吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (4): 1134-1143.doi: DOI:10.13229/j.cnki.jdxbgxb20180428

• • 上一篇

预应力钢丝绳加固钢筋混凝土梁桥抗剪性能

- 1. 东北林业大学 土木工程学院,哈尔滨 150040

2. 哈尔滨学院 工学院,哈尔滨 150086

Shear strengthening of reinforced concrete beam with prestressed steel wire ropes

Tian⁃lai YU1( ),Hai⁃sheng LI1,Wei HUANG2,Si⁃jia WANG1

),Hai⁃sheng LI1,Wei HUANG2,Si⁃jia WANG1

- 1. College of Civil Engineering, Northeast Forestry University, Harbin 150040, China

2. Engineering College, Harbin University, Harbin 150086, China

摘要:

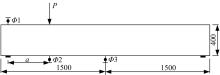

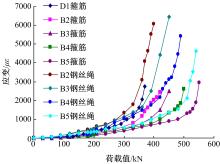

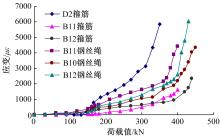

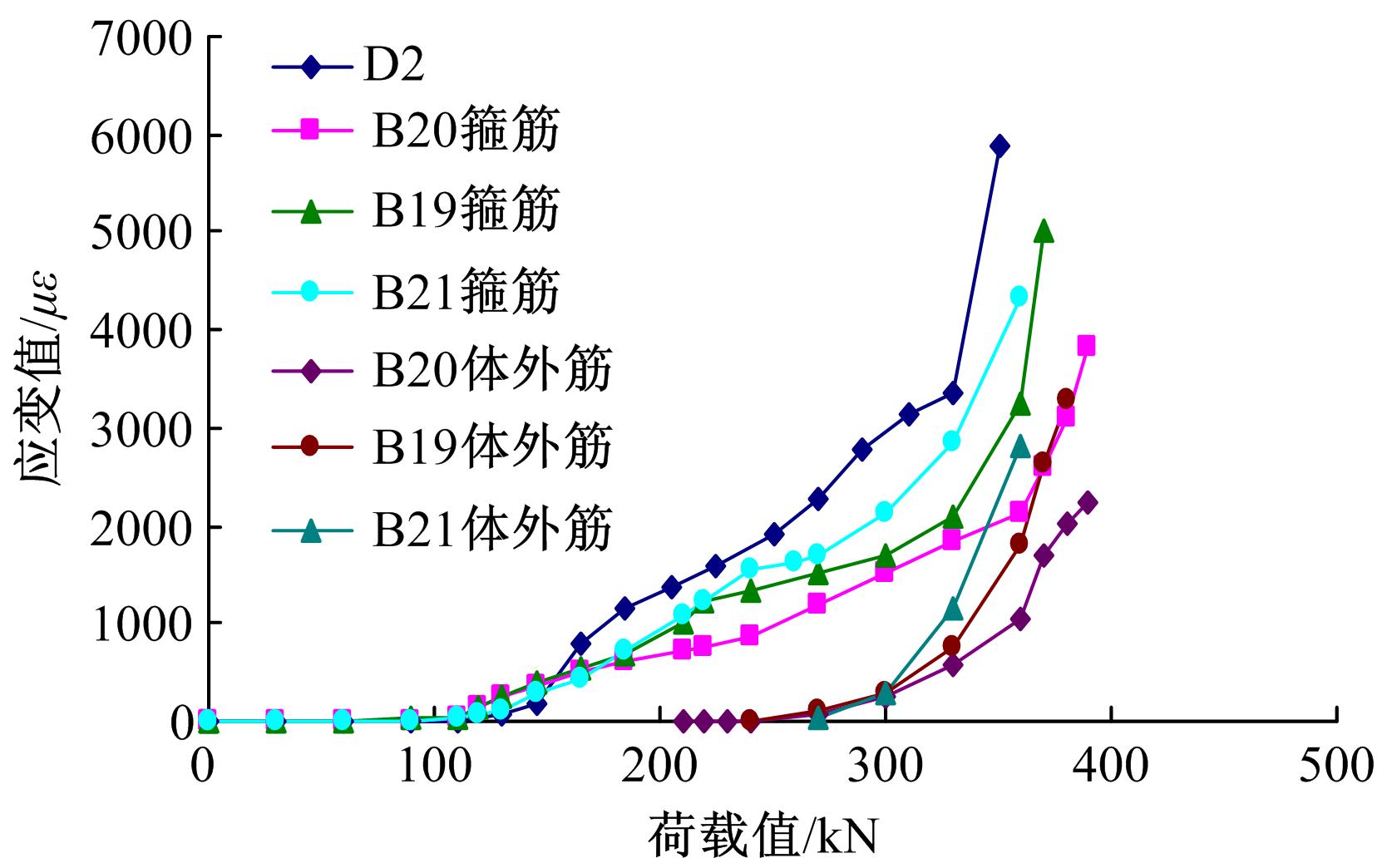

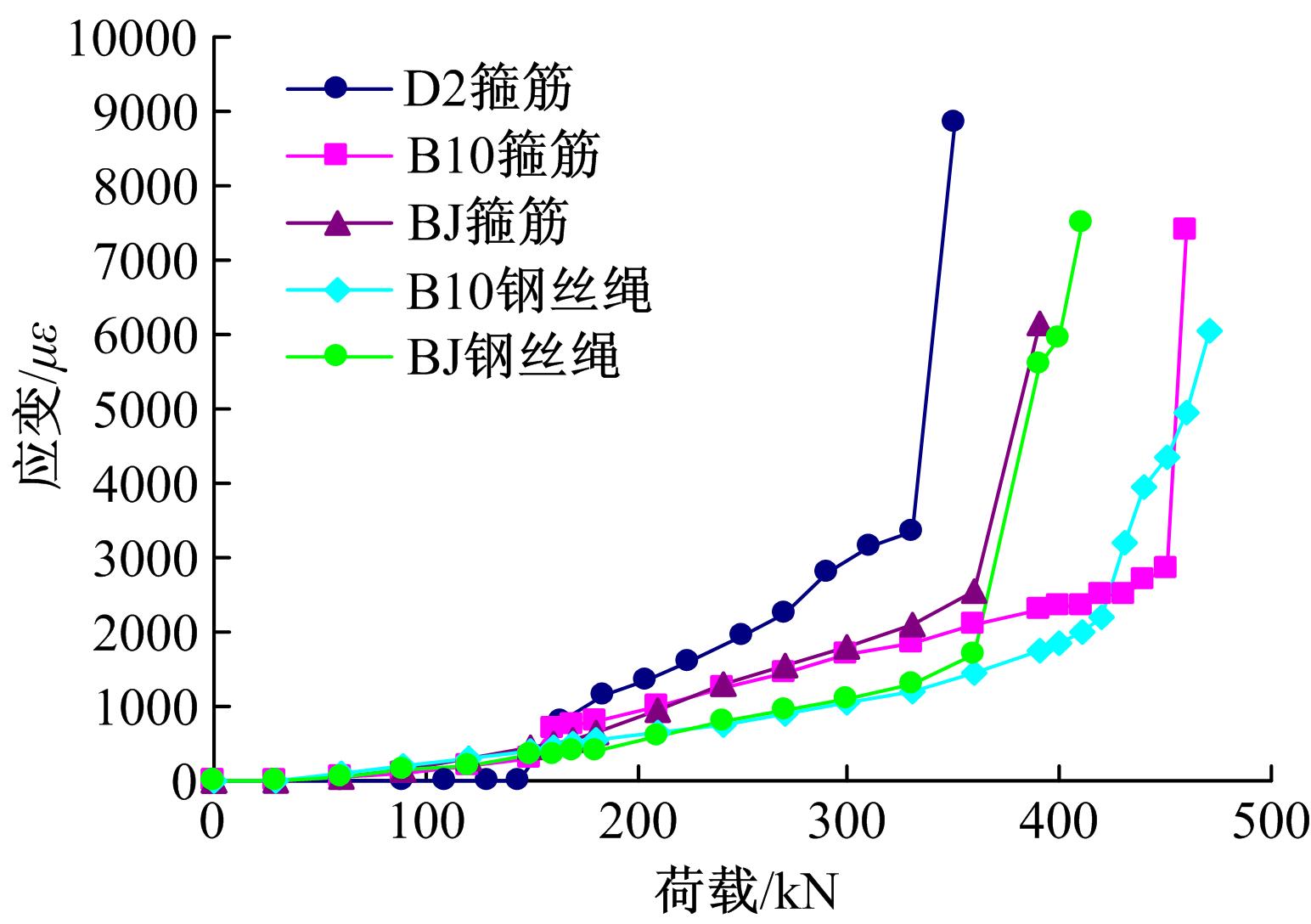

通过对24片RC梁的抗剪试验,系统研究了抗剪加固的机理以及原梁设计参数、带载水平、损伤度、钢丝绳布置方式对抗剪加固效果的影响。研究结果表明:预应力钢丝绳可有效延迟RC梁的斜截面开裂,限制斜裂缝的发展,提高极限抗剪承载能力;钢丝绳对抗剪承载力提高的作用机理与RC梁的腹筋作用相似;原梁的设计参数对抗剪加固效果具有较明显的影响;随着带载水平的提高,抗剪极限承载能力提高的程度逐渐降低;原梁损伤度对抗剪加固效果有一定的影响,原梁裂缝宽度小于0.2 mm时,注胶效果不理想,提高幅度较小,宽度大于0.2 mm后注胶效果改善,承载力有所提高,但当裂缝宽度大于0.5 mm后,加固效果处于稳定阶段;U型布束加固效果优于斜向布束;对于T梁,U型部束方案优于U型闭布束。

中图分类号:

- U446.1

| 1 | 赵晋,张雪丽.CFRP板条加固钢筋混凝土梁的抗剪性能试验研究[J].混凝土,2007(11):8-11. |

| ZhaoJin,ZhangXue-li.Experimental study of shear characteristic of reinforced concrete beams strengthened with CFRP laminates[J] Concrete, 2007(11):8-11. | |

| 2 | KhalifaA, NanniA . Rehabilitation of rectangular simply supported RC beams with shear deficiencies using CFRP composites[J]. Construction & Building Materials, 2002, 16(3):135-146. |

| 3 | 王兴国,周朝阳,曾宪桃,等.粘贴预应力CFRP板——混凝土梁抗剪加固试验研究[J].四川建筑科学研究,2005,31(5):46-49 |

| WangXing-guo,ZhouZhao-yang,ZengXian-tao,et al.Experimental study on shear reinforcement of prestressed CFRP plate-concrete beam[J].Sichuan Building Science, 2005,31(5):46-49. | |

| 4 | 卜良桃,王月红.复合砂浆钢筋网加固RC简支梁抗剪性能的试验研究[J].华中科技大学学报:自然科学版,2006,23(4):35-38. |

| BuLiang-tao,WangYue-hong.Experimental study on RC beams strengthened with ferrocement mortar shear performance[J]. Journal of Huazhong University of Science and Technology(Natural Science Edition),2006,23(4):35-38. | |

| 5 | 聂建国,蔡 奇,张天申,等.高强不锈钢绞线网-渗透性聚合砂浆抗剪加固的试验研究[J].建筑结构学报,2005,26(2):10-17. |

| NieJian-guo,CaiQi,ZhangTian-shen,et al.Experimental study on shear behavior of RC beams strengthend with stainless steel wire mesh and permeability polymer mortar[J].Journal of Building Structures, 2005,26(2):10-17. | |

| 6 | 黄华,刘伯权,刘卫铎,等.高强钢绞线网-聚合物砂浆抗剪加固梁二次受力试验研究[J].工业建筑,2009,39(2):123-127. |

| HuangHua,LiuBo-quan,LiuWei-duo,et al.Experimental study of shear behavior of RC beams strengthened with stainless steel wire mesh and polymer mortar under secondary load[J]. Industrial Construction,2009,39(2):123-127. | |

| 7 | KimS Y. Tests of reinforced concrete beams strengthened with wire rope units [J]. Engineering Structures,2007,29:2711-2722. |

| 8 | 崔长利.预应力钢丝绳加固RC混凝土梁桥抗剪性能试验[J].公路交通科技:应用技术版,2018,14(10):204-206. |

| CuiChang-li.Experimental study on shear performance of RC concrete beam bridge strengthened with prestressed steel wire rope[J].Journal of Highway and Transportation Technology(Application Technology Edition),2018,14(10):204-206. | |

| 9 | 司建辉, 赵恒, 刘茂社. 预应力绕丝加固RC梁抗剪性能试验研究[J]. 工程抗震与加固改造, 2018, 40(4):112-116. |

| SiJian-hui,ZhaoHeng, LiuMao-she. Experimental research on shear strengthening of reinforced concrete beams using prestressed wire-rope hoops[J].Earthquake Resistant Engineering and Retrofitting, 2018, 40(04):112-116. | |

| 10 | 许心怡. 预应力高强钢丝绳抗剪加固混凝土梁试验研究[D].南京:东南大学交通学院,2017. |

| XuXin-yi. Experimental study on shear-reinforced concrete beams with prestressed high-strength steel wire rope[D].Nanjing:School of Transportation, Southeast University, 2017. | |

| 11 | 于天来,黄巍.基于遗传算法的体外预应力钢丝绳加固RC梁抗剪承载力计算方法[J].公路交通科技,2015,32(10):82-90,96. |

| YuTian-lai, HuangWei. Calculation method of shear capacity of RC beams strengthened with external prestressed steel wire ropes based on genetic algorithm[J]. Journal of Highway and Transportation Research and Development, 2015, 32(10): 82-90,96. | |

| 12 | 郭子雄,杨军民,叶勇,等.闭合预应力钢丝绳加固RC梁抗剪性能试验研究[J].中南大学学报:自然科版,2015,46(7):2590-2596. |

| GuoZi-xiong, YangJun-min, YeYong, et al.Experimental study on shear resistance of RC beams strengthened with closed prestressed steel wire ropes[J].Journal of Central South University:Science and Technology,2015,46(7):2590 -2596. |

| [1] | 万世成,黄侨,关健,郭赵元. 预应力碳纤维板加固钢⁃混凝土组合连续梁负弯矩区试验[J]. 吉林大学学报(工学版), 2019, 49(4): 1114-1123. |

| [2] | 黄晓明,曹青青,刘修宇,陈嘉颖,周兴林. 基于路表分形摩擦理论的整车雨天制动性能模拟[J]. 吉林大学学报(工学版), 2019, 49(3): 757-765. |

| [3] | 王静,吕翔,曲肖龙,钟春玲,张云龙. 路基土抗剪强度与化学及矿物成分的关系[J]. 吉林大学学报(工学版), 2019, 49(3): 766-772. |

| [4] | 李伊,刘黎萍,孙立军. 沥青面层不同深度车辙等效温度预估模型[J]. 吉林大学学报(工学版), 2018, 48(6): 1703-1711. |

| [5] | 臧国帅, 孙立军. 基于惰性弯沉点的刚性下卧层深度设置方法[J]. 吉林大学学报(工学版), 2018, 48(4): 1037-1044. |

| [6] | 念腾飞, 李萍, 林梅. 冻融循环下沥青特征官能团含量与流变参数灰熵分析及微观形貌[J]. 吉林大学学报(工学版), 2018, 48(4): 1045-1054. |

| [7] | 宫亚峰, 申杨凡, 谭国金, 韩春鹏, 何钰龙. 不同孔隙率下纤维土无侧限抗压强度[J]. 吉林大学学报(工学版), 2018, 48(3): 712-719. |

| [8] | 程永春, 毕海鹏, 马桂荣, 宫亚峰, 田振宏, 吕泽华, 徐志枢. 纳米TiO2/CaCO3-玄武岩纤维复合改性沥青的路用性能[J]. 吉林大学学报(工学版), 2018, 48(2): 460-465. |

| [9] | 张仰鹏, 魏海斌, 贾江坤, 陈昭. 季冻区组合冷阻层应用表现的数值评价[J]. 吉林大学学报(工学版), 2018, 48(1): 121-126. |

| [10] | 季文玉, 李旺旺, 过民龙, 王珏. 预应力RPC-NC叠合梁挠度试验及计算方法[J]. 吉林大学学报(工学版), 2018, 48(1): 129-136. |

| [11] | 马晔, 尼颖升, 徐栋, 刁波. 基于空间网格模型分析的体外预应力加固[J]. 吉林大学学报(工学版), 2018, 48(1): 137-147. |

| [12] | 罗蓉, 曾哲, 张德润, 冯光乐, 董华均. 基于插板法膜压力模型的沥青混合料水稳定性评价[J]. 吉林大学学报(工学版), 2017, 47(6): 1753-1759. |

| [13] | 尼颖升, 马晔, 徐栋, 李金凯. 波纹钢腹板斜拉桥剪力滞效应空间网格分析方法[J]. 吉林大学学报(工学版), 2017, 47(5): 1453-1464. |

| [14] | 郑传峰, 马壮, 郭学东, 张婷, 吕丹, 秦泳. 矿粉宏细观特征耦合对沥青胶浆低温性能的影响[J]. 吉林大学学报(工学版), 2017, 47(5): 1465-1471. |

| [15] | 于天来, 郑彬双, 李海生, 唐泽睿, 赵云鹏. 钢塑复合筋带挡土墙病害及成因[J]. 吉林大学学报(工学版), 2017, 47(4): 1082-1093. |

|

||