吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (2): 648-653.doi: 10.13229/j.cnki.jdxbgxb20190006

• 交通运输工程·土木工程 • 上一篇

湿热养护时掺合料对玻纤增强水泥性能的影响

- 1.广州大学 土木工程学院,广州 510006

2.华南理工大学 材料科学与工程学院,广州 510640

Effect of admixture on properties of GRC under hydrothermal curing conditions

Juan HE1( ),Cong-mi CHENG1(

),Cong-mi CHENG1( ),Yi-nan YANG1,Ya-fang ZHANG1,Ming-feng ZHONG2

),Yi-nan YANG1,Ya-fang ZHANG1,Ming-feng ZHONG2

- 1.School of Civil Engineering, Guangzhou University, Guangzhou 510006, China

2.School of Materials Science & Engineering, South China University of Technology, Guangzhou 510640, China

摘要:

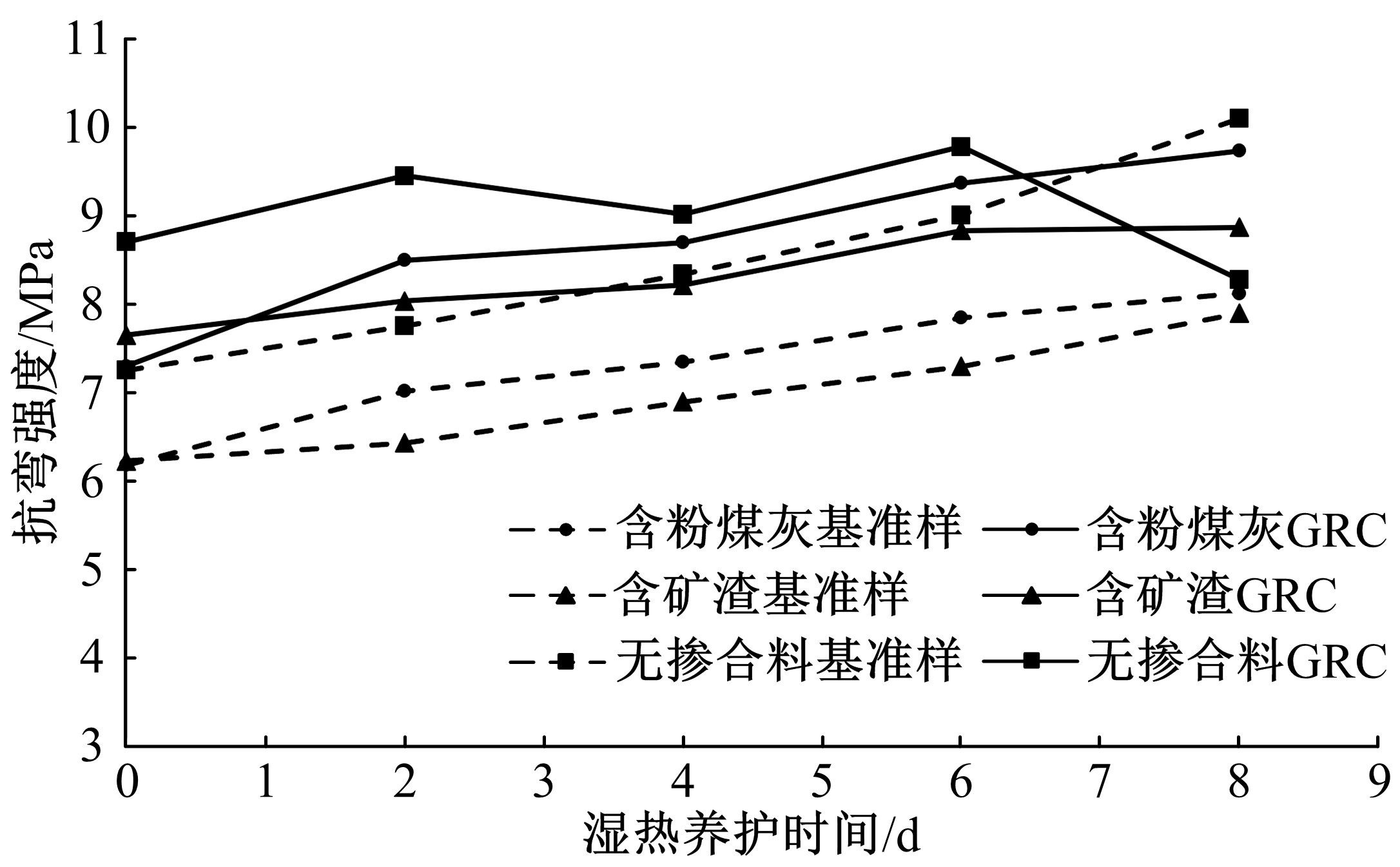

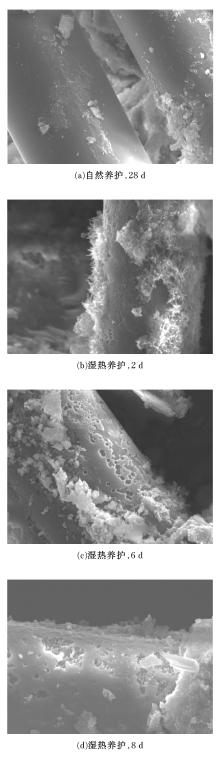

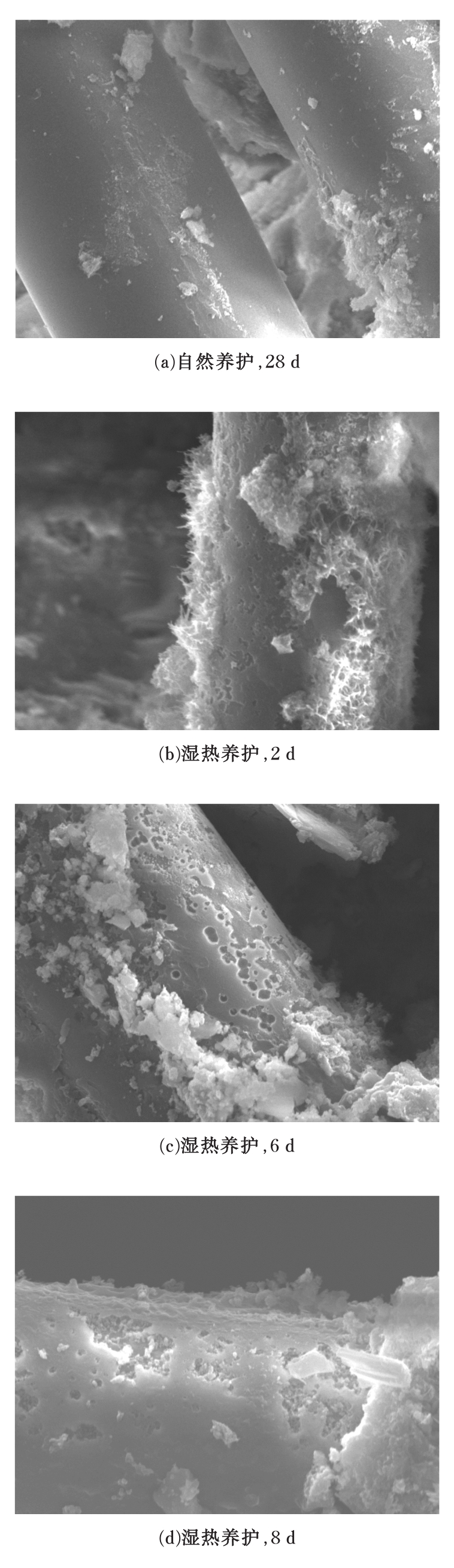

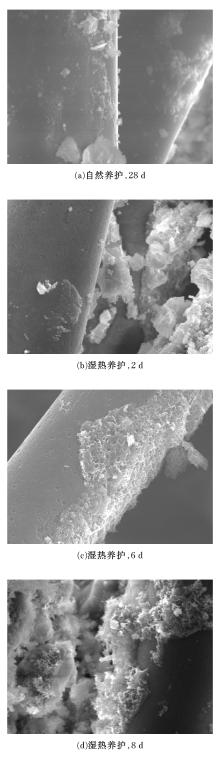

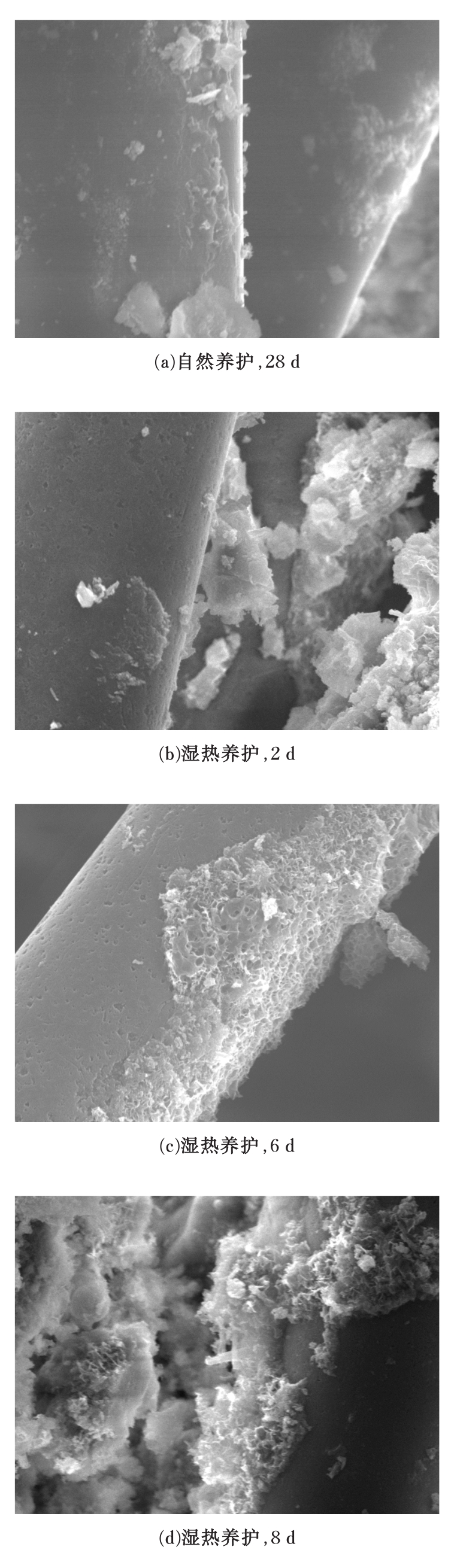

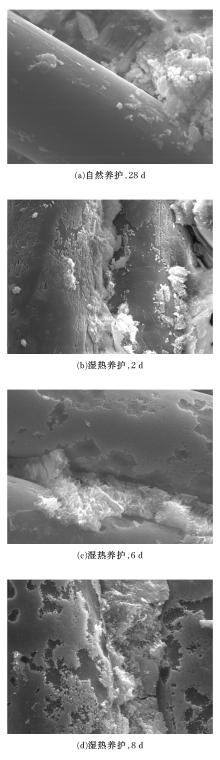

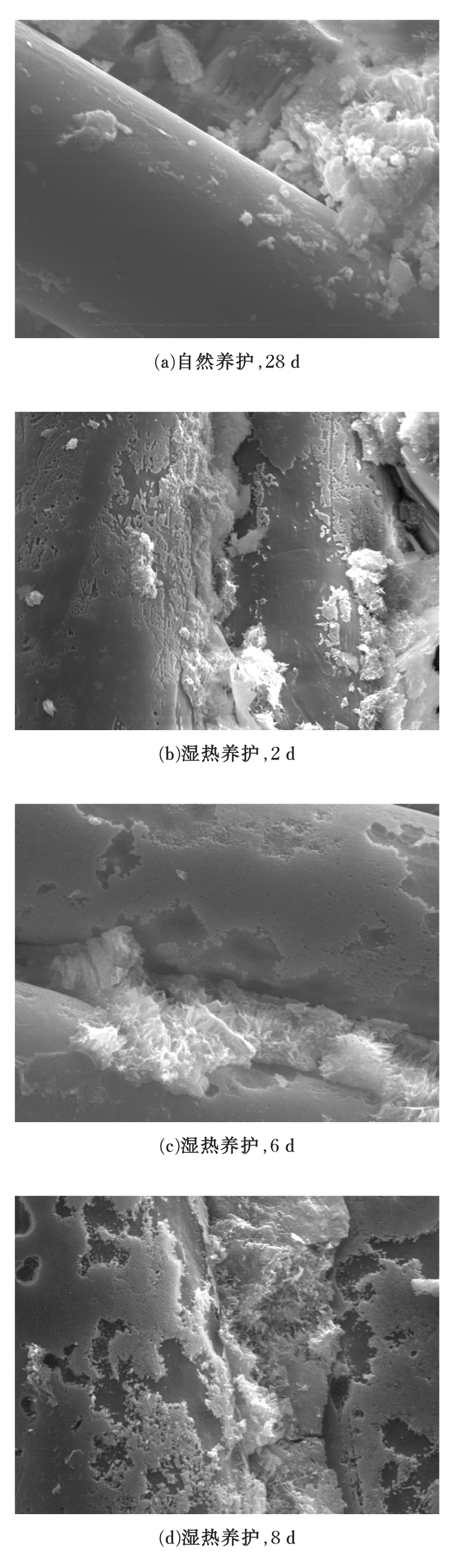

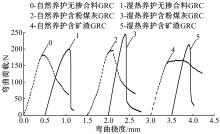

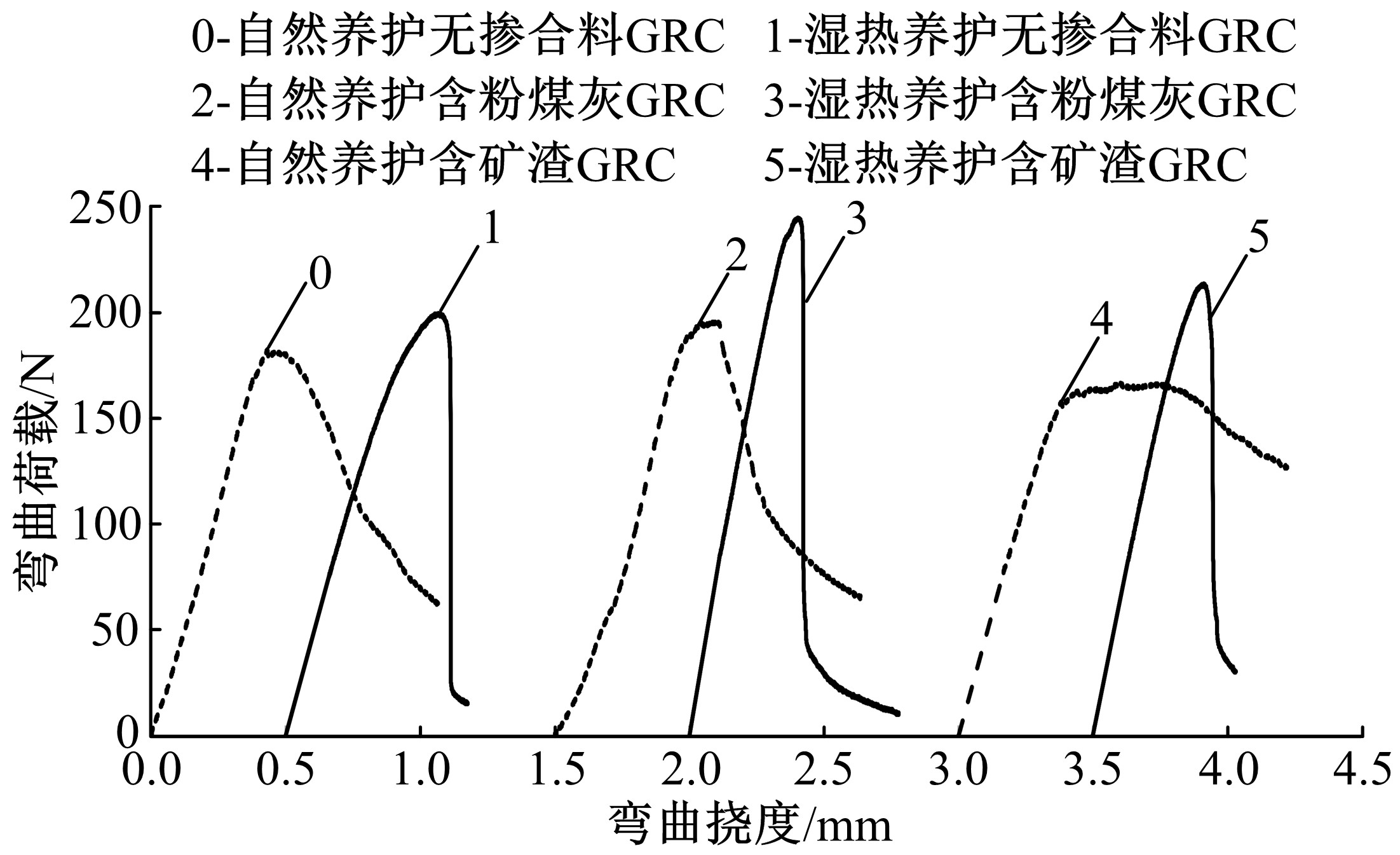

采用80 ℃湿热养护的加速老化方法,通过力学性能和微观分析研究掺合料对玻璃纤维增强硅酸盐水泥(GRC)中玻璃纤维腐蚀的影响。研究表明,GRC力学性能的经时变化是砂浆强度增长和玻璃纤维腐蚀破坏共同作用的结果,随着养护时间的延长,粉煤灰一方面使砂浆强度保持增长,另一方面抑制了玻璃纤维腐蚀,结果是玻璃纤维腐蚀减轻,GRC抗弯强度保持上升。玻璃纤维的轻微腐蚀会使其呈脆性破坏,而纤维间和周围的水化产物形成也导致其失去增韧作用,因而用韧性的变化评价GRC的退化比用强度变化来评价更有效。

中图分类号:

- TU528.581

| 1 | Dey V, Mobasher B. Quantitative characterization of accelerated aging in cement composites using flexural inverse analysis[J]. Cement & Concrete Composites, 2018, 89(5): 181-191. |

| 2 | Eiras J N, Kundu T, Bonilla M, et al. Nondestructive monitoring of ageing of alkali resistant glass fiber reinforced cement(GRC)[J]. Journal of Nondestructive Evaluation, 2013, 32(3): 300-314. |

| 3 | Alejandro E, Laura S P, Vicente S G. An alternative methodology to predict aging effects on the mechanical properties of glass fiber reinforced cements(GRC)[J]. Construction and Building Materials, 2012, 27(1) :425-431. |

| 4 | Aindow A J, Oakley D R, Proctor B A. Comparison of the weathering behaviour of GRC with predictions made from accelerated ageing tests[J]. Cement & Concrete Research, 1984, 14(2): 271-274. |

| 5 | Litherland K L, Oakley D R, Proctor B A. The use of accelerated ageing procedures to predict the long term strength of GRC composites[J]. Cement & Concrete Research, 1981, 11(3): 455-466. |

| 6 | 陈尚, 葛敦世. 83-10耐碱玻璃纤维在普硅水泥中长期强度的预测[J]. 玻璃纤维, 1987(3): 6-9. |

| Chen Shang, Ge Dun-shi. 83-10 alkali resistant glass fiber in the prediction of long-term strength of pervasive silicon cement[J]. Glass Fiber, 1987(3): 4-7. | |

| 7 | Qin X, Li X, Cai X. The applicability of alkaline-resistant glass fiber in cement mortar of road pavement: corrosion mechanism and performance analysis[J]. International Journal of Pavement Research & Technology, 2017, 10(6): 536-544. |

| 8 | 崔艳玲. GRC的耐久性及其机理研究[D]. 北京: 中国建筑材料科学研究总院, 2007. |

| Cui Yan-ling. Studies on durability of GRC and it’s mechanism[D]. Beijing: China Building Material Academy, 2007. | |

| 9 | Peled A, Jones J, Shah S P. Effect of matrix modification on durability of glass fiber reinforced cement composites[J]. Materials & Structures, 2005, 38(2): 163-171. |

| 10 | Marikunte S, Aldea C, Shah S P. Durability of glass fiber reinforced cement composites: effect of silica fume and metakaolin[J]. Advanced Cement Based Materials, 1997, 5(3/4): 100-108. |

| 11 | Purnell P, Short N R, Page C L, et al. Accelerated ageing characteristics of glass-fibre reinforced cement made with new cementitious matrices[J]. Composites Part A: Applied Science & Manufacturing, 1999, 30(9): 1073-1080. |

| 12 | Yurdakul A, Dolekcekic E, Gunkaya G, et al. The usage of newly developed glass fibre in cement structure and their characterization[J]. Construction & Building Materials, 2018, 170(5): 13-19. |

| 13 | 祖群, 赵谦. 高性能玻璃纤维[M]. 北京: 国防工业出版社, 2017: 64-65. |

| 14 | 梁宁慧, 缪庆旭, 刘新荣, 等. 聚丙烯纤维增强混凝土断裂韧度及软化本构曲线确定[J]. 吉林大学学报: 工学版, 2019, 49(4): 1144-1151. |

| Liang Ning-hui, Miao Qing-xu, Liu Xin-rong, et al. Determination of fracture toughness and softening traction-separation law of polypropylene fiber reinforced concrete[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(4): 1144-1151. | |

| 15 | 孙绪杰, 潘景龙, 郑文忠. 玻璃纤维增强聚合物混凝土小型空心砌块复合墙片的抗震性能[J]. 吉林大学学报: 工学版, 2008, 38(5): 1054-1059. |

| Sun Xu-jie, Pan Jing-long, Zheng Wen-zhong. Anti-seismic behavior of composite GFRP-concrete small hollow block wall[J]. Journal of Jilin University (Engineering and Technology Edition), 2008, 38(5): 1054-1059. | |

| 16 | Orlowsky J, Raupach M, Cuypers H, et al. Durability modeling of glass fibre reinforcement in cementitious environment[J]. Materials & Structures, 2005, 38(2): 155-162. |

| 17 | 葛敦世. 玻璃纤维碱侵蚀机理和耐碱性的探讨[J]. 玻璃纤维, 2007(1): 1-9, 14. |

| Ge Dun-shi. Discussion on alkali erosion mechanism and alkali resistance of glass fibers[J]. Glass Fiber, 2007(1): 1-9, 14. | |

| 18 | Song M, Purnell P, Richardson I. Microstructure of interface between fibre and matrix in 10-year aged GRC modified by calcium sulfoaluminate cement[J]. Cement & Concrete Research, 2015, 76: 20-26. |

| [1] | 袁杰,陈歆,何虹霖,杨博,朱小骏. 微生物矿化作用下混凝土裂缝修复与性能补偿[J]. 吉林大学学报(工学版), 2020, 50(2): 641-647. |

| [2] | 王鹏辉,乔宏霞,冯琼,曹辉,温少勇. 氯氧镁涂层钢筋混凝土两重因素耦合作用下的耐久性模型[J]. 吉林大学学报(工学版), 2020, 50(1): 191-201. |

| [3] | 王金国,任帅,闫瑞芳,黄恺,王志强. TiC颗粒对铸态球墨铸铁组织和力学性能的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 2010-2018. |

| [4] | 鲁金忠,周婉婷,张圣洋,邵亦锴,王长雨,罗开玉. 激光冲击强化层数对6061⁃T6铝合金抗腐蚀性能的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 842-849. |

| [5] | 罗开玉,邢月华,柴卿锋,吴世凯,尹叶芳,鲁金忠. 激光冲击强化对2Cr13不锈钢腐蚀 疲劳性能的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 850-858. |

| [6] | 关庆丰, 董书恒, 郑欢欢, 李晨, 张从林, 吕鹏. 强流脉冲电子束作用下45#钢表面Cr合金化[J]. 吉林大学学报(工学版), 2018, 48(4): 1161-1168. |

| [7] | 关庆丰, 张远望, 孙潇, 张超仁, 吕鹏, 张从林. 强流脉冲电子束作用下铝钨合金的表面合金化[J]. 吉林大学学报(工学版), 2017, 47(4): 1171-1178. |

| [8] | 高小建, 孙博超, 叶焕, 王子龙. 矿物掺合料对自密实混凝土流变性能的影响[J]. 吉林大学学报(工学版), 2016, 46(2): 439-444. |

| [9] | 关庆丰, 李艳, 侯秀丽, 杨盛志, 王晓彤. 固溶态Mg-Gd-Y-Nd合金强流脉冲电子束表面改性[J]. 吉林大学学报(工学版), 2015, 45(4): 1200-1205. |

| [10] | 宿晓萍,王清. 复合盐浸-冻融-干湿多因素作用下的混凝土腐蚀破坏[J]. 吉林大学学报(工学版), 2015, 45(1): 112-120. |

| [11] | 关庆丰,季乐,蔡杰,杨盛志,刘世超,张在强,侯秀丽. 强流脉冲电子束轰击作用下3Cr13不锈钢的微观结构及性能[J]. 吉林大学学报(工学版), 2014, 44(3): 712-717. |

| [12] | 关庆丰, 邹阳, 张在强, 关锦彤, 苏景新, 王志平. 强流脉冲电子束作用下纯铜的微观结构与腐蚀性能[J]. 吉林大学学报(工学版), 2013, 43(04): 964-969. |

| [13] | 肖锐, 邓宗才, 兰明章, 申臣良. 不掺硅粉的活性粉末混凝土配合比试验[J]. 吉林大学学报(工学版), 2013, 43(03): 671-676. |

| [14] | 阮德文, 苏达格, 梁雅琴, 伊兰哲田, 连建设. 表面活性剂对镁合金基体上的非铬化镀镍涂层的腐蚀特性的作用[J]. 吉林大学学报(工学版), 2013, 43(02): 363-367. |

| [15] | 赵高磊,张海龙,张波萍. 铜颗粒分散铌酸钾钠压电复合材料的制备与性能[J]. 吉林大学学报(工学版), 2011, 41(05): 1300-1304. |

|

||