吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (1): 188-199.doi: 10.13229/j.cnki.jdxbgxb20190169

• 材料科学与工程 • 上一篇

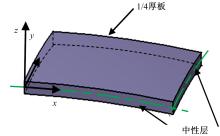

双曲率筋条壁板铣削回弹预测

刘纯国1,2( ),于晓彤1,2,岳韬1,2,李东来1,2,张明哲1,2

),于晓彤1,2,岳韬1,2,李东来1,2,张明哲1,2

- 1.吉林大学 辊锻工艺研究所,长春 130022

2.吉林大学 材料科学与工程学院,长春 130022

Springback prediction for double-curvature stiffened panel during milling

Chun-guo LIU1,2( ),Xiao-tong YU1,2,Tao YUE1,2,Dong-lai LI1,2,Ming-zhe ZHANG1,2

),Xiao-tong YU1,2,Tao YUE1,2,Dong-lai LI1,2,Ming-zhe ZHANG1,2

- 1.Roll-forging Research Institute,Jilin University,Changchun 130022,China

2.College of Materials Science and Engineering,Jilin University,Changchun 130022,China

摘要:

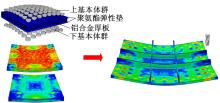

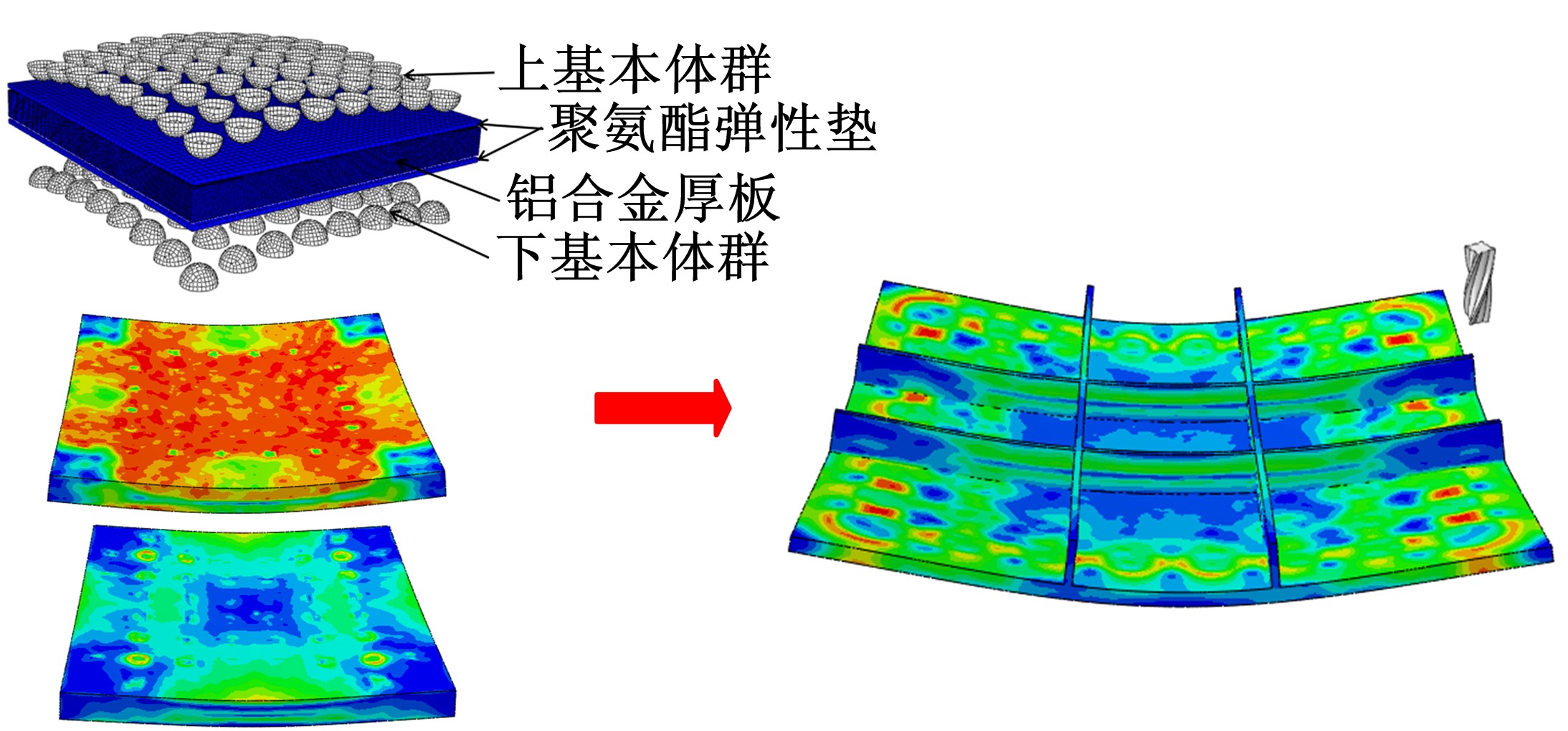

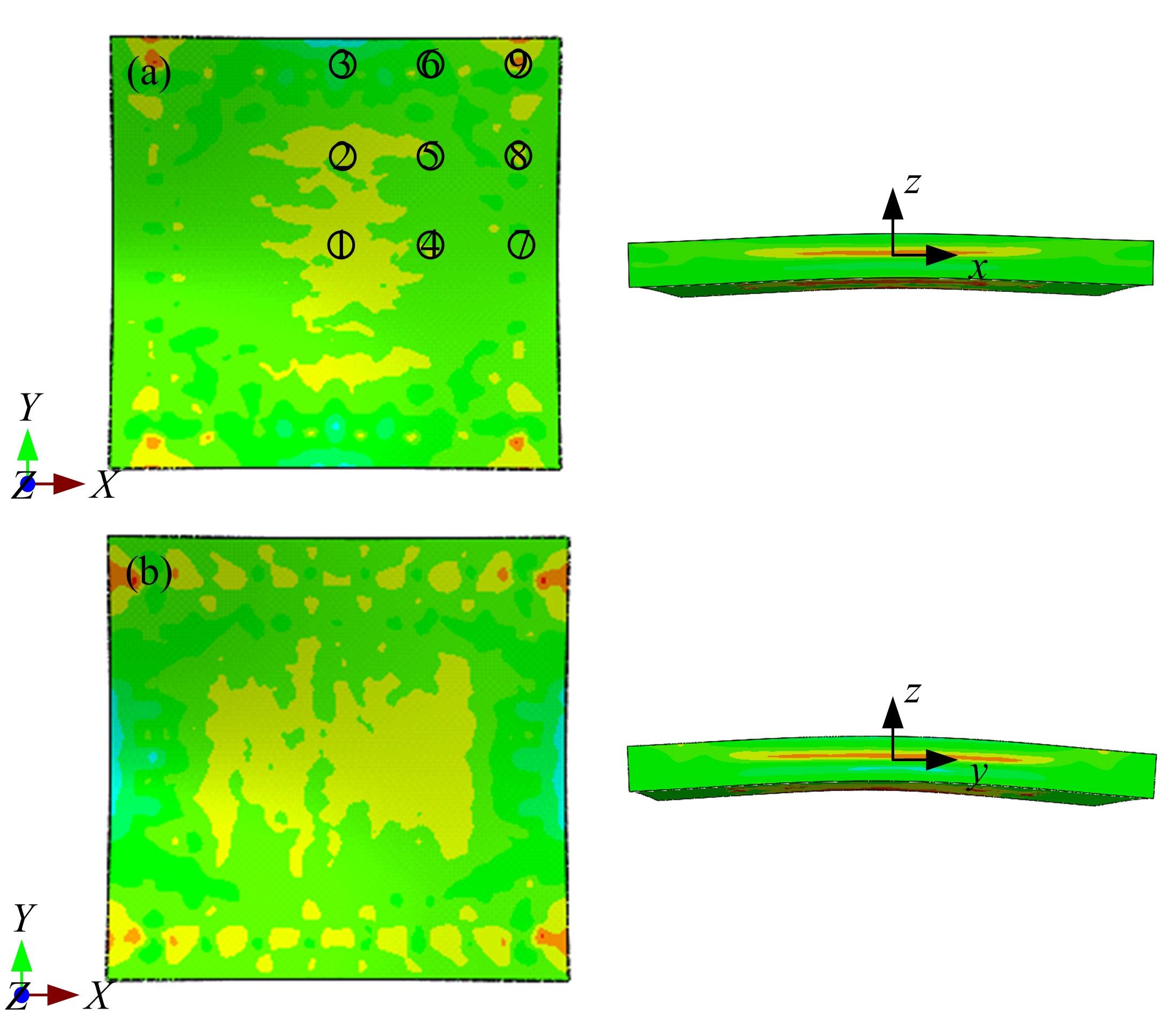

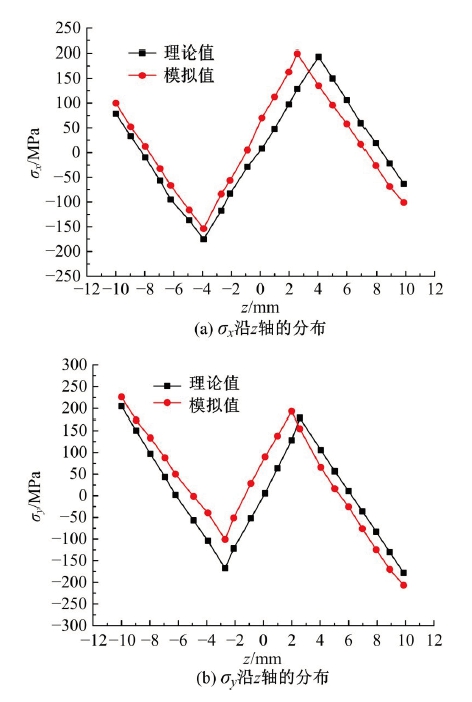

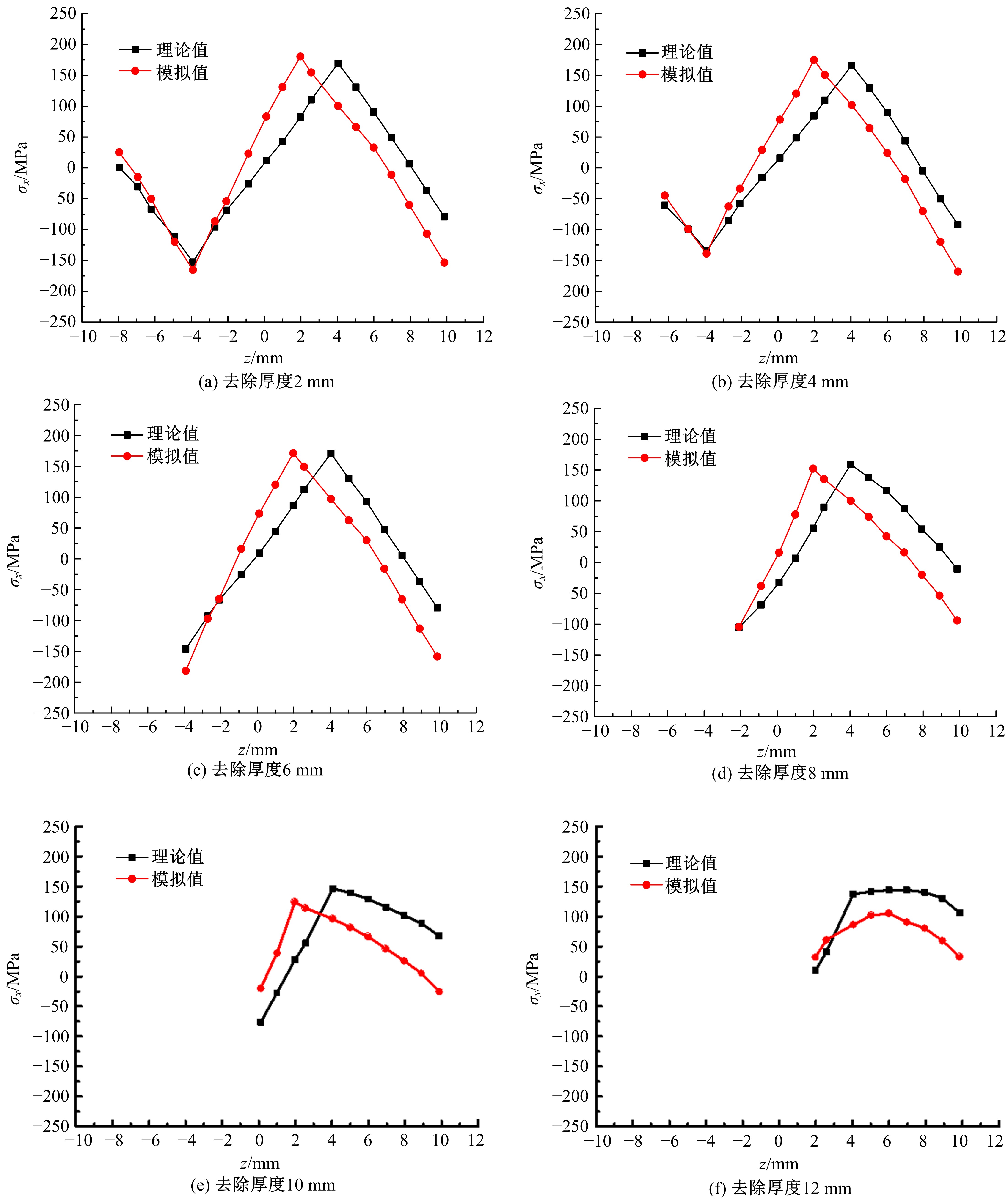

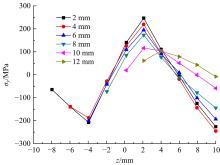

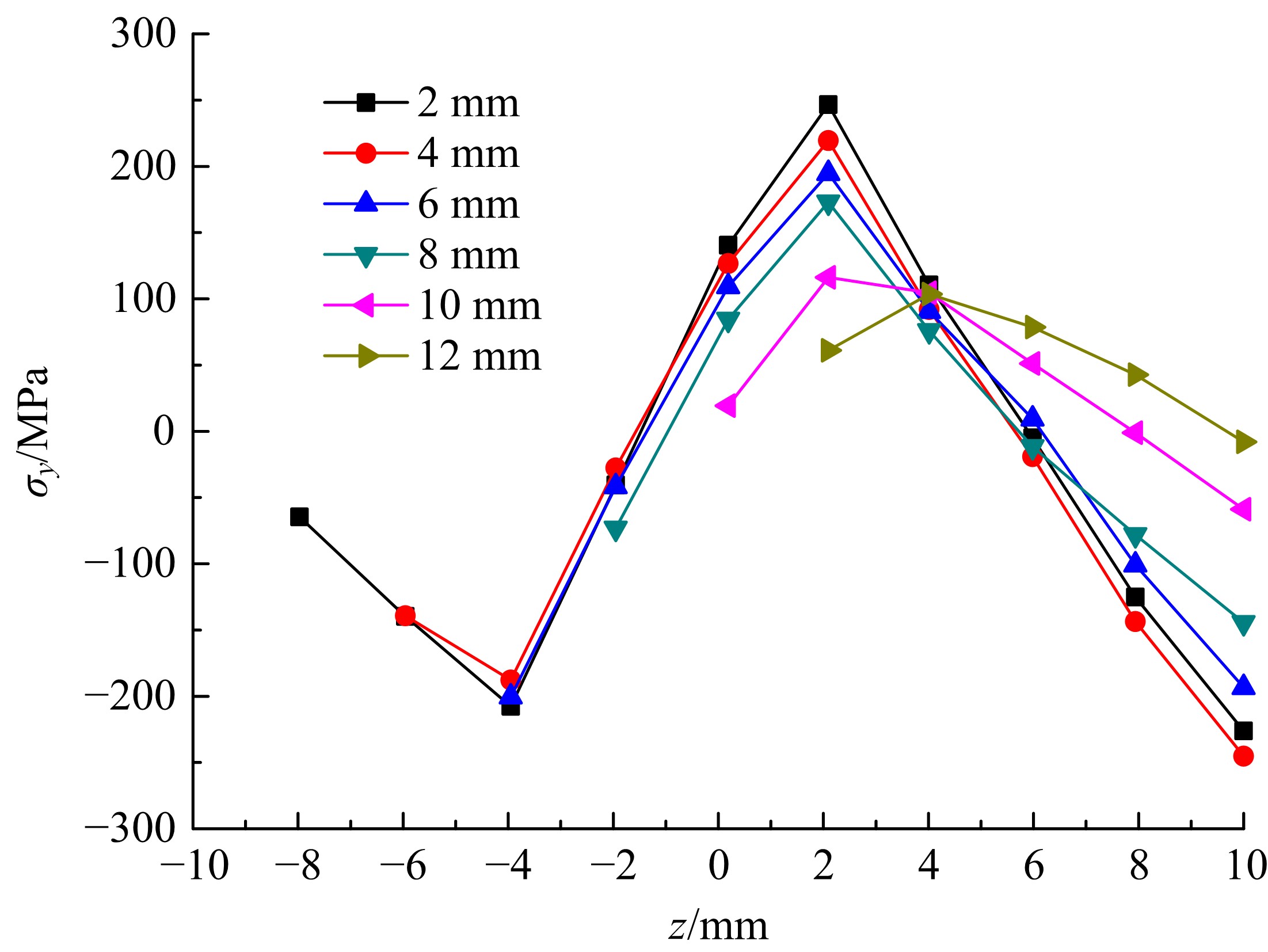

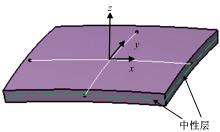

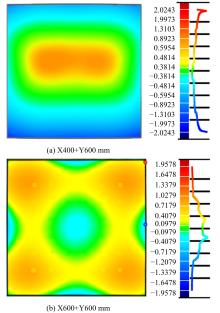

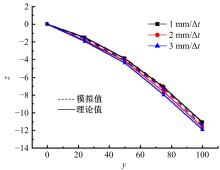

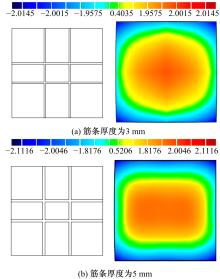

针对铝合金薄壁零件制造过程中的回弹问题,提出了一种双曲率壁板铣削回弹的预测方法。该方法根据材料逐层去除后板料内部残余应力的重新分布情况,估算板料两个弯曲方向的回弹值。有限元模拟结果表明,铣削过程中板料的应力分布和回弹与计算结果相近;当板料铣削至中性面时,两弯曲方向的应力变化最大;随着剩余板厚的减小,计算结果与模拟结果间的误差逐渐增大。另外,单层铣削厚度与回弹规律的模拟结果表明,单层铣削厚度越大,该方法误差越大,最大误差为9.07%。为验证计算结果,进行了铝合金双曲率板料的成形-铣削实验,结果表明本文方法能够较准确预测双曲率铝合金板料铣削后的回弹。

中图分类号:

- TG386

| 1 | 曾元松, 黄遐. 大型整体壁板成形技术[J]. 航空学报, 2008, 29(3): 721-727. |

| Zeng Yuan-song, Huang Xia. Forming technologies of large integral panel[J]. Acta Aeronautica Et Astronautica Sinica, 2008, 29(3): 721-727. | |

| 2 | 董亚男. 铝合金整体板多点冲压成形断裂的预测与控制[D]. 长春:吉林大学材料科学与工程学院, 2016. |

| Dong Ya-nan. Prediction and control of fracture in multi-point press forming of aluminum alloy integral panel[D]. Changchun: College of Materials Science and Engineering, Jilin University, 2016. | |

| 3 | 刘纯国, 岳韬, 邓玉山, 等. 一种高筋铝合金壁板制造方法[P]. 中国: 201610634093, 2016-10-26. |

| 4 | Rossini N S, Dassisti M, Benyounis K Y, et al. Methods of measuring residual stresses in components[J]. Materials & Design, 2012, 35(1): 572-588. |

| 5 | Sebastiani M, Eberl C, Bemporad E, et al. Focused ion beam four-slot milling for poisson's ratio and residual stress evaluation at the micron scale[J]. Surface and Coatings Technology, 2014(251): 151-161. |

| 6 | Liu C G, Zheng Y, Zhang X G. Investigation of through thickness residual stress distribution and springback in bent AL plate by slotting method[J]. The International Journal of Advanced Manufacturing Technology, 2017, 90(1-4): 299-308. |

| 7 | Meng L, Atli M, He N. Measurement of equivalent residual stresses generated by milling and corresponding deformation prediction[J]. Precision Engineering, 2017, 50: 160-170. |

| 8 | Shin S H. Prediction of the dimensional instability resulting from machining of residually stressed components[D]. Lubbock:Texas Tech University, 1995. |

| 9 | Wang S, Zuo D, Wang M, et al. Modified layer removal method for measurement of residual stress distribution in thick pre-stretched aluminum plate[J]. Transactions of Nanjing University of Aeronautics & Astronautics, 2004, 21(4): 286-290. |

| 10 | Sebastian N. A mathematical model for the estimation of the effects of residual stresses in aluminum plates[D]. City of Saint Louis: Washington University in St. Louis, 2005. |

| 11 | Yong K A. Machining-induced residual stress and distortion of thin parts[D]. City of Saint Louis: Washington University in St. Louis, 2005. |

| 12 | Wu Q, Li D P, Ren L, et al. Detecting milling deformation in 7075 aluminum alloy thin-walled plates using finite difference method[J]. The International Journal of Advanced Manufacturing Technology, 2016, 85(5-8): 1291-1302. |

| 13 | Wei Y, Wang X W. Computer simulation and experimental study of machining deflection due to original residual stress of aerospace thin-walled parts[J]. The International Journal of Advanced Manufacturing Technology, 2007, 33(3/4): 260-265. |

| 14 | Tang Z T, Yu T, Xu L Q, et al. Machining deformation prediction for frame components considering multifactor coupling effects[J]. The International Journal of Advanced Manufacturing Technology, 2013, 68(1-4): 187-196. |

| 15 | Izamshah R, Mo J P T, Ding S. Hybrid deflection prediction on machining thin-wall monolithic aerospace components[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2012, 226(4): 592-605. |

| 16 | 孙杰, 柯映林. 残余应力对航空整体结构件加工变形的影响分析[J]. 机械工程学报, 2005, 41(2): 117-122. |

| Sun Jie, Ke Ying-lin. Study on machining distortion of unitization airframe due to residual stress[J]. Chinese Journal of Mechanical Engineering, 2005, 41(2): 117-122. | |

| 17 | Li W, Ma L, Wan M, et al. Modeling and simulation of machining distortion of pre-bent aluminum alloy plate[J]. Journal of Materials Processing Technology, 2018, 258: 189-199. |

| 18 | Gao H, Zhang Y, Wu Q, et al. Investigation on influences of initial residual stress on thin-walled part machining deformation based on a semi-analytical model[J]. Journal of Materials Processing Technology, 2018, 262: 437-448. |

| 19 | 余同希, 章亮炽. 塑性弯曲理论及其应用[M]. 北京: 科学出版社, 1992. |

| 20 | Adibi H, Asadian Ardakani M H, Mollaei Dariani B. Springback analysis of sheet metal laminates after U-bending[C]∥The 19th International Conference on Metallurgy and Materials, Roznov pod Radhostem, Czech Republic, 2010. |

| 21 | 林胜. HSM在航空制造业中的应用[J].航空制造技术, 2003(3): 25-28, 76. |

| Lin Sheng. HSM application in aviation manufacturing industry [J]. Aeronautical Manufacturing Technology, 2003(3): 25-28, 76. | |

| 22 | Li B, Jiang X, Yang J, et al. Effects of depth of cut on the redistribution of residual stress and distortion during the milling of thin-walled part[J]. Journal of Materials Processing Technology, 2015, 216: 223-233. |

| [1] | 鲁金忠,周婉婷,张圣洋,邵亦锴,王长雨,罗开玉. 激光冲击强化层数对6061⁃T6铝合金抗腐蚀性能的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 842-849. |

| [2] | 周晓勤,杨璐,张磊,陈立军. 具有负压缩性的铰接八面体结构的有限元分析[J]. 吉林大学学报(工学版), 2019, 49(3): 865-871. |

| [3] | 刘子武, 李剑峰. 叶片材料FV520B再制造熔覆层冲蚀损伤行为及评价[J]. 吉林大学学报(工学版), 2018, 48(3): 835-844. |

| [4] | 刘程, 史文库, 陈志勇, 何伟, 荣如松, 宋怀兰. 汽车驱动桥准双曲面齿轮齿根弯曲应力预测与试验[J]. 吉林大学学报(工学版), 2017, 47(2): 344-352. |

| [5] | 梁继才, 李义, 高嵩, 滕菲. 型材多点柔性拉弯成形回弹预测[J]. 吉林大学学报(工学版), 2017, 47(1): 185-190. |

| [6] | 闫光, 庄炜, 刘锋, 祝连庆. 具有增敏效果的光纤光栅应变传感器的预紧封装及传感特性[J]. 吉林大学学报(工学版), 2016, 46(5): 1739-1745. |

| [7] | 胡玉明, 黄音, 古海东. 排桩支护结构内力与变形三维有限元数值分析[J]. 吉林大学学报(工学版), 2016, 46(2): 445-450. |

| [8] | 肖湘, 黄恩厚, 尼颖升. 预应力混凝土梁板体系有效翼缘的理论分析及试验[J]. 吉林大学学报(工学版), 2015, 45(6): 1784-1790. |

| [9] | 马彪1, 赵家昕1, 李和言1, 宁克炎2, 何春平3. 离合器结构参数对其热弹性不稳定性的影响[J]. 吉林大学学报(工学版), 2014, 44(4): 933-938. |

| [10] | 李晓军,梁路路,谢诚伟,杨硕. 沥青混凝土虚拟力学仿真模型自动生成及应用[J]. 吉林大学学报(工学版), 2014, 44(3): 655-660. |

| [11] | 彭勇, 孙立军. 集料水平向分布状态对沥青混合料劈裂试验影响数值模拟[J]. 吉林大学学报(工学版), 2013, 43(04): 891-896. |

| [12] | 张强, 张璐, 刘宪军, 于路路, 贾洪雷. 基于有限元法的仿生钩形深松铲耕作阻力[J]. 吉林大学学报(工学版), 2012, 42(增刊1): 117-121. |

| [13] | 邓兆祥, 高书娜. 结构声腔耦合系统的振型耦合特性分析及应用[J]. , 2012, 42(05): 1120-1126. |

| [14] | 闫清东, 崔红伟, 魏巍. 新型液力变矩减速装置变矩工况叶轮有限元强度分析[J]. 吉林大学学报(工学版), 2012, 42(02): 365-371. |

| [15] | 缪宏, 左敦稳, 王珉, 张瑞宏, 汪洪峰. 工艺参数对Q460高强度钢冷挤压内螺纹质量的影响[J]. 吉林大学学报(工学版), 2012, 42(01): 68-73. |

|

||