吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (1): 55-65.doi: 10.13229/j.cnki.jdxbgxb.20220253

气门控制策略对无节气门发动机性能的影响

周遊1,2( ),洪伟1,2,解方喜1,2(

),洪伟1,2,解方喜1,2( ),刘宇1,2,宫洵3,李小平1,2

),刘宇1,2,宫洵3,李小平1,2

- 1.吉林大学 汽车仿真与控制国家重点实验室,长春 130022

2.吉林大学 汽车工程学院,长春 130022

3.吉林大学 人工智能学院,长春 130012

Influence of valve control strategy to improve un⁃throttle engine performance

You ZHOU1,2( ),Wei HONG1,2,Fang-xi XIE1,2(

),Wei HONG1,2,Fang-xi XIE1,2( ),Yu LIU1,2,Xun GONG3,Xiao-ping LI1,2

),Yu LIU1,2,Xun GONG3,Xiao-ping LI1,2

- 1.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

2.College of Automotive Engineering,Jilin University,Changchun 130022,China

3.College of Artificial Intelligence,Jilin University,Changchun 130012,China

摘要:

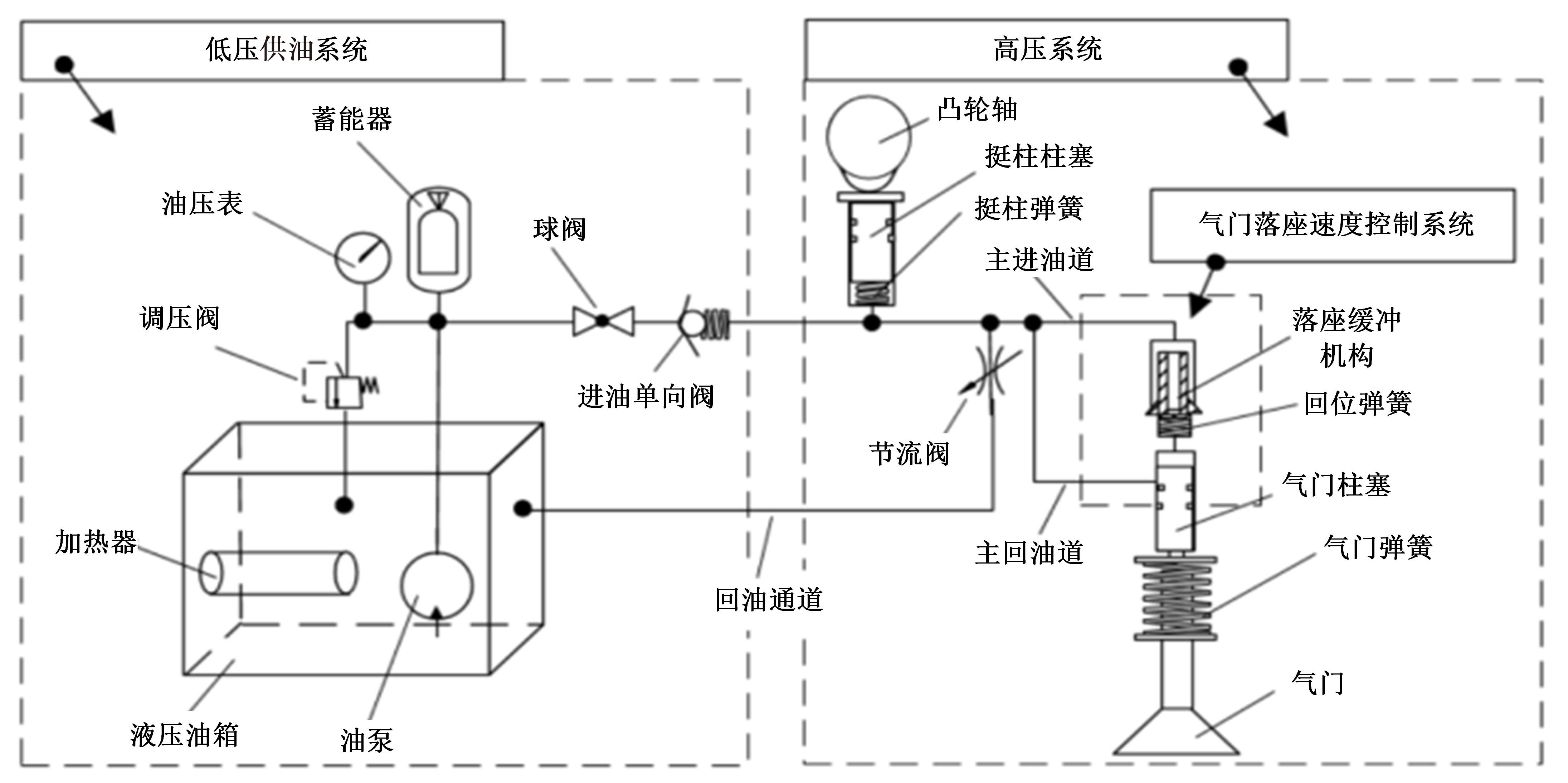

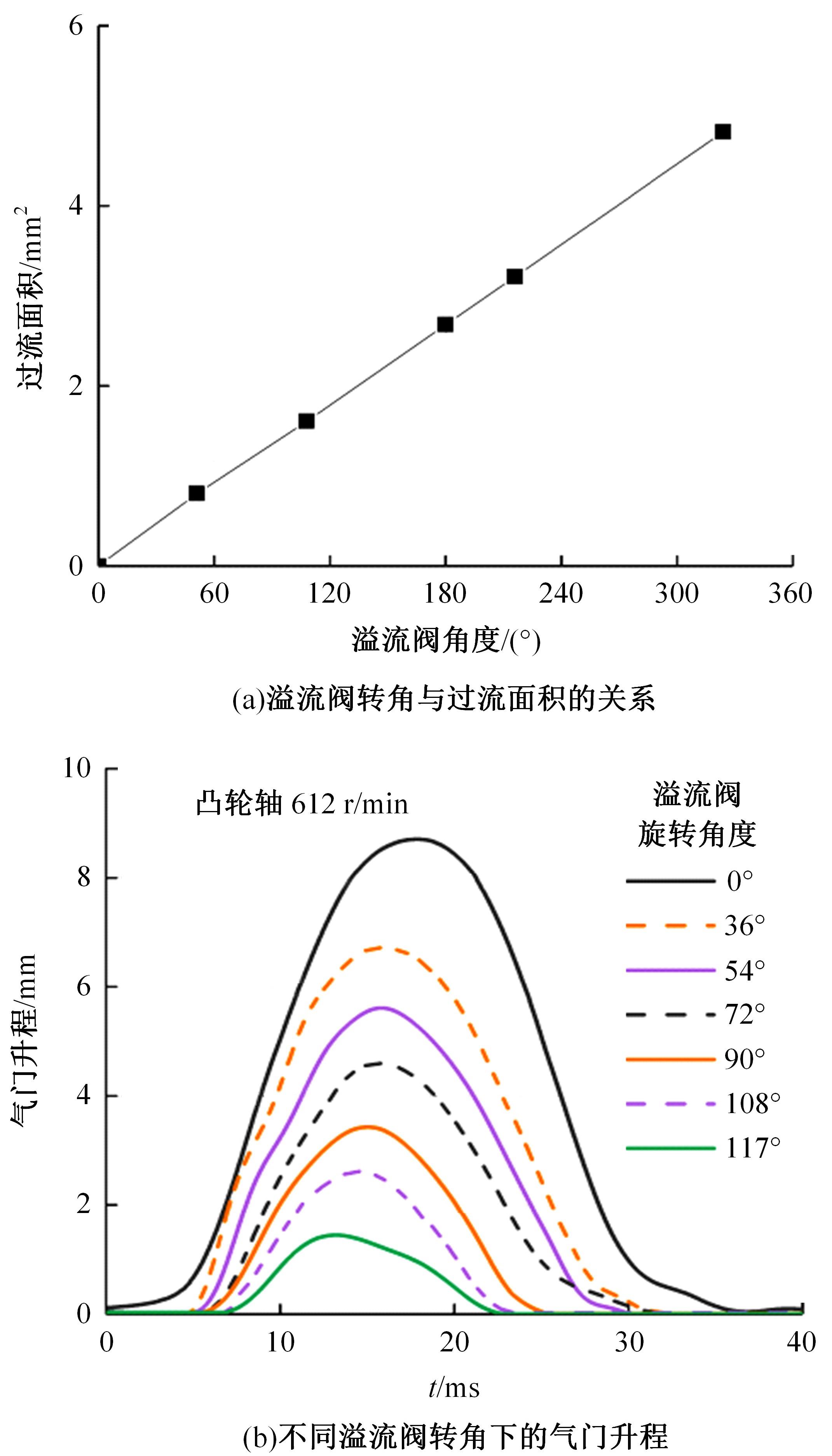

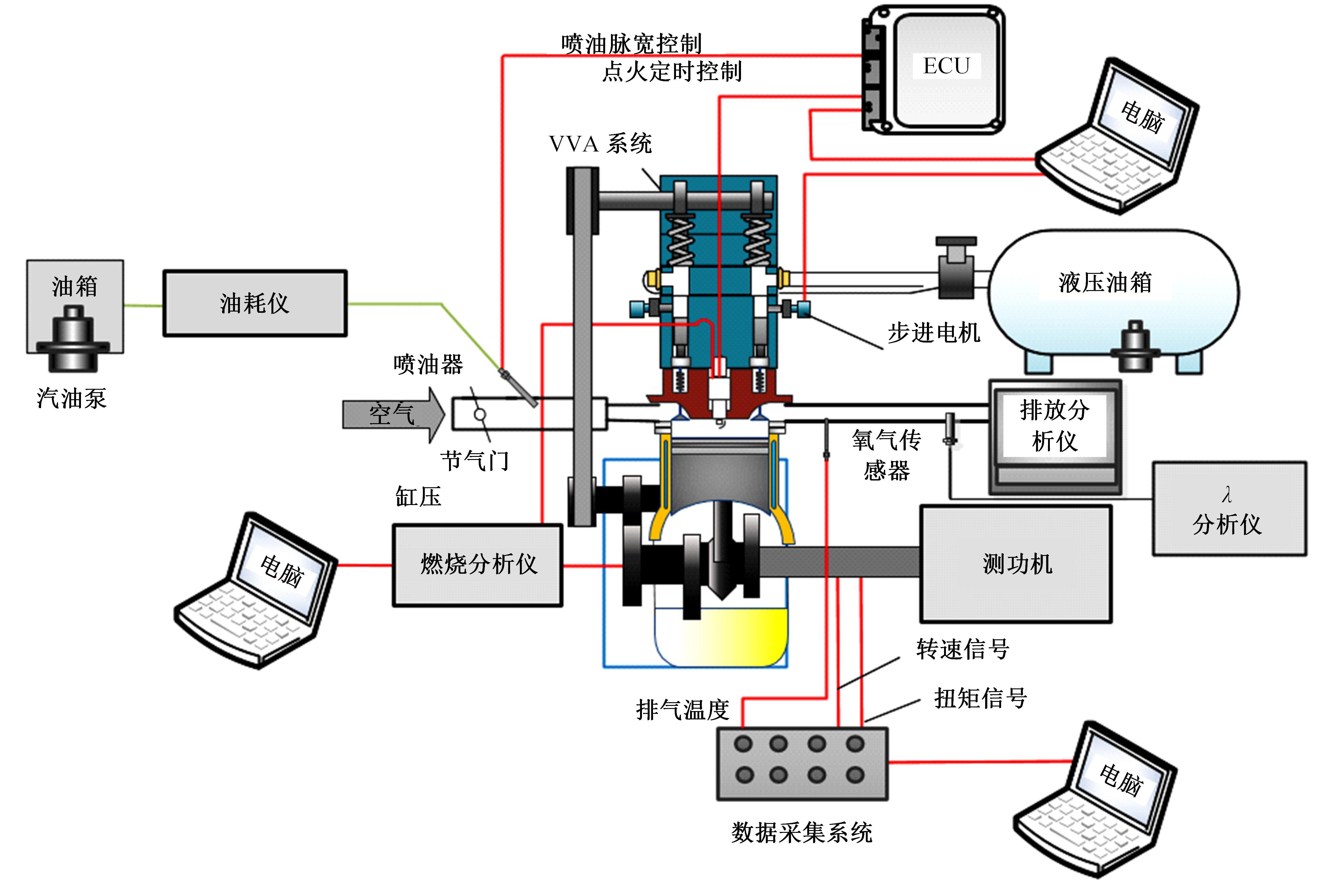

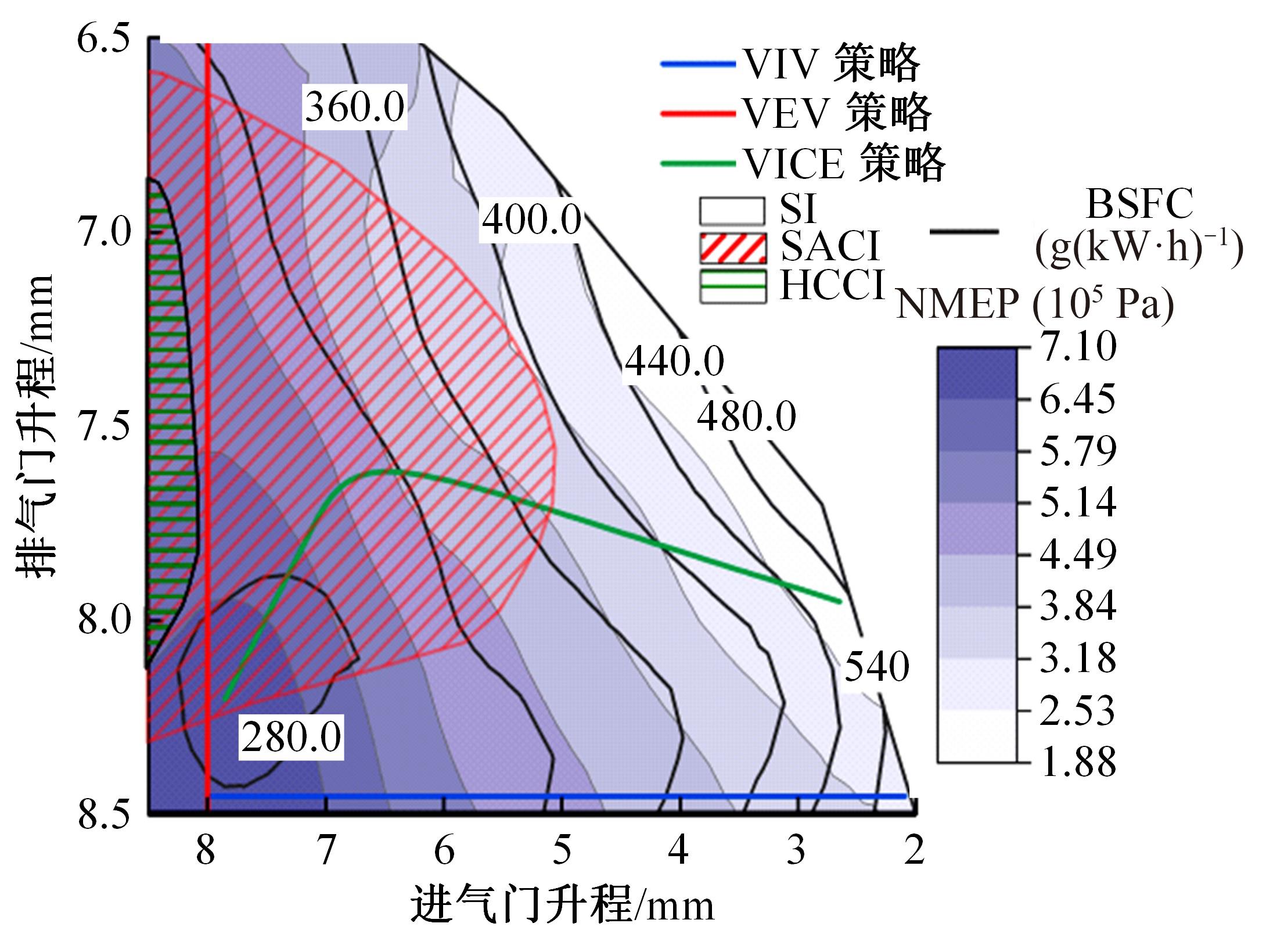

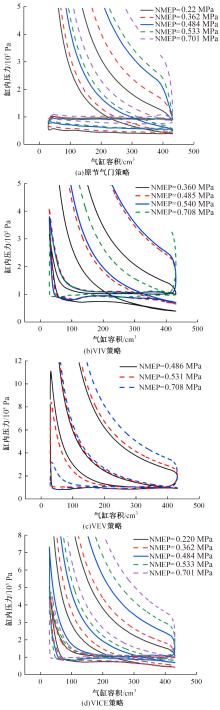

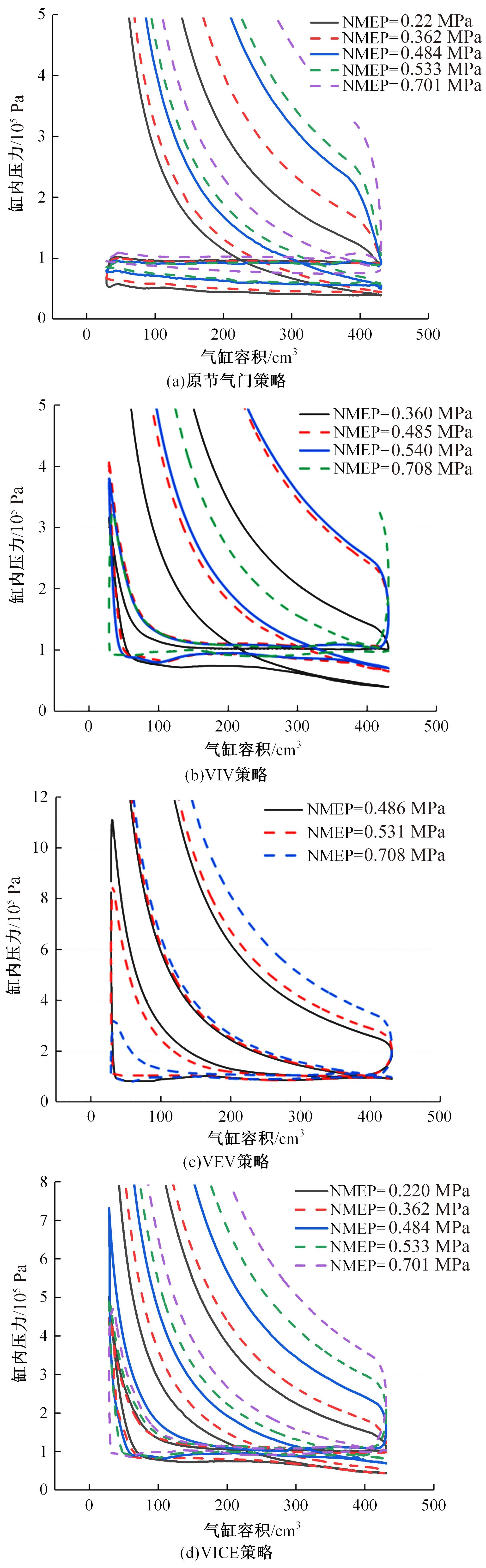

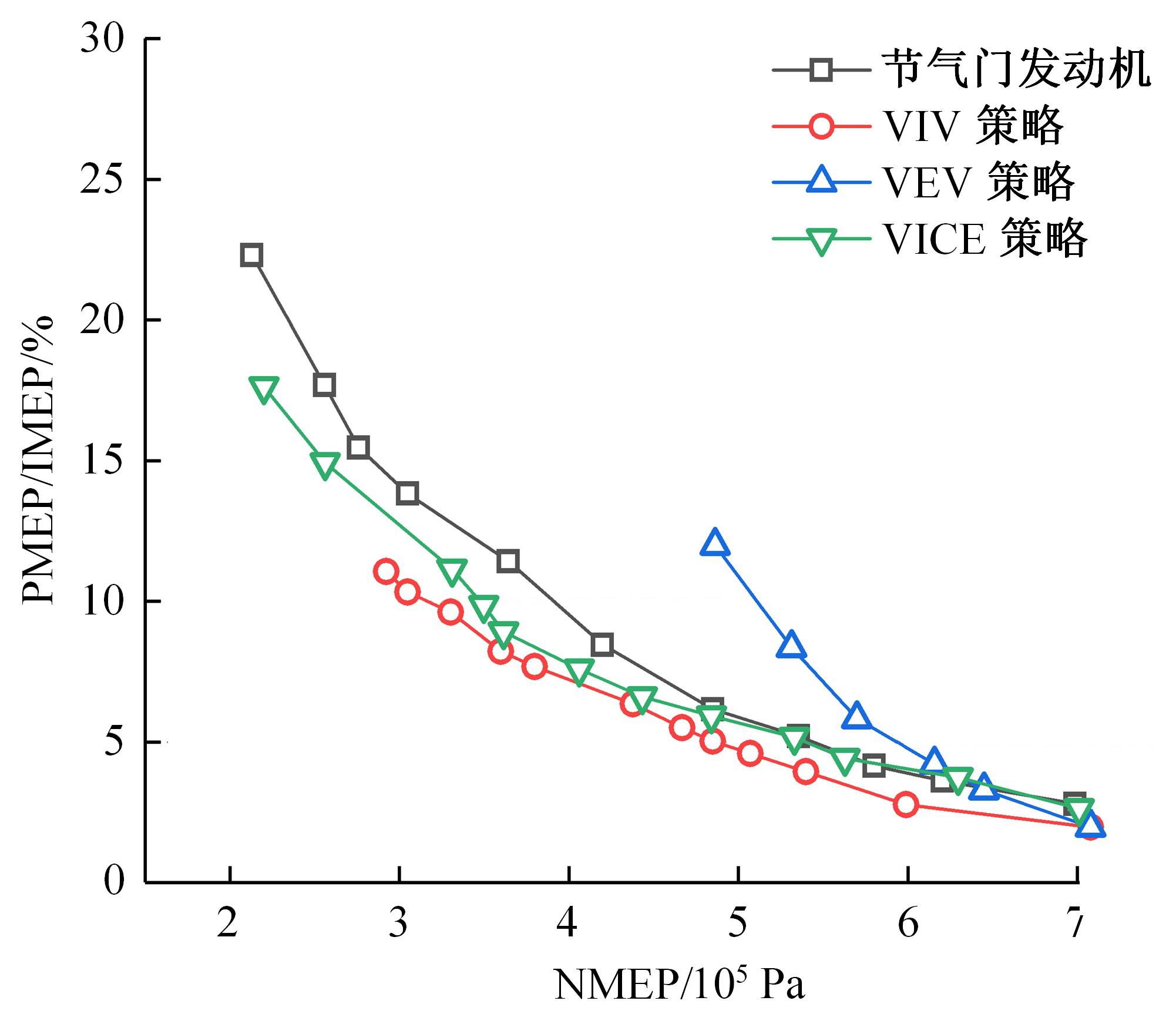

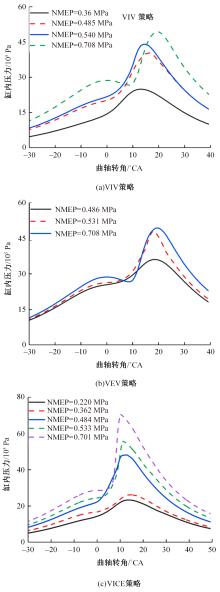

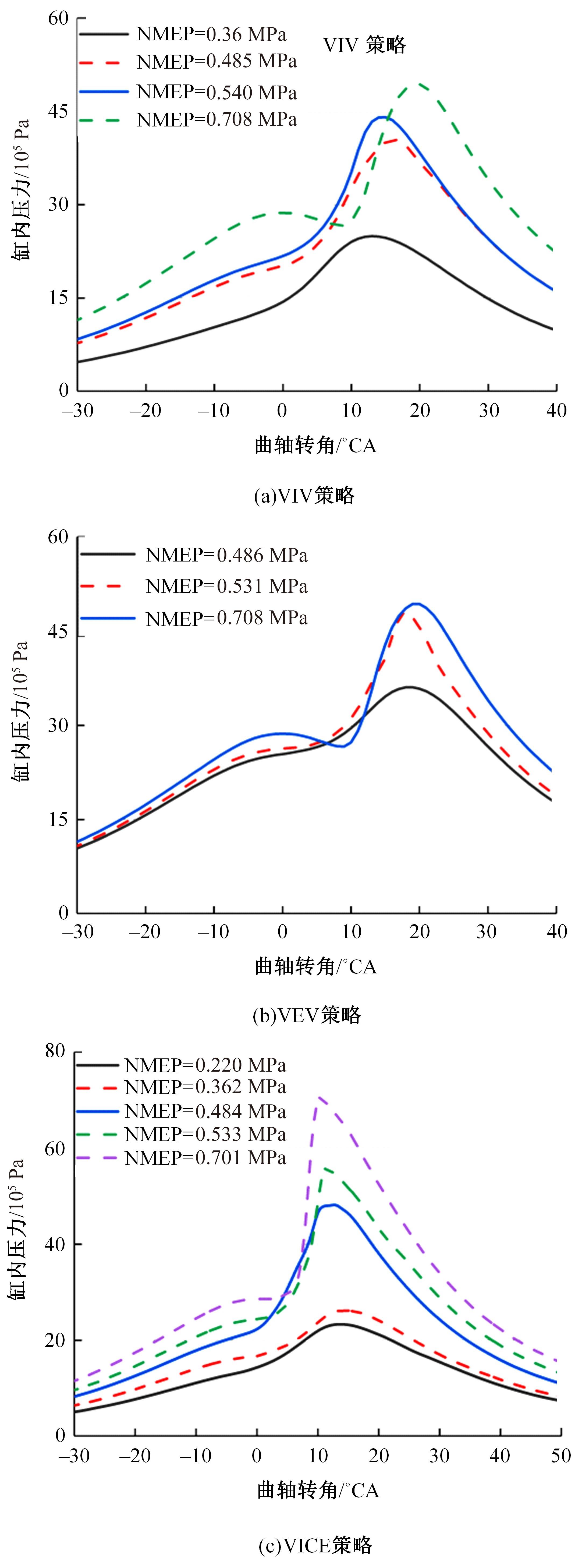

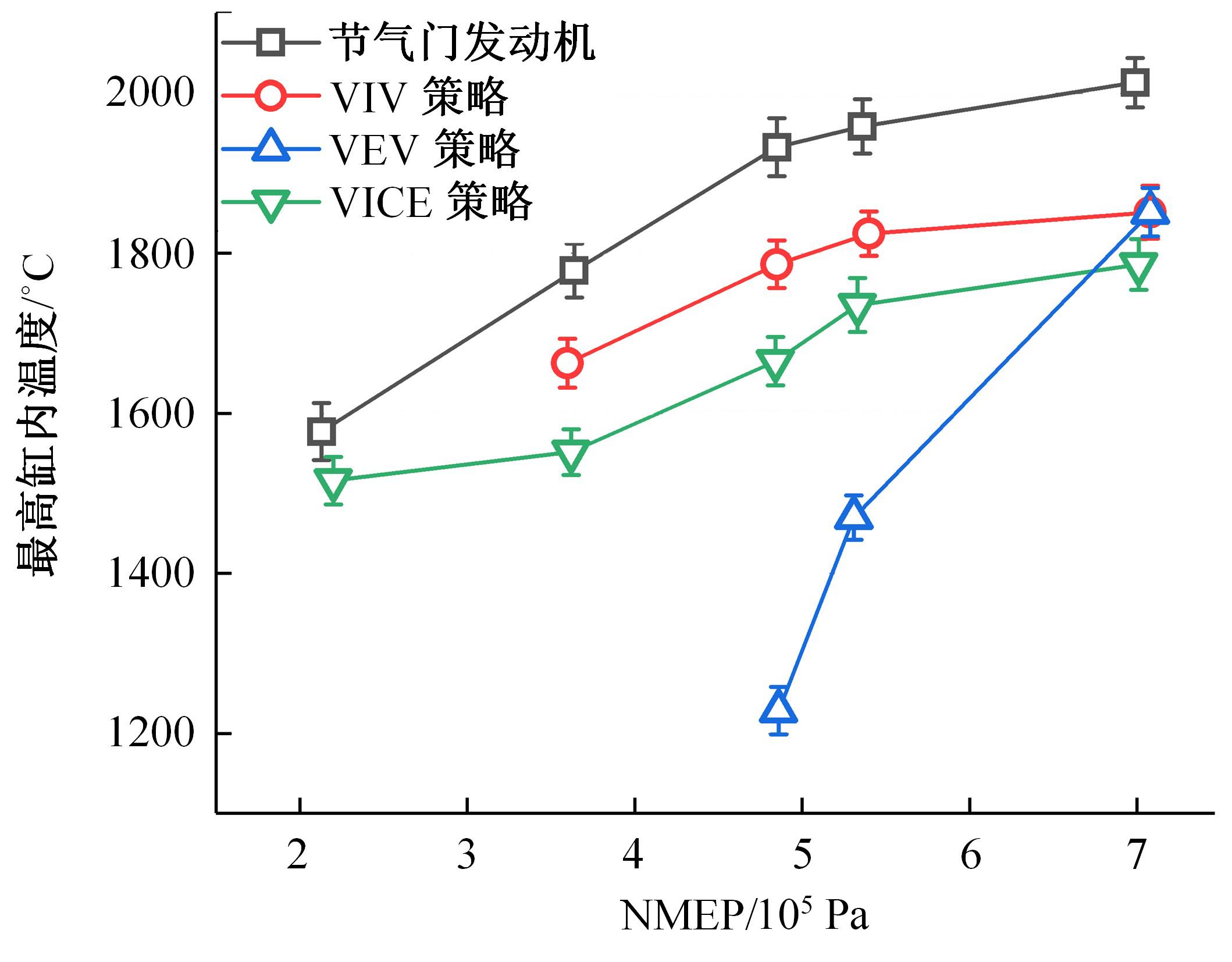

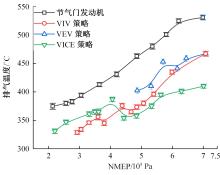

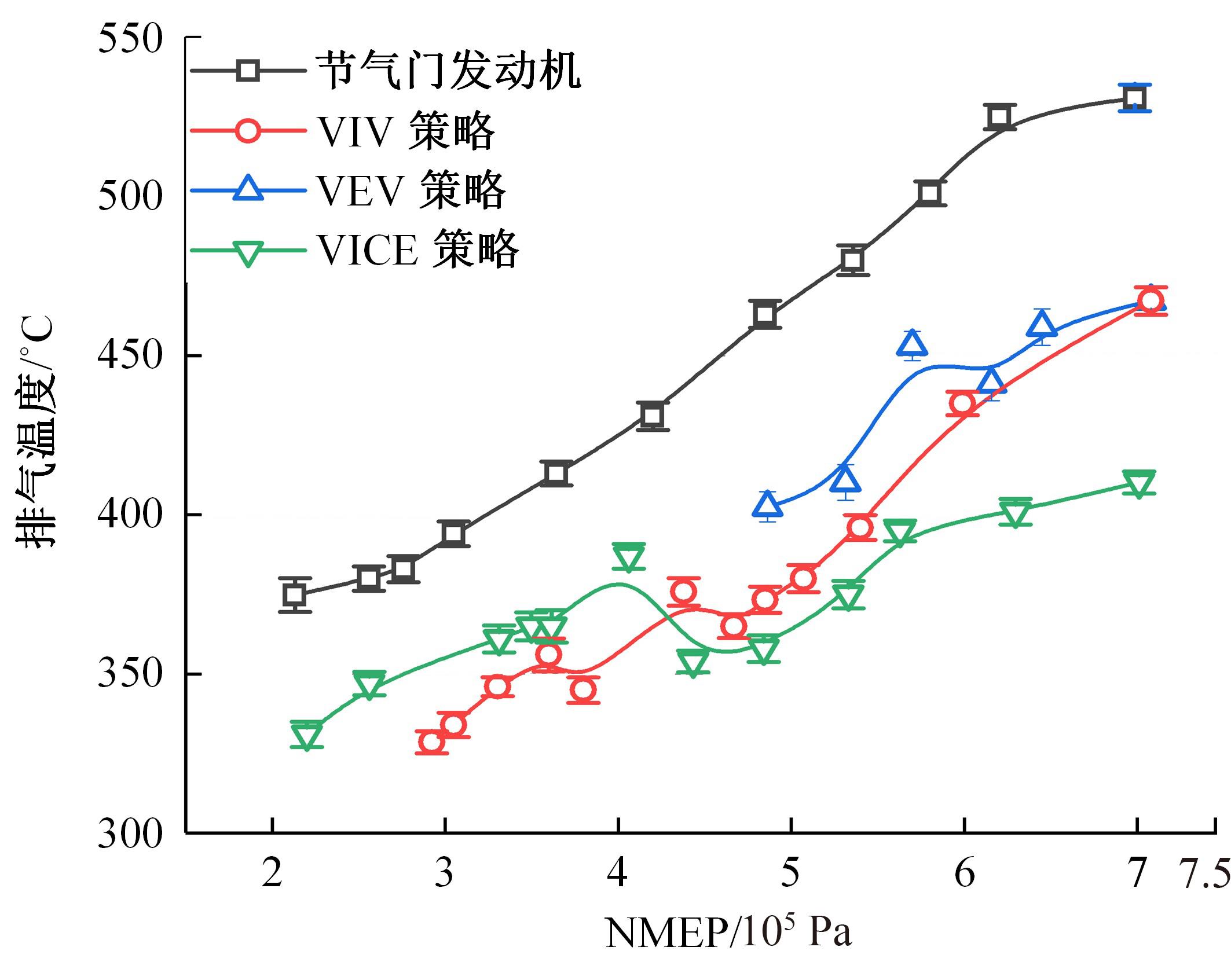

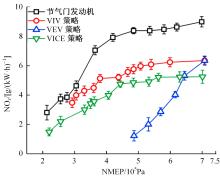

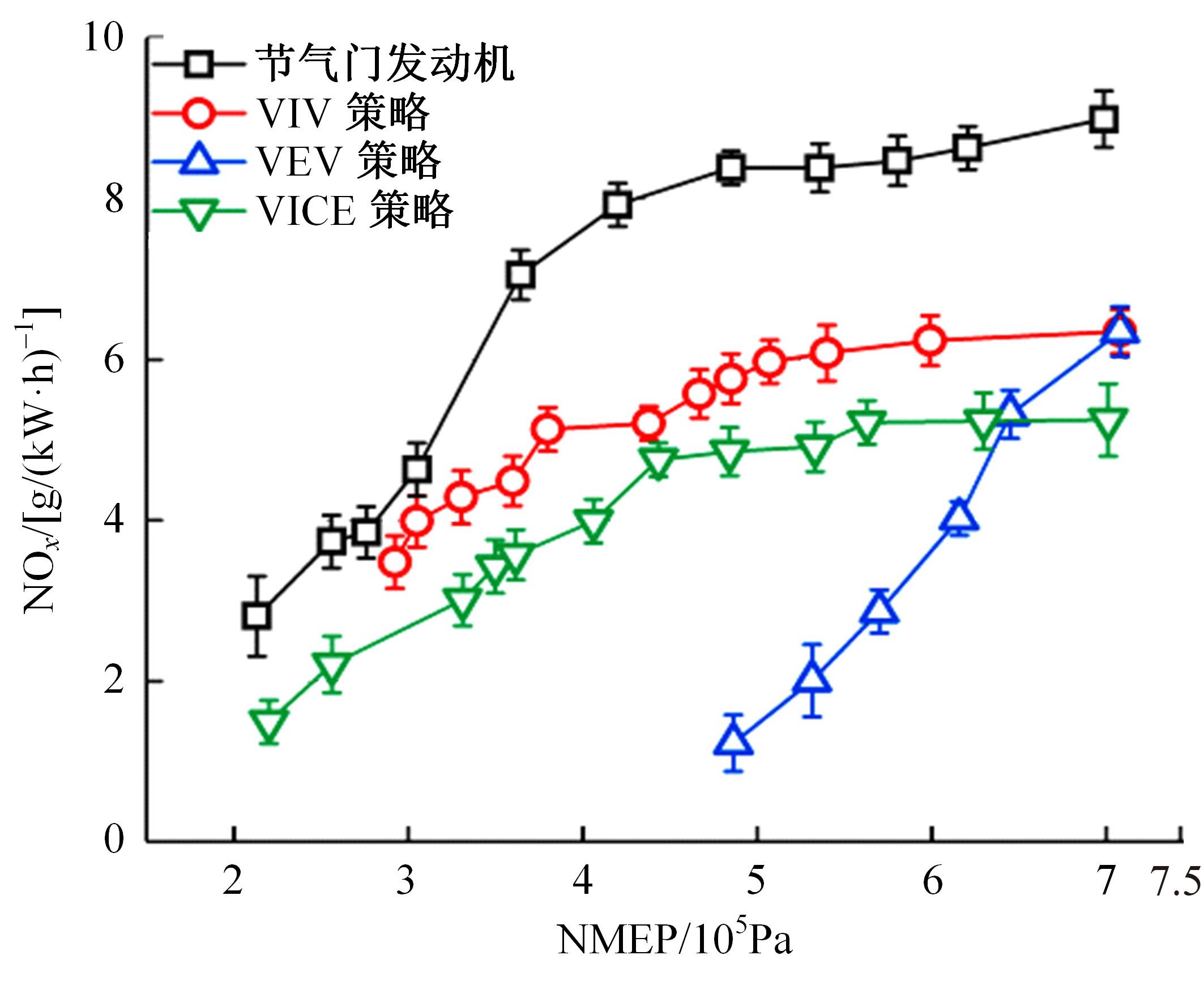

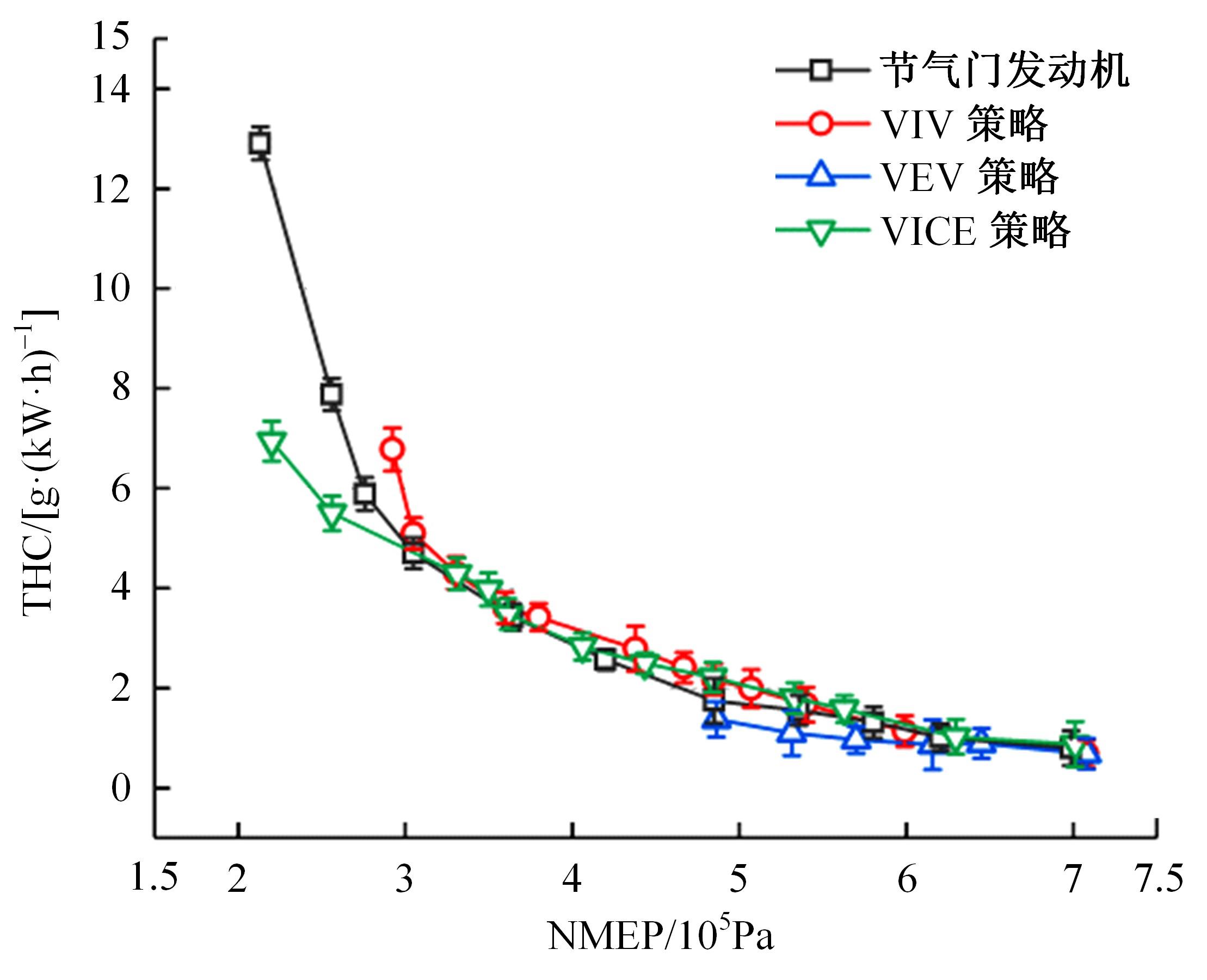

为了实现发动机高效清洁燃烧,利用自行开发的可变气门升程机构,在无节气门条件下研究了进气门调整策略(VIV)、排气门调整策略(VEV)和进排气门耦合调整策略(VICE)对发动机性能的影响。结果表明,与原发动机相比,3种气门控制策略都可以降低有效燃油消耗率(BSFC)并提高热效率(ITE);其中,VICE策略的效果最为突出,与原发动机相比BSFC和ITE最多可优化28%和6%;VIV策略和VICE策略都可以减小发动机泵气损失,尤其是VIV策略,与原发动机相比最多可以将泵气损失减少36%;3种策略都可以降低NO x 排放,其中VEV策略表现最优异;当NMEP超过0.3 MPa后,不同气门策略对THC排放的影响较小。

中图分类号:

- TK411

| 1 | Balmelli M, Zsiga N, Merotto L, et al. Effect of the intake valve lift and closing angle on part load efficiency of a spark ignition engine[J]. Energies, 2020, 13(7): No.1682. |

| 2 | Xu Zheng-xin, Fu Jian-qin, Liu Jin-ping, et al. Comparison of in-cylinder combustion and heat-work conversion processes of vehicle engine under transient and steady-state conditions[J]. Energy Convers Manage, 2017, 132(16): 400-409. |

| 3 | Millo F, Mirzaeian M, Luisi S, et al. Engine displacement modularity for enhancing automotive S.I. engines efficiency at part load[J]. Fuel, 2016, 180: 645-652. |

| 4 | Duan Xiong-bo, Fu Jian-qin, Zhang Zhi-zhong, et al. Experimental study on the energy flow of a gasoline-powered vehicle under the NEDC of cold starting[J]. Appl Therm Eng, 2017, 115: 1173-1186. |

| 5 | Xu Zheng-xin, Liu Jing-ping, Fu Jian-qin, et al. Analysis and comparison of typical exhaust gas energy recovery bottoming cycles[C]∥SAE Paper, 2013-01-1648. |

| 6 | Wei Sheng-li, Zhao Xi-qian, Liu Xin, et al. Research on effects of early intake valve closure EIVC miller cycle on combustion and emissions of marine diesel engines at medium and low loads[J]. Energy, 2019, 173: 48-58. |

| 7 | Osorio Julian D, Alejandro Rivera-Alvarez, et al. Efficiency enhancement of spark-ignition engines using a continuous variable valve timing system for load control[J]. Energy, 2018, 161:649-662. |

| 8 | Deng Bang-lin, Yang Jing, Zhang Da-ming, et al. The challenges and strategies of butanol application in conventional engines: the sensitivity study of ignition and valve timing[J]. Appl Energy, 2013,108:248-260. |

| 9 | Zou Peng, Liu Jing-ping, Chen Zheng, et al. Effect of a novel mechanical CVVL system on economic performance of a turbocharged spark-ignition engine fuelled with gasoline and ethanol blend[J]. Fuel, 2020,263: No.116697. |

| 10 | Li Qing-yu, Liu Jing-ping, Fu Jian-qin, et al. Comparative study on the pumping losses between continuous variable valve lift (CVVL) engine and variable valve timing (VVT) engine[J]. Applied Thermal Engineering, 2018, 137: 710-720. |

| 11 | Edara R B. Reciprocating engine piston secondray motion-Literature review[C]∥SAE Paper, 2008-01-1045. |

| 12 | 雷基林,申立中,程丁丁,等. 考虑热变形的活塞组件结构对活塞二阶运动的影响分析[J]. 内燃机工程,2012,33(2):86-92. |

| Lei Ji-lin, Shen Li-zhong, Cheng Ding-ding, et al. Effect of piston set structure on piston secondary motion considering thermal deformation[J]. Chinese Internal Combustion Engine Engineering, 2012, 33(2):86-92. | |

| 13 | 张健,胡铁刚,詹樟松,等. 基于排气VVT的直喷汽油发动机性能试验研究[J]. 内燃机工程, 2017, 38(2):79-90. |

| Zhang Jian, Hu Tie-gang, Zhan Zhang-song, et al. Experimental investigation of performance of GDI engine with exhaust variable valve timing system[J]. Chinese Internal Combustion Engine Engineering, 2017, 38(2):79-90. | |

| 14 | 钟兵,洪伟,杨国志,等. 液压可变气门机构压力波动及动作循环变动[J]. 吉林大学学报:工学版,2020,50(3):796-803. |

| Zhong Bing, Hong Wei, Yang Guo-zhi, et al. Pressure fluctuation and cyclic variation of movement of hydraulic variable valve mechanism[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(3):796-803. | |

| 15 | 钟兵,洪伟,金兆辉,等. 进气门早关液压可变气门机构运动特性研究 [J].吉林大学学报:工学版, 2018, 48(3):727-734. |

| Zhong Bing, Hong Wei, Jin Zhao-hui, et al. Movement characteristics of hydraulic variable valve train with early intake valve closing[J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(3):727-734. | |

| 16 | Heywood J B. Internal Combustion Engine Fundamentals[M]. New York: McGraw-Hill,1988. |

| 17 | 杨立平,马修真,李君,等. 废气再循环与过流空气系数联合的NO x 控制策略在天然气发动机上的应用[J]. 吉林大学学报:工学版,2010,40(4):942-946. |

| Yang Li-ping, Ma Xiu-zhen, Li Jun, et al. Application of EGR and excess air ratio combined No x emission control strategy on natural gas engine[J]. Journal of Jilin University(Engineering and Technology Edition), 2010, 40(4):942-946. |

| [1] | 秦静,郑德,裴毅强,吕永,苏庆鹏,王膺博. 基于PSO-GPR的发动机性能与排放预测方法[J]. 吉林大学学报(工学版), 2022, 52(7): 1489-1498. |

| [2] | 祖象欢,杨传雷,王贺春,王银燕. 船用柴油机废气再循环性能评估及应用[J]. 吉林大学学报(工学版), 2019, 49(3): 805-815. |

| [3] | 杨帅, 冯志炜, 赵治国, 周毅. 不同米勒循环方式对柴油机工作过程影响的一维模拟分析[J]. 吉林大学学报(工学版), 2018, 48(5): 1444-1454. |

| [4] | 唐志刚, 张力, 尚会超, 吕晓惠, 陈曦, 郑仁蔚. 电热塞点火微型内燃机燃烧特性及残余废气对其的影响[J]. 吉林大学学报(工学版), 2017, 47(3): 811-818. |

| [5] | 梁金广,于秀敏,高跃,王云开,许楠,于洪洋 . 起动电压对电控柴油机起动性能的影响 [J]. 吉林大学学报(工学版), 2009, 39(02): 315-0320. |

| [6] | 梁金广,于秀敏,高跃,于洪洋,李雅群,于晓璐 . 起动结束标志转速、供油量和环境温度 对电控柴油机起动性能的影响[J]. 吉林大学学报(工学版), 2007, 37(05): 1023-1027. |

| [7] | 聂建军,杜发荣,高峰 . 存在热漏的内燃机与斯特林联合循环的有限时间的热力学研究[J]. 吉林大学学报(工学版), 2007, 37(03): 518-0523. |

| [8] | 程鹏,刘忠长,郭英男,刘金山,谭满志,宫宝利,刘巽俊 . 测量多缸内燃机单缸充气量的流速-压力波方法[J]. 吉林大学学报(工学版), 2007, 37(01): 69-73. |

| [9] | 刘金山,郭英男,谭满志,黄为钧,杨立平,高原. 乙醇燃料内燃机均质压燃的工作区域[J]. 吉林大学学报(工学版), 2006, 36(03): 327-0330. |

| [10] | 孙剑涛, 刘忠长, 许允, 朱昌吉, 刘巽俊. YC4112ZLQ增压中冷柴油机排气再循环冷却器的设计计算[J]. 吉林大学学报(工学版), 2004, (4): 564-568. |

| [11] | 袁兆成, 丁万龙, 方华, 高峥. 排气消声器的边界元仿真设计方法[J]. 吉林大学学报(工学版), 2004, (3): 357-361. |

| [12] | 谭满志, 郭英男, 刘金山, 洪伟, 高海润, 吕庆胜. 增压中冷压燃式发动机燃用柴油醇的十三工况排放特性[J]. 吉林大学学报(工学版), 2004, (3): 352-356. |

| [13] | 杨晓萍, 洪伟, 赵梅. 天然气发动机自适应控制软件抗干扰设计[J]. 吉林大学学报(工学版), 2004, (3): 348-351. |

| [14] | 于秀敏, 李学民, 张建锐, 高跃. 柴油机分配泵电控系统的标定[J]. 吉林大学学报(工学版), 2004, (3): 342-347. |

| [15] | 刘忠长, 朱昌吉, 张振东. 车用柴油机排气再循环控制系统[J]. 吉林大学学报(工学版), 2004, (3): 337-341. |

|

||