吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (3): 816-821.doi: 10.13229/j.cnki.jdxbgxb20180263

金属表面特征与金属⁃塑料直接连接强度的相关性

马芳武1,2( ),陈实现1,2,韩露1,2,梁鸿宇1,2,蒲永锋1,2(

),陈实现1,2,韩露1,2,梁鸿宇1,2,蒲永锋1,2( )

)

- 1. 吉林大学 汽车仿真与控制国家重点实验室, 长春 130022

2. 吉林大学 青岛汽车研究院, 山东 青岛 266043

Correlation between metal surface morphology and metal⁃plastic direct adhesion strength

Fang⁃wu MA1,2( ),Shi⁃xian CHEN1,2,Lu HAN1,2,Hong⁃yu LIANG1,2,Yong⁃feng PU1,2(

),Shi⁃xian CHEN1,2,Lu HAN1,2,Hong⁃yu LIANG1,2,Yong⁃feng PU1,2( )

)

- 1. State Key Laboratory of Automotive Simulation and Control, Jilin University, Changchun 130022, China

2. Qingdao Automotive Research Institute, Jilin University, Qingdao 266043, China

摘要:

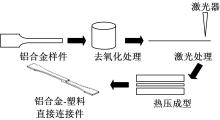

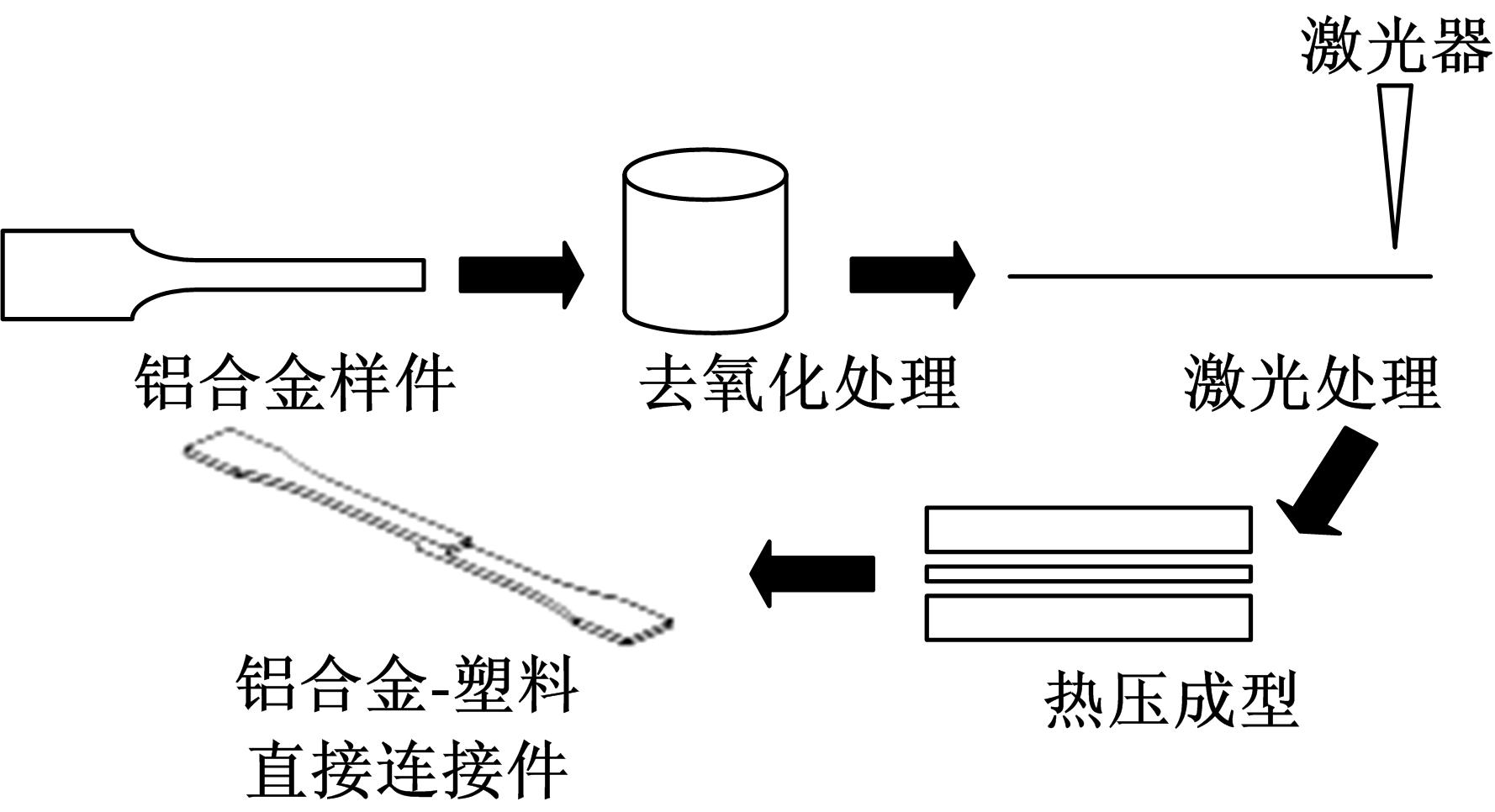

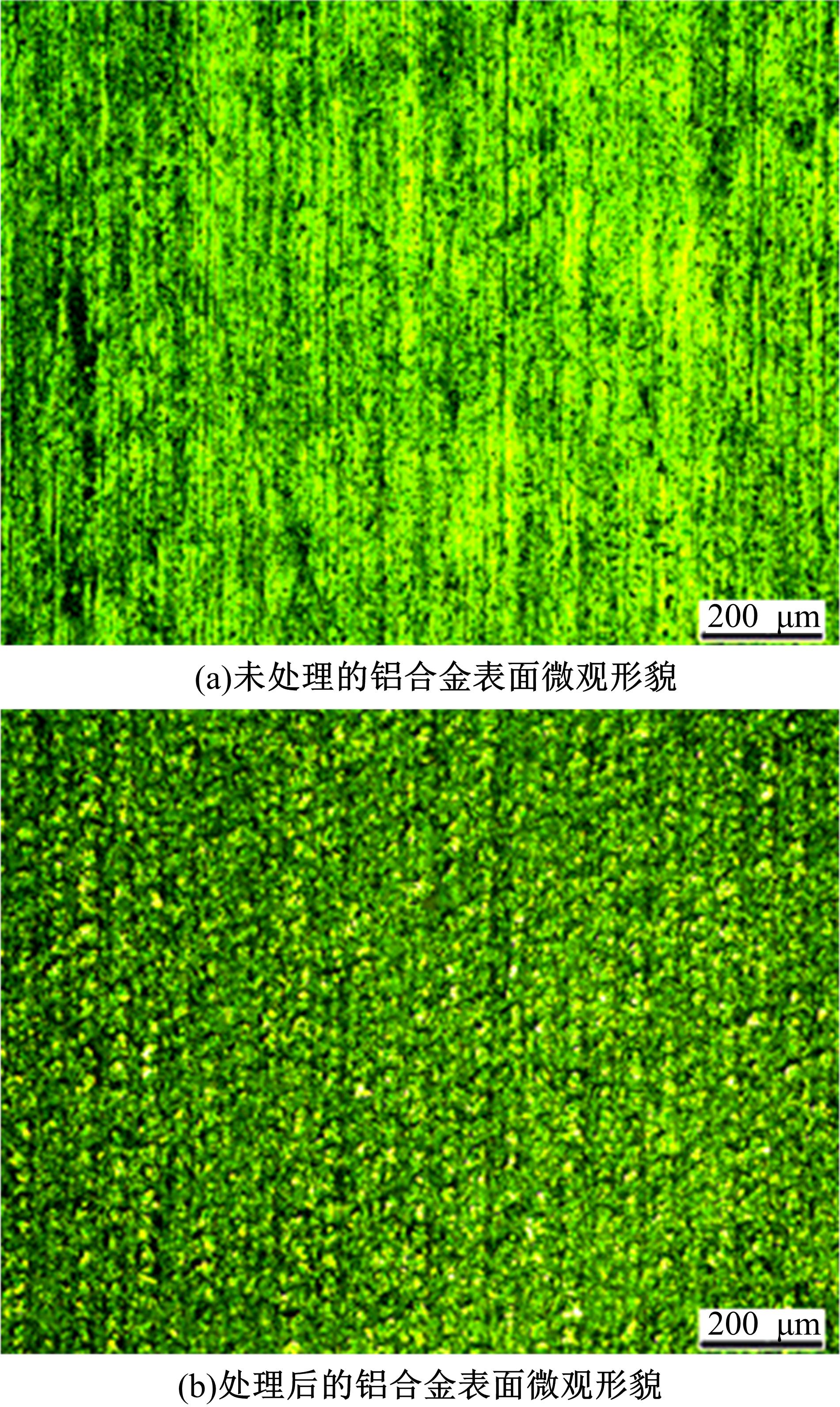

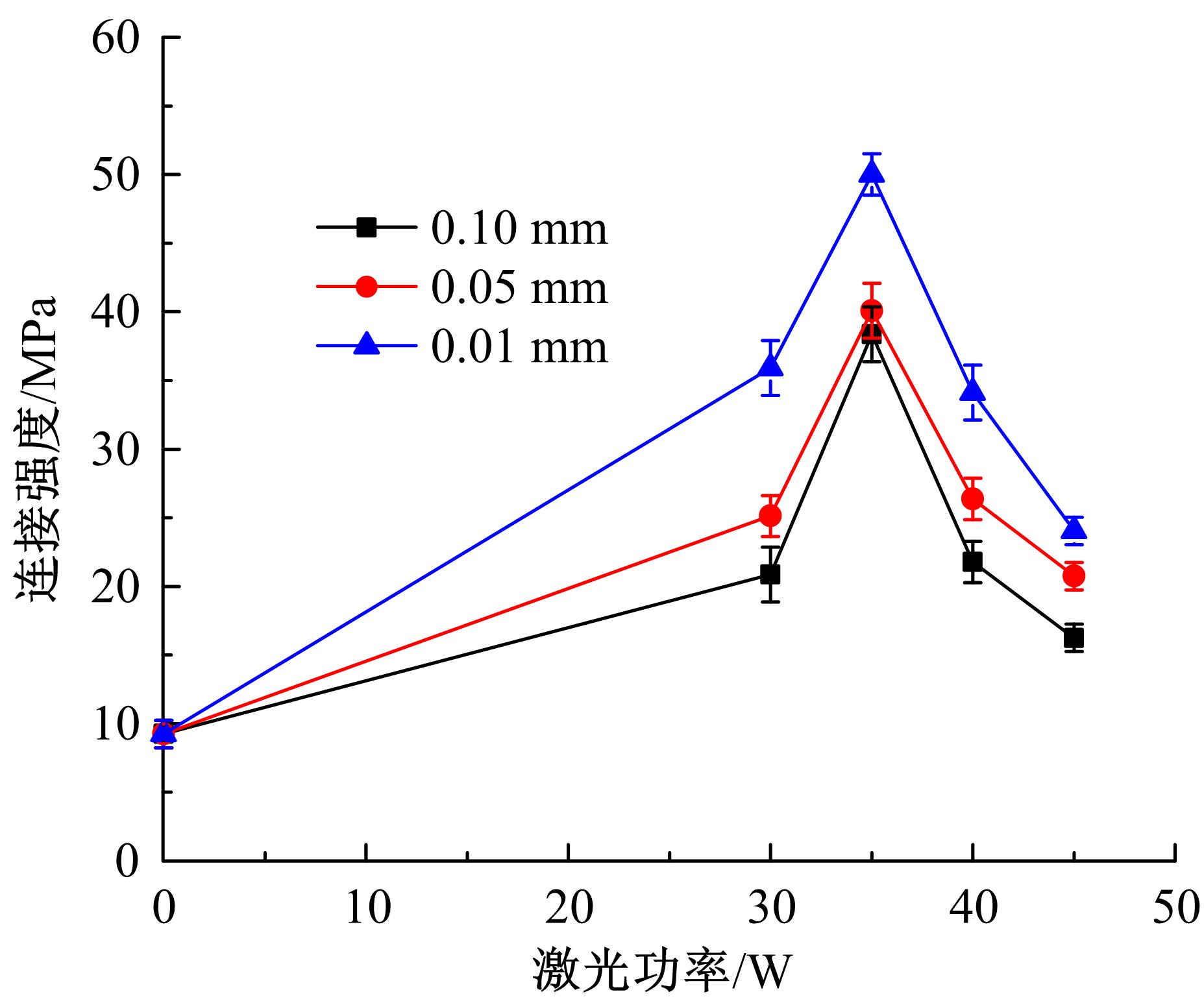

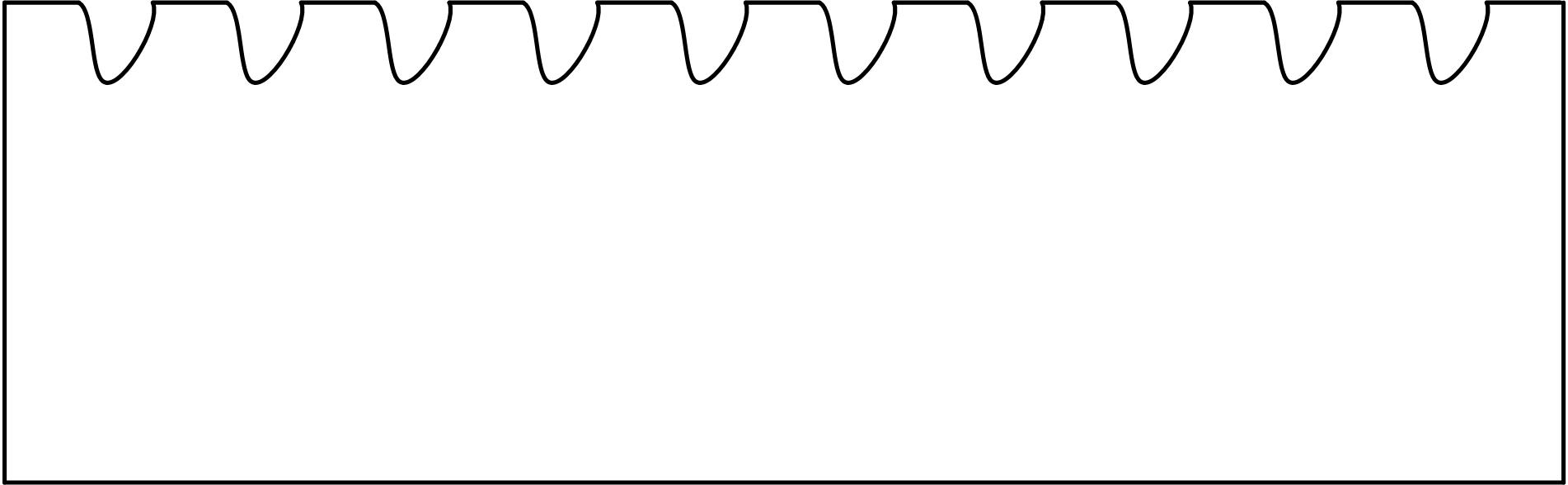

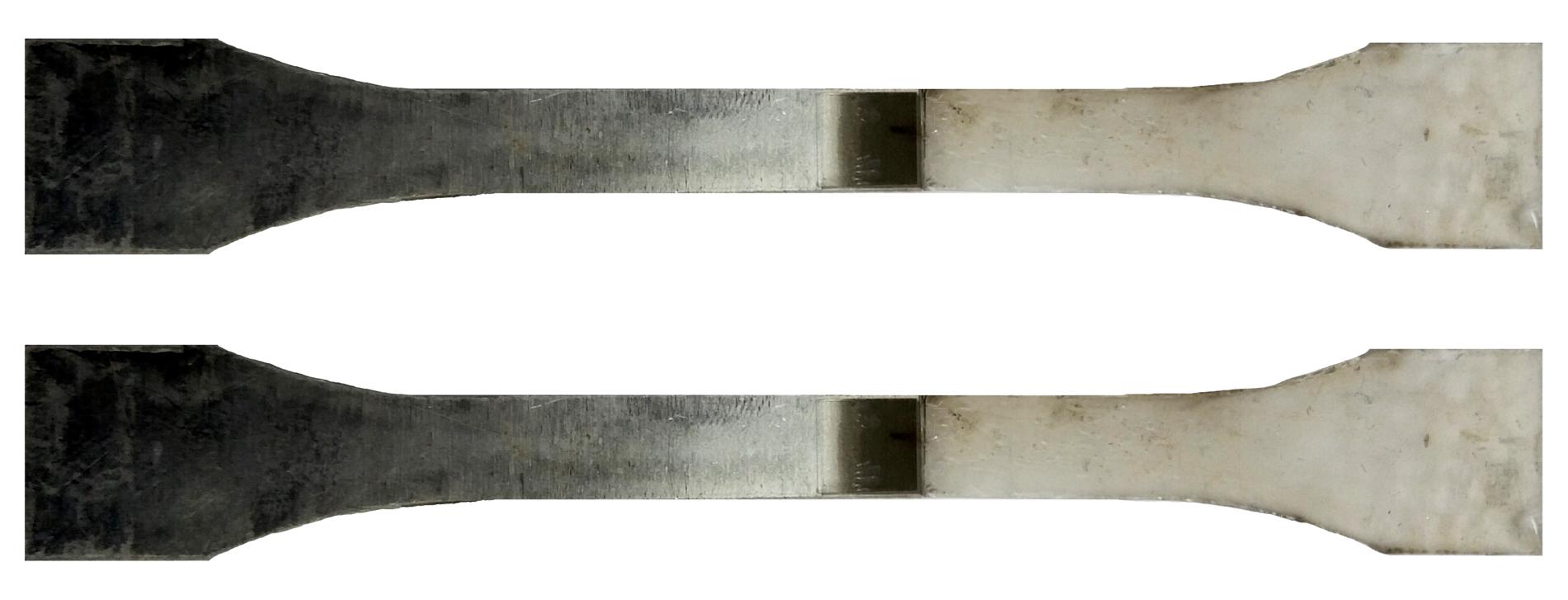

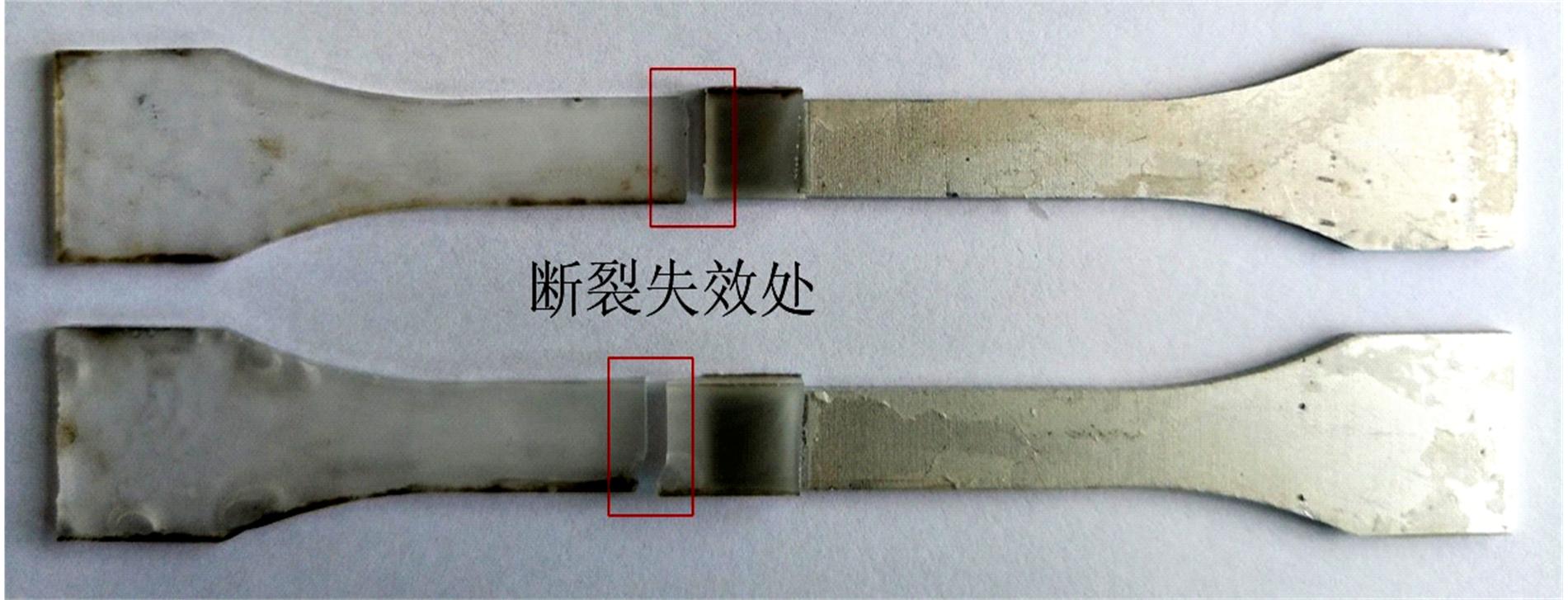

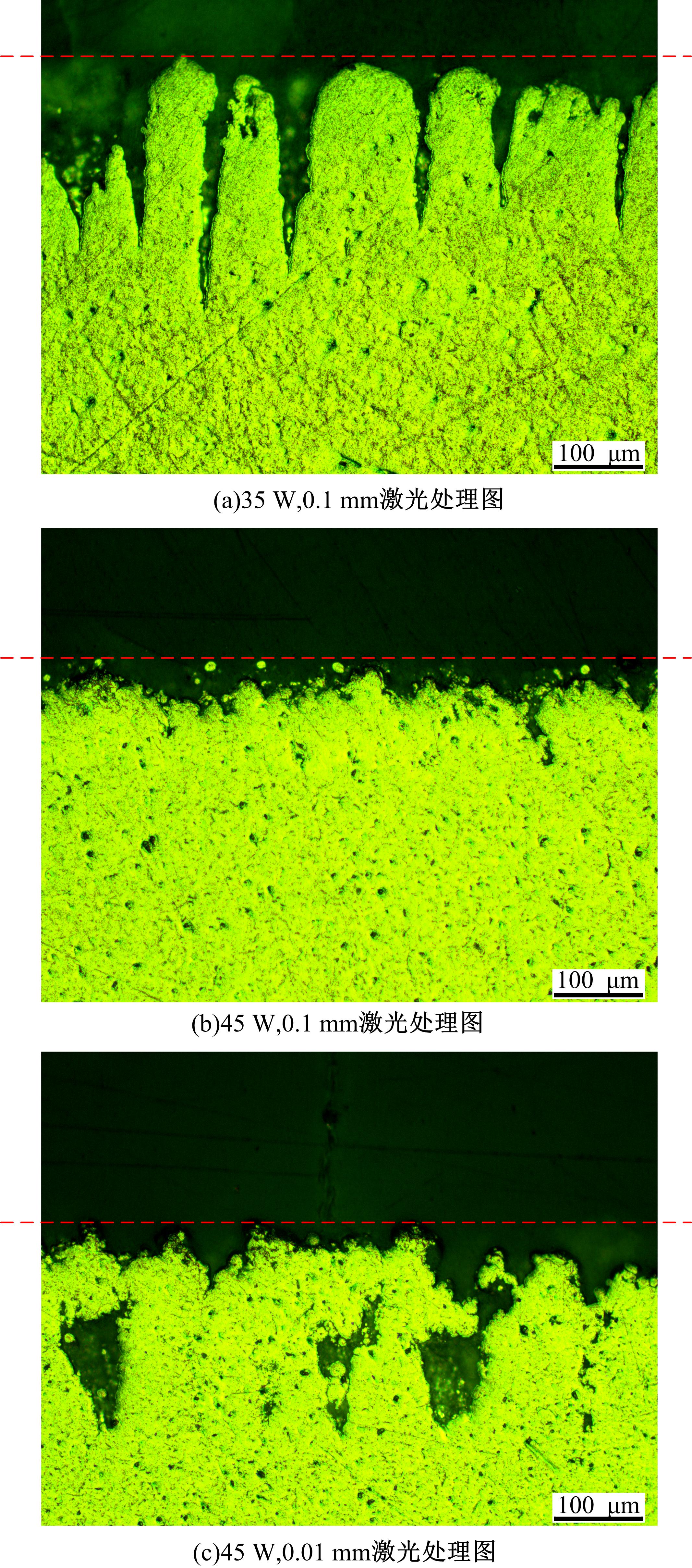

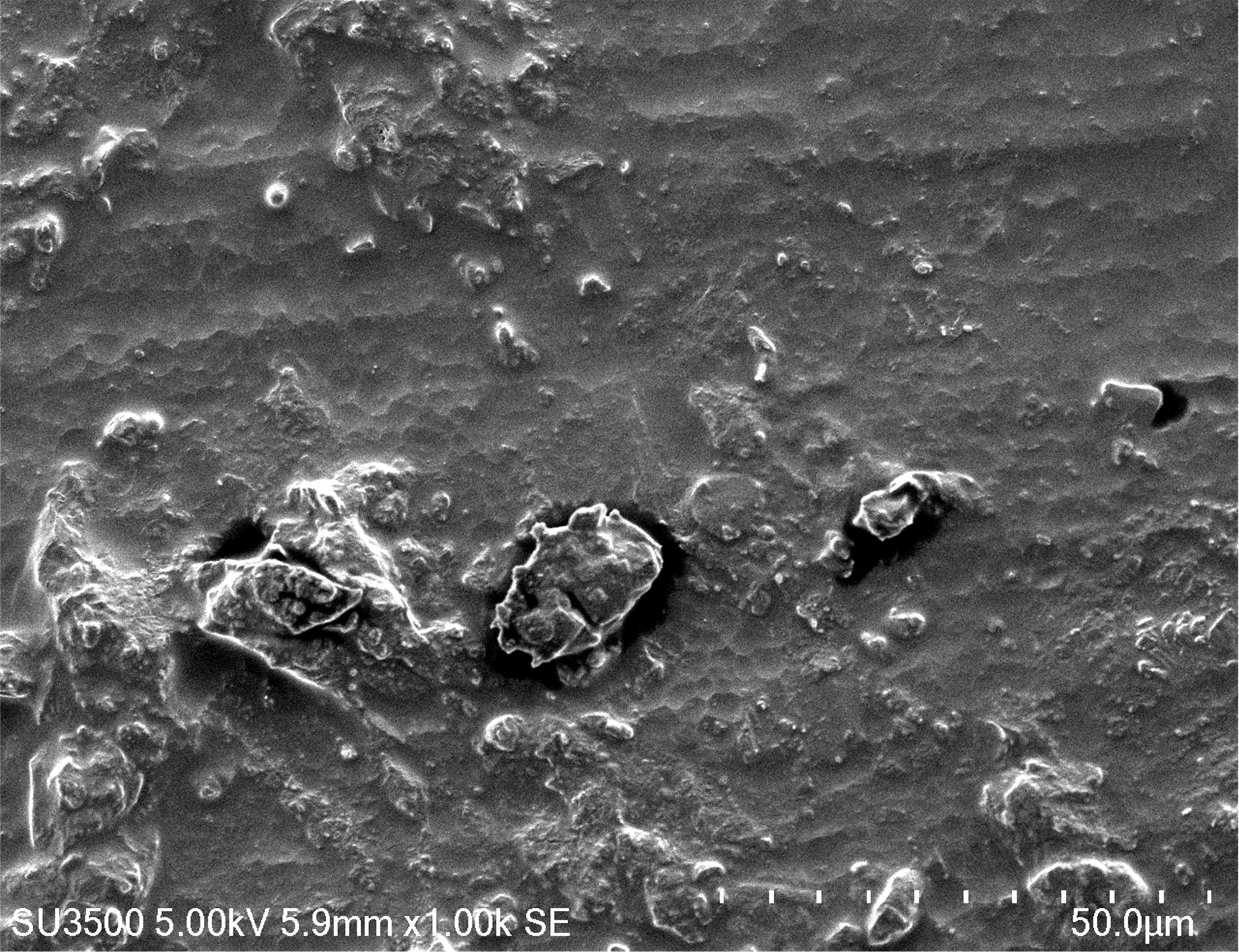

利用酸碱溶液去除金属表面的氧化膜,利用光纤激光器对金属表面进行处理,利用平板硫化机完成金属?塑料之间的热压连接成型。研究了不同激光功率和不同扫描密度对金属?塑料直接连接强度的影响。结合金属?塑料连接截面微观组织形貌和扫描电子显微镜(SEM)图,分析了金属表面特征与金属?塑料直接连接强度之间的相关性。结果表明:随着激光功率的增大,金属?塑料直接连接强度先增大后减小;随着扫描密度的增大,金属?塑料直接连接强度增大。

中图分类号:

- TH161

| 1 | 马芳武,陈实现,赵花垒,等 . 强度、刚度与模态约束下的FSC赛车车架轻量化[J]. 湖南大学学报:自然科学版,2018,45(4):18⁃25. |

| Ma Fang⁃wu , Chen Shi⁃xian , Zhao Hua⁃lei ,et al . Lightweight on frame of FSC with constriants of strength,stiffness and modal[J]. Journal of Hunan University (Natural Sciences),2018,45(4):18⁃25. | |

| 2 | 益小苏,张明,安学锋,等 . 先进航空树脂基复合材料研究与应用进展[J]. 工程塑料应用,2009,37(10):72⁃76. |

| Yi Xiao⁃su , Zhang Ming , An Xue⁃feng ,et al . Development and application of advanced aeronautical polymer matrix composites[J]. Engineering Plastics Application,2009,37(10):72⁃76. | |

| 3 | 李成,朱红红,铁瑛,等 . 单搭胶/螺栓混合连接结构的应力分布与载荷分配[J]. 吉林大学学报:工学版,2013,43(4):933⁃938. |

| Li Cheng , Zhu Hong⁃hong ,Tie Ying,et al . Stress distribution and load sharing in single⁃lap bonded/bolted joints[J]. Journal of Jilin University (Engineering and Technology Edition),2013,43(4):933⁃938. | |

| 4 | Byskov J , Boll J V , Holm A H , et al . Ultra⁃high⁃strength micro⁃mechanical interlocking by injection molding into laser⁃structured surfaces[J]. International Journal of Adhesion & Adhesives,2010,30(6):485⁃488. |

| 5 | 李熹平,刘傅文,王爽,等 . 金⁃塑微结构注射成型仿真与试验研究[J]. 机械工程学报,2016,52(22):61⁃69. |

| Li Xi⁃ping , Liu Fu⁃wen , Wang Shuang , et al . Simulation and experiment study of metal⁃polymer composite injected with microstructure[J]. Journal of Mechanical Engineering,2016,52(22):61⁃69. | |

| 6 | Huang B , Sun L , Li L ,et al . Experimental investigation of the strength of polymer⁃steel direct adhesion (PSDA) joints with micro⁃structures ablated by laser[J]. Journal of Materials Processing Technology,2017,249:407⁃414. |

| 7 | Su Y , Rooij M D , Grouve W ,et al . The effect of titanium surface treatment on the interfacial strength of titanium⁃thermoplastic composite joints[J]. International Journal of Adhesion & Adhesives,2017,72:98⁃108. |

| 8 | 刘傅文,李熹平,宫宁宁,等 . 界面微构对注射成型铝塑复合件性能的影响研究[J]. 机械工程学报,2018,54(12):148⁃155. |

| Liu Fu⁃wen , Li Xi⁃ping , Gong Ning⁃ning , et al . Effect of interfacial microstructure on properties of aluminum⁃plastic composite[J]. Journal of Mechanical Engineering,2018,54(12):148⁃155. | |

| 9 | Rauschenberger J , Cenigaonaindia A , Keseberg J ,et al . Laser hybrid joining of plastic and metal components for lightweight components[J]. Proceedings of SPIE—The International Society for Optical Engineering,San Francisco,California,USA,2015:93560B. |

| 10 | 杜彦丽 . PMH技术成形工艺对粘结强度影响的研究[D]. 上海:上海交通大学材料科学与工程学院,2010. |

| Du Yan⁃li . Research on the effect of polymer metal hybrid technology process parameters on adhesive strength[D]. Shanghai: School of Materials Science and Engineering,Shanghai Jiaotong University, 2010. | |

| 11 | Lin H Y , Chang C H , Young W B . Experimental study on the filling of nano structures with infrared mold surface heating[J]. International Polymer Processing Journal of the Polymer Processing Society,2011,26(1):73⁃81. |

| 12 | Jiang J , Wang S , Sun B ,et al . Effect of mold temperature on the structures and mechanical properties of micro⁃injection molded polypropylene[J]. Materials & Design,2015,88:245⁃251. |

| 13 | Kim S K , Kim D J , Jung J S ,et al . Flow instability of semicrystalline polymer melt during micro⁃injection molding[J]. Journal of Micromechanics & Microengineering,2014,24(8):085015. |

| 14 | Yeong⁃Eun Yoo , Tae⁃Hoon Kim , Tae⁃Jin Je , et al . Injection molding of micro patterned PMMA plate[J]. Transactions of Nonferrous Metals Society of China,2011,21(Sup.1):148⁃152. |

| [1] | 寇淑清, 石舟. 裂解连杆接合面三维重构及其强度与刚度[J]. 吉林大学学报(工学版), 2018, 48(5): 1515-1523. |

| [2] | 李俊烨, 胡敬磊, 杨兆军, 张心明, 周曾炜. 离散相磨粒粒径对磨粒流研抛共轨管质量的影响[J]. 吉林大学学报(工学版), 2018, 48(2): 492-499. |

| [3] | 陈超, 赵升吨, 崔敏超, 韩晓兰, 范淑琴, 石田徹. AL5052铝合金板平压重塑形连接试验[J]. 吉林大学学报(工学版), 2017, 47(5): 1512-1518. |

| [4] | 郎利辉, 阚鹏, 王耀, 孙志莹, 张泉达. 铝合金板材三向应力状态下的成形性能[J]. 吉林大学学报(工学版), 2017, 47(5): 1527-1533. |

| [5] | 张鹏, 寇淑清, 赵勇, 林宝君. 装配式凸轮轴三点式轴向滚花过程[J]. 吉林大学学报(工学版), 2016, 46(6): 1953-1960. |

| [6] | 王犇, 王晓力. 硅微球轴承关键工艺[J]. 吉林大学学报(工学版), 2016, 46(3): 824-830. |

| [7] | 郭哲锋, 汤文成. 杯形件二次拉深的应力分析[J]. 吉林大学学报(工学版), 2016, 46(2): 494-499. |

| [8] | 滕菲, 刘博, 张万喜, 高嵩. 柔性三维拉弯成形工艺稳健设计[J]. 吉林大学学报(工学版), 2015, 45(5): 1481-1487. |

| [9] | 寇淑清, 张鹏, 韩广秘, 杨慎华. 装配式凸轮轴多道次扩径联接工艺[J]. 吉林大学学报(工学版), 2014, 44(2): 398-403. |

| [10] | 寇淑清, 杨宏宇, 高岩, 杨慎华. 裂解连杆断裂结合面缺损面积定量描述与分析[J]. 吉林大学学报(工学版), 2013, 43(06): 1541-1545. |

| [11] | 洪肇斌, 杨兆军, 张学成, 王佰超. 基于齿面发生线的弧齿锥齿轮铣削加工仿真分析[J]. 吉林大学学报(工学版), 2013, 43(02): 334-339. |

| [12] | 宋占杰, 张美, 何改云, 刘佩佩. 基于质心Voronoi结构的自由曲面布点策略[J]. 吉林大学学报(工学版), 2013, 43(01): 34-38. |

| [13] | 曲兴田, 王滨, 张雷, 邵奎伟, 张亮. 焊缝磨抛图像预处理技术[J]. , 2012, (06): 1421-1425. |

| [14] | 李国发, 张栋林, 龚金龙, 王利斌. ZrO2陶瓷激光加热辅助切削加工技术[J]. , 2012, (06): 1409-1414. |

| [15] | 张雷, 耿伟强, 鲍勇吉, 赵继. 用于羟基磷灰石冷喷涂的超声波送粉系统[J]. , 2012, (06): 1402-1408. |

|

||