吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (3): 850-858.doi: 10.13229/j.cnki.jdxbgxb20180142

激光冲击强化对2Cr13不锈钢腐蚀 疲劳性能的影响

罗开玉1( ),邢月华1,柴卿锋1,吴世凯2,尹叶芳1,鲁金忠1

),邢月华1,柴卿锋1,吴世凯2,尹叶芳1,鲁金忠1

- 1. 江苏大学 机械工程学院,江苏 镇江 212013

2. 北京工业大学 北京市激光应用技术工程技术研究中心,北京 100124

Effects of laser shock peening on corrosion fatigue behaviour of 2Cr13 stainless steel

Kai⁃yu LUO1( ),Yue⁃hua XING1,Qing⁃feng CHAI1,Shi⁃kai WU2,Ye⁃fang YIN1,Jin⁃zhong LU1

),Yue⁃hua XING1,Qing⁃feng CHAI1,Shi⁃kai WU2,Ye⁃fang YIN1,Jin⁃zhong LU1

- 1. School of Mechanical Engineering, Jiangsu University, Zhenjiang 212013, China

2. Beijing Engineering Researching Center of Laser Technology, Beijng University of Technology, Beijng 100124, China

摘要:

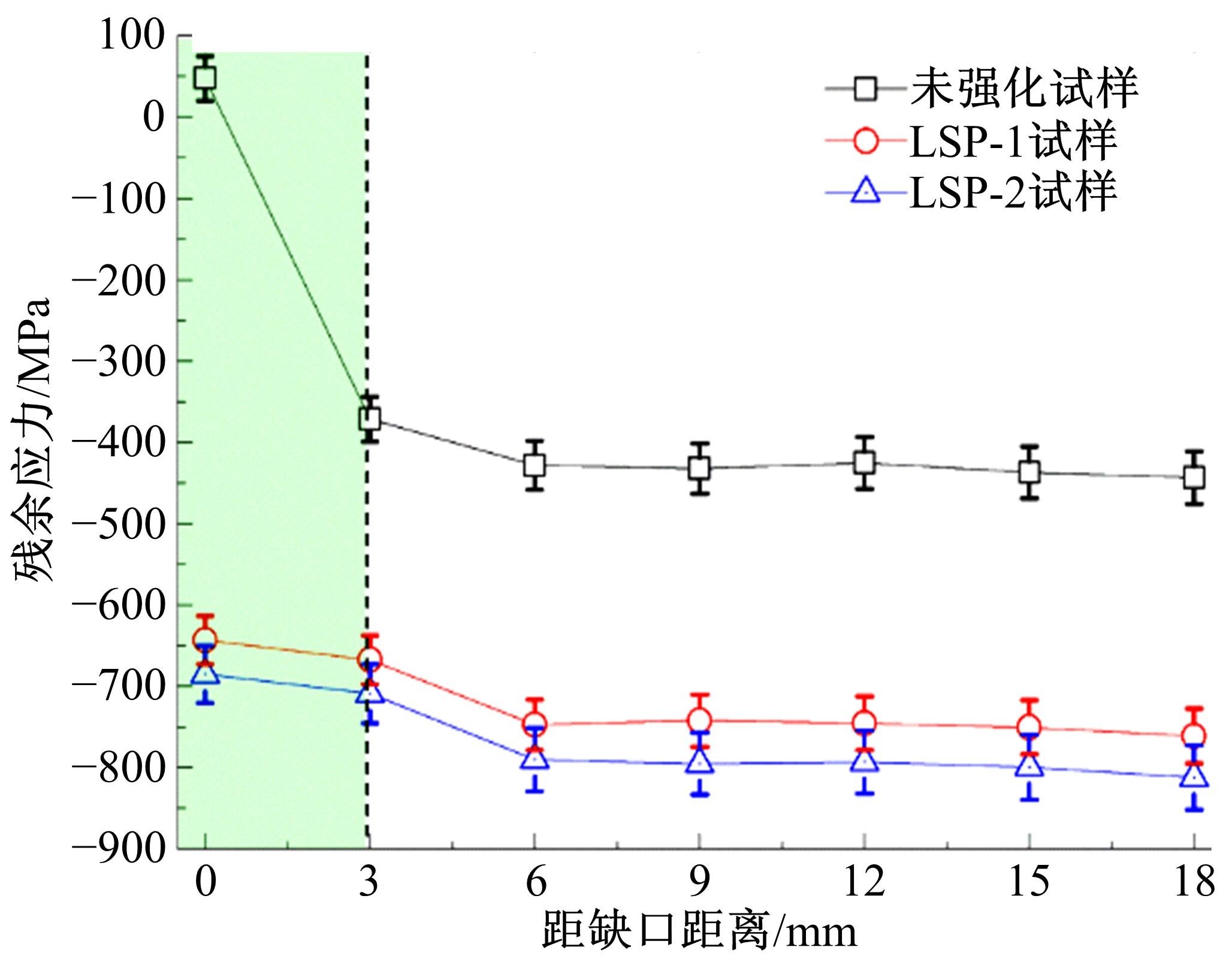

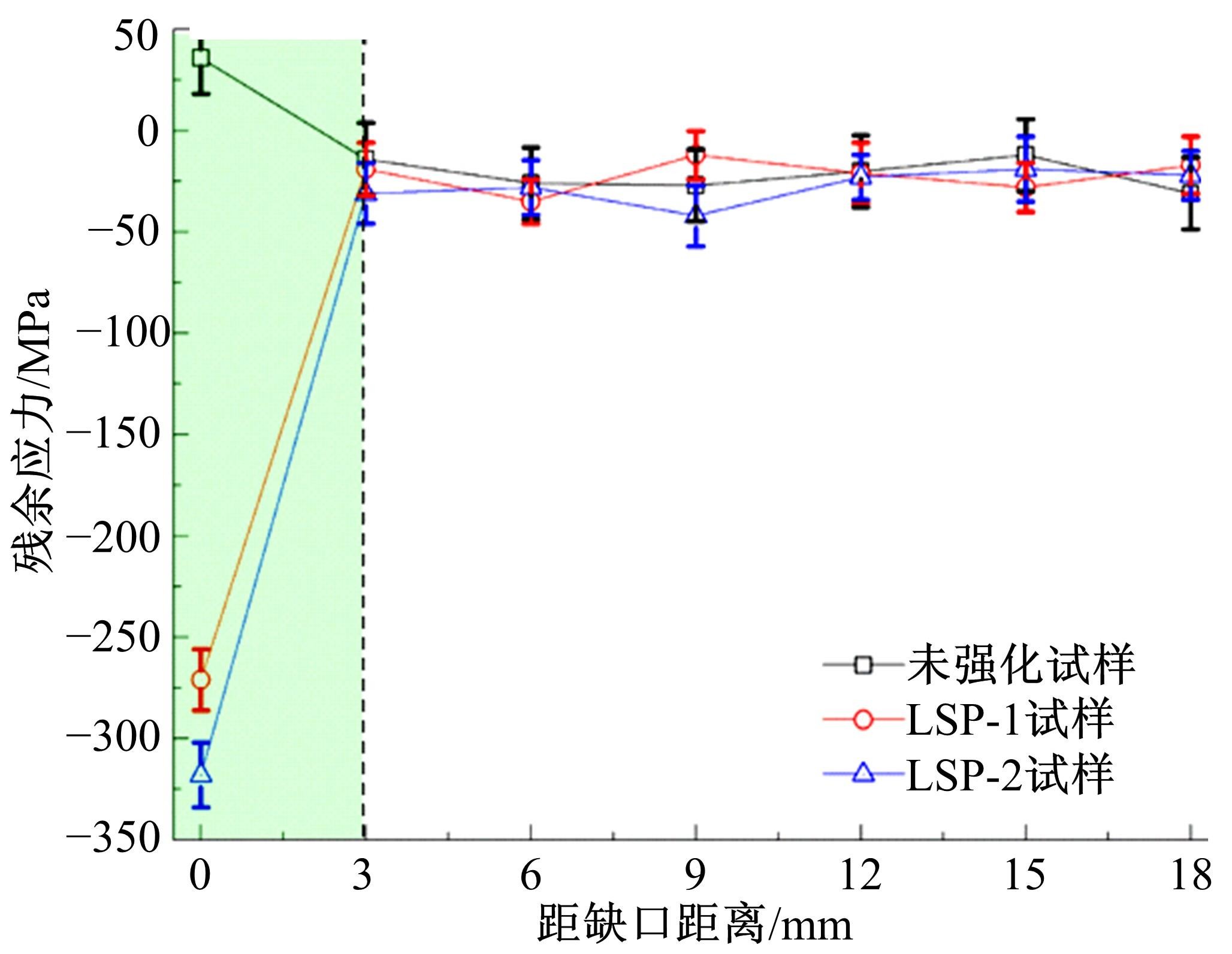

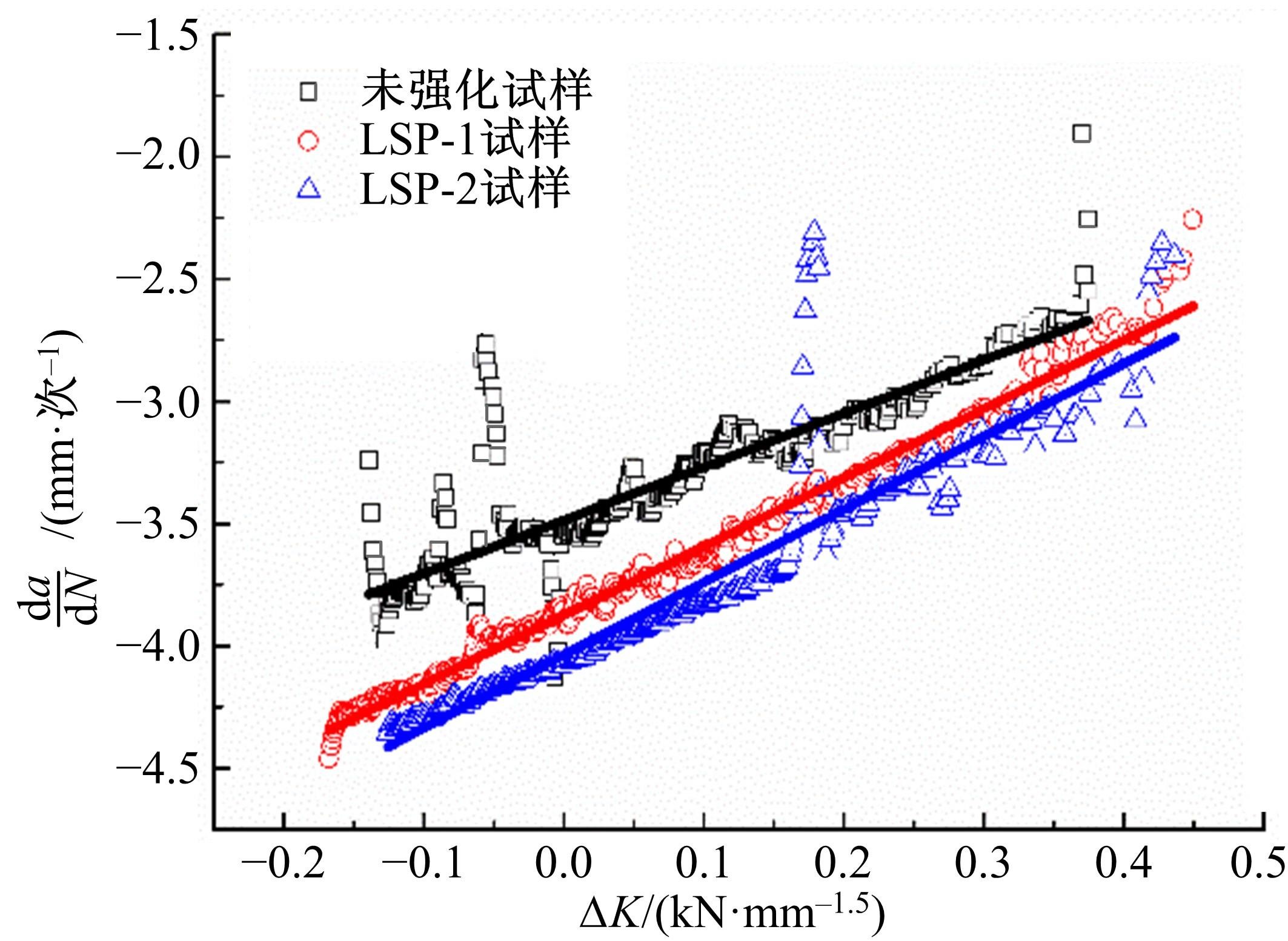

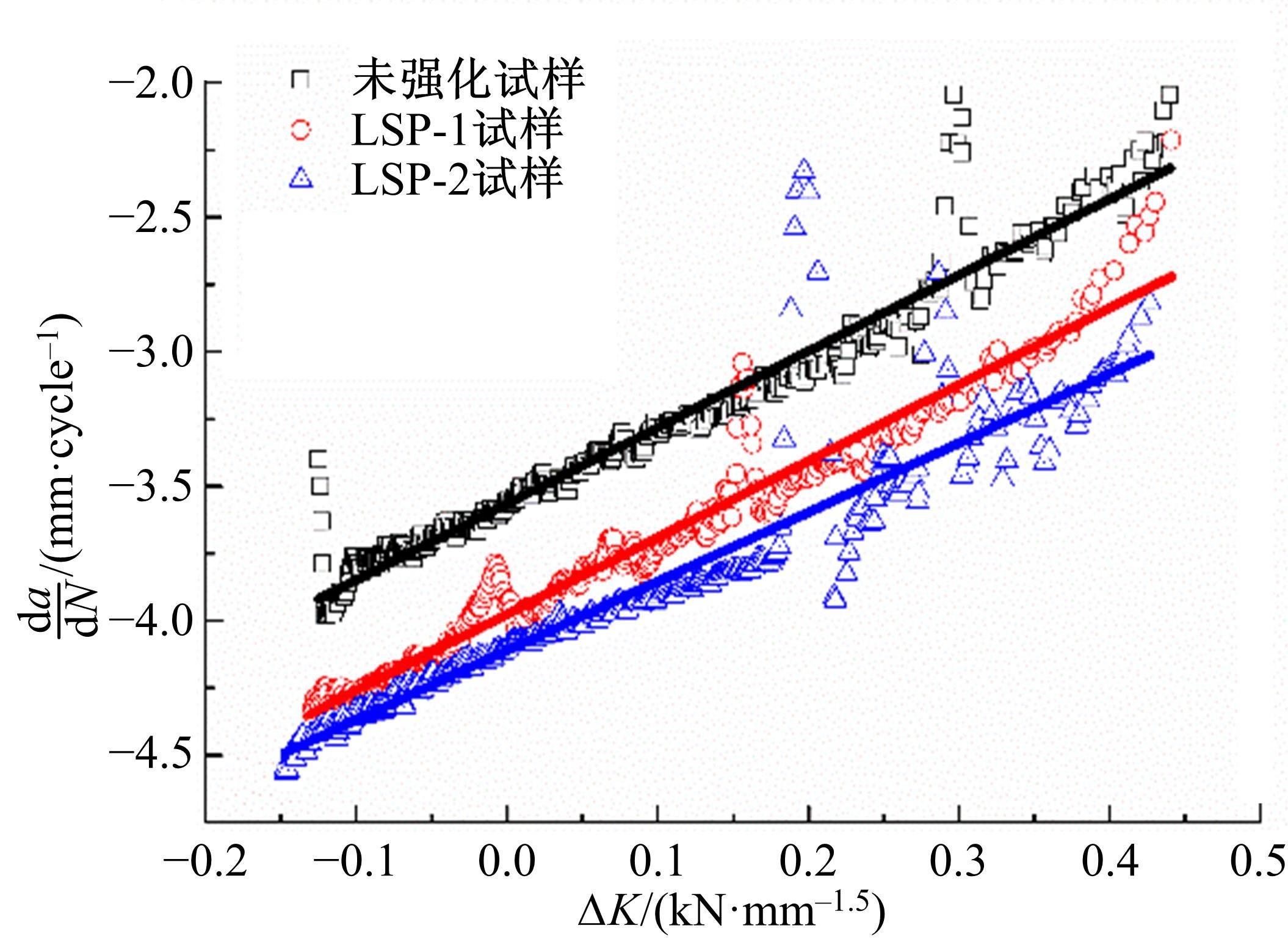

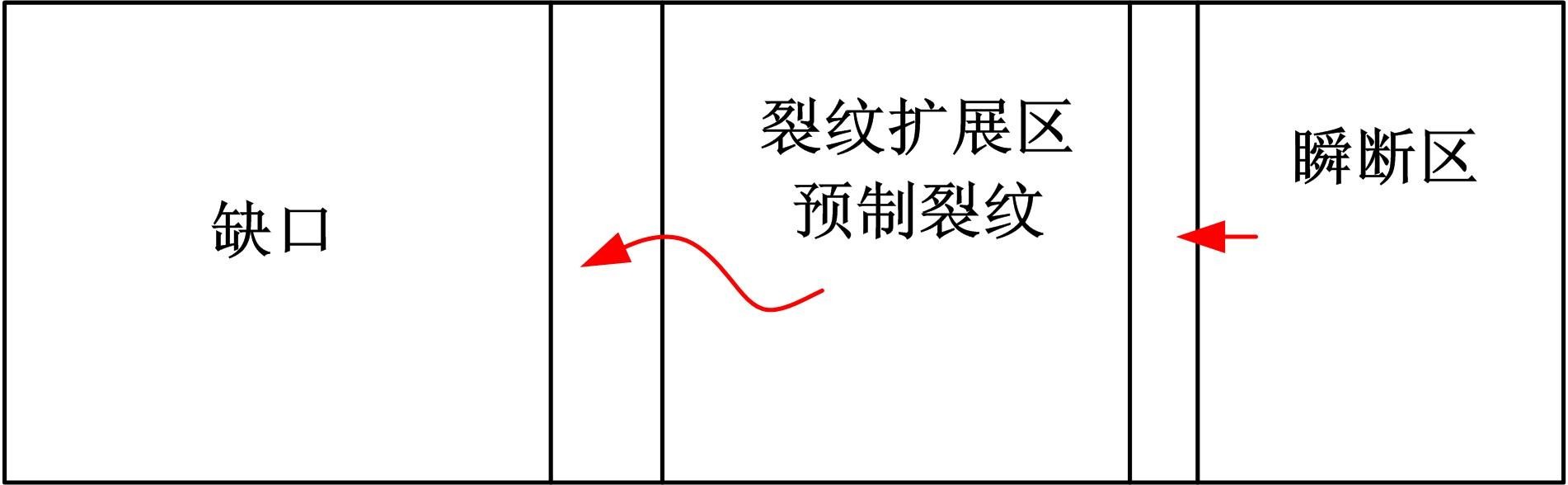

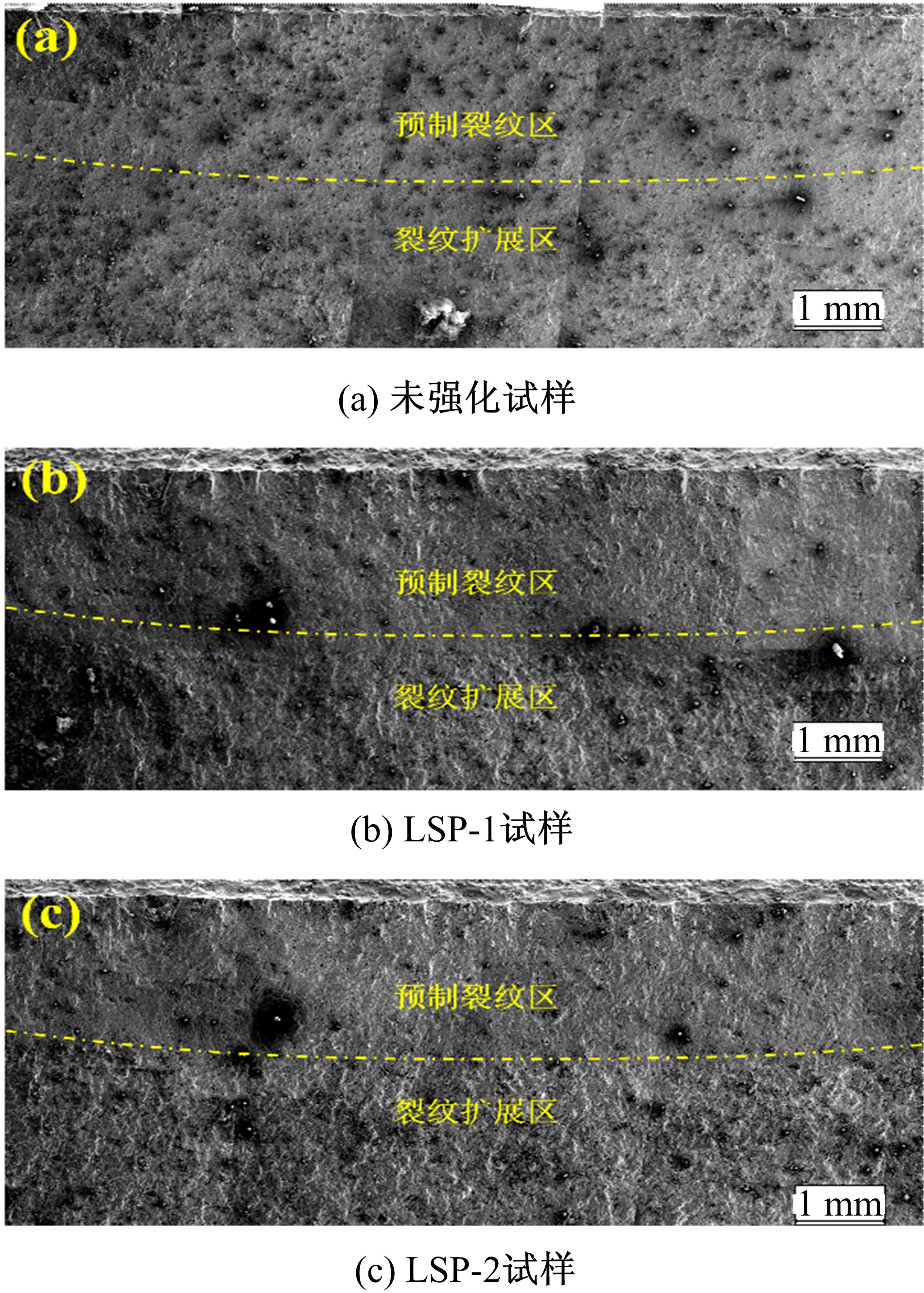

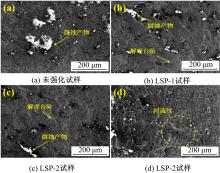

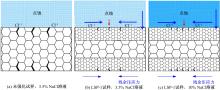

通过残余应力测量、腐蚀疲劳试验和疲劳断口形貌观察,研究了不同激光冲击层数对2Cr13不锈钢腐蚀疲劳性能的影响。试验结果表明,LSP会在2Cr13不锈钢表面产生高幅残余压应力,且表面残余压应力值随LSP冲击层数的增加而增加。与未强化试样相比,LSP试样的腐蚀疲劳寿命提升,且随LSP冲击层数的增加而提高;LSP试样的腐蚀疲劳裂纹扩展速率降低,且随LSP冲击层数的增加而降低。经分析,未强化试样疲劳断口形貌比较平坦,二次裂纹较少;LSP试样由于表面产生了较高的残余压应力,有效抑制了腐蚀疲劳裂纹的扩展,最终断口表现出河流花样形貌。

中图分类号:

- TH16

| 1 | 冯爱新, 周鹏程, 聂贵锋, 等. 热处理和激光冲击对2Cr13马氏体不锈钢冲击韧性的影响[J]. 中国激光, 2012, 39(8):0803002. |

| FengAi⁃xin, ZhouPeng⁃cheng, NieGui⁃feng, et al. Influence of heat treatment and laser shock processing on impact toughness of 2Cr13 martensite stainless steel[J]. Chinese Journal of Lasers, 2012, 39(8):0803002. | |

| 2 | 徐庆东, 林鑫, 宋梦华,等. 激光成形修复2Cr13不锈钢热影响区的组织研究[J]. 金属学报, 2013, 49(5):605⁃613. |

| XuQing⁃dong, LinXin, SongMeng⁃hua, et al. Microstructure of heat⁃affected zone of laser forming repaired 2Cr13 stainless steel[J]. Acta Metallurgica Sinica, 2013, 49(5):605⁃613. | |

| 3 | 韩栋, 刘道新, 刘树涛. 汽轮机低压转子2Cr13不锈钢叶片断裂分析[J]. 机械工程材料, 2007, 31(7):45⁃48. |

| HanDong, LiuDao⁃xin, LiuShu⁃tao. Failure analysis of 2Cr13 stainless steel blade in a low pressure steam turbine[J]. Materials for Mechanical Engineering, 2007, 31(7):45⁃48. | |

| 4 | 李明珠, 赵云龙. 提高2Cr13马氏体不锈钢疲劳强度的工艺研究[J]. 热加工工艺, 2010, 39(12):171⁃172. |

| LiMing⁃zhu, ZhaoYun⁃long. Study on improving fatigue strength technology of 2Cr13 martensitic stainless steel[J]. Hot Working Technology, 2010, 39(12):171⁃172. | |

| 5 | XiY T, LiuD X, DongH. Improvement of erosion and erosion⁃corrosion resistance of AISI420 stainless steel by low temperature plasma nitriding[J]. Applied Surface Science, 2008, 254(18):5953⁃5958. |

| 6 | 赖志林, 汪诚, 李应红, 等. 激光冲击强化与超声喷丸对1Cr11Ni2W2MoV不锈钢疲劳性能的影响[J]. 激光与光电子学进展, 2013, 50(5):051403. |

| LaiZhi⁃lin, WangCheng, LiYing⁃hong, et al. Effects of laser shock peening and ultrasonic shot peening on fatigue property of 1Cr11Ni2W2MoV stainless steel[J]. Laser & Optoelectronics Progress, 2013, 50(5):051403. | |

| 7 | ZhaoW, ZhangT, XinR, et al. Effects of thermally sprayed aluminum coating on the corrosion fatigue behavior of X80 steel in 3.5 wt.% NaCl[J]. Journal of Thermal Spray Technology, 2015, 24(6):974⁃983. |

| 8 | 王曼曼. 电弧喷涂铝涂层对X80钢海洋腐蚀疲劳裂纹萌生的影响[D]. 青岛:中国石油大学(华东)材料科学与工程学院, 2013. |

| WangMan⁃man. Effects of aluminum spray coating on marine corrosion fatigue crack initiation of X80 steel[D]. Qingdao: College of Materials Scinence and Engineering,China University of Petroleum (East China), 2013. | |

| 9 | 罗开玉, 周阳, 鲁金忠, 等. 激光冲击强化对316L不锈钢熔覆层微观结构和性能的影响[J]. 中国激光, 2017, 44(4):0402005. |

| LuoKai⁃yu, ZhouYang, LuJin⁃zhong, et al. Influence of laser shock peening on microstructure and property of cladding layer of 316L stainless steel[J]. Chinese Journal of Lasers, 2017, 44(4):0402005. | |

| 10 | 李兴成. 激光冲击强化AZ31镁合金的腐蚀性能研究[D]. 镇江:江苏大学材料科学与工程学院, 2014. |

| LiXing⁃cheng. Investigation of laser shock processing on corrosion resistance of AZ31 magnesium alloy[D]. Zhenjiang: College of Materials and Science, Jiangsu University, 2014. | |

| 11 | 孙昀杰, 周建忠, 黄舒,等. 激光喷丸医用Ti6Al4V合金的耐生物腐蚀性能研究[J]. 中国激光, 2017, 44(7):0702003. |

| SunYun⁃jie, ZhouJian⁃zhong, HuangShu, et al. Research on biological corrosion resistance of medical Ti6Al4V alloy subjected to laser peening[J]. Chinese Journal of Lasers, 2017, 44(7):0702003. | |

| 12 | 任旭东, 张田, 张永康, 等. 激光冲击处理提高00Cr12合金的疲劳性能[J]. 中国激光, 2010, 37(8):2111⁃2115. |

| RenXu⁃dong, ZhangTian, ZhangYong⁃kang, et al. Improving fatigue properties of 00Cr12 alloy by laser shock processing[J]. Chinese Journal of Lasers, 2010, 37(8):2111⁃2115. | |

| 13 | ZhouJ Z, HuangS, ZuoL D, et al. Effects of laser peening on residual stresses and fatigue crack growth properties of Ti⁃6Al⁃4V titanium alloy[J]. Optics & Lasers in Engineering, 2014, 52(1):189⁃194. |

| 14 | GeM Z, XiangJ Y. Effect of laser shock peening on microstructure and fatigue crack growth rate of AZ31B magnesium alloy[J]. Journal of Alloys & Compounds, 2016, 680:544⁃552. |

| 15 | BegumZ, PoonguzhaliA, BasuR, et al. Studies of the tensile and corrosion fatigue behaviour of austenitic stainless steels[J]. Corrosion Science, 2011, 53(4):1424⁃1432. |

| 16 | 周建忠, 徐增闯, 黄舒, 等. 基于不同应力比下激光喷丸强化6061⁃T6铝合金的疲劳裂纹扩展性能研究[J]. 中国激光, 2011, 38(9):0903006. |

| ZhouJian⁃zhong, XuZeng⁃chuang, HuangShu, et al. Effects of different stress ratios on fatigue crack growth in laser shot peened 6061⁃T6 aluminum alloy[J]. Chinese Journal of Lasers, 2011, 38(9):0903006. | |

| 17 | 汪诚, 赖志林, 何卫锋, 等. 激光冲击次数对1Cr11Ni2W2MoV不锈钢高周疲劳性能的影响[J]. 中国激光, 2014, 41(1):0103001. |

| WangCheng, LaiZhi⁃lin, HeWei⁃feng, et al. Effect of multi⁃impact on high cycle fatigue properties of 1Cr11Ni2W2MoV stainless steel subject to laser shock processing[J]. Chinese Journal of Lasers, 2014, 41(1):0103001. | |

| 18 | ParisP C, ErdoganF. A critical analysis of crack propagation laws[J]. Journal of Basic Engineering, 1963, 85(4):528⁃533. |

| 19 | 张洁, 顾祥, 祝乐, 等. 激光冲击强化后7050铝合金疲劳寿命的数值模拟[J]. 中国激光, 2010, 37(12):3192⁃3195. |

| ZhangJie, GuXiang, ZhuLe, et al. Numerical simulation of fatigue life of 7050 aluminum alloy processed by laser shock processing[J]. Chinese Journal of Lasers, 2010, 37(12):3192⁃3195. | |

| 20 | 李媛, 何卫锋, 聂祥樊, 等. 激光冲击TC17钛合金疲劳裂纹扩展试验[J]. 中国表面工程, 2017, 30(3):40⁃47. |

| LiYuan, HeWei⁃feng, NieXiang⁃fan, et al. Fatigue crack growth behavior of TC17 titanium alloy with laser shock peening[J]. China Surface Engineering, 2017, 30(3):40⁃47. | |

| 21 | BergantZ, TrdanU, GrumJ. Effects of laser shock processing on high cycle fatigue crack growth rate and fracture toughness of aluminium alloy 6082⁃T651[J]. International Journal of Fatigue, 2016, 87:444⁃455. |

| 22 | NieX F, HeW, ZangS, et al. Effect study and application to improve high cycle fatigue resistance of TC11 titanium alloy by laser shock peening with multiple impacts[J]. Surface & Coatings Technology, 2014, 253(9):68⁃75. |

| 23 | PrabhakaranS, KulkarniA, VasanthG, et al. Laser shock peening without coating induced residual stress distribution, wettability characteristics and enhanced pitting corrosion resistance of austenitic stainless steel[J]. Applied Surface Science, 2017, 428:17⁃30. |

| 24 | 葛茂忠, 项建云, 张永康. 激光冲击处理对AZ31B镁合金力学性能的影响[J]. 材料工程, 2013(9):54⁃59. |

| GeMao⁃zhong, XiangJian⁃yun, ZhangYong⁃kang. Effect of laser shock processing on mechanical properties of AZ31B magnesium alloy[J]. Journal of Materials Engineering, 2013(9):54⁃59. |

| [1] | 马芳武,陈实现,韩露,梁鸿宇,蒲永锋. 金属表面特征与金属⁃塑料直接连接强度的相关性[J]. 吉林大学学报(工学版), 2019, 49(3): 816-821. |

| [2] | 鲁金忠,周婉婷,张圣洋,邵亦锴,王长雨,罗开玉. 激光冲击强化层数对6061⁃T6铝合金抗腐蚀性能的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 842-849. |

| [3] | 寇淑清, 石舟. 裂解连杆接合面三维重构及其强度与刚度[J]. 吉林大学学报(工学版), 2018, 48(5): 1515-1523. |

| [4] | 任庆磊, 魏昕, 谢小柱, 胡伟. 硅片自旋转磨削中基于力的微接触机理[J]. 吉林大学学报(工学版), 2018, 48(3): 796-802. |

| [5] | 李俊烨, 胡敬磊, 杨兆军, 张心明, 周曾炜. 离散相磨粒粒径对磨粒流研抛共轨管质量的影响[J]. 吉林大学学报(工学版), 2018, 48(2): 492-499. |

| [6] | 陈超, 赵升吨, 崔敏超, 韩晓兰, 范淑琴, 石田徹. AL5052铝合金板平压重塑形连接试验[J]. 吉林大学学报(工学版), 2017, 47(5): 1512-1518. |

| [7] | 郎利辉, 阚鹏, 王耀, 孙志莹, 张泉达. 铝合金板材三向应力状态下的成形性能[J]. 吉林大学学报(工学版), 2017, 47(5): 1527-1533. |

| [8] | 李俊烨, 乔泽民, 杨兆军, 张心明. 介观尺度下磨料浓度对磨粒流加工质量的影响[J]. 吉林大学学报(工学版), 2017, 47(3): 837-843. |

| [9] | 曲兴田, 赵永兵, 刘海忠, 王昕, 杨旭, 陈行德. 串并混联机床几何误差建模与实验[J]. 吉林大学学报(工学版), 2017, 47(1): 137-144. |

| [10] | 张鹏, 寇淑清, 赵勇, 林宝君. 装配式凸轮轴三点式轴向滚花过程[J]. 吉林大学学报(工学版), 2016, 46(6): 1953-1960. |

| [11] | 任书楠, 杨向东, 王国磊, 刘志, 陈恳. 大部件喷涂中的移动机械臂站位规划[J]. 吉林大学学报(工学版), 2016, 46(6): 1995-2002. |

| [12] | 王犇, 王晓力. 硅微球轴承关键工艺[J]. 吉林大学学报(工学版), 2016, 46(3): 824-830. |

| [13] | 沈志煌, 姚斌, 陆如升, 冯伟, 张祥雷, 王萌萌. 精密螺杆转子齿廓成形磨削的误差分析[J]. 吉林大学学报(工学版), 2016, 46(3): 831-838. |

| [14] | 郭哲锋, 汤文成. 杯形件二次拉深的应力分析[J]. 吉林大学学报(工学版), 2016, 46(2): 494-499. |

| [15] | 王延忠, 侯良威, 吕庆军, 赵兴福, 吴灿辉. 基于总线控制的面齿轮复杂曲面加工技术[J]. 吉林大学学报(工学版), 2015, 45(6): 1836-1843. |

|