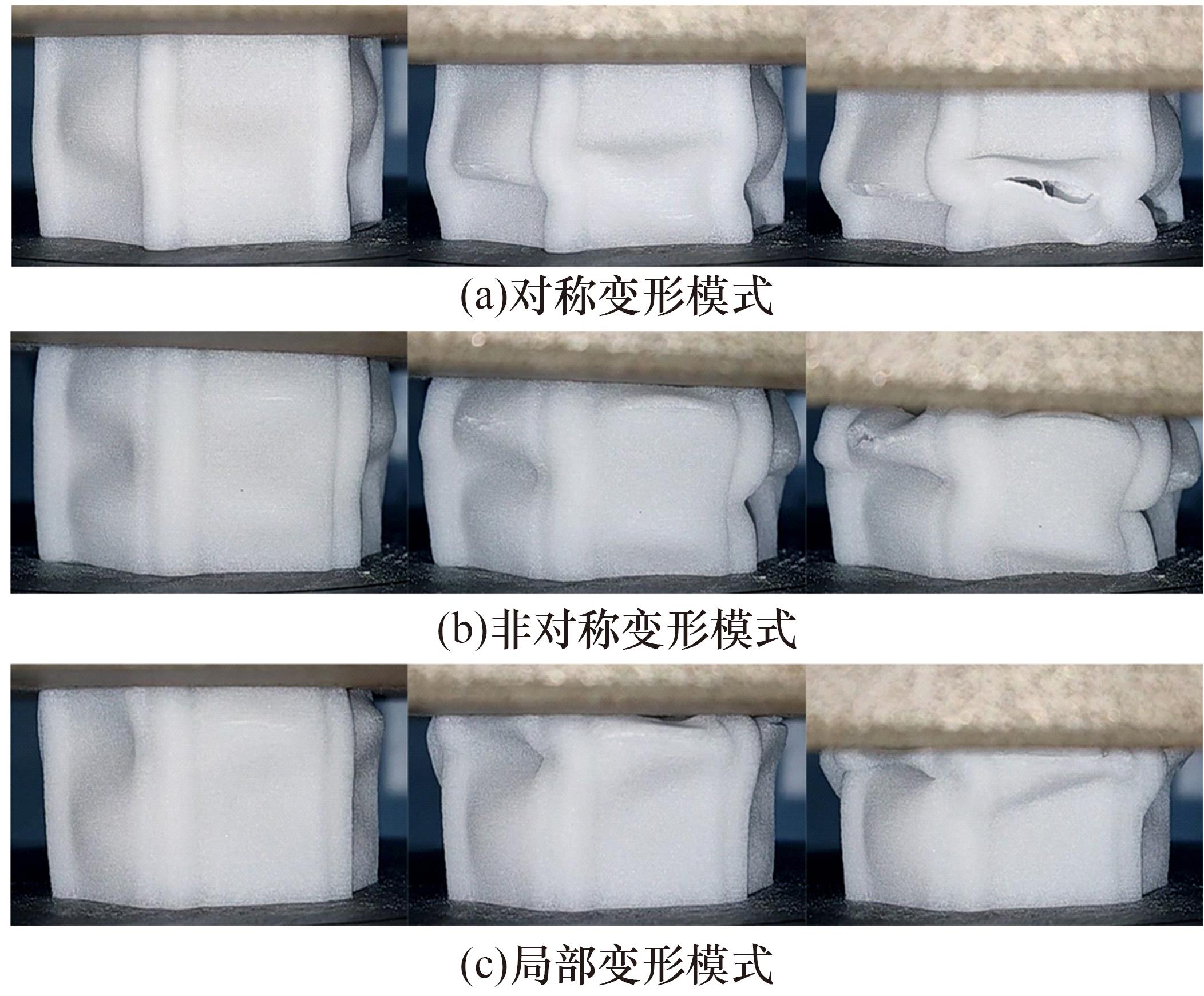

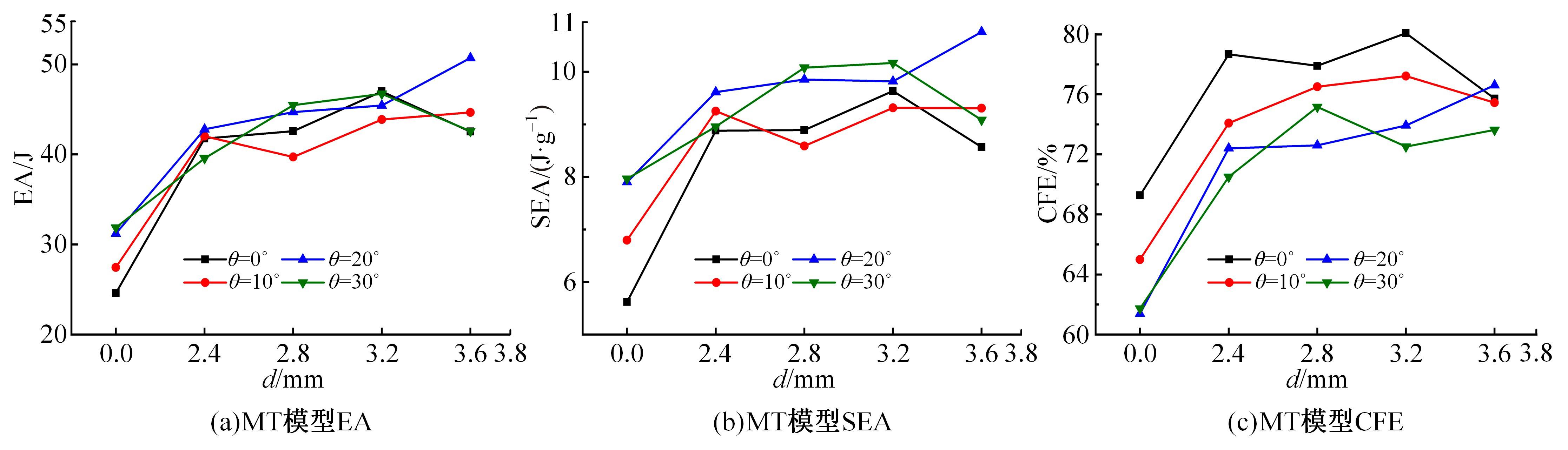

针对现有薄壁结构存在比吸能不高、压缩力效率较低的问题,以蜂窝为原型,模拟蜂窝多级嵌套结构,进行仿生结构优化设计。为了更好地探究形状参数对吸能能力的影响,进一步以相对旋转角度及加强柱直径为设计变量,设计了共20种仿蜂窝多级薄壁结构。运用3D打印技术,制备了尼龙材质的仿蜂窝多级薄壁结构样件,并进行准静态压缩试验。最后,对比分析了数值模拟结果与试验结果,得出以下结论:本文吸能能力最强的模型为YMT20-3.6,比吸能达到了10.87 J·g-1,较初始模型YMT0-0提高了约86%;旋转角度越大,加强柱直径越大,模型截面面积分布越均匀,模型变形模式也趋于对称,其能量吸收能力也更强;较大的旋转角度拥有更优异的吸能能力,但是其压缩力效率较小。增大模型加强柱直径能够减少旋转角度对压缩力效率的影响,提高模型的压缩力效率,从而得到吸能能力强、压缩力效率高的薄壁结构。

中图分类号:

- TP391

| 1 | 范晓文, 杨欣, 许述财, 等. 仿骨单位薄壁结构轴向和斜向耐撞性研究[J]. 载人航天, 2020, 26(2): 142-151. |

| Fan Xiao-wen, Yang Xin, Xu Shu-cai, et al. Study on axial and oblique crashworthiness of thin wall structure of bone imitation unit[J]. Manned Spaceflight, 2020, 26(2): 142-151. | |

| 2 | 吕掌权. 面向增材制造的汽车薄壁结构轻量化建模方法[D]. 大连:大连理工大学汽车工程学院, 2016. |

| Lu Zhang-quan. Lightweight modeling method for automotive thin-wall structure oriented to additive manufacturing[D]. Dalian: College of Automotive Engineering, Dalian University of Technology, 2016. | |

| 3 | Zhang Lin-wei, Bai Zhong-hao, Bai Fang-hua. Crashworthiness design for bio-inspired multi-cell tubes with quadrilateral, hexagonal and octagonal sections[J]. Thin-Walled Structures, 2018, 122: 42-51. |

| 4 | Zhang Wen, Yu T X, Xu Jun. Uncover the underlying mechanisms of topology and structural hierarchy in energy absorption performances of bamboo-inspired tubular honeycomb[J]. Extreme Mechanics Letters, 2022, 52:No. 101640. |

| 5 | Wang Jin, Zhang Yong, He Ning, et al. Crashworthiness behavior of Koch fractal structures[J]. Materials & Design, 2018, 144: 229-244. |

| 6 | Xia Ping, Liu Qian-cheng, Fu Hua, et al. Mechanical properties and energy absorption of 3D printed double-layered helix honeycomb under in-plane compression[J]. Composite Structures, 2023, 315:No. 116982. |

| 7 | Wu Fei, Chen Ya-ting, Zhao Shun-qiu, et al. Mechanical properties and energy absorption of composite bio-inspired multi-cell tubes[J]. Thin-Walled Structures, 2023, 184. |

| 8 | 黄晗, 许述财, 杜雯菁, 等. 基于虾螯结构的仿生薄壁管吸能特性分析及优化[J]. 北京理工大学学报, 2020, 40(3): 267-274. |

| Huang Han, Xu Shu-cai, Du Wen-jing, et al. Analysis and optimization of energy absorption characteristics of biomimetic thin-walled tube based on chelate structure of shrimp[J]. Transactions of Beijing Institute of Technology, 2020, 40(3): 267-274. | |

| 9 | 肖勇. 面向车用的碳纤维薄壁梁铝蜂窝填充结构耐撞性研究[D]. 武汉:武汉理工大学材料科学与工程学院, 2018. |

| Xiao Yong. Crashworthiness of Aluminum Honeycomb Filled Structure of Carbon Fiber Thin-wall Beam for Vehicle[D]. Wuhan: College of Materials Sciences and Engineering,Wuhan University of Technology, 2018. | |

| 10 | 于征磊, 信仁龙, 陈立新, 等. 仿蜂窝防护结构的承载特性[J]. 吉林大学学报: 工学版, 2021, 51(3): 1140-1145. |

| Yu Zheng-lei, Xin Ren-long, Chen Li-xin, et al. Load bearing characteristics of honeycomb protection structure[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(3): 1140-1145. | |

| 11 | Goyal S, Anand C S, Sharma S K, et al. Crashworthiness analysis of foam filled star shape polygon of thin-walled structure[J]. Thin-Walled Structures, 2019, 144:No. 106312. |

| 12 | 丁明. 仿藕类蜂窝多胞薄壁结构的耐撞性研究[D]. 长沙:湖南大学机械与运载工程学院, 2020. |

| Ding Ming. Crashworthiness of Honeycomb Multicellular Thin-walled Structures of lotus root[D]. Changsha:College of Mechinacal and Vehicle Engineering, Hunan University, 2020. | |

| 13 | Huang Jia-le, Zheng Zi-yu, Deng Xiao-lin, et al. Crashworthiness analysis of gradient fractal thin-walled structure[J]. Thin-Walled Structures, 2022, 181:No. 110102. |

| 14 | Palombini F L, Mariath J E D A, Oliveira B F D. Bionic design of thin-walled structure based on the geometry of the vascular bundles of bamboo[J]. Thin-Walled Structures 2020,155:No. 106936. |

| 15 | Qiu Na, Gao Yun-kai, Fang Jiang-guang, et al. Crashworthiness analysis and design of multi-cell hexagonal columns under multiple loading cases[J]. Finite Elements in Analysis and Design, 2015, 104: 89-101. |

| 16 | 邓敏杰, 刘志芳. 仿马尾草薄壁结构的设计与耐撞性研究[J]. 高压物理学报, 2022, 36(3): 111-120. |

| Deng Min-jie, Liu Zhi-fang. Design and crashworthiness of thin wall structure imitating horsetail grass[J]. Chinese Journal of High Pressure Physics, 2022, 36(3): 111-120. | |

| 17 | Wei Zhi-quan, Xu Xiang-hong. Numerical study on impact resistance of novel multilevel bionic thin-walled structures[J]. Journal of Materials Research and Technology, 2022, 16: 1770-1780. |

| 18 | 李瑞涛, 唐刚, 夏辉, 等. 二维随机蜂巢网格熔断动力学过程和熔断面标度性质的数值模拟[J]. 物理学报, 2019, 68(5): 25-34. |

| Li Rui-tao, Tang Gang, Xia Hui, et al. Numerical Simulation of Fusion Dynamic Process and scale Properties of Fusion surface in two-dimensional Random Honeycomb Grid[J]. Acta Physica Sinica, 2019, 68(5): 25-34. | |

| 19 | 许欣, 郑丰, 孔俊, 等. 冷链运输包装纸板的研究现状及发展趋势[J]. 包装工程, 2021, 42(21): 133-142. |

| Xu Xin, Zheng Feng, Kong Jun, et al. Research status and development trend of cold chain transport packaging board[J]. Packaging Engineering, 201, 42(21): 133-142. | |

| 20 | Huang Jiang-ping, He Kai, Liu Rong-qiang, et al. Theoretical and numerical investigation of mean crushing load of uniform and non-uniform multi-cell tube[J]. Thin-Walled Structures, 2022, 180:No. 109956. |

| [1] | 邹猛,郭子琦,陈朕,曹洪涛,朱建中,徐丽涵. 模拟月尘与典型金属材料摩擦磨损特性试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2307-2315. |

| [2] | 于征磊,陈立新,徐泽洲,信仁龙,马龙,金敬福,张志辉,江山. 基于增材制造的仿生防护结构力学及回复特性分析[J]. 吉林大学学报(工学版), 2021, 51(4): 1540-1547. |

| [3] | 翁小辉,孙友宏,张书军,谢军,常志勇. 基于仿生鼻腔优化的油气检测方法与实验新技术[J]. 吉林大学学报(工学版), 2020, 50(1): 382-388. |

| [4] | 陈东良,臧睿,段鹏,赵伟鹏,翁旭涛,孙杨,唐艺鹏. 基于新月鱼尾推进理论的多连杆鱼骨仿生设计[J]. 吉林大学学报(工学版), 2019, 49(4): 1246-1257. |

| [5] | 钱志辉, 周亮, 任雷, 任露泉. 具有仿生距下关节和跖趾关节的完全被动步行机[J]. 吉林大学学报(工学版), 2018, 48(1): 205-211. |

| [6] | 陈东辉, 刘伟, 吕建华, 常志勇, 吴婷, 慕海锋. 基于虾夷扇贝体表结构的玉米茬根捡拾器仿生设计[J]. 吉林大学学报(工学版), 2017, 47(4): 1185-1193. |

|

||