吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (4): 1540-1547.doi: 10.13229/j.cnki.jdxbgxb20210304

• 农业工程·仿生工程 • 上一篇

基于增材制造的仿生防护结构力学及回复特性分析

于征磊1,2( ),陈立新2,徐泽洲2,信仁龙2,马龙3,金敬福4(

),陈立新2,徐泽洲2,信仁龙2,马龙3,金敬福4( ),张志辉2,江山5

),张志辉2,江山5

- 1.吉林大学 汽车仿真与控制国家重点实验室,长春 130022

2.吉林大学 工程仿生教育部重点实验室,长春 130022

3.空军航空大学 作战勤务学院,长春 130022

4.吉林大学 生物与农业工程学院,长春 130022

5.中国科学院 长春光学精密机械与物理研究所,长春 130033

Analysis of mechanical characteristics and recovery characteristics of bionic protective structures based on additive manufacturing

Zheng-lei YU1,2( ),Li-xin CHEN2,Ze-zhou XU2,Ren-long XIN2,Long MA3,Jing-fu JIN4(

),Li-xin CHEN2,Ze-zhou XU2,Ren-long XIN2,Long MA3,Jing-fu JIN4( ),Zhi-hui ZHANG2,Shan JIANG5

),Zhi-hui ZHANG2,Shan JIANG5

- 1.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

2.Key of Bionic Engineering,Ministry of Education,Jilin University,Changchun 130022,China

3.College of Combat Service,Aviation University Air Force,Changchun 130022

4.College of Biological and Agricultural Engineering,Jilin University,Changchun 130022,China

5.Changchun Institute of Optics,Fine Mechanics and Physics,Chinese Academy of Sciences,Changchun 130033,China

摘要:

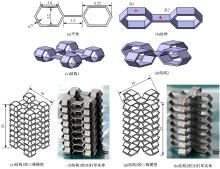

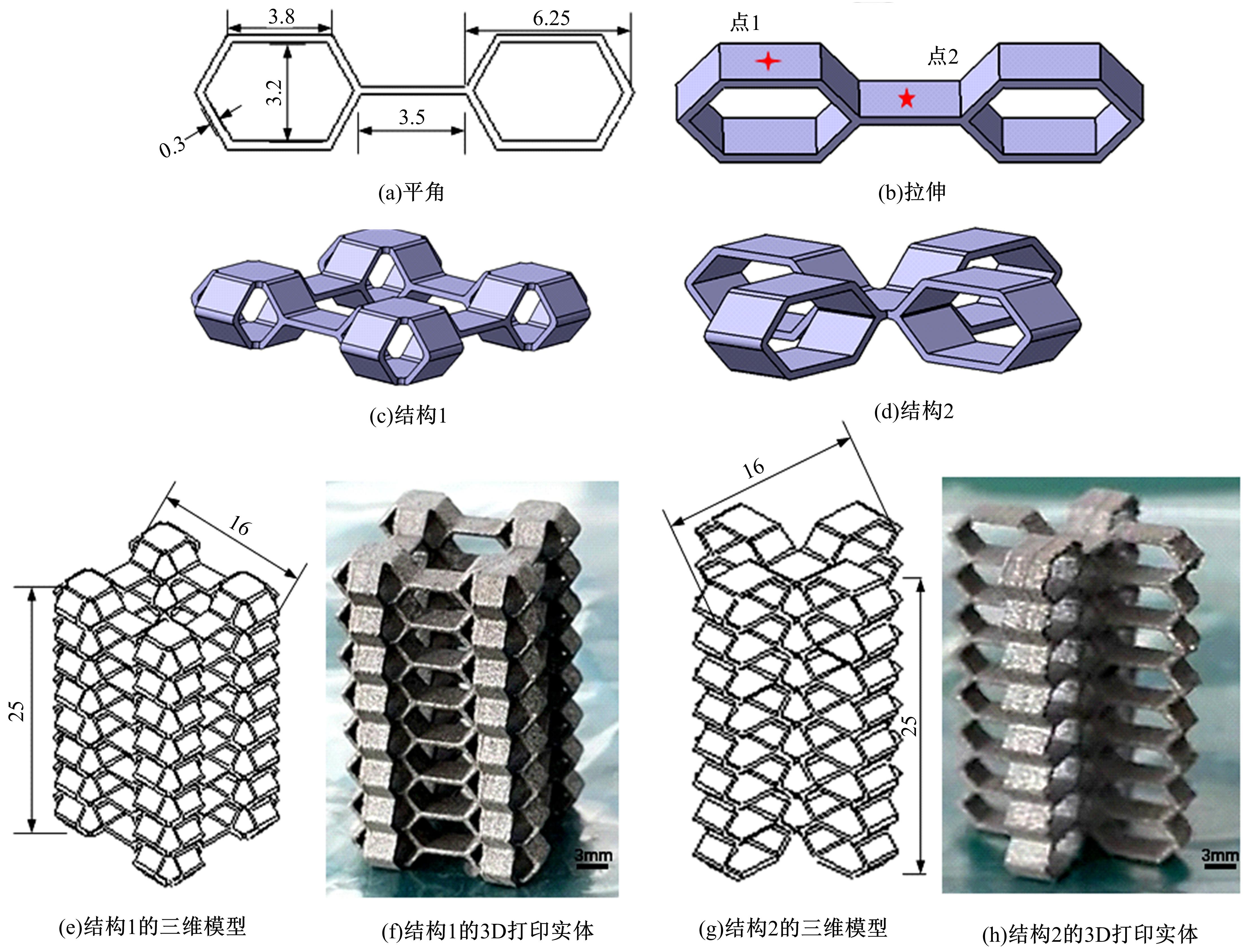

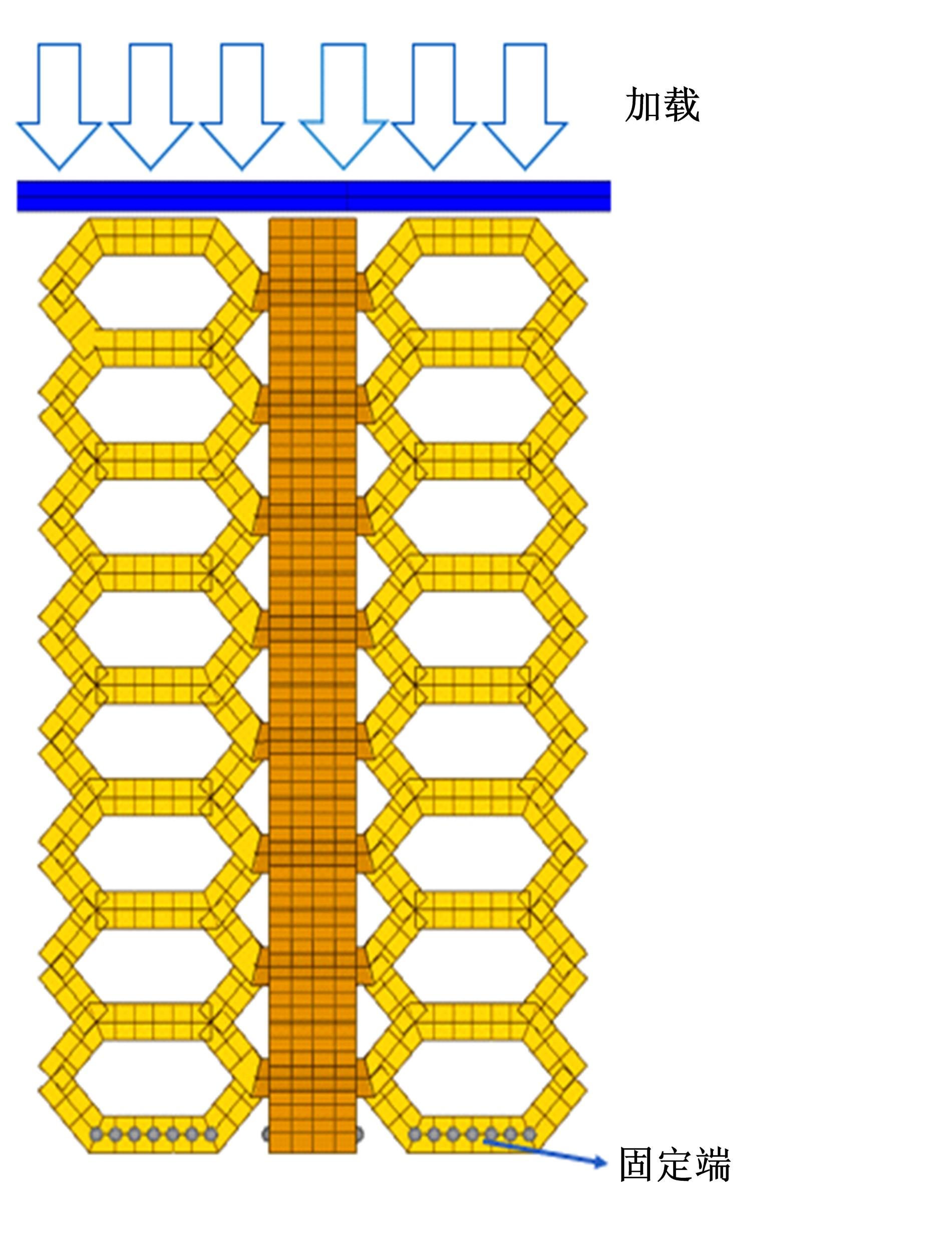

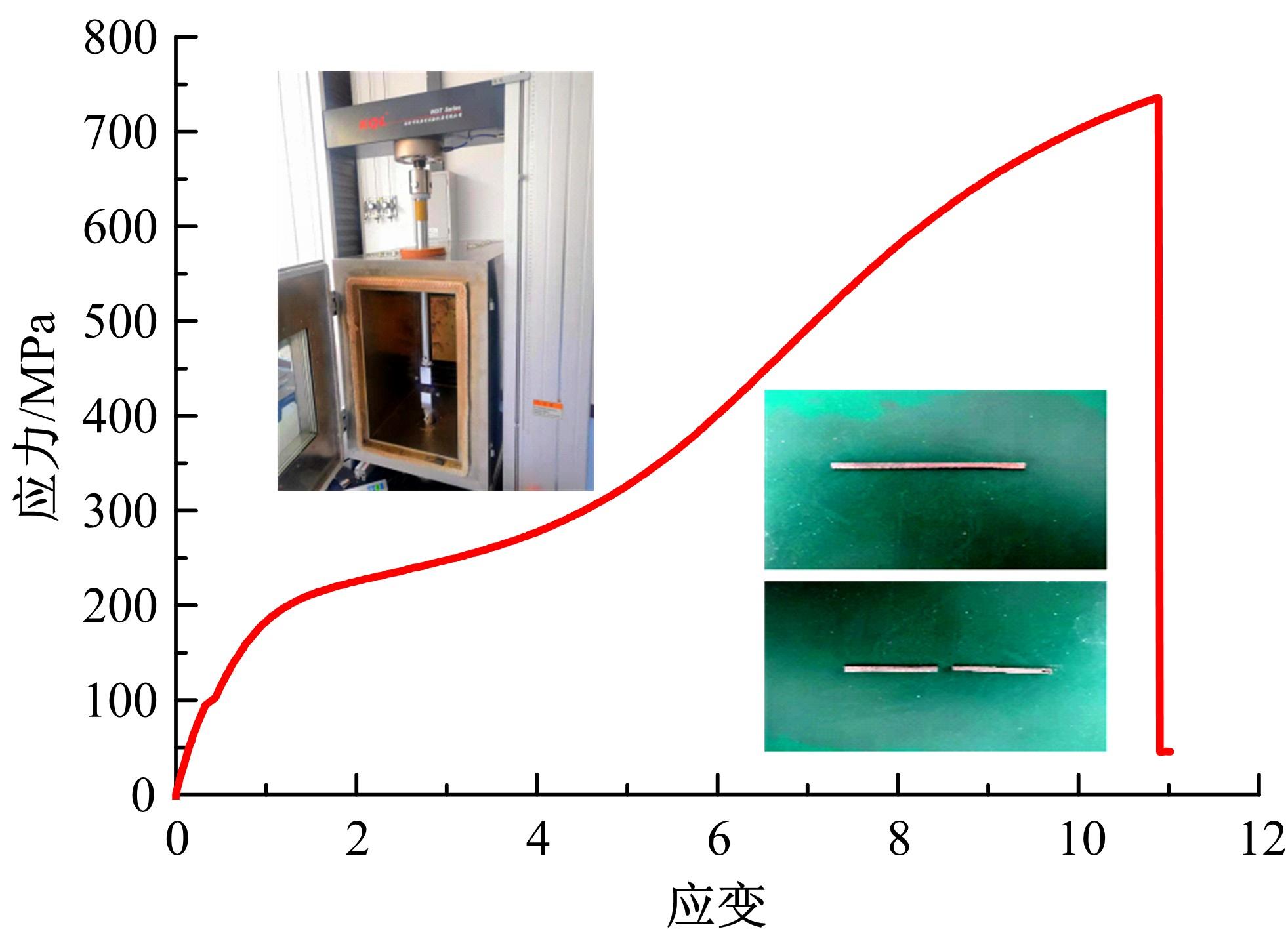

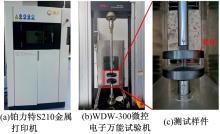

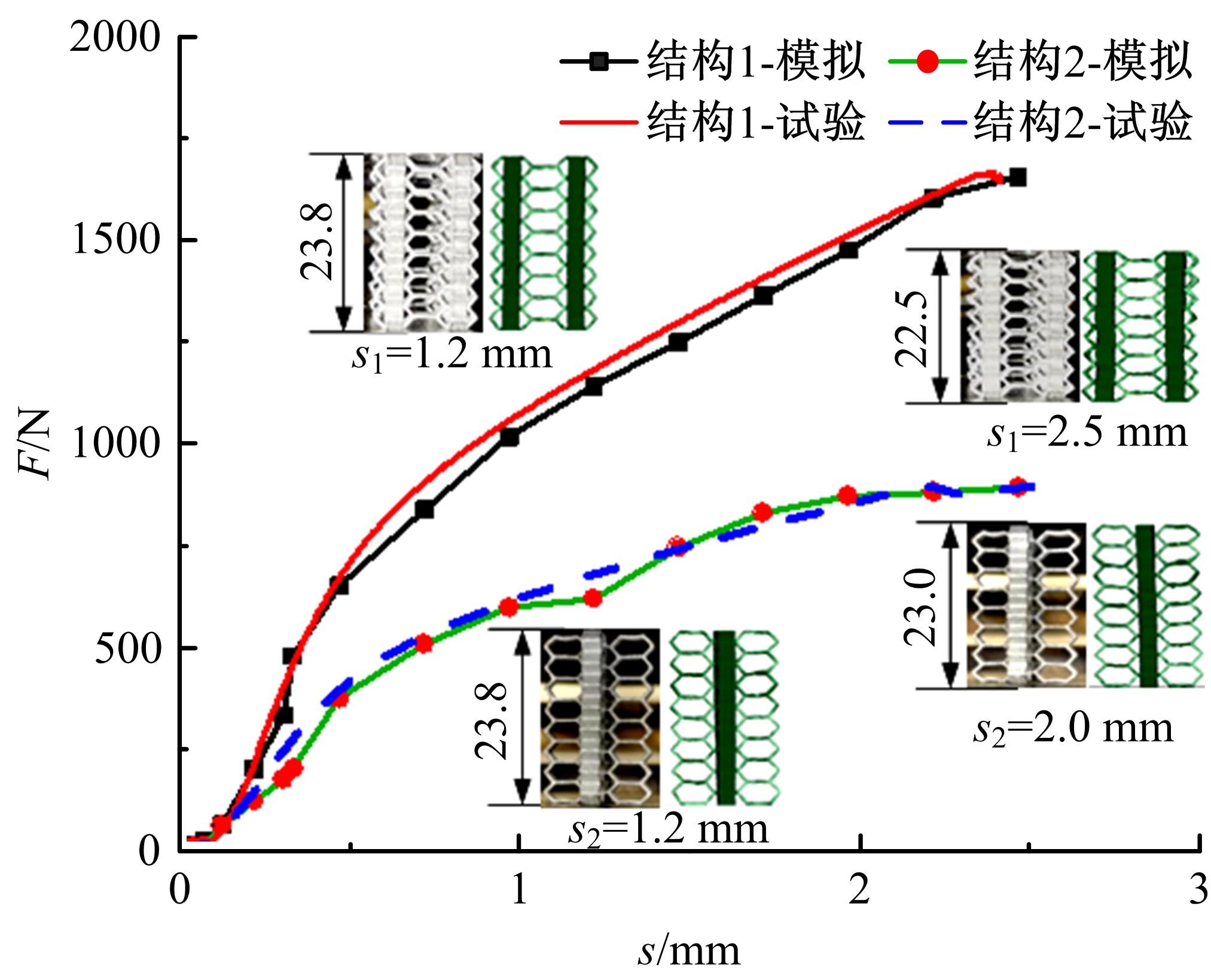

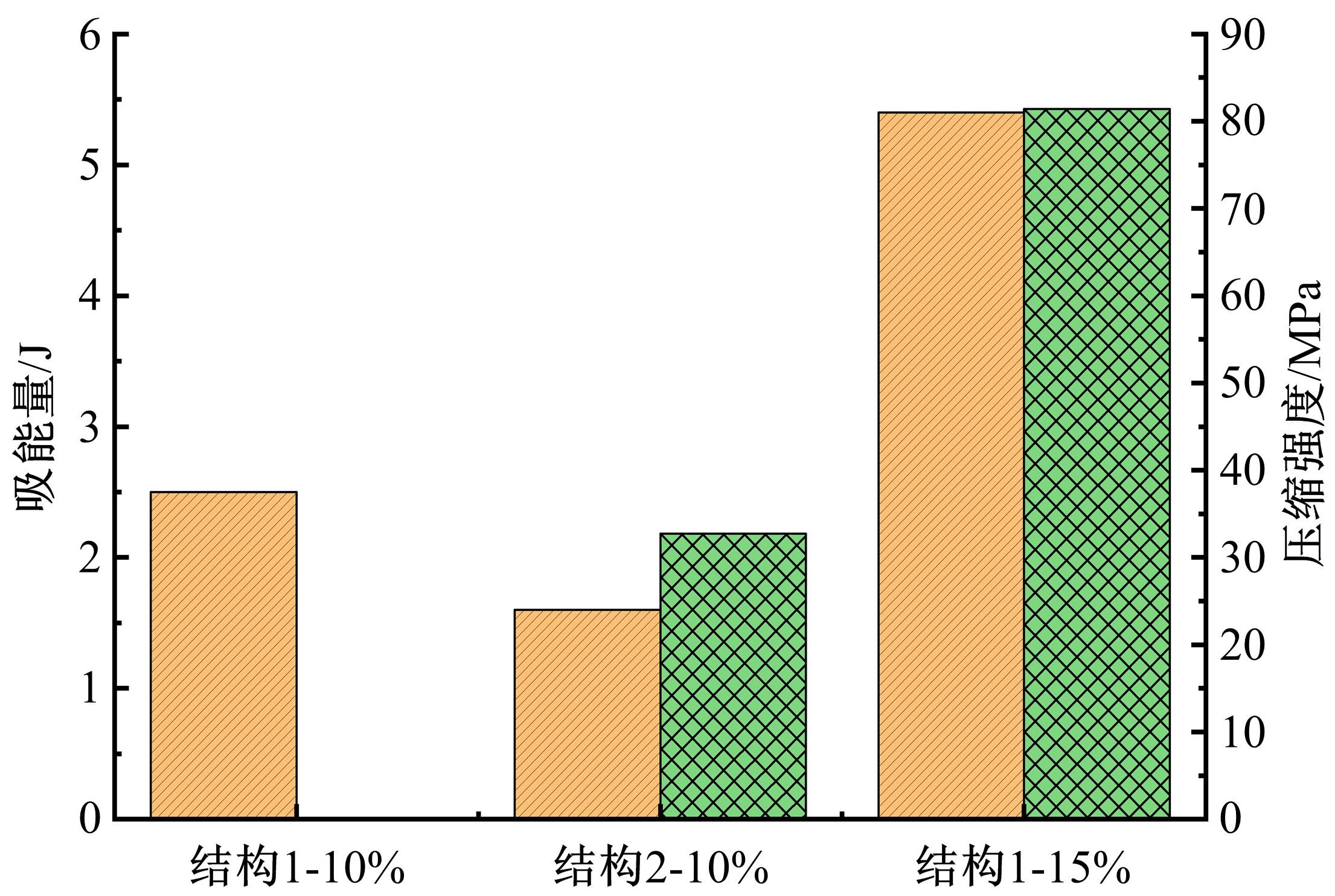

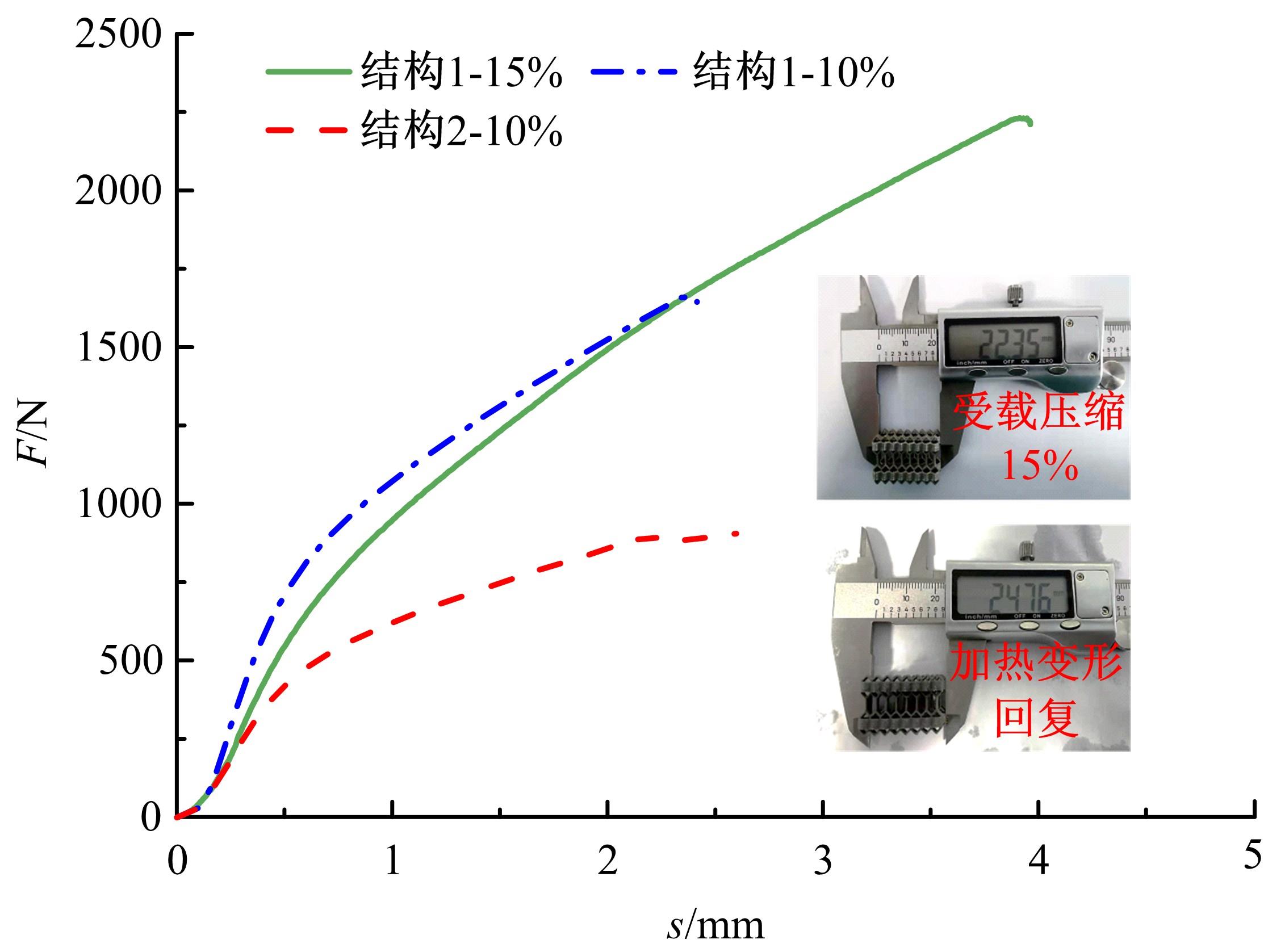

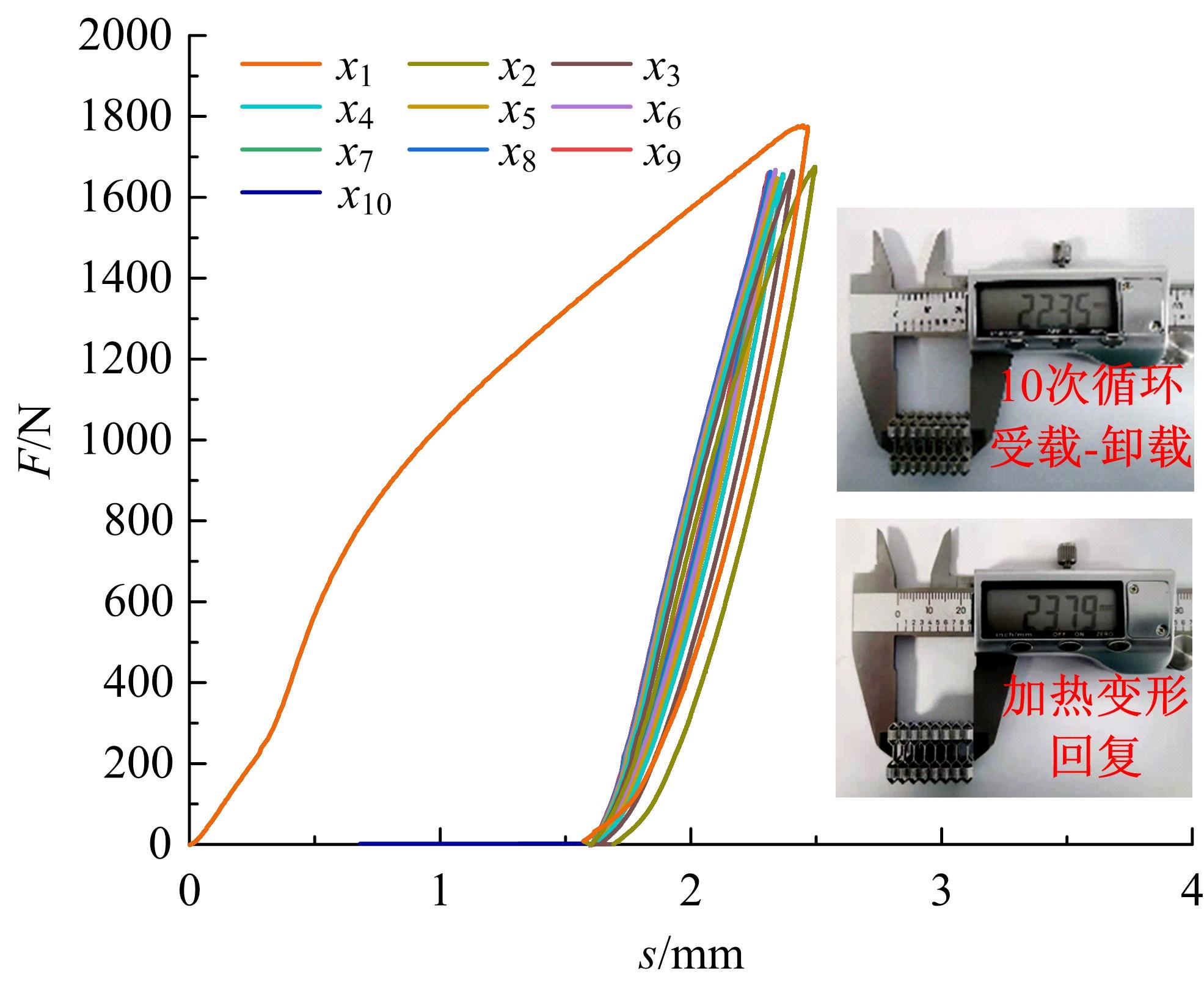

运用结构仿生学设计原理,建立了两种具有记忆恢复特性的智能仿生防护结构,利用选择性激光熔融增材制造技术制备了仿生结构模型,通过数值模拟和试验测试方法分别对其进行了力学特性分析和变形回复特性测试。结果表明:对比试验力-位移曲线及其变形模式,仿真计算结果较为准确地模拟了仿生防护结构模型样件在静压过程中的变形特性及承载特性;仿生防护结构的压缩量可达15%,其压缩强度为81.4 MPa;卸载后在加热工况下其变形回复率达到99.04%。该研究实现了利用增材制造方法对于压力载荷下仿生防护结构的制备及其回复变形的功能的验证,为开发新型智能仿生防护结构提供了理论依据。

中图分类号:

- TB17

| 1 | 姚艳玲, 赵宝荣, 钟涛, 等. 铝合金板抗枪弹倾角效应试验研究[J]. 兵器材料科学与工程, 2005, 28(3): 33-36. |

| Yao Yan-lin, Zhao Bao-rong, Zhong Tao, et al. Study on obliquity effect of aluminum alloy plates against bullet[J]. Ordnance Material Science and Engineering, 2005, 28(3): 33-36. | |

| 2 | 苟瑞君, 孙丹, 张博. 陶瓷/泡沫铝/铝合金复合装甲抗射流侵彻性能[J]. 含能材料, 2017, 25(6): 451-458. |

| Gou Rui-jun, Sun Dan, Zhang Bo. Anti-jet penetration performances of the Ceramic/Aluminum Foam/Aluminum alloy composite armor[J]. Chinese Journal of Energetic Materials, 2017, 25(6): 451-458. | |

| 3 | Fan Wei, Shen Dong-jie, Zhang Zhi-yong, et al. A novel UHPFRC-based protective structure for bridge columns against vehicle collisions: experiment, simulation, and optimization[J]. Engineering Structures, 2020, 207: 110247. |

| 4 | 张媛, 郑白哲, 李妮. 蜂窝夹心板的理论研究[J]. 北京工商大学学报:自然科学版, 2001, 19(4): 47-50. |

| Zhang Yuan, Zheng Bai-zhe, Li Ni. Theoretical research of honeycomb sandwich panel[J]. Journal of Beijing Technology and Business University(Natural Science Edition), 2001, 19(4): 47-50. | |

| 5 | Liu Ping, Liu Yan, Zhang Xiong. Internal-structure model based simulation research of shielding properties of honeycomb sandwich panel subjected to high-velocity impact[J]. International Journal of Impact Engineering, 2015, 77: 120-133. |

| 6 | 王显会, 师晨光, 周云波, 等. 车辆底部防护蜂窝夹层结构抗冲击性能分析[J]. 北京理工大学学报, 2016, 36(11): 1122-1126. |

| Wang Xian-hui, Shi Chen-guang, Zhou Yun-bo, et al. Impact resistance analysis of honeycomb sandwich structure for the vehicle bottom protection[J]. Journal of Beijing Institute of Technology, 2016, 36(11): 1122-1126. | |

| 7 | 侯策, 刘天生, 王凤英, 等. 不同填充物三角孔蜂窝板抗弹性能数值模拟研究[J]. 科技通报, 2017, 33(4): 1-5. |

| Hou Ce, Liu Tian-sheng, Wang Feng-ying, et al. Numerical simulation research on ballistic performance of triangle hole honeycomb panel with different substances[J]. Bulletin of Science and Technology, 2017, 33(4): 1-5. | |

| 8 | 梅相全, 宋小宁, 董野峰. 轻量化前下防护的设计研究[J]. 汽车零部件, 2020(12): 39-44. |

| Mei Xiang-quan, Song Xiao-ning, Dong Ye-feng. Design and research of lightweight front underrun protection[J]. Automobile Parts, 2020(12): 39-44. | |

| 9 | Rakesh Kumar, Manoj Kumar, Chohan Jasgurpreet Singh. The role of additive manufacturing for biomedical applications: a critical review[J]. Journal of Manufacturing Processes, 2021, 64: 828-850. |

| 10 | Cagri Oztan, Victoria Coverstone. Utilization of additive manufacturing in hybrid rocket technology: a review[J]. Acta Astronautica, 2021, 180: 130-140. |

| 11 | Cámara Torres Maria, Stacy Duarte, Ravi Sinha, et al. 3D additive manufactured composite scaffolds with antibiotic-loaded lamellar fillers for bone infection prevention and tissue regeneration[J]. Bioactive Materials, 2021, 6(4): 157-168. |

| 12 | Zhang Lei, Stefanie Feih, Stephen Daynes, et al. Energy absorption characteristics of metallic triply periodic minimal surface sheet structures under compressive loading[J]. Additive Manufacturing, 2018, 23: 505-515. |

| 13 | Pawel Baranowski, Pawel Płatek, Anna Antolak-Dudka, et al. Deformation of honeycomb cellular structures manufactured with laser engineered net shaping (LENS) technology under quasi-static loading: experimental testing and simulation[J]. Additive Manufacturing, 2019, 25: 307-316. |

| 14 | Zhang Xin, Ma Jun. Photothermal effect of 3D printed hydroxyapatite composite scaffolds incorporated with graphene nanoplatelets[J]. Ceramics International, 2021, 47(5): 46-53. |

| 15 | 朱雪洁, 钟诗江, 杨晓霞, 等. NiTi基形状记忆合金弹热效应及其应用研究进展[J]. 材料工程, 2021(3): 1-13. |

| Zhu Xue-jie, Zhong Shi-jiang, Yang Xiao-xia, et al. Research progress in electrocaloric effect and its application of NiTi-based shape memory alloys[J]. Journal of Materials Engineering, 2021(3): 1-13. | |

| 16 | 郭良, 张修庆. 金属基形状记忆合金研究进展[J]. 功能材料与器件学报, 2020, 26(5): 323-330. |

| Guo Liang, Zhang Xiu-qing. Research progress of metal-based shape memory alloys[J]. Journal of Functional Materials and Devices, 2020, 26(5): 323-330. | |

| 17 | 王硕, 王元昊. 形状记忆合金及其研究进展综述[J]. 科学技术创新, 2020(21): 39-40. |

| Wang Shuo, Wang Yuan-hao. Scientific and Technological Innovation[J], 2020(21): 39-40. | |

| 18 | 廖赞, 汤京龙, 袁志山, 等. 钛镍形状记忆合金医疗器械评价方法研究进展[J]. 金属功能材料, 2020, 27(4): 55-60. |

| Liao Zan, Tang Jing-long, Yuan Zhi-shan, et al. Research progress of assessment method for performance tests of NiTi shape memory alloy medical devices[J]. Metallic Functional Materials, 2020, 27(4): 55-60. | |

| 19 | Zhang Wei, Zhang Feng-hua, Lan Xin, et al. Shape memory behavior and recovery force of 4D printed textile functional composites[J]. Composites Science and Technology, 2018, 160: 224-230. |

| 20 | 孙凡越, 赵梓裕, 王文健, 等. 温度对形状记忆合金蜂窝材料动力学响应的影响[J]. 山西建筑, 2021, 47(2): 91-92. |

| Sun Fan-yue, Zhao Zi-yu, Wang Wen-jian, et al. The influence of temperature on the dynamic performance of shape memory alloy honeycombs[J]. Shanxi Architecture, 2021, 47(2): 91-92. | |

| 21 | Kim Sangbae, Elliot Hawkes, Kyujin Choy, et al. Micro artificial muscle fiber using NiTi spring for soft robotics[C]∥IROS, St.Louis, USA, 2009:2228-2234. |

| 22 | 王琳.镍钛合金复合结构保险杠性能的研究[D].哈尔滨:哈尔滨工业大学汽车工程学院,2005. |

| Wang Lin. Study on the properties of Ni-Ti alloy composite structure bumper[D] Harbin: School of Automotive Engineering,Harbin Institute of Technology, 2005. | |

| 23 | Smith M, Guan Z, Cantwell W J. Finite element modelling of the compressive response of lattice structures manufactured using the selective laser melting technique[J]. International Journal of Mechanical Sciences, 2013, 67:28-41. |

| 24 | 张凯雯. 3D打印膝关节假体多孔结构对骨组织应力遮挡影响的数值仿真研究[D].长春:吉林大学机械与航空航天工程学院,2019. |

| Zhang Kai-wen. Numberical simulation on the effect of 3D printed knee joint prosthesis on stress shielding of bone tissue[D]. Changchun:Shool of Mechnical and Aerospace,Jilin University, 2019. | |

| 25 | Ali M H, Sagidolla B, Dulat K. Material minimization in 3D printing with novel hybrid cellular structures[J]. Materials Today: Proceedings, 2021,,42(5):1800-1809. |

| 26 | Wang Xie-bin, Yu Jing-ya, Liu Jiang-wei, et al. Effect of process parameters on the phase transformation behavior and tensile properties of NiTi shape memory alloys fabricated by selective laser melting[J]. Additive Manufacturing, 2020, 36: No.101545. |

| 27 | Sa Edi S, Moghaddam N S, Amerinatanzi A, et al. On the effects of selective laser melting process parameters on microstructure and thermomechanical response of Ni-rich NiTi[J].Acta Materialia, 2018, 144: 552-560. |

| 28 | Yu Zheng-lei, Xu Ze-zhou, Guo Yun-ting, et al. Study on properties of SLM-NiTi shape memory alloy under the same energy density[J]. Journal of Materials Research and Technology, 2021, 13: 241-250. |

| [1] | 于征磊,信仁龙,陈立新,朱奕凝,张志辉,曹青,金敬福,赵杰亮. 仿蜂窝防护结构的承载特性[J]. 吉林大学学报(工学版), 2021, 51(3): 1140-1145. |

| [2] | 宫亚峰,逄蕴泽,王博,谭国金,毕海鹏. 基于吉林省路况的新型预制装配式箱涵结构的力学性能[J]. 吉林大学学报(工学版), 2021, 51(3): 917-924. |

| [3] | 苏畅,韩颖,张英朝,苗振华. 轮辐设计特征参数对整车气动特性的影响[J]. 吉林大学学报(工学版), 2021, 51(1): 107-113. |

| [4] | 谷诤巍,陈琳,赵立辉,徐虹,李欣,于歌. 轨道车辆窗下补强板冲压成形模拟[J]. 吉林大学学报(工学版), 2020, 50(2): 504-511. |

| [5] | 陈鑫,王宁,沈传亮,冯晓,杨昌海. 后视镜造型对前侧窗气动噪声的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 426-436. |

| [6] | 刘春宝,陈山石,盛闯,钱志辉,任露泉,任雷. 蜘蛛生物液压驱动原理及其功能仿生探索[J]. 吉林大学学报(工学版), 2020, 50(1): 375-381. |

| [7] | 施卫平,赵旭,胡兴军,余天明,柳博文,段彦. 天然气开采阻水装置AICD的设计和数值模拟[J]. 吉林大学学报(工学版), 2019, 49(6): 1986-1991. |

| [8] | 宫亚峰,王博,谭国金,张立敏,吴文丁,毕海鹏. 吉林省两种典型装配式箱涵受力特性对比分析[J]. 吉林大学学报(工学版), 2019, 49(6): 1865-1870. |

| [9] | 依卓,付文智,李明哲. 双层剖分式超高压模具数值模拟及实验[J]. 吉林大学学报(工学版), 2019, 49(5): 1593-1599. |

| [10] | 李欣,孙延朋,王丹,陈军绪,谷诤巍,徐虹. 汽车前地板成形有限元数值模拟[J]. 吉林大学学报(工学版), 2019, 49(5): 1608-1614. |

| [11] | 陈东良,臧睿,段鹏,赵伟鹏,翁旭涛,孙杨,唐艺鹏. 基于新月鱼尾推进理论的多连杆鱼骨仿生设计[J]. 吉林大学学报(工学版), 2019, 49(4): 1246-1257. |

| [12] | 李欣,王丹,陈军绪,孙延朋,谷诤巍,徐虹. 手刹固定板冲压成形数值模拟[J]. 吉林大学学报(工学版), 2019, 49(4): 1258-1265. |

| [13] | 张学广,贾明萌,刘纯国,何广忠. 基于增量控制的型材拉弯轨迹设计及有限元仿真[J]. 吉林大学学报(工学版), 2019, 49(4): 1272-1279. |

| [14] | 吴娜,庄健,张克松,王慧鑫,马云海. 毛蚶贝壳曲面承压力学特性及断裂机理[J]. 吉林大学学报(工学版), 2019, 49(3): 897-902. |

| [15] | 郭昊添,徐涛,梁逍,于征磊,刘欢,马龙. 仿鲨鳃扰流结构的过渡段换热表面优化设计[J]. 吉林大学学报(工学版), 2018, 48(6): 1793-1798. |

|

||