吉林大学学报(工学版) ›› 2018, Vol. 48 ›› Issue (6): 1787-1792.doi: 10.13229/j.cnki.jdxbgxb20170955

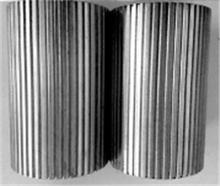

仿生条纹形磨辊磨损试验及耐磨机理分析

- 吉林大学 工程仿生教育部重点实验室,长春 130022

Wear test and anti-friction mechanism analysis of bionic stripe grinding roll

XI Peng( ),CONG Qian(

),CONG Qian( ),WANG Qing-bo,GUO Hua-xi

),WANG Qing-bo,GUO Hua-xi

- Key Laboratory of Bionic Engineering, Ministry of Education, Jilin University, Changchun 130022,China

摘要:

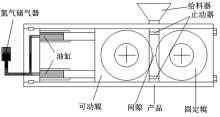

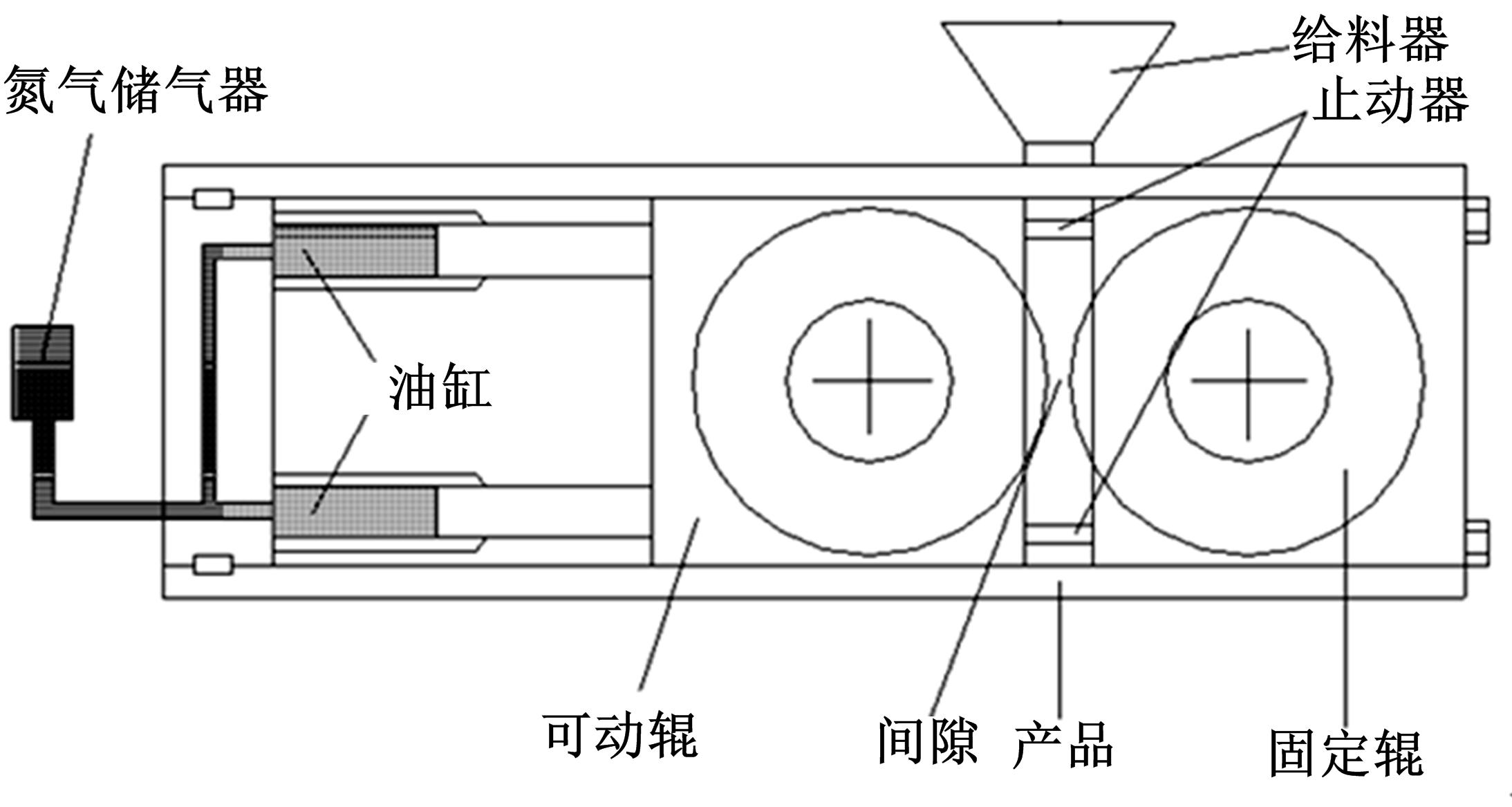

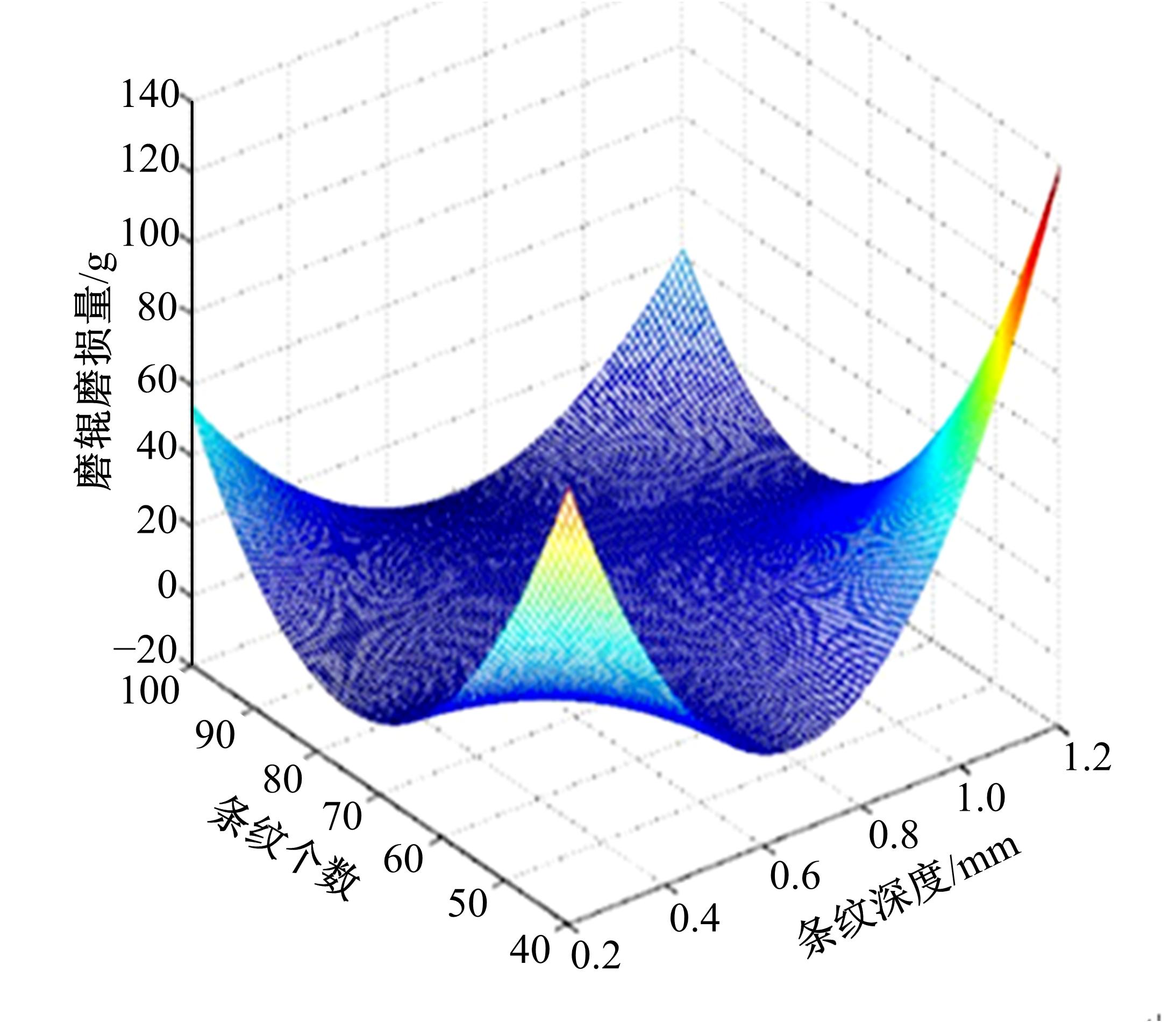

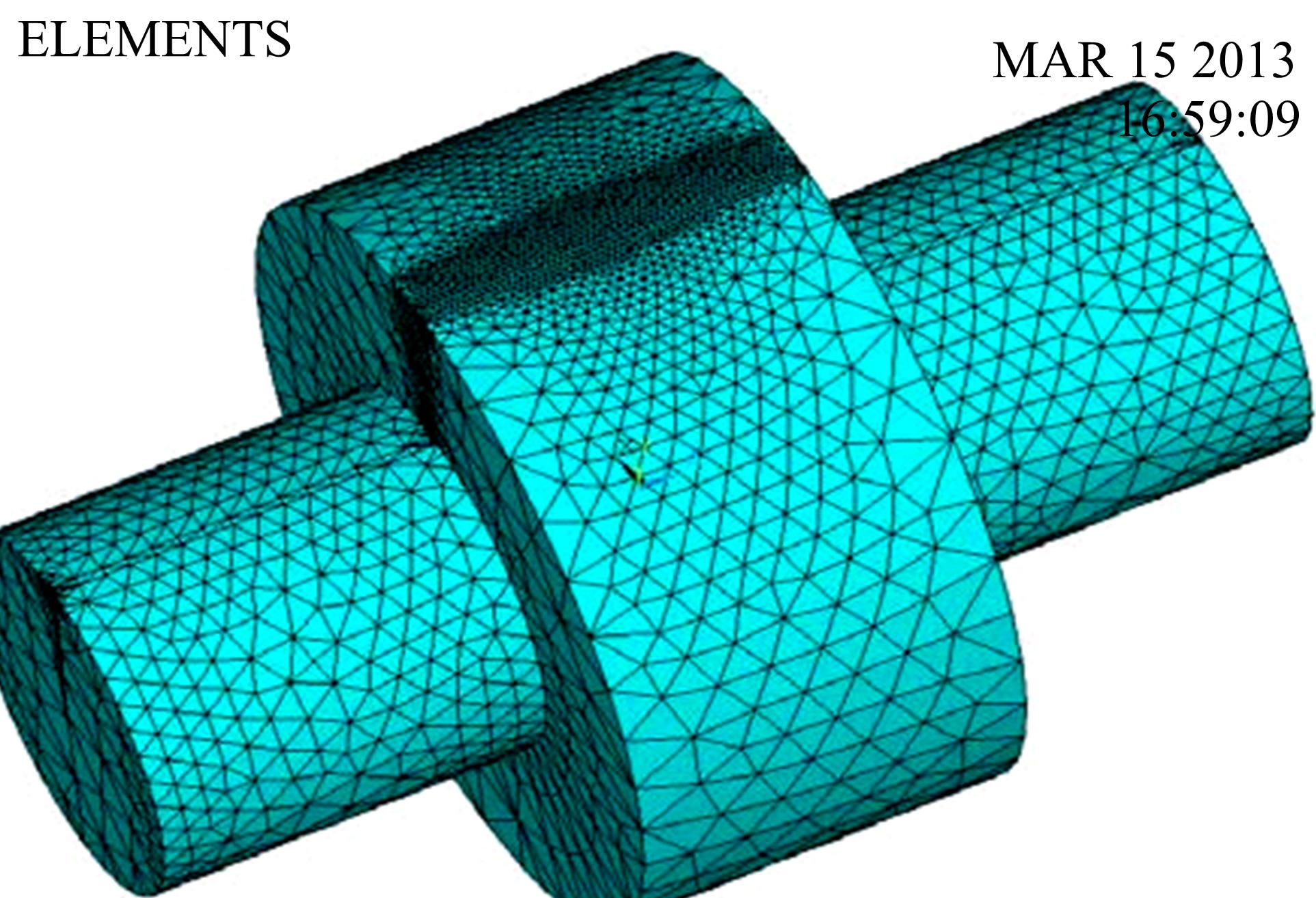

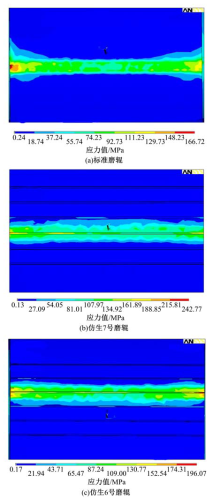

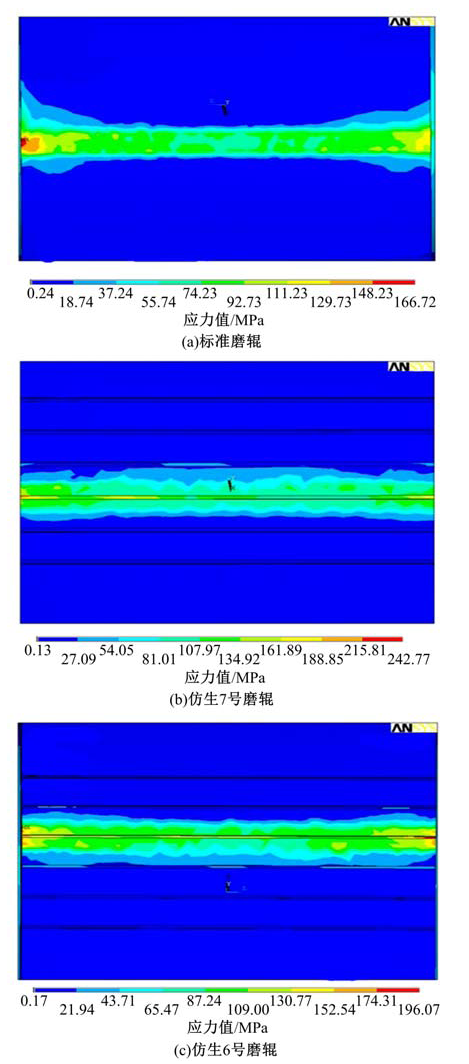

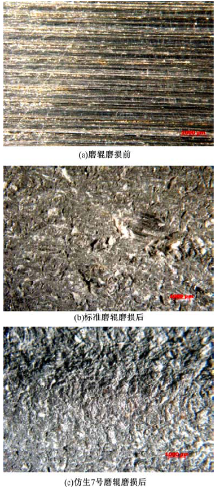

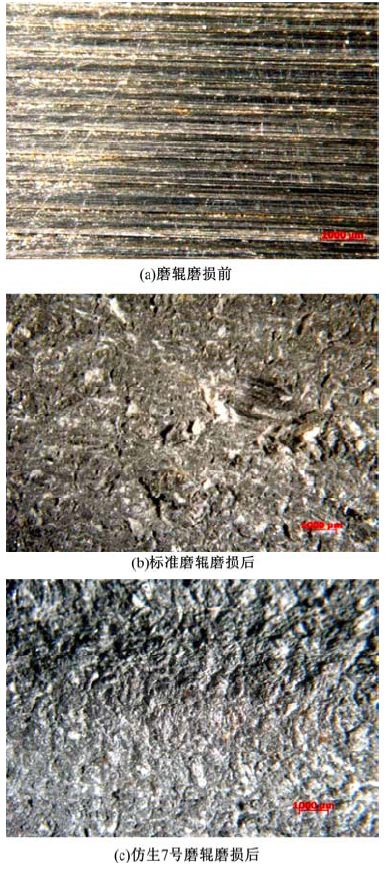

为了提高辊压机磨辊的耐磨性能,模仿自然界中生物体表形态,在磨辊表面设计并加工出不同深度、不同周向个数的仿生条纹形结构,并根据正交试验设计方案对磨辊进行磨损试验。结果表明:仿生条纹形结构能有效提高磨辊的耐磨性能,条纹深度和条纹周向个数对磨损量均有影响。相较于标准磨辊,仿生磨辊的耐磨性最大可提高72.1%。分析仿生磨辊耐磨机理发现:条纹形结构使磨辊与石英砂接触更加充分均匀,同时减少了石英砂在其表面滑磨的机率,从而优化了磨辊整体及各局部的受力情况,是提高磨辊耐磨性的重要原因。

中图分类号:

- TH69

| [1] |

鲍崇高 . 磨辊表层的材料与耐磨性[J]. 现代面粉工业, 2010,24(4):16-19.

doi: 10.3969/j.issn.1674-5280.2010.04.007 |

|

Bao Chong-gao . The material and wear resistance of the grinding roller surface[J]. Modern Flour Milling Industry, 2010,24(4):16-19.

doi: 10.3969/j.issn.1674-5280.2010.04.007 |

|

| [2] | 明亮 . 德国KHD公司三工位转台式振动成型机[J]. 设备管理与维修, 2010(7):71-72. |

| Ming Liang . Three station turntable type vibration forming machine of German KHD company[J]. Plant Maintenance Engineering, 2010(7):71-72. | |

| [3] |

张莉, 张茂花 . CDG型辊压机的结构特点[J]. 新世纪水泥导报, 2010,16(2):25-27.

doi: 10.3969/j.issn.1008-0473.2010.02.006 |

|

Zhang Li, Zhang Mao-hua . Structural features of CDG roller press[J]. Cement Guide for New Epoch, 2010,16(2):25-27.

doi: 10.3969/j.issn.1008-0473.2010.02.006 |

|

| [4] |

Matthijs G, Rymen D, Beatriz M , et al. Approaches to homozygosity mapping and exome sequencing for the identification of novel types of CDG[J]. Glycoconjugate Journal, 2013,30(1):67-76.

doi: 10.1007/s10719-012-9445-7 |

| [5] |

Jaeken J, Hennet T, Matthijs G , et al. CDG nomenclature: time for a change![J]. Biochim Biophys Acta, 2009,1792(9):825-826.

doi: 10.1016/j.bbadis.2009.08.005 pmid: 3917312 |

| [6] |

Coorg R, Lotze T E . Child neurology: a case of PMM2-CDG (CDG 1a) presenting with unusual eye movements[J]. Neurology, 2012,79(15):131-133.

doi: 10.1212/WNL.0b013e31826e2617 pmid: 23045520 |

| [7] |

Fernández I, Belzunce F J . Wear and oxidation behavior of high chromium white cast irons[J]. Materials Characterization, 2008,59(6):669-674.

doi: 10.1016/j.matchar.2007.05.021 |

| [8] | Lv Hai-feng, Cao Hai-ning, Xu Zhong-zhou . Efficient energy-saving roller press[P]. China Patent:CN 202762472 U, 2012-09-04. |

| [9] |

张维果, 王学成 . 浅谈煤矿机械磨料磨损机理[J]. 煤炭工程, 2010(6):76-78.

doi: 10.3969/j.issn.1671-0959.2010.06.030 |

|

Zhang Wei-guo, Wang Xue-cheng . Abrasive wear mechanism of coal mine machinery[J]. Coal Engineering, 2010(6):76-78.

doi: 10.3969/j.issn.1671-0959.2010.06.030 |

|

| [10] |

孙艺文, 汝绍锋, 丛茜 . 仿生凹坑形钻井泥浆泵活塞磨损寿命试验[J]. 石油学报, 2017,38(2):234-240.

doi: 10.7623/syxb201702011 |

|

Sun Yi-wen, Ru Shao-feng, Cong Qian . Wear-life experiment of drilling mud pump piston with dimple-shaped bionic surface[J]. Acta Petrolei Sinica, 2017,38(2):234-240.

doi: 10.7623/syxb201702011 |

|

| [11] |

Harsha A P, Jha S K . Erosive wear studies of epoxy-based composites at normal incidence[J]. Wear, 2008,265(7/8):1129-1135.

doi: 10.1016/j.wear.2008.03.003 |

| [12] | Li Yan-bin, Gao You-hua. Finite element analysis for platform of 3 DOF spacecraft simulator based on the theory of deformable body mechanics [C]//2010 International Conference on Mechanic Automation and Control Engineering(MACE),Wuhan,China, 2010: 709-712. |

| [13] | 黄胜 . 高压辊磨机粉碎行为研究[D]. 长沙:中南大学机电工程学院, 2012. |

| Huang Sheng . Research on crush behavior of high pressure grinding rolls[D]. Changsha: College of Mechanical and Electrical Engineering, Central South University, 2012. | |

| [14] | 金向明, 高德平, 蔡显新 , 等. 航空发动机静不定转子支撑载荷的有限元分析[J]. 航空动力学报, 2008,23(7):1323-1327. |

| Jin Xiang-ming, Gao De-ping, Cai Xian-xin , et al. Finite element analysis of inertial load of the statically indeterminate rotor stay bearing[J]. Journal of Aerospace Power, 2008,23(7):1323-1327. | |

| [15] | 刘超 . 高压辊磨机振动特征提取与分析[D]. 长沙:中南大学机电工程学院, 2012. |

| Liu Chao . Vibration feature extraction and analysis of high pressure grinding roll[D]. Changsha:College of Mechanical and Electrical Engineering, Central South University, 2012. | |

| [16] |

Cimilli S, Nergis F B U, Candan C . Modeling of heat transfer measurement unit for cotton plain knitted fabric using a finite element method[J]. Textile Research Journal, 2008,78(1):53-59.

doi: 10.1177/0040517507082186 |

| [17] |

Zuo Xiao-ming, Xu Zhao-mei . Thermal analysis and optimization of plant-fiber and starch dishware mould based on ANSYS[J]. Advanced Materials Research, 2010, 102-104:125-129.

doi: 10.4028/www.scientific.net/AMR.102-104.125 |

| [18] |

Qin Xian-yun, Zhang Jian-ming, Li Guang-yao , et al. An element implementation of the boundary face method for 3D potential problems[J]. Engineering Analysis with Boundary Elements, 2010,34(11):934-943.

doi: 10.1016/j.enganabound.2010.04.009 |

| [1] | 吴娜,庄健,张克松,王慧鑫,马云海. 毛蚶贝壳曲面承压力学特性及断裂机理[J]. 吉林大学学报(工学版), 2019, 49(3): 897-902. |

| [2] | 郭昊添,徐涛,梁逍,于征磊,刘欢,马龙. 仿鲨鳃扰流结构的过渡段换热表面优化设计[J]. 吉林大学学报(工学版), 2018, 48(6): 1793-1798. |

| [3] | 郑孝义, 孙大千, 李欣, 都桂刚, 辛伟达, 任振安. NbAl3强化Al-Nb熔覆层的组织与性能[J]. 吉林大学学报(工学版), 2018, 48(5): 1531-1536. |

| [4] | 田为军, 王骥月, 李明, 张兴旺, 张勇, 丛茜. 面向水上机器人的水黾运动观测[J]. 吉林大学学报(工学版), 2018, 48(3): 812-820. |

| [5] | 钱志辉, 周亮, 任雷, 任露泉. 具有仿生距下关节和跖趾关节的完全被动步行机[J]. 吉林大学学报(工学版), 2018, 48(1): 205-211. |

| [6] | 田丽梅, 王养俊, 李子源, 商延赓. 仿生功能表面内流减阻测试系统的研制[J]. 吉林大学学报(工学版), 2017, 47(4): 1179-1184. |

| [7] | 陈东辉, 刘伟, 吕建华, 常志勇, 吴婷, 慕海锋. 基于虾夷扇贝体表结构的玉米茬根捡拾器仿生设计[J]. 吉林大学学报(工学版), 2017, 47(4): 1185-1193. |

| [8] | 王颖, 李建桥, 张广权, 黄晗, 邹猛. 基于多种介质的仿生步行足力学特性[J]. 吉林大学学报(工学版), 2017, 47(2): 546-551. |

| [9] | 葛长江, 叶辉, 胡兴军, 于征磊. 鸮翼后缘噪声的预测及控制[J]. 吉林大学学报(工学版), 2016, 46(6): 1981-1986. |

| [10] | 李梦, 苏义脑, 孙友宏, 高科. 高胎体仿生异型齿孕镶金刚石钻头[J]. 吉林大学学报(工学版), 2016, 46(5): 1540-1545. |

| [11] | 梁云虹, 任露泉. 自然生境及其仿生学初探[J]. 吉林大学学报(工学版), 2016, 46(5): 1746-1756. |

| [12] | 梁云虹, 任露泉. 人类生活及其仿生学初探[J]. 吉林大学学报(工学版), 2016, 46(4): 1373-1384. |

| [13] | 钱志辉, 苗怀彬, 任雷, 任露泉. 基于多种步态的德国牧羊犬下肢关节角[J]. 吉林大学学报(工学版), 2015, 45(6): 1857-1862. |

| [14] | 邹猛, 于用军, 张荣荣, 魏灿刚, 王会霞. 仿牛角结构薄壁管吸能特性仿真分析[J]. 吉林大学学报(工学版), 2015, 45(6): 1863-1868. |

| [15] | 杨卓娟, 王庆成, 高英, 门玉琢, 杨晓东. 不同溶液对荷叶润湿性能的影响[J]. 吉林大学学报(工学版), 2015, 45(6): 1869-1873. |

|