吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (7): 1607-1619.doi: 10.13229/j.cnki.jdxbgxb20210031

• 交通运输工程·土木工程 • 上一篇

新型分形防屈曲支撑参数设计及受力性能

罗小博1,2( ),宋彧1,2,王腾2,金子秋1,2,谢国鑫1,2

),宋彧1,2,王腾2,金子秋1,2,谢国鑫1,2

- 1.兰州理工大学 土木工程学院,兰州 730050

2.潍坊科技学院 建筑与艺术学院,山东 潍坊 262700

Parameter design and mechanical performance of a new type of fractal buckling restrained brace

Xiao-bo LUO1,2( ),Yu SONG1,2,Teng WANG2,Zi-qiu JIN1,2,Guo-xin XIE1,2

),Yu SONG1,2,Teng WANG2,Zi-qiu JIN1,2,Guo-xin XIE1,2

- 1.College of Civil Engineering,Lanzhou University of Technology,Lanzhou 730050,China

2.College of Architecture and Arts,Weifang University of Science and Technology,Weifang 262700,China

摘要:

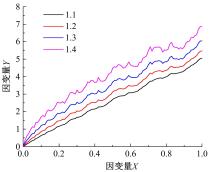

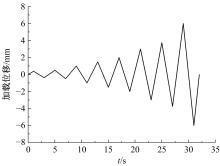

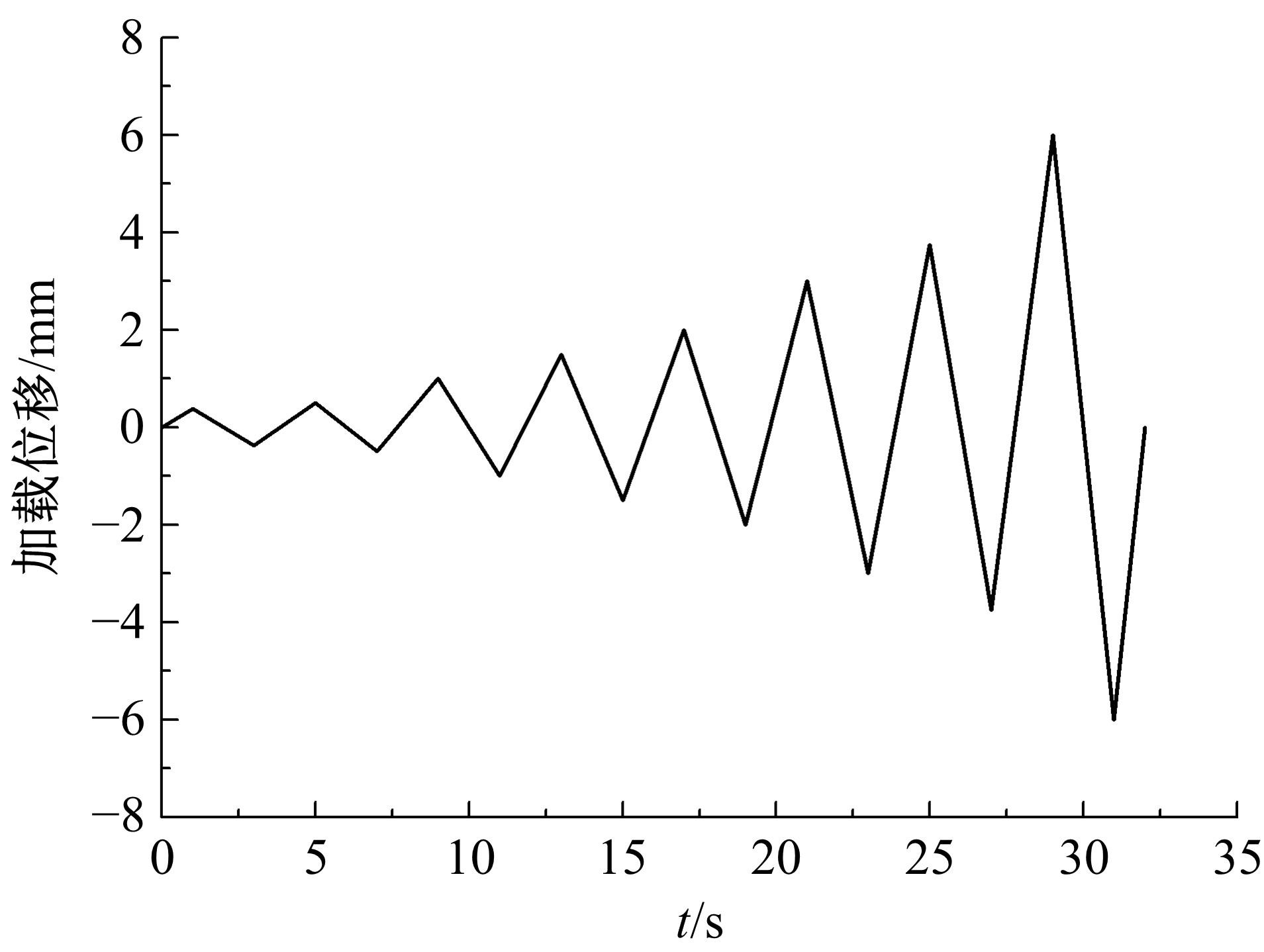

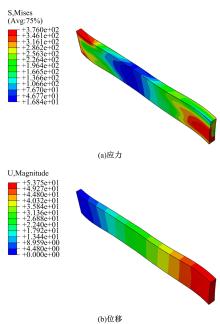

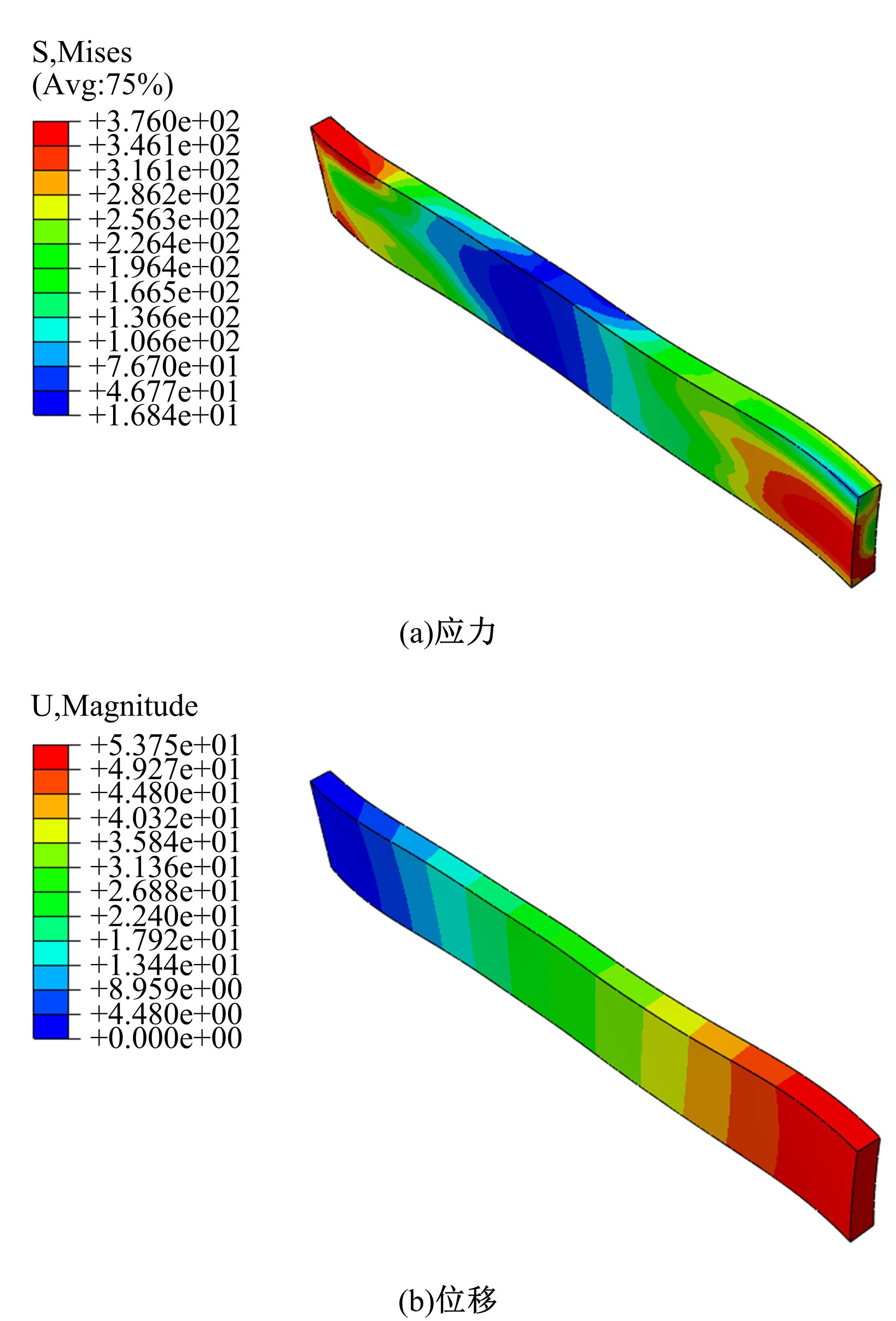

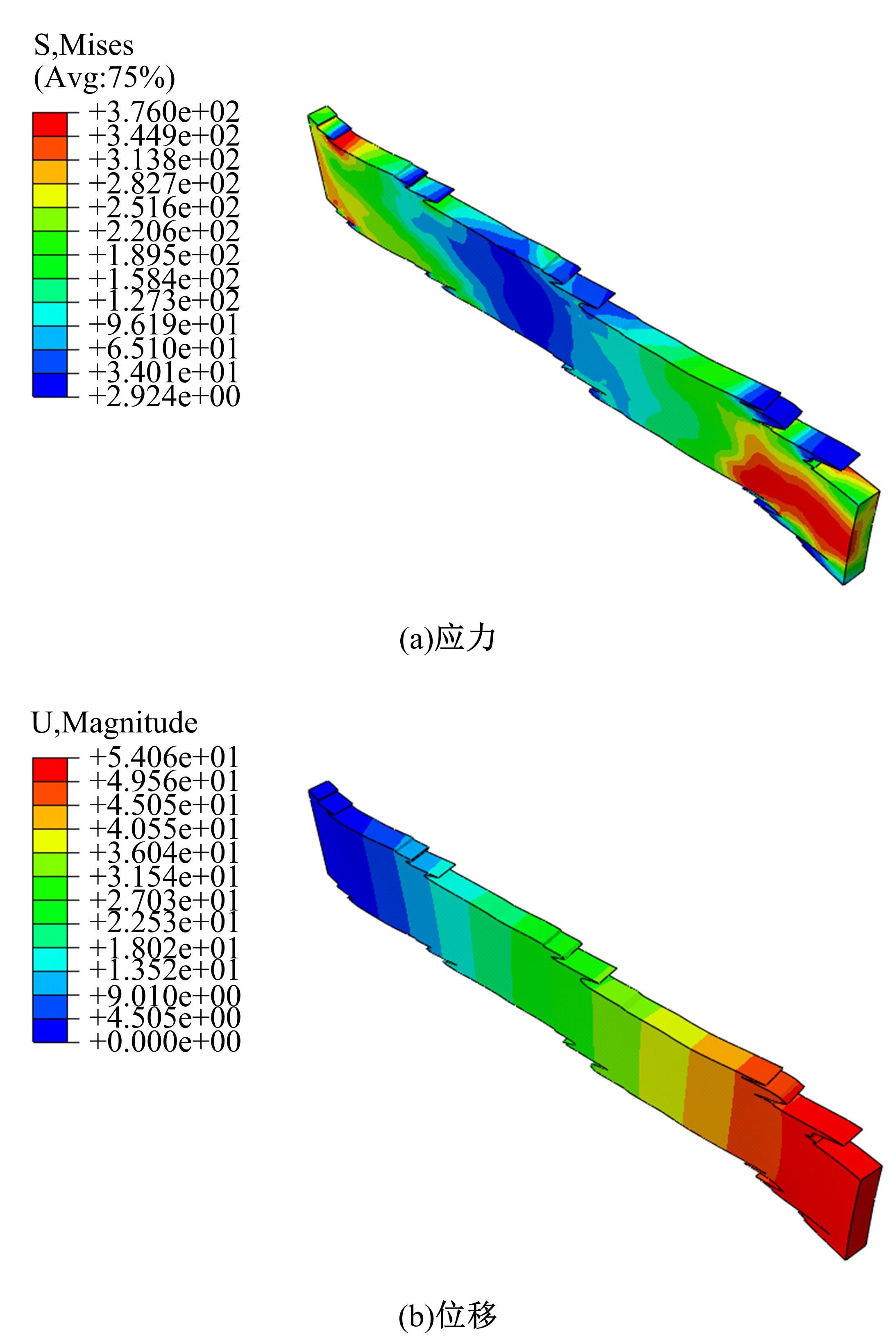

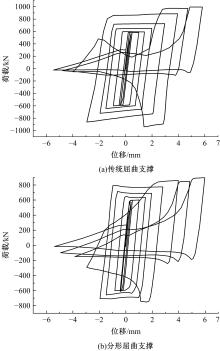

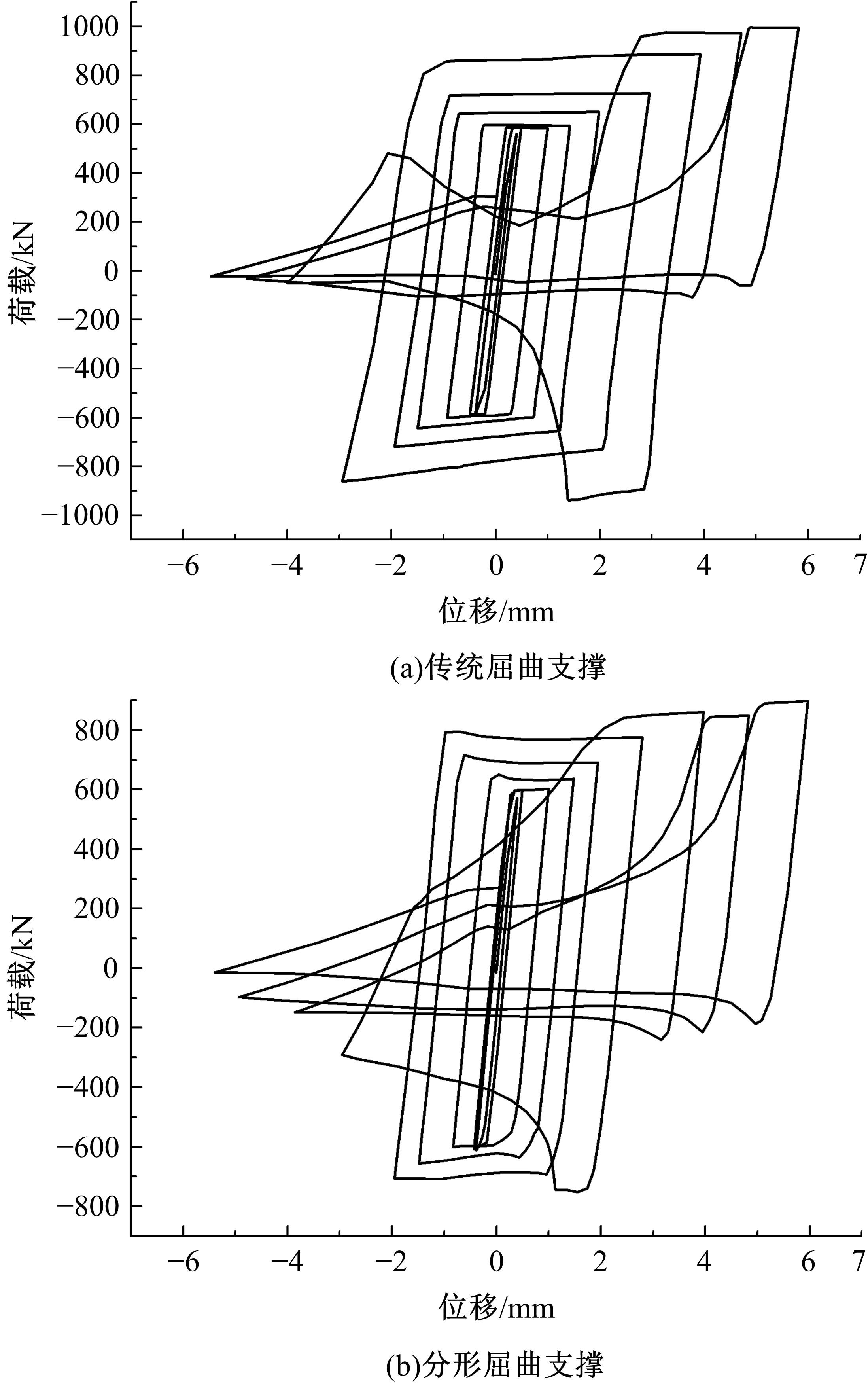

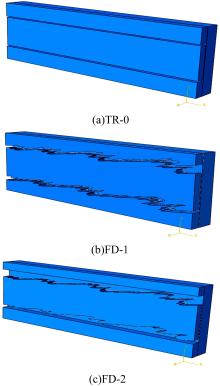

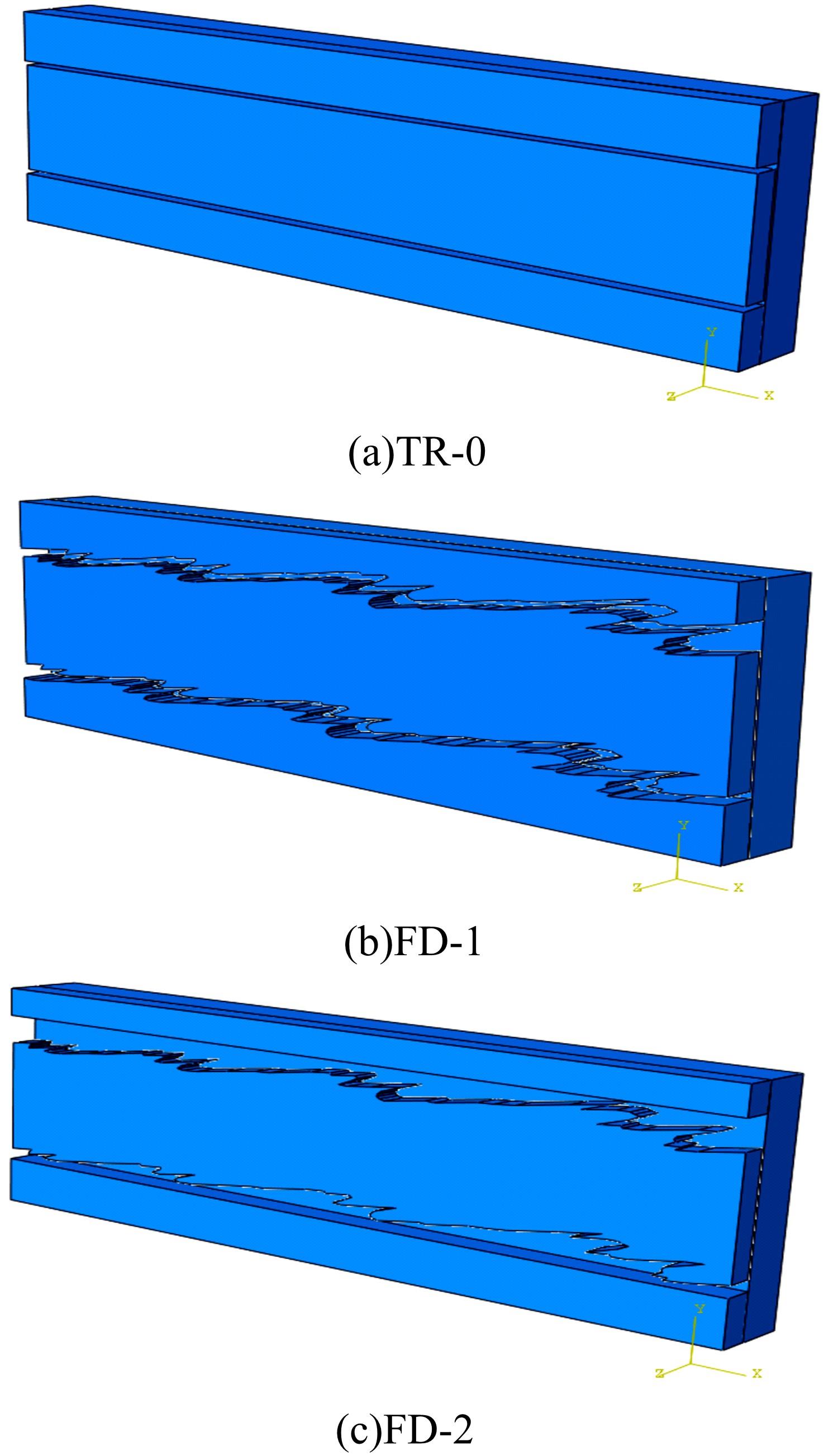

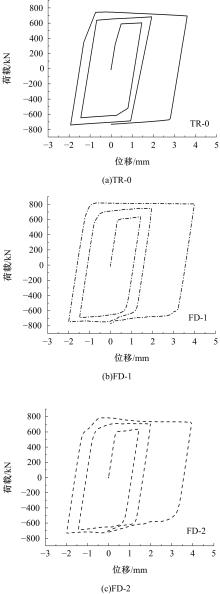

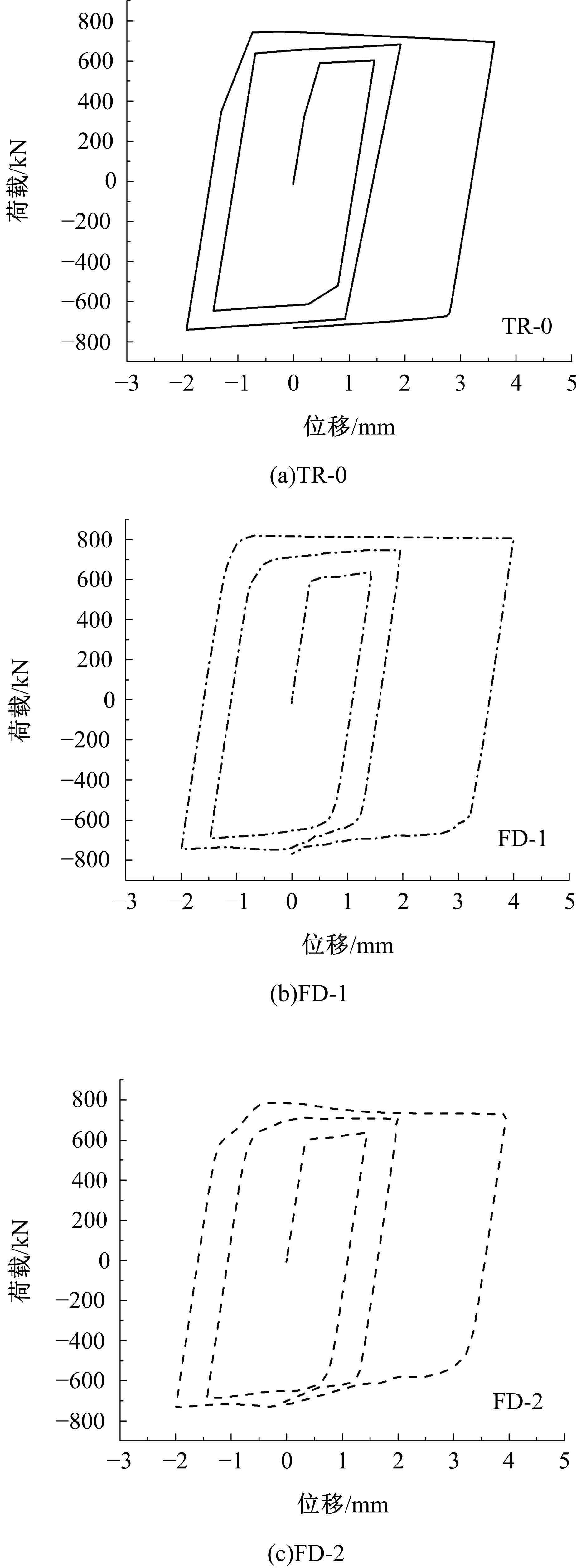

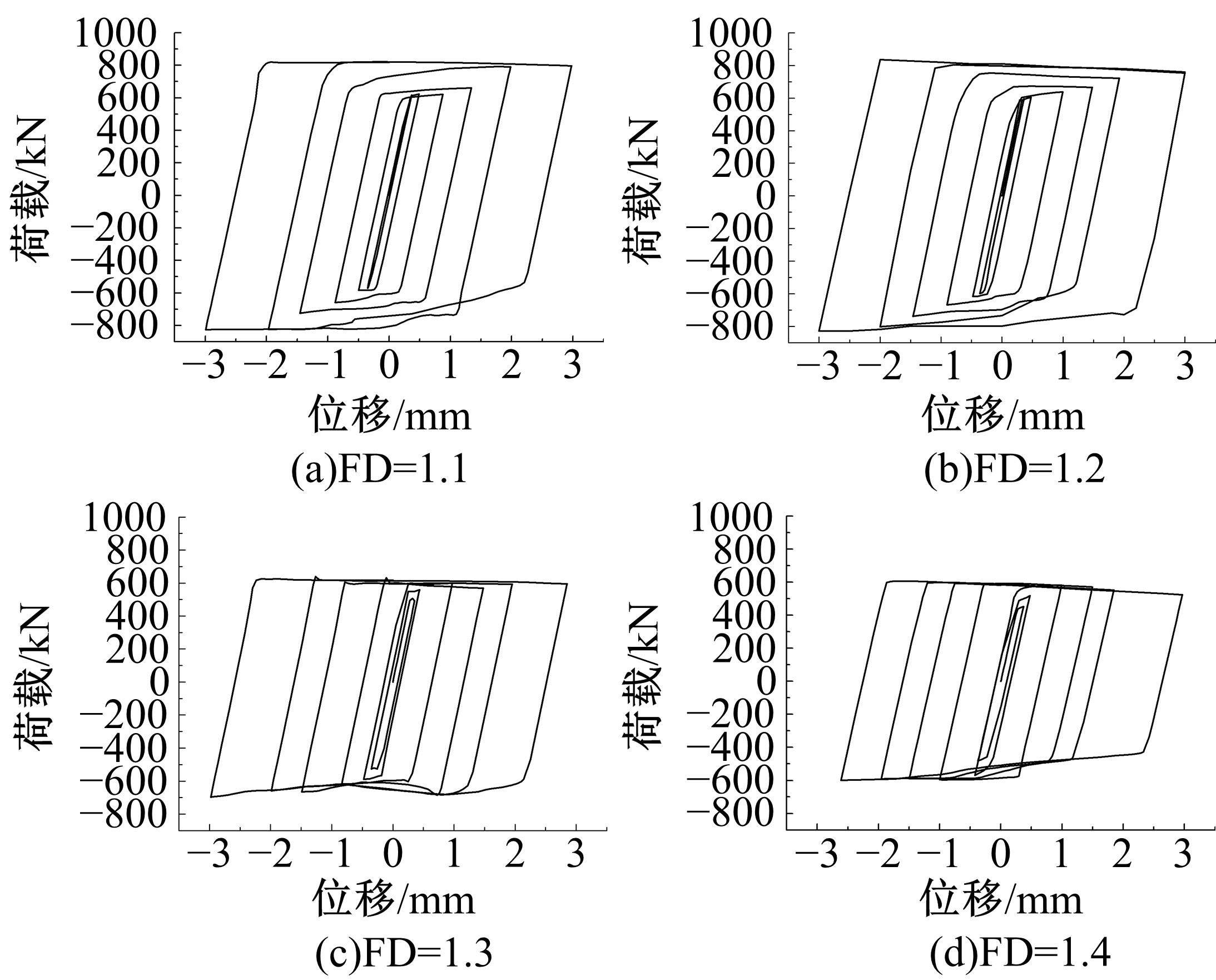

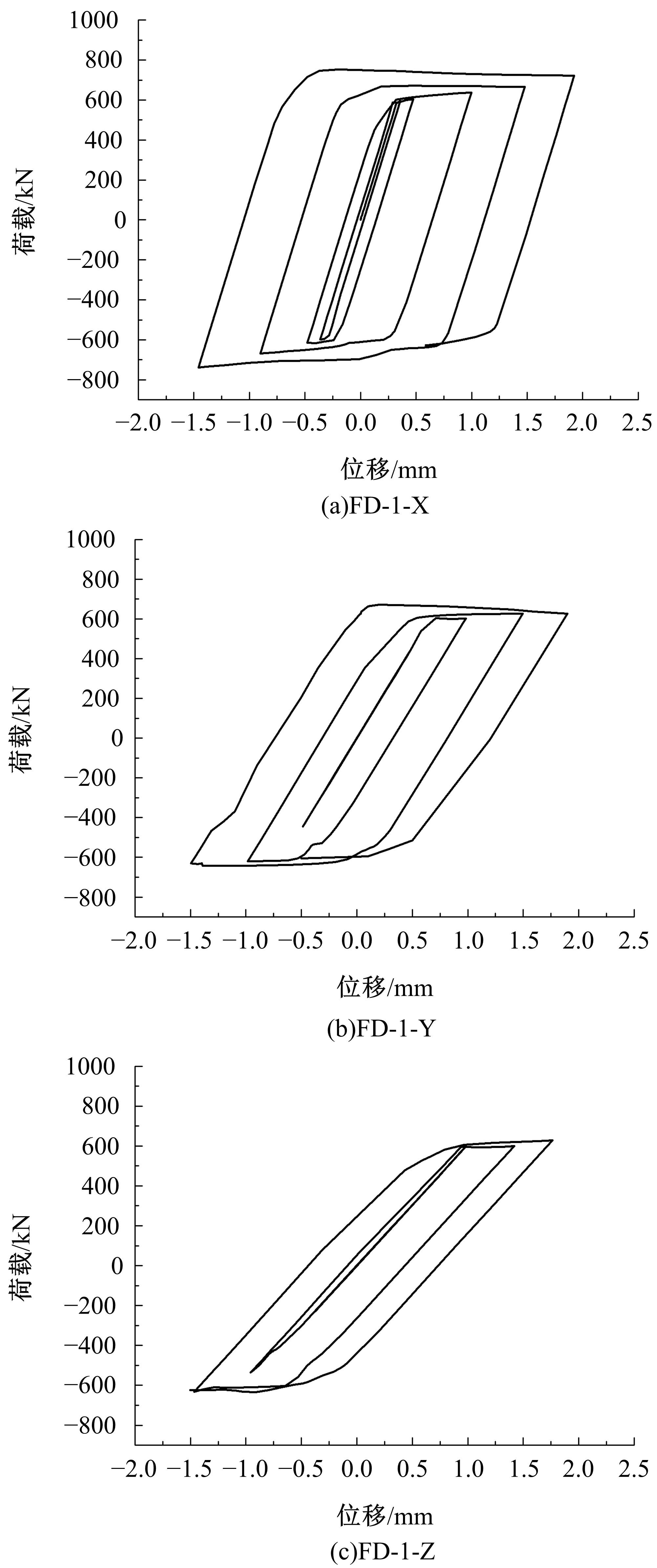

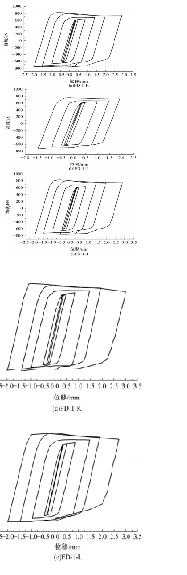

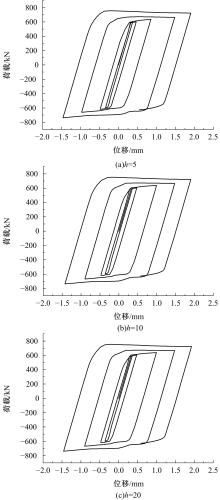

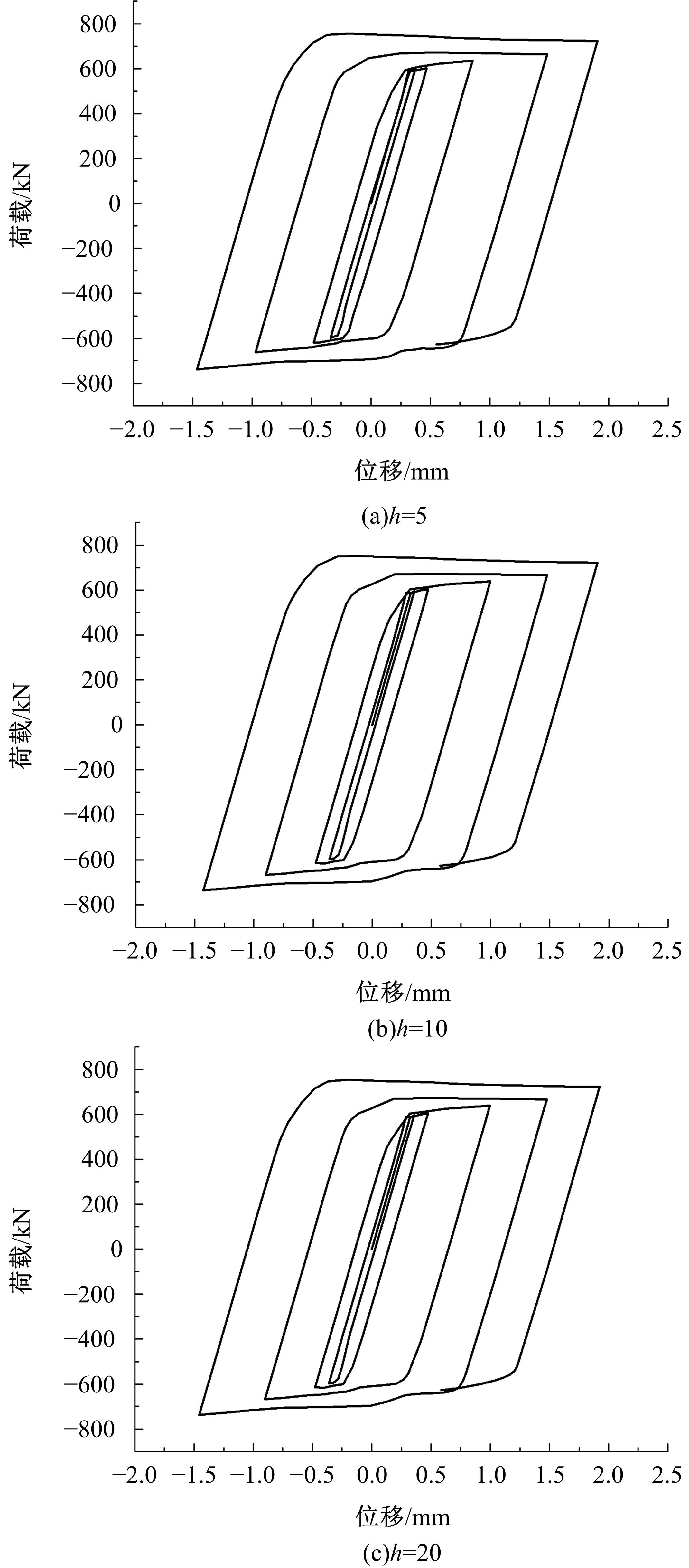

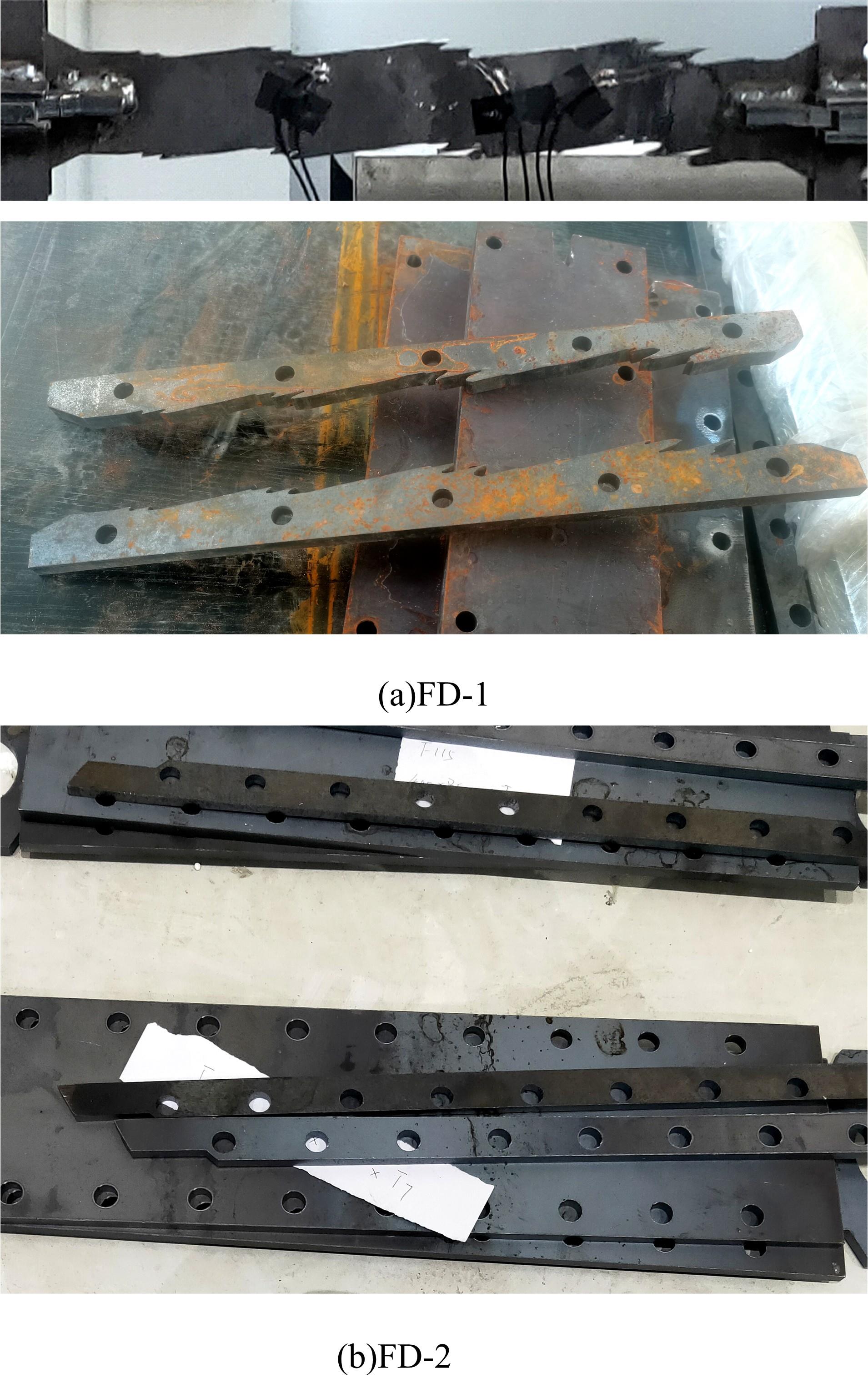

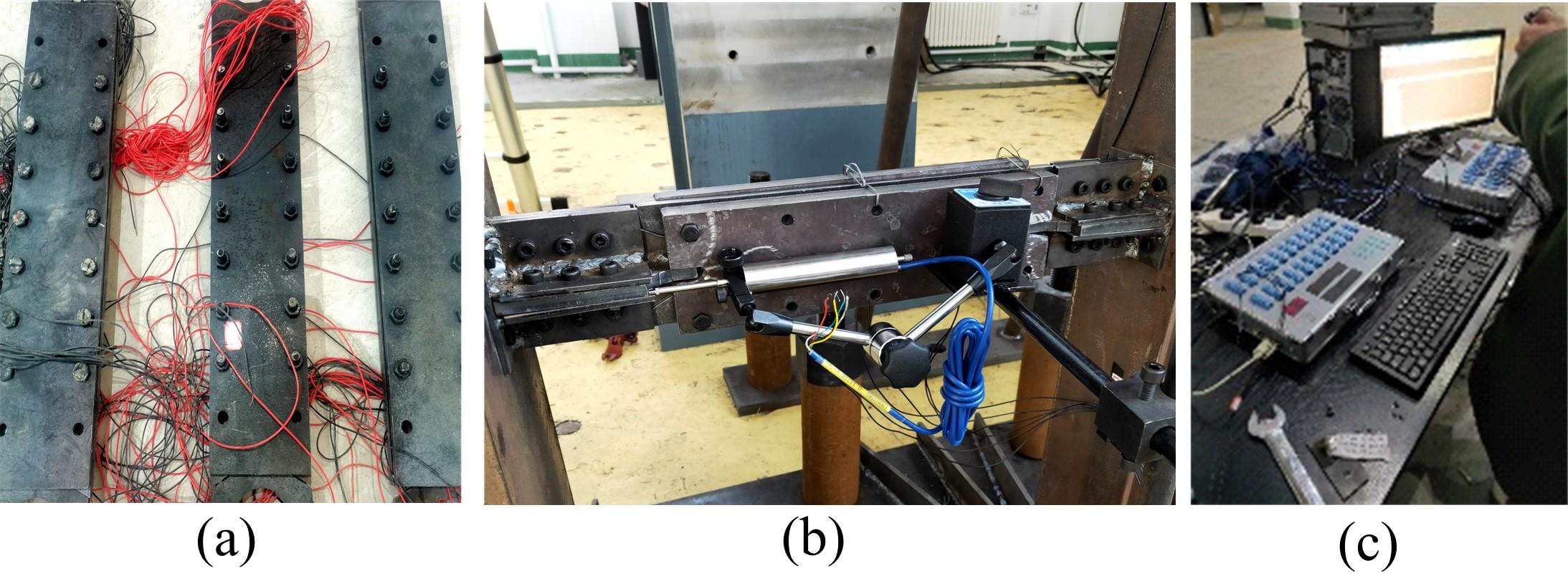

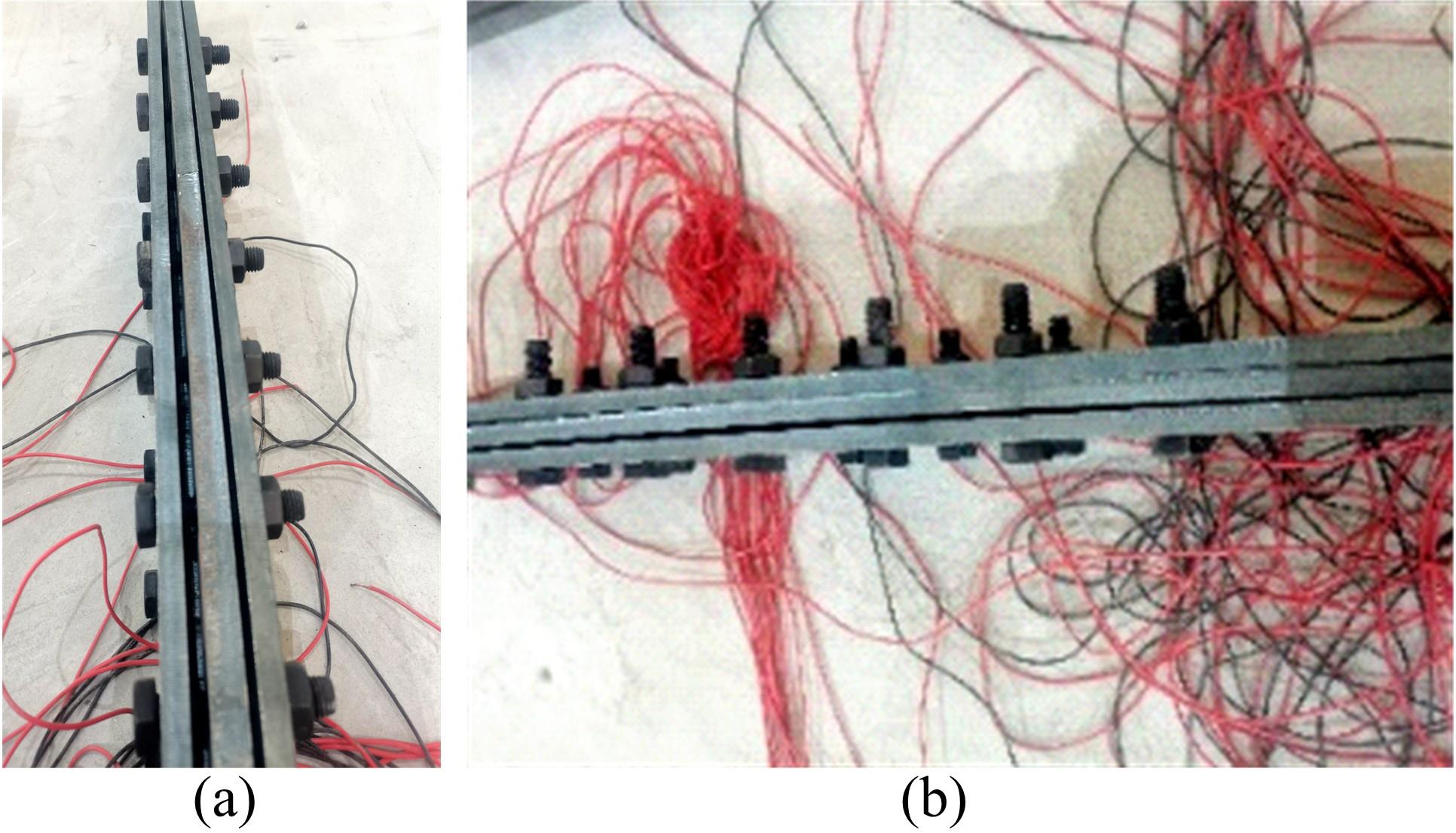

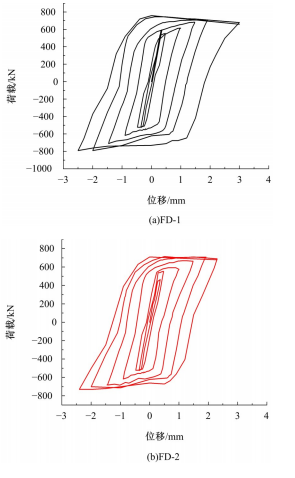

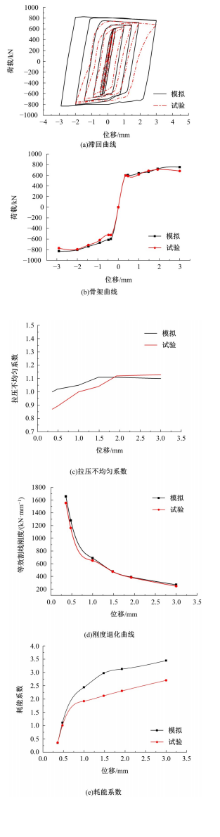

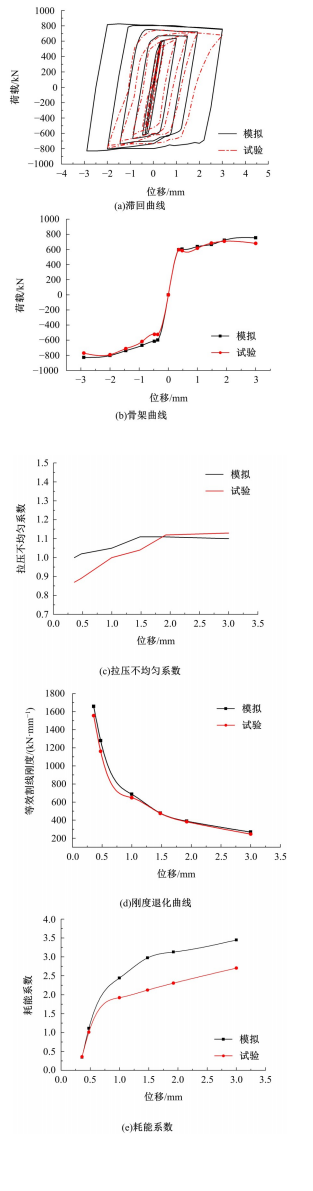

为克服传统钢筋混凝土防屈曲支撑自重大、制作成本高及施工速度慢等众多缺点,亟需寻找一种轻型、高强、成本低、耗能大、便于安装、易更换的全钢防屈曲支撑。受其他学者对防屈曲支撑核心单元削弱的研究基础上的启发,本文结合分形Mandelbrot函数,利用MATLAB构思出一种新型的分形防屈曲支撑雏形;借助ABAQUS软件,对比分析了分形防屈曲支撑较传统屈曲支撑、分形屈曲支撑及传统防屈曲支撑的优越性;对部分界面及全界面约束型分形防屈曲支撑的分形维数、长宽比、宽厚比、间厚比及外约束钢板厚度各参数设计进行了对比分析,选出了最优耗能试件,并通过试验采集了一些真实数据对其加以验证,为后续工程加固研究与应用提供了理论依据和设计新思路。研究结果表明:分形屈曲支撑较传统屈曲支撑应力分散,端部连接处应力、位移亦较小,后期由于削弱部位在外力作用下多点逐渐屈服,耗能性较好;分形防屈曲支撑较传统防屈曲支撑(TR-0)耗能性良好,可提高5.11%~8.97%;全界面外约束分形屈曲支撑(FD-1)较部分界面外约束分形屈曲支撑(FD-2)的核心单元受力更加分散,滞回曲线较饱满,耗能效果更佳。

中图分类号:

- TU323.2

| 1 | 王佼娇, 石永久, 严红, 等. 低屈服点全钢防屈曲支撑抗震性能试验研究[J]. 土木工程学报, 2013, 46(10): 9-16. |

| Wang Jiao-jiao, Shi Yong-jiu, Yan Hong, et al. Experimental study on the seismic behavior of all-steel buckling-restrained brace with low yield point[J]. China Civil Engineering Journal, 2013, 46(10): 9-16. | |

| 2 | 殷占忠, 徐德宇, 杨博, 等. 端部配置延性铸造件的装配式防屈曲支撑抗震性能试验研究[J]. 建筑结构学报, 2021,43(1):77-85. |

| Yin Zhan-zhong, Xu De-yu, Yang Bo, et al. Experimental study of prefabricated buckling-restrained braces with ductile casting connectors[J]. Journal of Building Structures, 2021,43(1):77-85. | |

| 3 | 吴志平, 胡大柱, 陈欣宇, 等. 钢棒防屈曲支撑受力性能研究[J]. 建筑结构学报, 2018, 41(3): 163-171. |

| Wu Zhi-ping, Hu Da-zhu, Chen Xin-yu, et al. Mechanical behavior of steel bar buckling restrained braces[J]. Journal of Building Structures, 2018, 41(3): 163-171. | |

| 4 | 陈志华, 黄培华, 余玉洁. 局部低强防屈曲支撑耗能性能试验研究[J]. 天津大学学报, 2017, 50():59-67. |

| Chen Zhi-hua, Huang Pei-hua, Yu Yu-jie. Energy dissipation performance of local steel strength weakened buckling-restrained brace[J]. Journal of Tianjin University(Science and Technology), 2017, 50(Sup.):59-67. | |

| 5 | Alhamaydeh M, Abed F, Mustapha A. Key parameters influencing performance and failure modes for BRBs using nonlinear FEA[J]. Journal of Constructional Steel Research, 2016, 116: 1-18. |

| 6 | Takeuchi T, Hajjar J F, Matsui R, et al. Local buckling restraint condition for core plates in buckling restrained braces[J]. Journal of Constructional of Steel Research, 2010, 66(2): 139-149. |

| 7 | Guo Y L, Zhou P, Bradford M A, et al. Theoretical and numerical studies of elastic buckling and load resistance of double cross-arm pre-tensioned cable stayed buckling-restrained braces[J]. Engineering Structures, 2017, 153: 674-699. |

| 8 | 周云, 陈真, 邓雪松, 等. 开孔与开槽式三重钢管防屈曲耗能支撑设计方法研究[J]. 土木工程学报, 2012, 45(2): 20-25. |

| Zhou Yun, Chen Zhen, Deng Xue-song, et al. Study on design method of perforated and notched triple-steel tube buckling-restrained brace[J]. China Civil Engineering Journal, 2012, 45(2): 20-25. | |

| 9 | 邓雪松, 陈真, 周云. 开孔三重钢管防屈曲耗能支撑性能试验研究[J]. 建筑结构学报, 2012, 33(6): 42-49. |

| Deng Xue-song, Chen Zhen, Zhou Yun. Experimental study on performance of perforating triple-steel tube buckling-restrained brace[J]. Journal of Building Structures, 2012, 33(6): 42-49. | |

| 10 | 邓雪松, 陈真, 周云. 开孔三重钢管防屈曲耗能支撑影响因素分析[J]. 振动与冲击, 2012, 31(2): 101-108. |

| Deng Xue-song, Chen Zhen, Zhou Yun. Analysis of influence factors on behavior of a buckling-restrained brace with perforated triple-steel tube[J]. Journal of Vibration and Shock, 2012, 31(2): 101-108. | |

| 11 | Dehghani M, Tremblay R. Design and full-scale experimental evaluation of a seismically endurant steel buckling-restrained brace system[J]. Earthquake Engineering and Structural Dynamics, 2018, 47(1): 105-129. |

| 12 | Xu W J, Pantelides C P. Strong-axis and weak-axis buckling and local bulging of buckling-restrained braces with prismatic core plates[J]. Engineering Structures, 2018, 153: 279-289. |

| 13 | Zhu B L, Guo Y L, Zhou P, et al. Numerical and experimental studies of corrugated-web-connected buckling-restrained braces[J]. Engineering Structures, 2017, 134: 107-124. |

| 14 | Ozcelik R, Dikiciasik Y, Erdil E F. The development of the buckling restrained braces with new end restrains[J]. Journal of Constructional Steel Research, 2017, 138: 208-220. |

| 15 | Zhang D B, Nie X, Pan P, et al. Experimental study and finite element analysis of a buckling-restrained brace consisting of three steel tubes with slotted holes in the middle tube[J]. Journal of Constructional Steel Research, 2016, 124: 1-11. |

| 16 | 周云, 钱洪涛, 褚洪民, 等. 新型防屈曲耗能支撑设计原理与性能研究[J]. 土木工程学报, 2009, 42(4): 64-71. |

| Zhou Yun, Qian Hong-tao, Zhu Hong-min, et al. A study on the design principle and performance of a new type of Buckling-Resistant Brace[J]. China Civil Engineering Journal, 2009, 42(4): 64-71. | |

| 17 | 张济忠. 分形[M]. 北京: 清华大学出版社, 1995: 106-112. |

| 18 | 朱华, 姬翠翠. 分形理论及其应用[M]. 北京: 科学出版社, 2011: 8-16. |

| 19 | Liu P, Zhao H, Huang K, et al. Research on normal contact stiffness of rough surface considering friction based on fractal theory[J]. Applied Surface Science, 2015, 349(4): 3-8. |

| 20 | 孔庆鸽. 分形插值函数的盒维数及应用[D]. 杭州: 浙江大学数学科学学院, 2018: 4-12. |

| Kong Qing-ge. Box dimension and applications of fractal interpolation functions[D]. Hangzhou: College of Mathematical Sciences,Zhejiang University, 2018: 4-12. | |

| 21 | 原园, 成雨, 张静. 基于分形的三维粗糙表面弹塑性接触力学模型与试验验证[J]. 工程力学, 2018, 35(6): 209-221. |

| Yuan Yuan, Cheng Yu, Zhang Jing. Elastic plastic contact mechanics model and experimental verification of three dimensional rough surface based on Fractal Theory[J]. Engineering Mechanics, 2018, 35(6): 209-221. | |

| 22 | .金属材料室温拉伸试验方法 [S]. |

| [1] | 李艺,苏悦琦. 基于不同孔径范围的碳化作用下纤维混凝土的气体渗透性能和细观结构[J]. 吉林大学学报(工学版), 2021, 51(4): 1287-1295. |

| [2] | 于江,赵志浩,秦拥军. 基于声发射和分形的钢筋混凝土受剪梁损伤[J]. 吉林大学学报(工学版), 2021, 51(2): 620-630. |

| [3] | 张姝玮,郭忠印,杨轸,柳本民. 驾驶行为多重分形特征在驾驶疲劳检测中的应用[J]. 吉林大学学报(工学版), 2021, 51(2): 557-564. |

| [4] | 毛昱,李萍,念腾飞,林梅,魏西应. 基于分形理论的沥青路面层间机械摩阻强度行为[J]. 吉林大学学报(工学版), 2020, 50(2): 594-605. |

| [5] | 黄晓明,曹青青,刘修宇,陈嘉颖,周兴林. 基于路表分形摩擦理论的整车雨天制动性能模拟[J]. 吉林大学学报(工学版), 2019, 49(3): 757-765. |

| [6] | 那景新, 贺午阳, 张师源, 袁正, 陈立军. 客车粘接式车窗玻璃参数化串联刚度模型[J]. 吉林大学学报(工学版), 2017, 47(4): 1017-1023. |

| [7] | 郭玉泉, 李雄飞. 复杂网络社区的分形聚类检测方法[J]. 吉林大学学报(工学版), 2016, 46(5): 1633-1638. |

| [8] | 祝宏, 张海, 唐高弟, 李中云, 刘以农. 基于信息维数的欺骗干扰存在性检测[J]. 吉林大学学报(工学版), 2016, 46(2): 616-620. |

| [9] | 富爽,李一兵,叶方,高振国. 利用频域Sevcik分形维数进行快速盲频谱感知[J]. 吉林大学学报(工学版), 2014, 44(3): 854-860. |

| [10] | 马彬, 许洪国, 刘宏飞. 路面分形和橡胶特性对轮胎滑动摩擦因数的影响[J]. 吉林大学学报(工学版), 2013, 43(02): 317-322. |

| [11] | 吴晓璇, 倪志伟, 倪丽萍. 基于分形维数的聚类融合算法[J]. 吉林大学学报(工学版), 2012, 42(增刊1): 364-367. |

| [12] | 尚涛, 李涛, 刘先黎, 任露泉. 基于分形理论的纤维材料微粒捕集器捕集效率模型[J]. 吉林大学学报(工学版), 2012, 42(02): 397-402. |

| [13] | 王继新, 季景方, 张英爽, 王乃祥, 章二平, 黄建兵. 基于小波分形理论的工程车辆时域载荷信号降噪方法[J]. 吉林大学学报(工学版), 2011, 41(增刊2): 221-225. |

| [14] | 杨冬风, 马秀莲. 基于分形纹理分析的蛋壳裂纹识别[J]. 吉林大学学报(工学版), 2011, 41(增刊1): 348-352. |

| [15] | 曾小华,王庆年,宋大凤. 汽车功率需求的简单求解方法[J]. 吉林大学学报(工学版), 2011, 41(03): 613-617. |

|

||