吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (1): 25-36.doi: 10.13229/j.cnki.jdxbgxb20200980

汽车轮毂加工夹具的研究现状及展望

郑伟1( ),孙见君1(

),孙见君1( ),马晨波1,於秋萍1,张玉言1,牛韬2

),马晨波1,於秋萍1,张玉言1,牛韬2

- 1.南京林业大学 机械电子工程学院,南京 210037

2.江苏速力达精密科技有限公司,南京 210039

Research status and prospect of automobile wheel hub machining fixture

Wei ZHENG1( ),Jian-jun SUN1(

),Jian-jun SUN1( ),Chen-bo MA1,Qiu-ping YU1,Yu-yan ZHANG1,Tao NIU2

),Chen-bo MA1,Qiu-ping YU1,Yu-yan ZHANG1,Tao NIU2

- 1.School of Mechanical and Electronic Engineering,Nanjing Forestry University,Nanjing 210037,China

2.Jiangsu Sulida Advanced Technology Co. ,Ltd. ,Nanjing 210039,China

摘要:

基于国内外研究进展,从夹具结构设计与夹具性能分析两方面对汽车轮毂夹具的研究现状进行了综述。在夹具结构设计方面,指出了传统汽车轮毂夹具结构存在不具备柔性化或柔性化程度较低的问题;在夹具性能分析方面,分别从夹紧力损失、夹具定位误差、夹具元件振动与噪声、夹持刚度以及夹紧力检测技术5个方面对汽车轮毂夹具的研究现状进行了探讨,指出了现有研究存在的不足。针对这些问题进行了相应的分析,并对汽车轮毂夹具未来的发展趋势及值得关注的问题进行了展望。

中图分类号:

- TG751

| 1 | 李宏禹. 汽车轮毂造型与结构设计一体化方法研究[D]. 秦皇岛: 燕山大学机械工程学院, 2010. |

| Li Hong-yu. Research on the integrated method of aut-omobile wheel hub modeling and structure design[D]. Qinhuangdao: School of Mechanical Engineering,Yanshan University, 2010. | |

| 2 | Yang X D, Men Y Z, Yu L, et al. The design of automobile wheel hub runout online detection system[J]. Applied Mechanics & Materials, 2015, 741: 298-301. |

| 3 | 麻柏慧. 基于ANSYS Workbench的轿车轮毂车削夹具仿真分析及二次开发研究[D]. 秦皇岛: 燕山大学机械工程学院, 2017. |

| Ma Bai-hui. Simulation analysis and secondary development of car wheel turning fixture based on ANSYS Workbench[D]. Qinhuangdao: School of Mechanical Engineering, Yanshan University,2017. | |

| 4 | 杨久鑫, 臧毅, 何连洋, 等. 关于铝轮毂数控加工技术的研究[J]. 中外企业家, 2019(6): 138. |

| Yang Jiu-xin, Zang Yi, He Lian-yang, et al. Researchon CNC machining technology of aluminum wheel[J]. Chinese and Foreign Entrepreneurs, 2019(6):138. | |

| 5 | 牛韬, 孙见君, 张玉言. 汽车轮毂柔性加工自动化生产线开发技术分析[J]. 机械制造与自动化, 2017, 46(6): 216-218. |

| Niu Tao, Sun Jian-jun, Zhang Yu-yan. Technical analysis of the development of automatic production line for flexible manufacturing of automobile wheels[J]. Machinery Manufacturing & Automation, 2017, 46(6): 216-218. | |

| 6 | 赵一平. 汽车轮毂加工工艺分析[J]. 内燃机与配件, 2020(9): 121-123. |

| Zhao Yi-ping. Analysis of processing technology of automobile wheel hub[J]. Internal Combustion Engine and Parts, 2020(9): 121-123. | |

| 7 | 王世龙. 关于汽车轮毂柔性加工自动化生产线开发技术研究[J]. 中国高新区, 2018(11): 157. |

| Wang Shi-long. Research on the development technology of flexible manufacturing automated production linefor automobile wheels[J]. China Hightech Zone, 2018(11): 157. | |

| 8 | Liu J, Du X, Zhou H, et al. A digital twin-based approach for dynamic clamping and positioning of the flexible tooling system[J]. Procedia CIRP, 2019, 80: 746-749. |

| 9 | Chen C, Sun Y, Ni J. Optimization of flexible fixture layout using N-M principle[J]. International Journal of Advanced Manufacturing Technology, 2018, 96: 4303-4311. |

| 10 | Ivanov V, Zajac J. Flexible fixtures for CNC machining centers in multiproduct manufacturing[J]. Industrial Networks and Intelligent Systems, 2018, 4(12): 153552. |

| 11 | 吴玉光, 张根源, 李春光. 夹具定位误差分析自动建模方法[J]. 机械工程学报, 2012,48(5): 172-179. |

| Wu Yu-guang, Zhang Gen-yuan, Li Chun-guang. Automatic modeling method for fixture positioning error analysis[J]. Chinese Journal of Mechanical Engineering, 2012, 48(5): 172-179. | |

| 12 | 张俊, 王拓, 张星, 等. 超密齿面铣刀的铣削力波动特性及其影响[J]. 东北大学学报:自然科学版, 2018, 39(4): 543-548. |

| Zhang Jun, Wang Tuo, Zhang Xing, et al. Milling force fluctuation characteristics and influence of ultra-dense tooth face milling cutters[J]. Journal of Northeastern University(Natural Science Edition), 2018, 39(4): 543-548. | |

| 13 | 宋玉宇. 基于ANSYS的轮毂车削夹具拓扑优化设计[J].机械设计与研究, 2017, 33(1): 110-113. |

| Song Yu-yu. Topology optimization design of wheel turning fixture based on ANSYS[J]. Mechanical Design and Research, 2017, 33(1): 110-113. | |

| 14 | 李玉东. 轿车铝轮毂数控立车专用夹具的设计[D]. 秦皇岛: 燕山大学机械工程学院, 2015. |

| Li Yu-dong. Design of special fixtures for car aluminum wheels CNC vertical lathes[D]. Qinhuangdao: School of Mechanical Engineering, Yanshan University, 2015. | |

| 15 | Bi Z M, Zhang W J. Flexible fixture design and automation: review, issues and future directions[J]. International Journal of Production Research, 2010, 39(13): 2867-2894. |

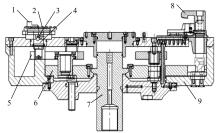

| 16 | 王健健, 张建富, 冯平法, 等. 楔式动力卡盘的静态夹紧力特性研究[J]. 四川大学学报:工程科学版, 2015, 47(1): 207-214. |

| Wang Jian-jian, Zhang Jian-fu, Feng Ping-fa, et al. Research on the static clamping force characteristics of wedge power chucks[J]. Journal of Sichuan University (Engineering Science Edition), 2015, 47(1): 207-214. | |

| 17 | Qin G H, Zhang W H, Wan M. A machining dimension based approach to locating scheme design[J]. Journal of Manufacturing Science and Engineering, 2008, 130(5): 0510101-0510107. |

| 18 | 李新水, 崔岗卫, 施兆伟, 等. 一种提高缸体定位孔位置度的夹具设计与应用[J]. 机械设计, 2019, 36(S1): 433-436. |

| Li Xin-shui, Cui Gang-wei, Shi Zhao-wei, et al. Design and application of a fixture for improving the position of cylinder positioning holes[J]. Machinery Design, 2019, 36(S1): 433-436. | |

| 19 | Cai W, Hu S J, Yuan J X. A variational method of robust fixture configuration design for 3-D workpieces[J]. Journal of Manufacturing Science and Engineering, 1997, 119(4A): 593-602. |

| 20 | Choudhuri S A, de Meter E C. Tolerance analysis of machining fixture locators[J]. Journal of Manufacturing Science and Engineering, 1999, 121: 273-281. |

| 21 | 罗晨, 朱利民, 丁汉. 夹具定位分析模型的统计特征及相对误差分析[J]. 机械工程学报, 2013, 49(5): 110-115. |

| Luo Chen, Zhu Li-min, Ding Han. Statistical characteristics and relative error analysis of fixture positioning analysis model[J]. Chinese Journal of Mechanical Engineering, 2013, 49(5): 110-115. | |

| 22 | 宁龙, 吴玉光. 基于ADAMS的夹具定位误差分析方法[J]. 制造业自动化, 2012, 34(1): 86-89, 93. |

| Ning Long, Wu Yu-guang. Analysis of fixture positioning error based on ADAMS[J]. Manufacturing Automation, 2012, 34(1): 86-89, 93. | |

| 23 | 刘亚雄, 梁庆华, 罗磊. 基于蒙特卡洛模拟的夹具定位误差分析与预测[J]. 机械设计与研究, 2019, 35(3): 104-109, 113. |

| Liu Ya-xiong, Liang Qing-hua, Luo Lei. Analysis and prediction of fixture positioning error based on Monte Carlo simulation[J]. Machinery Design and Research, 2019, 35(3): 104-109, 113. | |

| 24 | 郑伟, 孙见君, 马晨波, 等. 汽车轮毂柔性加工夹具的定位误差分析[J]. 机械设计, 2020, 38(3): 46-52. |

| Zheng Wei, Sun Jian-jun, Ma Chen-bo, et al. Positioning error analysis of flexible machining fixture for automobile wheel hub[J]. Machine Design, 2020, 38(3): 46-52. | |

| 25 | 万小金. 工件⁃夹具⁃刀具系统的几何误差分析与预测研究[D]. 武汉: 华中科技大学机械科学与工程学院, 2010. |

| Wan Xiao-jin. Research on geometric error analysis and prediction of workpiece-fixture-tool system[D]. Wuhan: School of Mechanical Science and Engineering, Huazhong University of Science and Technology,2010. | |

| 26 | 王凯. 工件-夹具系统综合误差建模及夹具优化设计方法研究[D]. 天津: 天津大学机械工程学院, 2014. |

| Wang Kai. Research on comprehensive error modeling of workpiece-fixture system and optimization design method of fixture [D]. Tianjin: School of Mechanical Engineering,Tianjin University,2014. | |

| 27 | 龚俊, 汤文成, 韦鸣, 等. 高速精密动力卡盘的失效形式分析研究[J]. 中国制造业信息化, 2012, 41(3): 70-73, 76. |

| Gong Jun, Tang Wen-cheng, Wei Ming, et al. Analysis of failure modes of high-speed precision power chucks[J]. China Manufacturing Information Technology, 2012, 41(3): 70-73, 76. | |

| 28 | Solaja V, Malajdzic M. Some experiments with three and four jaw chucks[J]. CIRP Annals-Manufacturing Technology, 1968, 16:131-136. |

| 29 | 王健健, 冯平法, 张建富, 等. 卡盘定心精度建模及其保持特性与修复方法[J]. 吉林大学学报:工学版, 2016, 46(2): 487-493. |

| Wang Jian-jian, Feng Ping-fa, Zhang Jian-fu, et al. Chuck centering accuracy modeling and its retention characteristics and repair methods[J]. Journal of Jilin University(Engineering and Technology Edition), 2016, 46(2): 487-493. | |

| 30 | 朱丽敏. 多阶段加工误差流与成本预测数学建模及定位算法研究[D]. 天津: 天津大学数学学院, 2015. |

| Zhu Li-min. Multi-stage machining error flow and cost prediction mathematical modeling and positioning algorithm research[D]. Tianjin: School of Mathematics,Tianjin University, 2015. | |

| 31 | 陈会金. 楔式动力卡盘定心精度与夹紧力特性研究[D]. 烟台:烟台大学机械工程学院, 2016. |

| Chen Hui-jin. Research on centering accuracy and clamping force characteristics of wedge power chuck[D]. Yantai: School of Mechanical Engineering, Yantai University,2016. | |

| 32 | 杨华勇, 周城. 自定心液压动力卡盘的研究综述[J]. 中国机械工程, 2007(2): 244-251. |

| Yang Hua-yong, Zhou Cheng. A review of self-centering hydraulic power chucks [J]. China Mechanical Engineering, 2007(2): 244-251. | |

| 33 | Kalajdzic M J, Solaja V B. Rotational speed limits for basic types of chucks[J]. Annals of the CIRP, 1979, 28(1): 297-301. |

| 34 | Rahman M, Tsutsumi M. Effect of spindle speed on clamping force in turning[J]. Journal of Materials Processing Technology, 1993, 38(1/2):407-415. |

| 35 | 冯平法, 郁鼎文, 吴志军, 等. 高速旋转卡盘及工件刚度对动态夹紧力的影响[J]. 清华大学学报:自然科学版, 2007(8): 1334-1337. |

| Feng Ping-fa, Yu Ding-wen, Wu Zhi-jun, et al. The effect of high-speed rotating chuck and workpiece stiffness on dynamic clamping force[J]. Journal of Tsinghua University (Natural Science Edition), 2007(8): 1334-1337. | |

| 36 | 冯平法, 郁鼎文, 吴志军, 等. 离心力补偿卡盘高速回转夹紧特性研究[J]. 中国机械工程, 2007(14): 1648-1652. |

| Feng Ping-fa, Yu Ding-wen, Wu Zhi-jun, et al. Research on the clamping characteristics of centrifugal force compensation chuck in high-speed rotation[J]. China Mechanical Engineering, 2007(14): 1648-1652. | |

| 37 | 周城. 数控机床高速液压动力卡盘的研究[D]. 杭州: 浙江大学机械工程学院, 2011. |

| Zhou Cheng. Research on high-speed hydraulic power chuck of CNC machine tool[D]. Hangzhou: School of Mechanical Engineering,Zhejiang University, 2011. | |

| 38 | 王健健, 冯平法, 张建富, 等. 高速旋转动力卡盘动态夹紧力的有限元计算方法[J]. 华中科技大学学报(自然科学版), 2015, 43(3): 7-11, 27. |

| Wang Jian-jian, Feng Ping-fa, Zhang Jian-fu, et al. Finite element calculation method for dynamic clamping force of high-speed rotating power chuck[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2015, 43(3): 7-11, 27. | |

| 39 | Doi M, Masuko M. Considerations of chucking force in chuck work[J]. Bulletin of JSME, 1986, 51(468): 2129-2134. |

| 40 | Kofi N, Mudiam S S. A model for predicting the initial static gripping force in lathe chuck[J]. International Journal of Advanced Manufacturing Tecnology, 1992(7): 285-291. |

| 41 | Spur G, Bahrke U, Mette U. Spannkraftoptimierung beim Drehen[J]. Zeitschrift fuer Wirtschaftlichen Fabrikbetrieb, 1997, 92(9): 453-456. |

| 42 | 蔺建波. 基于SolidWorks的动力卡盘离心力补偿机构建模及仿真设计与研究[D]. 呼和浩特: 内蒙古农业大学机电工程学院, 2014. |

| Lin Jian-bo. Modeling and simulation design and research of centrifugal force compensation mechanism for power chuck based on SolidWorks[D]. Hohhot: Mechanical and Electrical Engineering, Inner Mongolia Agricultural University, 2014. | |

| 43 | Lee J H, Lee S K. Chucking compliance compensation with a linear motor-driven tool system[J]. International Journal of Advanced Manufacturing Technology, 2004, 23(1/2): 102-109. |

| 44 | Kundrák J, Karpuschewski B, Gyani K, et al. Accuracy of hard turning[J]. Journal of Materials Processing Technology, 2008, 202(1-3): 328-338. |

| 45 | 王健健, 张建富, 冯平法, 等. 楔式动力卡盘的径向夹持刚度特性研究[J]. 机械工程学报, 2016, 52(11): 129-139. |

| Wang Jian-jian, Zhang Jian-fu, Feng Ping-fa, et al. Research on radial clamping stiffness characteristics of wedge power chuck[J]. Chinese Journal of Mechanical Engineering, 2016, 52(11): 129-139. | |

| 46 | Doi Masahiro,Nakazawa Syunsuke,Yamaguchi Hirofumi. Study on determination of chatter vibration in turning (3rd report): examination of mixed excitation mechanism[J]. Proceedings of Japan Mechanics Society C, 1996, 62 (600): 3308-3312. |

| 47 | 冯平法, Uhlmann E. 爪式卡盘刚度特性研究[J]. 现代制造工程, 2008(1): 12-15. |

| Feng Ping-fa, Uhlmann E. Study on stiffness characteristics of jaw chuck[J]. Modern Manufacturing Engineering, 2008(1): 12-15. | |

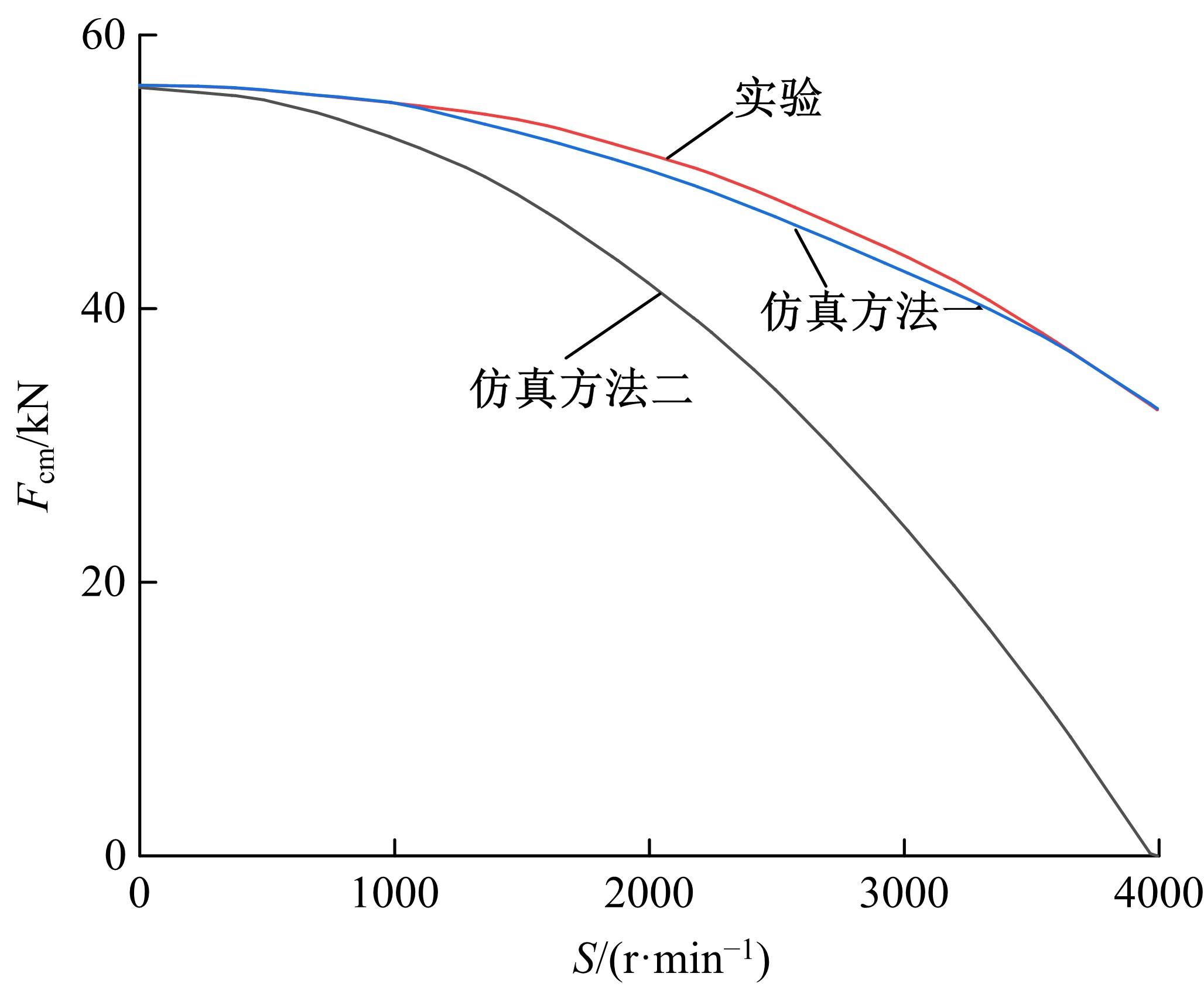

| 48 | Cheng Z, Huayong Y, Likui Y, et al. Piecewise model and experiment of power chuck's gripping force loss during high speed turning[J]. Science China Technological Sciences, 2011, 54(4): 972-982. |

| 49 | Yoshinori Konda, Shin'ichi Warisawa, Yoshitsugu Kadowaki. The axial and entrained air flow around the lathe chuck: observation of air flow using the tuft and smoke wire methods[J]. The Japan Society of Mechanical Engineers, 1998, 41(4): 963-968. |

| 50 | 宣俊杰, 郑晓强, 韩国强, 等. 关节轴承精加工夹具设计和夹紧力的计算[J]. 制造技术与机床, 2020(6): 61-64, 71. |

| Xuan Jun-jie, Zheng Xiao-qiang, Han Guo-qiang, et al. Fix machining fixture design and clamping force calculation for joint bearings[J]. Manufacturing Technology and Machine Tool, 2020(6): 61-64, 71. | |

| 51 | 高升, 王细洋, 张昆仑, 等. 基于PLC的飞机结构件变夹紧力柔性夹具研究[J].制造技术与机床, 2019(9): 147-151. |

| Gao Sheng, Wang Xi-yang, Zhang Kun-lun, et al. Research on flexible fixture with variable clamping force for aircraft structure based on PLC[J]. Manufacturing Technology and Machine Tool, 2019(9): 147-151. | |

| 52 | 周城, 杨华勇, 杨利奎. 数控车床动力卡盘输入推拉力的在线监测方法[J]. 农业机械学报, 2011, 42(6): 224-229, 223. |

| Zhou Cheng, Yang Hua-yong, Yang Li-kui. Online monitoring method of input push-pull force of power chuck of CNC lathe[J]. Transactions of the Chinese Society of Agricultural Machinery, 2011, 42(6): 224-229, 223. | |

| 53 | 杨森林. 高速动力卡盘的力学特性及安全性研究[D]. 沈阳: 沈阳理工大学机械学院, 2008. |

| Yang Sen-lin. Research on the mechanical characteristics and safety of high-speed power chucks[D]. Shenyang: School of Mechanical Engineering, Shenyang Ligong University, 2008. | |

| 54 | 安虎平, 张志梅, 王黎萍. 三爪卡盘机构及其夹紧力模型分析[J]. 制造技术与机床, 2020(6): 89-95. |

| An Hu-ping, Zhang Zhi-mei, Wang Li-ping. Three-jaw chuck mechanism and its clamping force model analysis[J]. Manufacturing Technology and Machine Tool, 2020(6): 89-95. | |

| 55 | Basavaraja J S, Mujawar S M S. Modelling, simulation and analysis of gripping force loss in high speed power chuck[J]. Procedia Materials Science, 2014, 5:1417-1423. |

| 56 | 贾志奇. 工程机械液压油缸压力信号分析及故障诊断系统设计[D]. 石家庄: 石家庄铁道大学机械工程学院, 2017. |

| Jia Zhi-qi. Pressure signal analysis and fault diagnosis system design for construction machinery hydraulic cylinders[D]. Shijiazhuang: School of Mechanical Engineering,Shijiazhuang Railway University,2017. | |

| 57 | 周宇, 李粤, 李维平, 等. 激光位移传感器设计与标定测试[J]. 传感器与微系统, 2020, 39(11): 92-95. |

| Zhou Yu, Li Yue, Li Wei-ping, et al. Laser displacement sensor design and calibration test[J]. Sensors and Microsystems, 2020, 39(11): 92-95. | |

| 58 | 林野. 数控转台回转轴夹紧力不足改造方案及夹紧力的检测方法[J]. 数字化用户, 2013, 19(10): 39. |

| Lin Ye. Renovation plan for insufficient clamping force of rotary axis of CNC turntable and detection method of clamping force[J]. Digital Users, 2013, 19(10): 39. | |

| 59 | Jhang K Y, Quan H H, Ha J, et al. Estimation of clamping force in high-tension bolts through ultrasonic velocity measurement[J]. Ultrasonics, 2006, 44(8): e1339-e1342. |

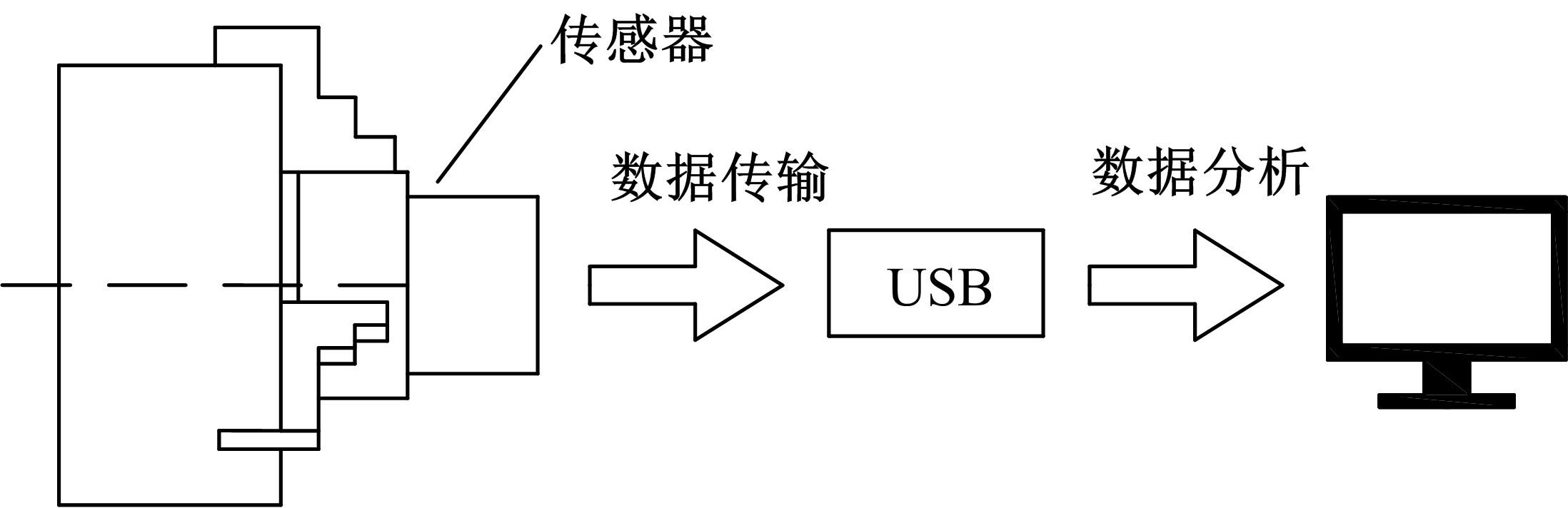

| 60 | 王岩松, 张国斌, 闫培龙, 等. 高速旋转卡盘夹紧力测试仪的研制[J]. 内蒙古科技与经济, 2014(20): 100-101. |

| Wang Yan-song, Zhang Guo-bin, Yan Pei-long, et al. Development of a high-speed rotating chuck clamping force tester[J]. Inner Mongolia Science and Technology and Economy, 2014(20): 100-101. | |

| 61 | 李晔维. 工装夹具设计中材料及热处理问题的处理[J].机械工程师, 2013(4): 203-204. |

| Li Ye-wei. Handling of material and heat treatment issues in tooling fixture design[J]. Mechanical Engineer, 2013(4): 203-204. | |

| 62 | 黄甦, 宾远红, 骆亍, 等. 提高双相不锈钢夹具强度和韧性的热处理工艺研究[J]. 机电工程技术, 2017, 46(8): 34-37. |

| Huang Su, Yuan-hong Bin, Luo Tu, et al. Research on heat treatment process for improving the strength and toughness of duplex stainless steel fixtures[J]. Mechanical & Electrical Engineering Technology, 2017, 46(8): 34-37. | |

| 63 | 孙杰, 王积森, 陈艳秋, 等. 用聚合矿物复合材料制造的机床夹具[J]. 制造技术与机床, 1999(5): 43-45. |

| Sun Jie, Wang Ji-sen, Chen Yan-qiu, et al. Machine tool fixtures made of polymer mineral composite materials[J]. Manufacturing Technology and Machine Tool, 1999(5): 43-45. | |

| 64 | Gandhi M V, Thompson B S. Phase-change fixturing for FMS[J]. Manufacturing Engineering, 1984, 93(6): 79-80. |

| 65 | 宋灿. 基于相变材料的柔性夹具技术研究[D]. 无锡: 江南大学机械工程学院, 2015. |

| Song Can. Research on flexible fixture technology based on phase change materials[D]. Wuxi: School of Mechanical Engineering,Jiangnan University, 2015. | |

| 66 | 袁立祥, 龙斌, 杨志伟, 等. 基于智能网络信息系统的车轮加工自动化生产线设计与应用[J].机械设计, 2019, 36(S1): 295-297. |

| Yuan Li-xiang, Long Bin, Yang Zhi-wei, et al. Design and application of wheel processing automation production line based on intelligent network information system[J]. Mechanical Design, 2019, 36(S1):295-297. | |

| 67 | 赵元, 张丽丽. 柔性夹具技术研究[J].机械制造, 2020, 58(2): 77-79. |

| Zhao Yuan, Zhang Li-li. Research on flexible fixture technology[J]. Machinery Manufacturing, 2020,58(2):77-79. | |

| 68 | 张明波, 王玮, 庄涛. 柔性夹具在数控机床中的发展以及应用[J]. 科技创新与应用, 2017(36): 135-136. |

| Zhang Ming-bo, Wang Wei, Zhuang Tao. Development and application of flexible fixtures in CNC machine tools[J]. Science and Technology Innovation and Application, 2017(36): 135-136. |

| [1] | 陈魏,雷雨龙,李兴忠,付尧,扈建龙,侯利国. 低速工况下渐开线圆柱直齿轮齿面粘着磨损计算[J]. 吉林大学学报(工学版), 2021, 51(5): 1628-1634. |

| [2] | 郭震,于红英,滑忠鑫,赵娣. 刚性折纸机构运动分析及折叠过程仿真[J]. 吉林大学学报(工学版), 2020, 50(1): 66-76. |

| [3] | 朱伟,王传伟,顾开荣,沈惠平,许可,汪源. 一种新型张拉整体并联机构刚度及动力学分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1777-1786. |

| [4] | 毛宇泽, 王黎钦. 鼠笼支撑一体化结构对薄壁球轴承承载性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1508-1514. |

| [5] | 贾树强, 尚涛, 王昕, 宫文斌, 李琪, 金松哲. 新型摆动式球磨机运动机理及性能[J]. 吉林大学学报(工学版), 2012, 42(增刊1): 71-76. |

| [6] | 王方伟, 张运凯, 马建峰. 非结构化对等网中被动蠕虫传播的性能[J]. 吉林大学学报(工学版), 2009, 39(04): 1069-1074. |

| [7] | 魏延辉,朱延和,赵杰,蔡鹤皋 . 基于柔性化工作的可重构机器人系统设计[J]. 吉林大学学报(工学版), 2008, 38(02): 449-0453. |

| [8] | 谢宁,赵晓晖,莫秀玲,孙玉晶 . Pre-Rake合并超宽带无线接收机的性能[J]. 吉林大学学报(工学版), 2007, 37(05): 1192-1196. |

| [9] | 王健,葛安林,雷雨龙,田华 . 液力变矩器叶片三维成型法及其性能分析[J]. 吉林大学学报(工学版), 2007, 37(01): 43-47. |

|

||