吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (3): 859-864.doi: 10.13229/j.cnki.jdxbgxb20180667

基于纳米压痕分析的往复扭转载荷下45号钢的力学性能

- 吉林大学 机械与航空航天工程学院,长春 130022

Mechanical property of 45 steel under reciprocating torsional load based on nanoindentation analysis

Cong LI( ),Hong⁃wei ZHAO(

),Hong⁃wei ZHAO( ),Lin⁃lin SUN

),Lin⁃lin SUN

- Collegeof Mechanical and Aerospace Engineering, Jilin University, Changchun 130022, China

摘要:

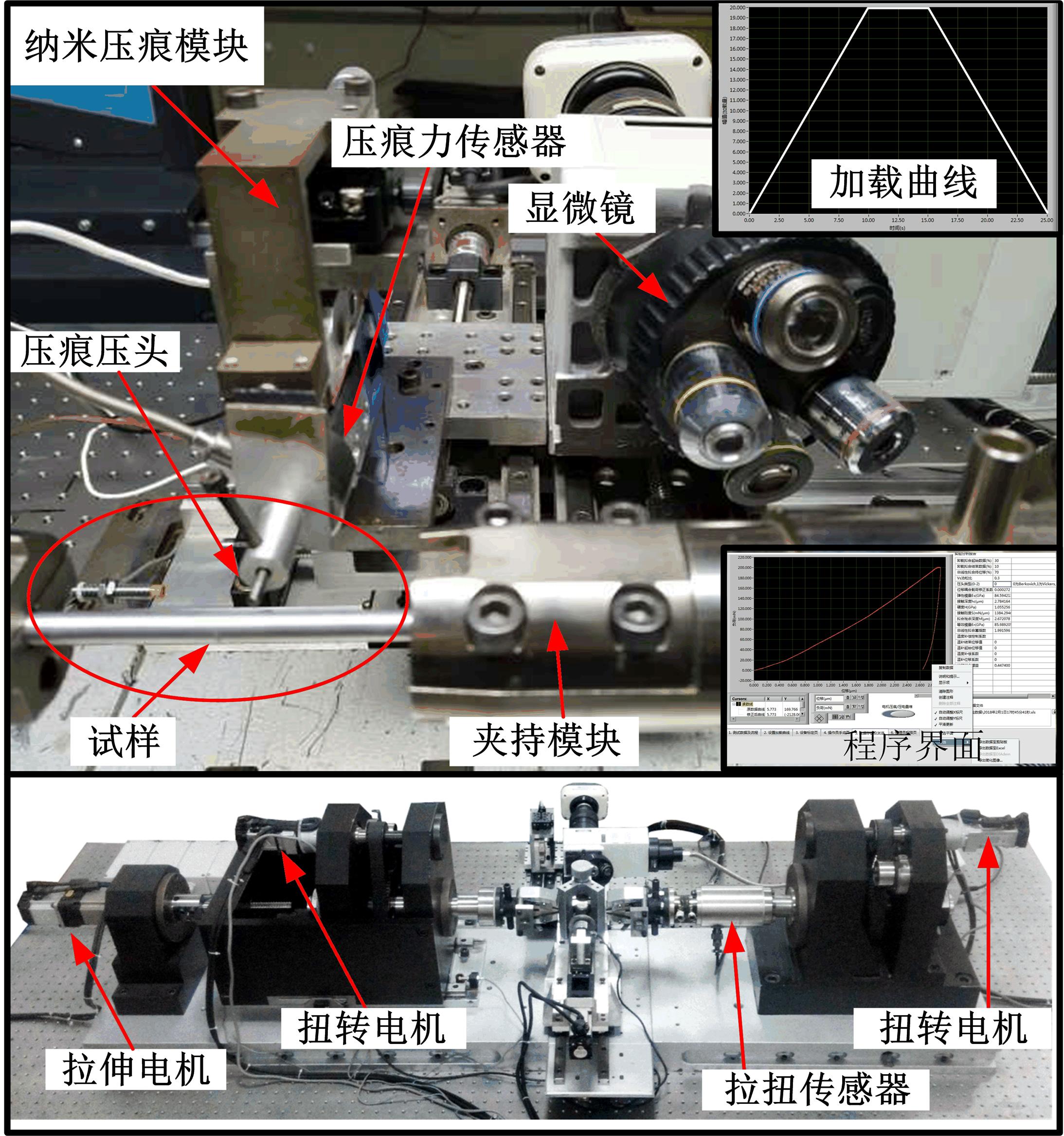

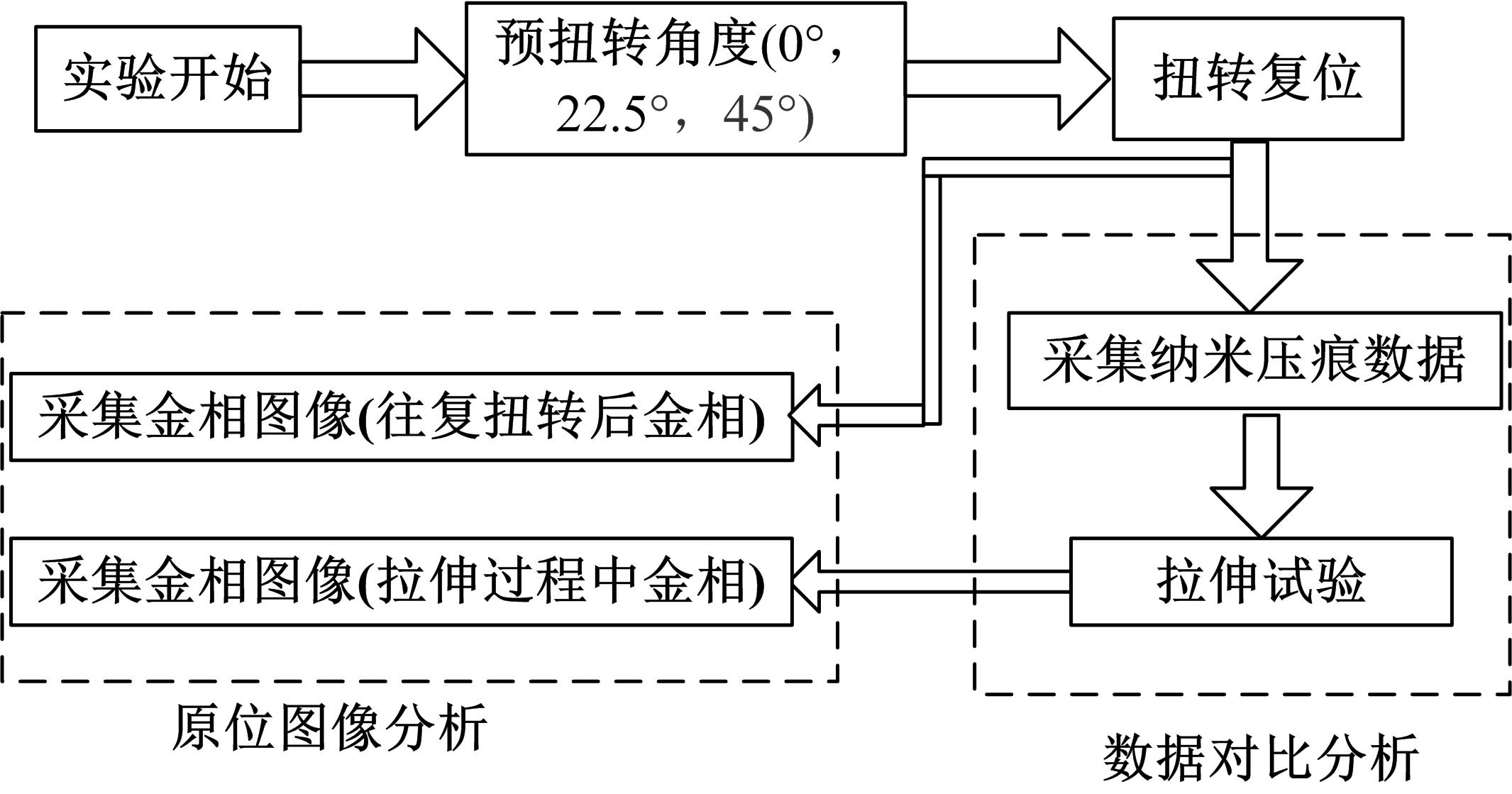

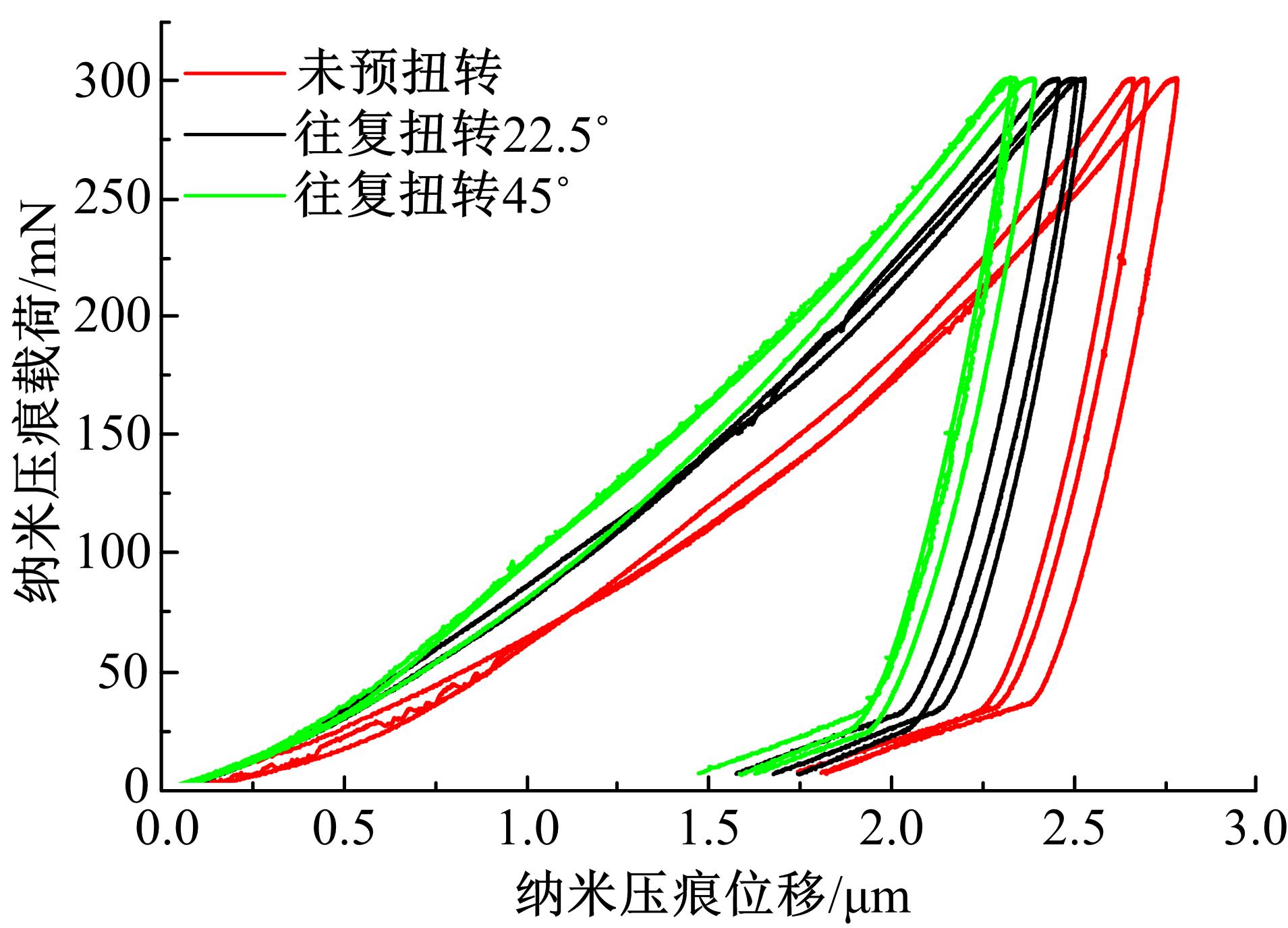

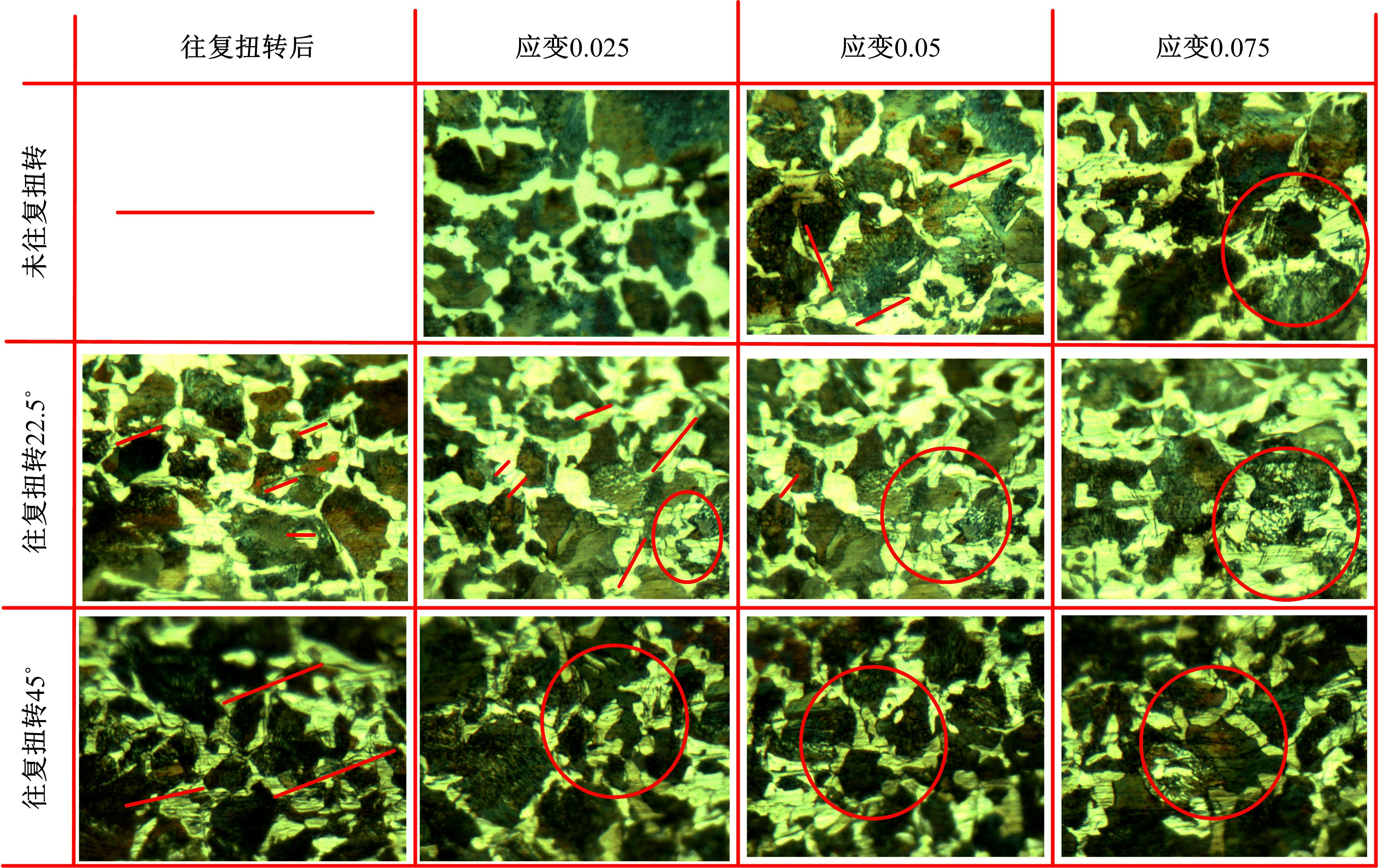

通过自制的原位拉扭?压痕力学性能测试装置,开展了往复扭转后45号钢拉伸力学性能测试。首先,由纳米压痕试验分析并获得了往复扭转后45号钢的力学性能曲线及其弹性模量、硬度、屈服强度和应变硬化指数等参数的变化。然后,通过原位拉伸试验证实了纳米压痕试验计算45号钢力学性能的可行性。结果表明,拉伸试验和压痕试验计算获得的材料力学参数具有很好的一致性。本文通过原位图像,还进一步分析了材料在往复扭转载荷下的损伤机理,证实了试验结论的正确性,为通过纳米压痕试验获取服役状态下材料力学性能提供了试验依据。

中图分类号:

- O341

| 1 | 陈刚,陈忠富,陶俊林,等.45钢动态塑性本构参量与验证[J].爆炸与冲击,2005,25(5):451⁃456. |

| ChenGang, ChenZhong⁃fu, TaoJun⁃lin, et al. Investigation and validation on plastic constitutive parameters of 45 steel[J]. Explosion and Shock Waves,2005,25(5):451⁃456. | |

| 2 | 周海波,朱晓勇,郑玉春,等.45钢螺栓断裂失效分析[J].金属热处理,2009,34(12):107⁃109. |

| ZhouHai⁃bo, ZhuXiao⁃yong, ZhengYu⁃chun, et al. Fracture analysis of 45 steel bolt[J]. Heat Treatment of Metals, 2009,34(12):107⁃109. | |

| 3 | 王长健.45钢锥套淬火裂纹失效分析[J].金属热处理,2017,42(4):204⁃207. |

| WangChang⁃jian. Failure analysis on quenching cracks of 45 steel taper sleeve[J]. Heat Treatment of Metals, 2017,42(4):204⁃207. | |

| 4 | 朱萍. GH4169盘件径轴向裂纹无损检测方法研究[D].哈尔滨:哈尔滨工业大学材料科学工程学院,2017. |

| ZhuPing. Research on nondestructive inspecting method for radial⁃axial crack of GH4169 disk[D]. Harbin:College of Materials Science and Engineering, Harbin Institute of Technology,2017. | |

| 5 | OliverW C, PharrG M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments[J]. Journal of Mmaterials Research,1992,7(6):1564⁃1583. |

| 6 | OliverW C, PharrG M. Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology[J]. Journal of Materials Research,2004,19(1):3⁃20. |

| 7 | De BonoD M, LondonT, BakerM, et al. A robust inverse analysis method to estimate the local tensile properties of heterogeneous materials from nanoindentation data[J]. International Journal of Mechanical Sciences, 2017,123:162⁃176. |

| 8 | ChoiY, ChooW Y, KwonD. Analysis of mechanical property distribution in multiphase ultra⁃fine⁃grained steels by nanoindentation[J]. Scripta Materialia, 2001,45(12):1401⁃1406. |

| 9 | DasG, DasM, SinhaS, et al. Characterization of cast stainless steel weld pools by using ball indentation technique[J]. Materials Science and Engineering A, 2009,389⁃393:513⁃514. |

| 10 | MingDao, ChollacoopNuwong, Van VlietK J, et al.Computational modeling of the forward and reverse problems in instrumented sharp indentation [J]. Acta Materialia, 2001,49(19):3899⁃3918. |

| 11 | FernandesJ V, ChaparroB M, AntunesJ M, et al. A new approach for reverse analyses in depth⁃sensing indentation using numerical simulation[J]. Acta Materialia, 2007,55:69⁃81. |

| 12 | ChengG, ZhangF, RuimiA, et al. Quantifying the effects of tempering on individual phase properties of DP980 steel with nanoindentation[J]. Materials Science and Engineering: A, 2016,667:240⁃249. |

| 13 | 申宇,张珂,岑风,等.IF钢晶界的微观力学性能及其对宏观力学性能的影响[J].机械工程材料,2018,42(2):31⁃34. |

| ShenYu, ZhangKe, QinFeng, et al. Micro⁃mechanical properties at grain boundaries of IF steel and their effect on macro⁃mechanical properties[J]. Materials for Mechanical Engineering, 2018,42(2):31⁃34. | |

| 14 | 张东生,李新涛,夏汇浩,等.纳米压痕技术表征T800碳纤维的弹性模量和硬度[J].宇航材料工艺,2017,47(4):79⁃85. |

| ZhangDong⁃sheng, LiXin⁃tao, XiaHui⁃hao, et al. Characterization of elastic modulus and hardness of T800 carbon fiber via nanoindentation technique[J]. Aerospace Materials & Technology,2017,47(4):79⁃85. | |

| 15 | 陈今龙,周素洪,叶兵,等.纳米压痕表征技术的应用与发展[J].热加工工艺,2018,47(16):13⁃17. |

| ChenJin⁃long, ZhouSu⁃hong,YeBing, et al. Application and development of nanoindentation characterization technology[J]. Hot Working Technology,2018,47(16):13⁃17. | |

| 16 | Diez⁃Pascual AnaM, Gómez⁃Fatou MariánA, Ania. Nanoindentation in polymer nanocomposites[J]. Progress in Materials Science,2015,67:1⁃94. |

| 17 | ChenLing, AylinAhadi, ZhouJin⁃ming. Quantitative study of roughness effect in nanoindentation on AISI 316L based on simulation and experiment[J]. Proceedings of the Institution of Mechanical Engineers,Part C: Journal of Mechanical Engineering Science,2016,231(21):4067⁃4075. |

| 18 | IshikawaNobuyuki, YasudaKyono, SueyoshiHitoshi, et al. Microscopic deformation and strain hardening analysis of ferrite⁃bainite dual⁃phase steels using micro⁃grid method[J].Acta Materialia, 2015,97:257⁃268. |

| 19 | 马亚鑫,高怡斐,曾雨吟,等.利用纳米压痕表征高铁车轮微观相的力学性能[J].材料导报,2015,29(6):102⁃106. |

| MaYa⁃xin, GaoYi⁃fei, ZengYu⁃yin,et al. Characterizing mechanical properties of micro⁃phases in high⁃speed railway wheel steel by nano⁃indentation[J]. Materials Review, 2015,29(6):102⁃106. | |

| 20 | 梁文,吴润,胡俊,等.显微组织对FB60钢板延伸凸缘性能的影响[J].上海金属,2018,40(4):22⁃28. |

| LiangWen, WuRun, HuJun, et al. Effect of microstructure on strength⁃flange⁃formability of FB60 steel plate[J]. Shanghai Metals, 2018,40(4):22⁃28. |

| [1] | 马尧, 董晓龙, 李泽君, 沈林, 赵宏伟. 不同接触零点对纳米压痕测试影响的有限元解析[J]. 吉林大学学报(工学版), 2014, 44(5): 1366-1370. |

| [2] | 张霖, 赵宏伟, 杨倚寒, 马智超, 黄虎, 马志超. 单层石墨烯薄膜材料纳米压痕过程的分子动力学解析[J]. 吉林大学学报(工学版), 2013, 43(06): 1558-1565. |

| [3] | 马云海, 王悦明, 潘春祥, 张志君. 鲍鱼壳体纳米力学特性及有限元分析[J]. 吉林大学学报(工学版), 2012, 42(增刊1): 437-439. |

| [4] | 韩勇, 杨济匡, 李凡, 刘凯扬. 汽车-行人碰撞中人体下肢骨折的有限元分析[J]. 吉林大学学报(工学版), 2011, 41(01): 6-0011. |

| [5] | 嵇佳斌, 王义强, 赵宏伟, 周晓勤, 曹力, 彭振兴. 测试原位纳米压痕的微小型加载装置[J]. 吉林大学学报(工学版), 2010, 40(02): 471-0474. |

|