吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (6): 1563-1569.doi: 10.13229/j.cnki.jdxbgxb.20220958

• 材料科学与工程 • 上一篇

2024-O铝合金搅拌摩擦焊接头疲劳裂纹扩展行为及寿命预测

- 1.苏州科技大学 机械工程学院,江苏 苏州 215009

2.沈阳航空航天大学 机电工程学院,沈阳 110136

3.沈阳航空航天大学 航空制造工艺数字化国防重点学科实验室,沈阳 110136

Fatigue crack propagation behavior and life prediction of 2024-O aluminum alloy FSW joints

Lei WANG1,2( ),Dong-xia LI2,Song ZHOU2,3,Li HUI3,Zhen-xin SHEN2

),Dong-xia LI2,Song ZHOU2,3,Li HUI3,Zhen-xin SHEN2

- 1.College of Mechanical Engineering,Suzhou University of Science and Technology,Suzhou 215009,China

2.School of Mechatronics Engineering,Shenyang Aerospace University,Shenyang 110136,China

3.Key Laboratory of Fundamental Science for National Defense of Aeronautical Digital Manufacturing Process,Shenyang Aerospace University,Shenyang 110136,China

摘要:

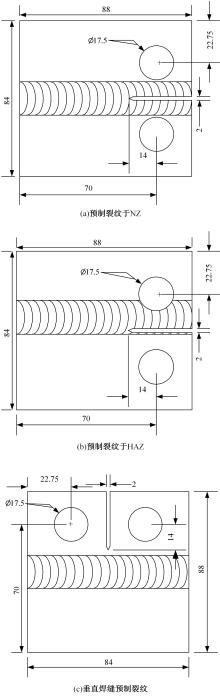

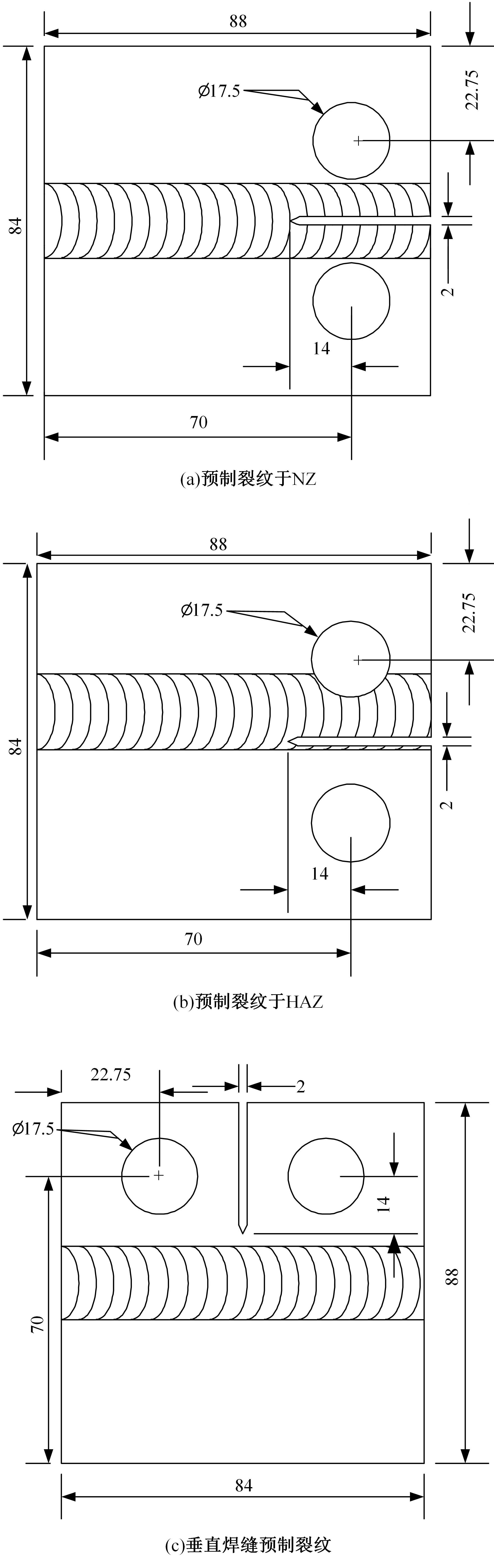

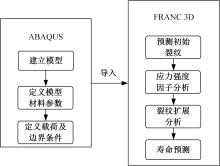

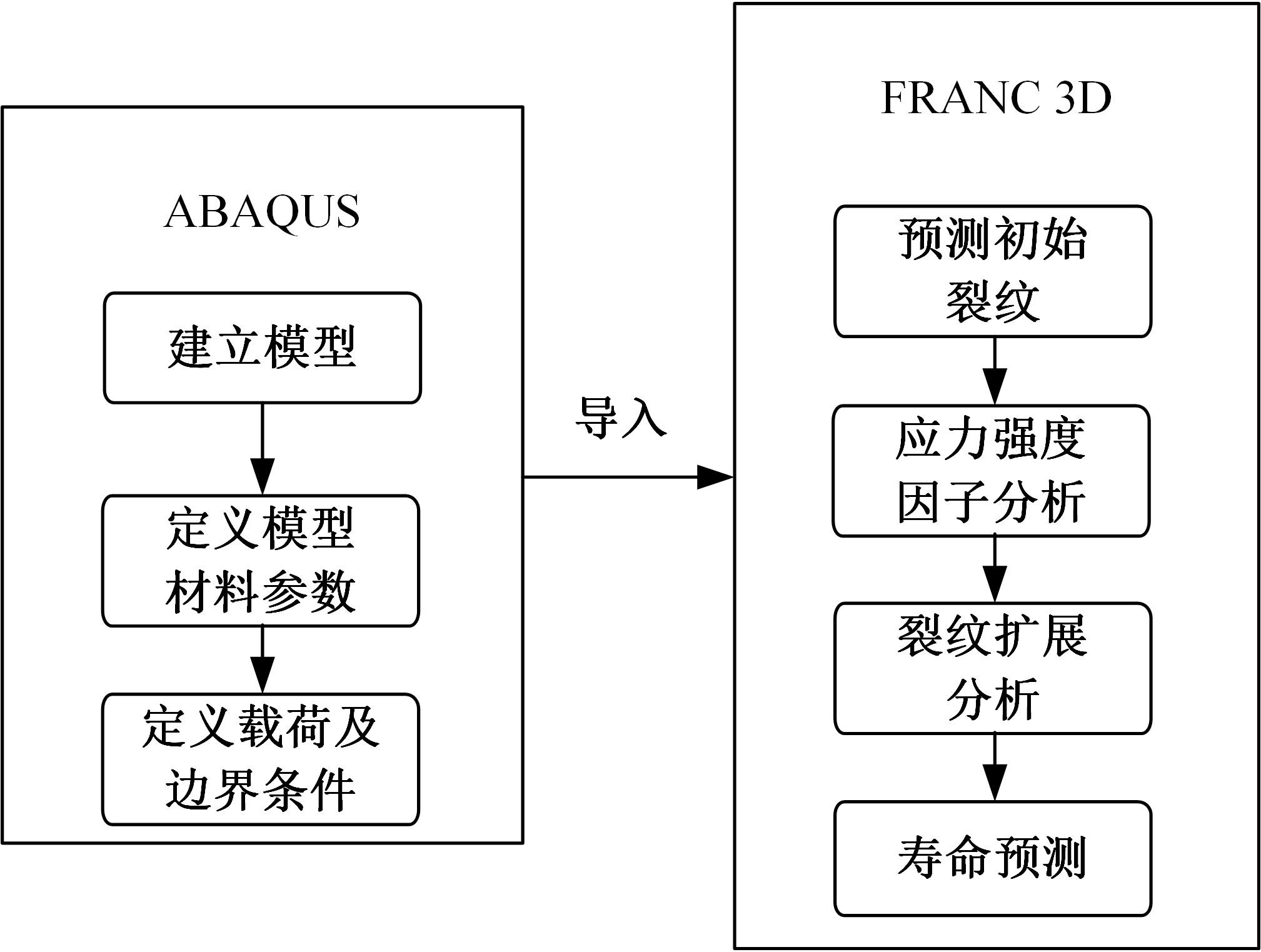

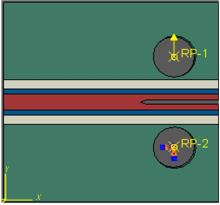

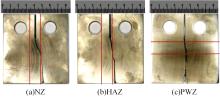

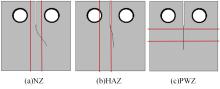

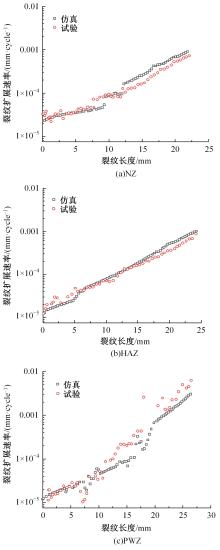

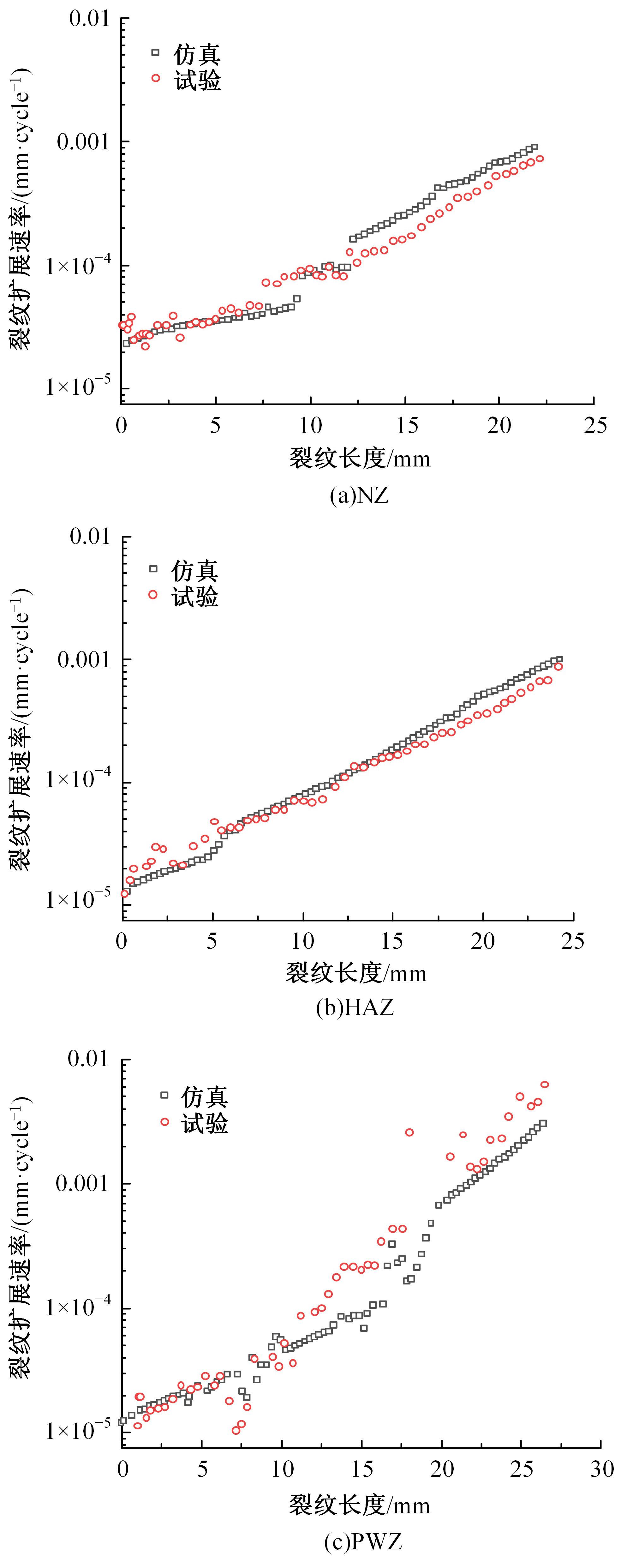

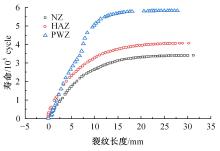

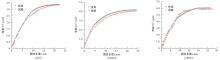

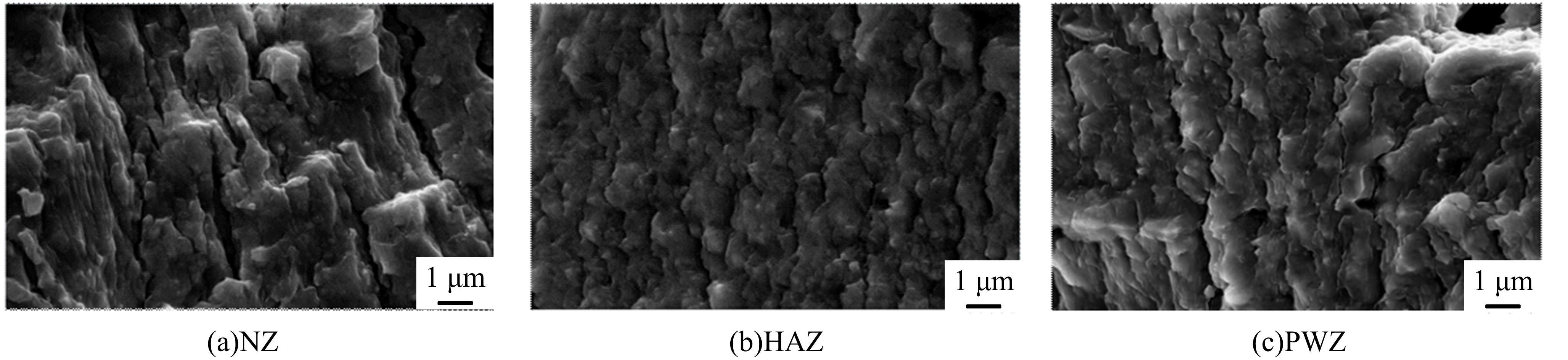

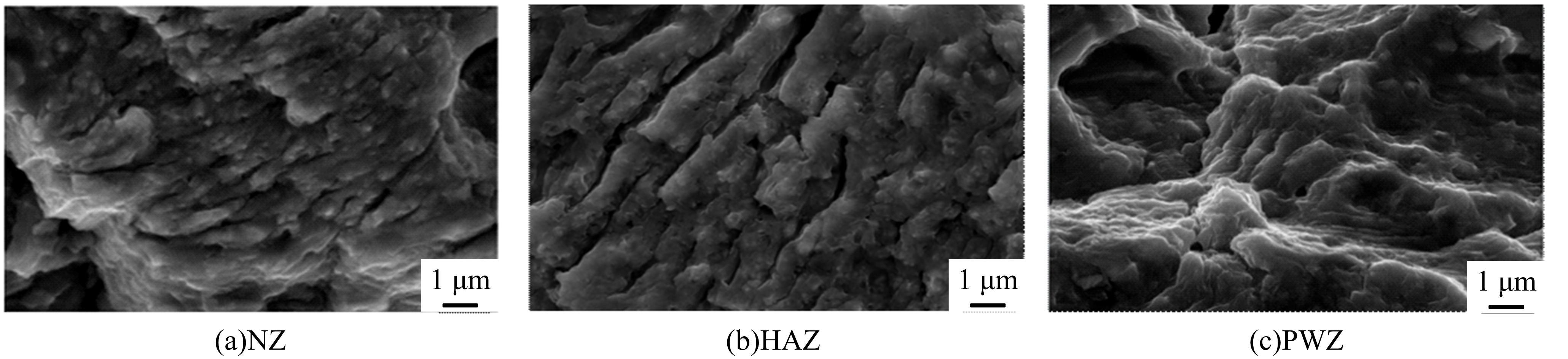

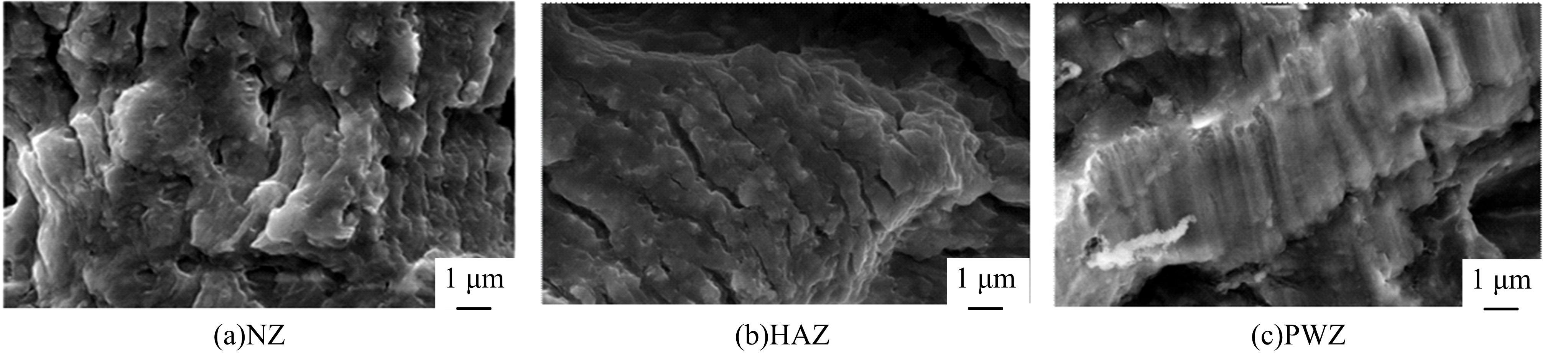

通过试验和基于FRANC 3D与ABAQUS联合仿真的方法对2024-O高配铝合金搅拌摩擦焊预制裂纹于焊核区、热影响区和垂直于焊缝方向的裂纹扩展行为进行了分析及寿命预测。结果表明,预制裂纹于3个区域裂纹扩展路径和裂纹扩展速率的仿真结果与试验结果基本吻合;预制裂纹于3个区域的裂纹扩展寿命由短到长依次为:焊核区、热影响区、垂直于焊缝方向;通过FRANC 3D对3种试样进行寿命预测结果与试验结果的相对误差在5%左右,验证了通过联合仿真的方法对焊接接头分区域模拟高配铝合金搅拌摩擦焊裂纹扩展行为和寿命预测的准确可行性。

中图分类号:

- TG405

| 1 | 张鹏,陈明和,谢兰生. 热处理2024-O铝合金在自然时效下的拉伸性能及断口形貌演变[J]. 稀有金属材料与工程, 2020, 49(3): 819-824. |

| Zhang Peng, Chen Ming-he, Xie Lan-sheng. Effect of natural aging time on tensile properties and fracture of heat-treated AA2024-O Al-alloy[J]. Rare Metal Materials and Engineering, 2020, 49(3): 819-824. | |

| 2 | Lin Y, Cui X, Chen K, et al. Forming limit and mechanical properties of 2024-O aluminum alloy under electromagnetic forming[J]. Metals and Materials International, 2022,28(10): 2472-2482. |

| 3 | Wang Z W, Zheng R X, Ma C L, et al. Fabrication and mechanical properties of 2024 aluminum alloy reinforced by FeNiCrCoAl3 high entropy particles[J]. Journal of Harbin Institute of Technology, 2013, 20(5): 119-122. |

| 4 | 王淼,李天景,黄婷婷,等. 6061铝合金FSW接头组织与耐蚀性能的研究[J]. 热加工工艺, 2024(15): 31-34. |

| Wang Miao, Li Tian-jing, Huang Ting-ting, et al. Study on microstructure and corrosion resistance of 6061 aluminium alloy friction stir welded joint[J]. Hot Working Technology, 2024(15): 31-34. | |

| 5 | Arora K S. Microstructure evolution during friction stir welding of aluminum alloy AA2219[J]. Journal of Materials Science & Technology, 2010, 26(8): 747-753. |

| 6 | Yokoyama T, Nakai K, Sukedai E, et al. Tensile properties and constitutive modeling of friction stir welded AA6061-T6butt joints[J]. Journal of Solid Mechanics & Materials Engineering, 2011, 5(12): 780-792. |

| 7 | 王希靖,李树伟,牛勇,等. A7075搅拌摩擦焊疲劳裂纹扩展速率试验分析[J].焊接学报, 2008(9): 5-7, 113. |

| Wang Xi-jing, Li Shu-wei, Niu Yong, et al. Experimental analysis of fatigue crack growth rate in friction stir welding A7075[J]. Transactions of the China Welding Institution, 2008(9): 5-7, 113. | |

| 8 | Huang B H, Wang L, Hui L, et al. Analysis of multi-zone fatigue crack growth behavior of friction stir welded 5083 aluminum alloy[J]. Journal of Materials Engineering and Performance, 2022, 31(1):53-63. |

| 9 | Sivaraj P, Kanagarajan D, Balasubramanian V. Fatigue crack growth behaviour of friction stir welded AA7075-T651 aluminium alloy joints[J]. Transactions of Nonferrous Metals Society of China, 2014,24(8):2459-2467. |

| 10 | Muzvidziwa Milton, Okazaki Masakazu, Suzuki Kenji, et al. Role of microstructure on the fatigue crack propagation behavior of a friction stir welded Ti-6Al⁃4V[J]. Materials Science & Engineering A, 2016, 652:59-68. |

| 11 | 王磊,付强,周松,等. 2A12-O铝合金搅拌摩擦焊缝裂纹扩展行为研究[J].热加工工艺, 2022(15): 14-17. |

| Wang Lei, Fu Qiang, Zhou Song, et al. Study on crack propagation behavior of 2A12-O aluminum alloy friction stir weld[J]. Hot Working Technology, 2022(15): 14-17. | |

| 12 | 黄伟辰, 龙江. 基于FRANC3D的飞机蒙皮谱载疲劳裂纹扩展分析[J]. 西安航空学院学报,2020,38(1):32-38. |

| Huang Wei-chen, Long Jiang. Fatigue crack propagation analysis of aircraft skin under spectrum load based on FRANC 3D[J]. Journal of Xi'an Aeronautical University, 2020,38(1):32-38. | |

| 13 | 王磊,张璐,赵新华,等. 力学失配2A12铝合金搅拌摩擦焊接头拉伸性能分析[J].科学技术与工程,2020,20(16):6419-6423. |

| Wang Lei, Zhang Lu, Zhao Xin-hua, et al. Analysis of tensile properties of mechanical mismatched friction stir weld of 2A12 aluminum alloy[J]. Science Technology and Engineering,2020,20(16) : 6419-6423. |

| [1] | 刘洋,江涛. 计及安装角的六自由度平台虎克铰干涉计算模型[J]. 吉林大学学报(工学版), 2024, 54(6): 1519-1527. |

| [2] | 谭晓丹,王勇澎,Hall Robert,徐天爽,黄庆学. 面向电铲自主装卸的矿用自卸车斗型优化[J]. 吉林大学学报(工学版), 2024, 54(5): 1227-1236. |

| [3] | 王世俊,罗冠炜. 含多种碰撞约束振动系统的周期运动转迁特性[J]. 吉林大学学报(工学版), 2024, 54(4): 902-916. |

| [4] | 回丽,金磊,宋万万,周松,安金岚. 转向架用SMA490BW钢不同焊接区域裂纹扩展速率[J]. 吉林大学学报(工学版), 2024, 54(3): 650-656. |

| [5] | 孙伟,杨俊. 等角贴敷压电分流片圆柱壳有限元建模及减振分析[J]. 吉林大学学报(工学版), 2024, 54(2): 365-374. |

| [6] | 胡斌,蔡一全,罗昕,毛自斌,李俊伟,郭孟宇,王剑. 基于种群胁迫的有限齿侧空间高速充种理论与试验[J]. 吉林大学学报(工学版), 2024, 54(2): 574-588. |

| [7] | 王佳怡,刘昕晖,王展,陈晋市,韩亚方,王禹琪. 基于AMESim的恒流量控制阀流量特性分析[J]. 吉林大学学报(工学版), 2023, 53(9): 2499-2507. |

| [8] | 程亚兵,杨泽宇,李岩,安立持,徐泽辉,曹鹏宇,陈璐翔. 基于混合动力汽车正时齿形链系统的振动噪声特性[J]. 吉林大学学报(工学版), 2023, 53(9): 2465-2473. |

| [9] | 黄贤振,孙楷铂,栾晓刚,胡兵. 螺栓预紧连接可靠性灵敏度分析[J]. 吉林大学学报(工学版), 2023, 53(8): 2219-2226. |

| [10] | 申富媛,李炜,蒋栋年. 四旋翼无人机寿命预测和自主维护方法[J]. 吉林大学学报(工学版), 2023, 53(3): 841-852. |

| [11] | 杨艳,侍玉青,张晓蓉,罗冠炜. 一类多刚性限幅振动系统的动态稳定性分析[J]. 吉林大学学报(工学版), 2023, 53(2): 364-375. |

| [12] | 宋剑锋,黄鑫磊,仪帅,杨振熙,董永刚,李树林. 列车制动过程踏面温度场及应力⁃应变分布特性[J]. 吉林大学学报(工学版), 2023, 53(10): 2773-2784. |

| [13] | 刘洋. 动臂塔机防后倾缓冲力计算方法[J]. 吉林大学学报(工学版), 2023, 53(10): 2785-2794. |

| [14] | 卢晓红,乔金辉,周宇,马冲,隋国川,孙卓. 搅拌摩擦焊温度场研究进展[J]. 吉林大学学报(工学版), 2023, 53(1): 1-17. |

| [15] | 刘洋. 动臂塔机卸载冲击仿真及试验[J]. 吉林大学学报(工学版), 2022, 52(6): 1292-1300. |

|

||