吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (1): 1-17.doi: 10.13229/j.cnki.jdxbgxb20210716

• 综述 •

搅拌摩擦焊温度场研究进展

- 大连理工大学 机械工程学院,辽宁 大连 116024

Research progress of temperature field in friction stir welding

Xiao-hong LU( ),Jin-hui QIAO,Yu ZHOU,Chong MA,Guo-chuan SUI,Zhuo SUN

),Jin-hui QIAO,Yu ZHOU,Chong MA,Guo-chuan SUI,Zhuo SUN

- School of Mechanical Engineering,Dalian University of Technology,Dalian 116024,China

摘要:

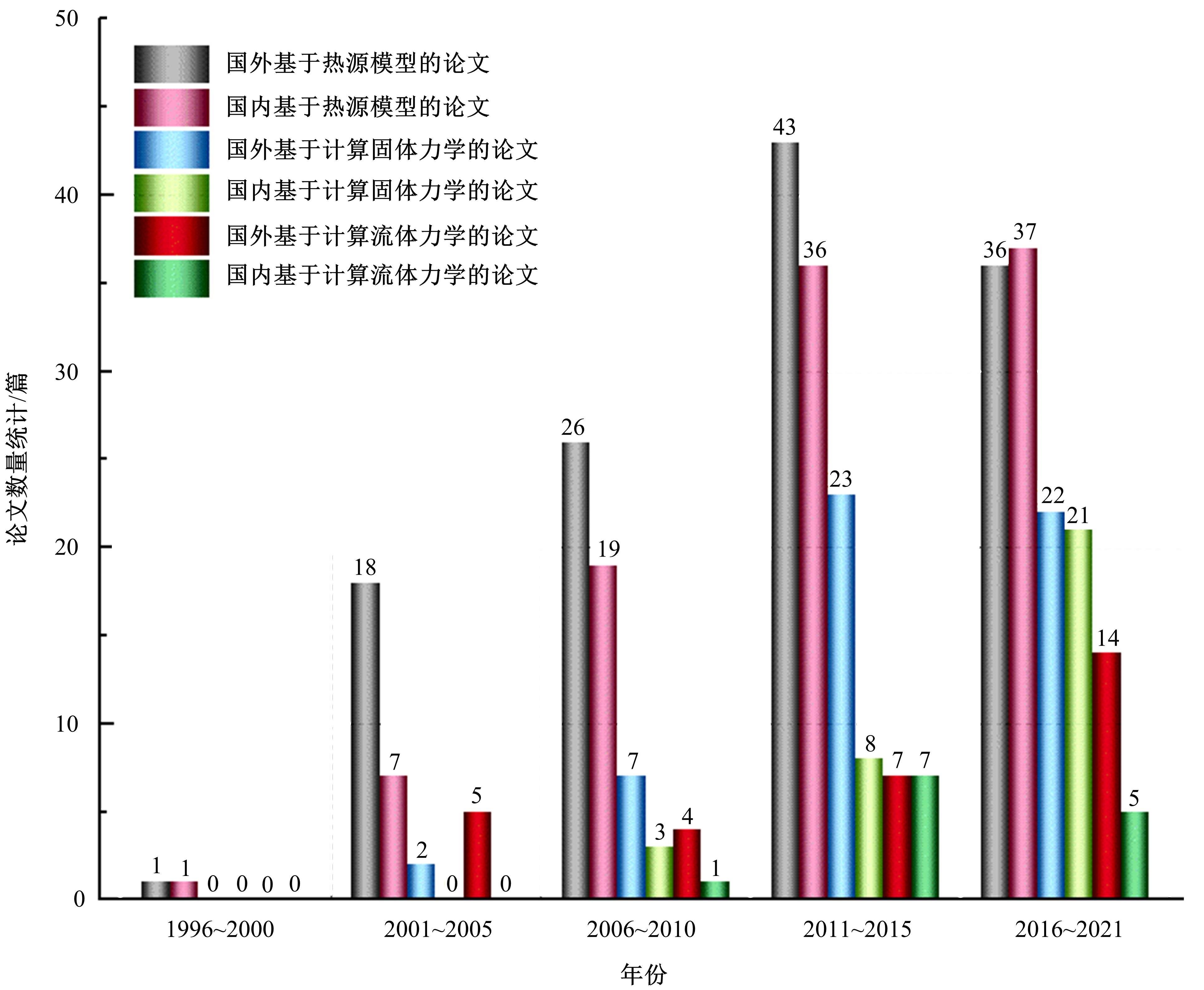

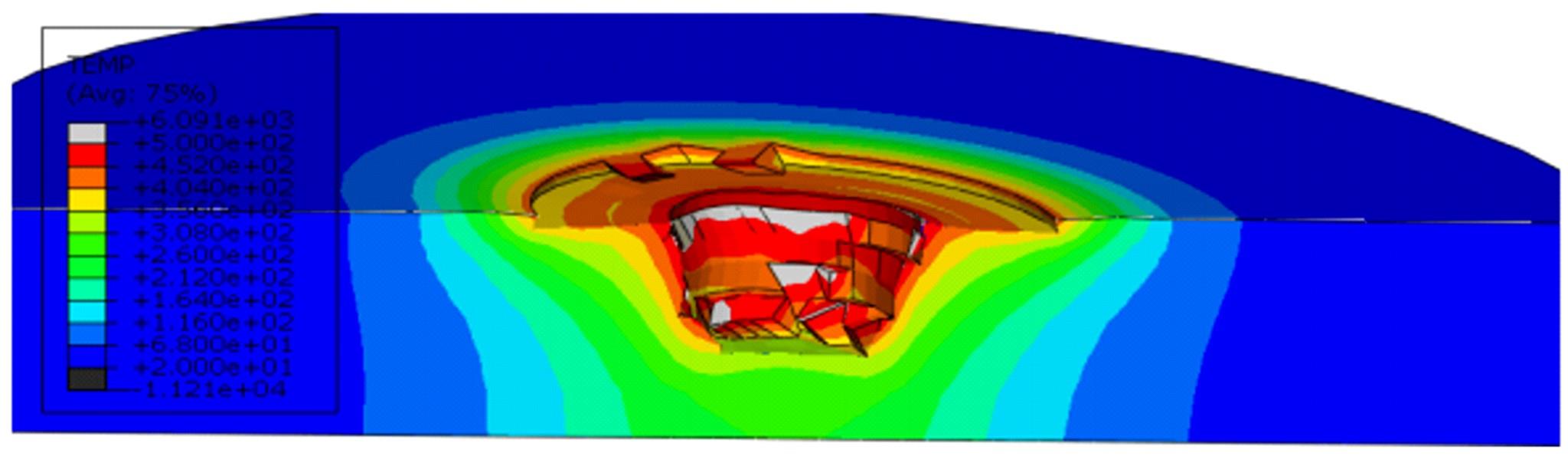

系统归纳论述了搅拌摩擦焊(FSW)温度场有限元仿真方法与实验测量方法的研究现状。对基于有限元仿真方法的国内外论文数量进行统计分析,分别从基于热源模型、计算固体力学和计算流体力学的仿真技术3个方面展开论述;对于实验测量方法,梳理了采用热电偶、红外热像仪的测温原理和研究思路,分析了不同测温方法的特点。对上述各种方法的优势和弊端进行了对比分析,并提出了未来研究方向。

中图分类号:

- TG453

| 1 | Thomas W M, Nicholas E D, Needham J C, et al. Friction stir butt welding[P]. GB Patent Application No: 9125978.8, 1991. |

| 2 | 陈高强, 史清宇. 搅拌摩擦焊中材料流动行为数值模拟的研究进展[J]. 机械工程学报, 2015, 51(22): 11-21. |

| Chen Gao-qiang, Shi Qing-yu. Recent advances in numerical simulation of material flow behavior during frictions stir welding[J]. Journal of Mechanical Engineering, 2015, 51(22): 11-21. | |

| 3 | 武凯, 贾贺鹏, 孙宇, 等. 搅拌摩擦焊技术的研究进展[J]. 机械制造与自动化, 2020, 49(6): 1-9. |

| Wu Kai, Jia He-peng, Sun Yu, et al. Research progress of friction stir welding technology[J]. Machine Buiding and Automation, 2020, 49(6): 1-9. | |

| 4 | 刘其鹏, 顾乃建, 刘泽, 等. AA6061-T6板材搅拌摩擦焊温度场仿真[J]. 大连交通大学学报, 2018, 39(3): 80-85. |

| Liu Qi-peng, Gu Nai-jian, Liu Ze, et al. Simulation of temperature field of AA6061-T6 sheet in friction stir welding[J]. Journal of Dalian Jiaotong University, 2018, 39(3): 80-85. | |

| 5 | McClure J C, Tang W, Murr L E, et al. A thermal model of friction stir welding[C]∥ASM Proceedings of the International Conference: Trends in Welding Research, Georgia, United States, 1998: 590-595. |

| 6 | Russell M J, Shercliff H. Analytical modelling of friction stir welding[J]. Analytical Modelling of Friction Stir Welding Russell, 1999, 98: 197-207. |

| 7 | Song M, Kovacevic R. Thermal modeling of friction stir welding in a moving coordinate system and its validation[J]. International Journal of Machine Tools and Manufacture, 2003, 43(6): 605-615. |

| 8 | 郭柱, 朱浩, 崔少朋, 等. 7075铝合金搅拌摩擦焊接头温度场及残余应力场的有限元模拟[J]. 焊接学报, 2015, 36(2): 92-96. |

| Guo Zhu, Zhu Hao, Cui Shao-peng, et al. Finite element simulation of friction stir welding temperature field and residual stress field of 7075 aluminum alloy[J]. Transactions of the China Welding Institution, 2015, 36(2): 92-96. | |

| 9 | 曹文胜, 赵亮. TC4钛合金搅拌摩擦焊接新工艺及计算机仿真分析[J]. 铸造技术, 2016, 37(4):774-777. |

| Cao Wen-sheng, Zhao Liang. New friction stir welded technology and simulation analysis of TC4 titanium alloy[J]. Foundry Technology, 2016, 37(4): 774-777. | |

| 10 | 江旭东, 黄俊, 周琦, 等. 铝-铜异种材料对接搅拌摩擦焊温度场数值模拟[J]. 焊接学报, 2018, 39(3): 16-20. |

| Jiang Xu-dong, Huang Jun, Zhou Qi, et al. Numerical simulation of the temperature field for butt friction stir welding of dissimilar 6061-T6 and T2 alloys[J]. Transactions of the China Welding Institution, 2018, 39(3): 16-20. | |

| 11 | 张渝, 杨霖. 铝合金差厚板搅拌摩擦焊温度场及残余应力分析[J]. 热加工工艺, 2020, 49(1): 142-147. |

| Zhang Yu, Yang Lin. Temperature field and residual stress analysis of friction stir welding of aluminum alloy blank with different thickness[J]. Hot Working Technology, 2020, 49(1): 142-147. | |

| 12 | 周文静, 杜柏松, 卢小明. 铝合金搅拌摩擦焊温度场数值模拟及参数影响分析[J]. 热加工工艺, 2021, 50(7): 156-160. |

| Zhou Wen-jing, Du Bai-song, Lu Xiao-ming. Numerical simulation of temperature field and parameter influence analysis of friction stir welding of aluminum alloy[J]. Hot Working Technology, 2021, 50(7): 156-160. | |

| 13 | 丁清苗, 秦永祥, 崔艳雨. 飞机蒙皮2A12铝合金搅拌摩擦焊的数值模拟研究[J]. 热加工工艺, 2021, 50(7): 144-150. |

| Ding Qing-miao, Qin Yong-xiang, Cui Yan-yu. Numerical simulation study on friction stir welding of aircraft skin 2A12 aluminum alloy[J]. Hot Working Technology, 2021, 50(7): 144-150. | |

| 14 | Mandal S, Williamson K. A thermomechanical hot channel approach for friction stir welding[J]. Journal of Materials Processing Technology, 2006, 174(1-3): 190-194. |

| 15 | 汪建华, 姚舜, 魏良武, 等. 搅拌摩擦焊接的传热和力学计算模型[J]. 焊接学报, 2000(4): 61-64. |

| Wang Jian-hua, Yao Shun, Wei Liang-wu, et al. Thermal and thermo-mechanical modeling of friction stir welding[J]. Transactions of the China Welding Institution, 2000(4): 61-64. | |

| 16 | Chang W S, Bang H S, Jung S B, et al. Joint properties and thermal behaviors of friction stir welded age hardenable 6061Al alloy[J]. Materials Science Forum, 2003, 426-432: 2953-2958. |

| 17 | Zhu X K, Chao Y J. Numerical simulation of transient temperature and residual stresses in friction stir welding of 304L stainless steel[J]. Journal of Materials Processing Technology, 2004, 146(2): 263-272. |

| 18 | Vuyst T D, D'Alvise L, Simar A, et al. Finite element modelling of friction stir welding of aluminium alloy plates-inverse analysis using a genetic algorithm[J]. Welding in the World, 2005, 49(3/4): 47-55. |

| 19 | Lu S X, Yan J C, Li W G, et al. Simulation on temperature field of friction stir welded joints of 2024-T4 Al[J]. Acta Metallurgica Sinica (English Letters), 2005, 18(4): 552-556. |

| 20 | 王磊, 谢里阳, 张丹, 等. 搅拌摩擦焊接过程温度场动态仿真[J]. 东北大学学报:自然科学版, 2008, 29(7): 1025-1028. |

| Wang Lei, Xie Li-yang, Zhang Dan, et al. Dynamic simulation of temperature field during friction stir welding[J]. Journal of Northeastern University, 2008, 29(7): 1025-1028. | |

| 21 | Frigaard O, Grong O, Midling O T. A process model for friction stir welding of age hardening aluminum alloys[J]. Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science, 2001, 32(5): 1189-1200. |

| 22 | 张华, 林三宝, 吴林, 等. 镁合金AZ31搅拌摩擦焊接温度场数值模拟[J]. 宇航材料工艺, 2004(6): 58-61. |

| Zhang Hua, Lin San-bao, Wu Lin, et al. Temperature simulation of friction stir welded AZ31 magnesium alloy[J]. Aerospace Materials and Technology, 2004(6): 58-61. | |

| 23 | 徐韦锋, 刘金合, 朱宏强. 2219铝合金厚板搅拌摩擦焊接温度场数值模拟[J]. 焊接学报, 2010, 31(2): 63-66. |

| Xu Wei-feng, Liu Jin-he, Zhu Hong-qiang. Numerical simulation of thermal field of friction stir welded 2219 aluminum alloy thick plate[J]. Transactions of the China Welding Institution, 2010, 31(2): 63-66. | |

| 24 | Kiral B G, Tabanoglu M, Serindag H T. Finite element modeling of friction stir welding in aluminum alloys joint[J]. Mathematical and Computational Applications, 2013, 18(2): 122-131. |

| 25 | 吕赞, 王琳, 岳玉梅, 等. 搅拌头压入速度和停留时间对2024铝合金搅拌摩擦焊接温度场的影响[J]. 热加工工艺, 2013, 42(1): 171-173. |

| Lv Zan, Wang Lin, Yue Yu-mei, et al. Effect of penetration speed and reserving time of rotational tool on temperature field of friction stir welded 2024 aluminum alloy[J]. Hot Working Technology, 2013, 42(1): 171-173. | |

| 26 | 马英磊, 郑洋, 张建军, 等. 铝/镁搅拌摩擦焊异质接头热-力场仿真研究[J]. 焊接技术, 2021, 50(3): 6-10. |

| Ma Ying-lei, Zheng Yang, Zhang Jian-jun, et al. Simulation study on the thermal-stress fields of Al/Mg dissimilar joint prepared by friction stir welding[J]. Welding Technology, 2021, 50(3): 6-10. | |

| 27 | 卢翔, 邵良臣, 李志勇, 等. DP590钢/AA6061-T6铝合金异种金属对接搅拌摩擦焊温度场的数值模拟[J]. 热加工工艺, 2021, 50(1): 151-155. |

| Lu Xiang, Shao Liang-chen, Li Zhi-yong, et al. Numerical simulation of temperature field of friction stir butt welding of DP590 steel/AA6061-T6 aluminum alloy[J]. Hot Working Technology, 2021, 50(1): 151-155. | |

| 28 | Schmidt H, Hattel J, Wert J. An analytical model for the heat generation in friction stir welding[J]. Modelling and Simulation in Materials Science and Engineering, 2004, 12(1): 143-157. |

| 29 | 周鹏展, 贺地求, 舒霞云, 等. 旋转速度对高强铝厚板搅拌摩擦焊温度场的影响[J]. 焊接技术, 2005(2): 10-11. |

| Zhou Peng-zhan, He Di-qiu, Shu Xia-yun, et al. Effect of revs on the temperature field of stir welding of thick high-strength aluminum plate[J]. Welding Technology, 2005(2): 10-11. | |

| 30 | Gadakh V S, Adepu K. Heat generation model for taper cylindrical pin profile in FSW[J]. Journal of Materials Research and Technology, 2013, 2(4): 370-375. |

| 31 | Yaduwanshi D K, Bag S, Pal S. Heat transfer analyses in friction stir welding of aluminium alloy[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2015, 229(10): 1722-1733. |

| 32 | Bonifaz E A. A new thermal model in SAE-AISI 1524 friction stir welding[J]. Defect and Diffusion Forum, 2019, 390: 53-63. |

| 33 | 任朝晖, 李存旭, 谢吉祥, 等. 超声辅助搅拌摩擦焊温度场及残余应力场分析[J]. 焊接学报, 2018, 39(11): 53-57. |

| Ren Zhao-hui, Li Cun-xu, Xie Ji-xiang, et al. Analysis on temperature field and residual stress field of ultrasonic assisted friction stir welding[J]. Transactions of the China Welding Institution, 2018, 39(11): 53-57. | |

| 34 | 万胜强, 吴运新, 龚海, 等. 2219铝合金搅拌摩擦焊温度与残余应力热力耦合模拟[J].热加工工艺, 2019, 48(13): 159-163. |

| Wan Sheng-qiang, Wu Yun-xin, Gong Hai, et al. Thermal mechanical coupling simulation of temperature and residual stress in friction stir welding of 2219 aluminum alloy[J]. Hot Working Technology, 2019, 48(13): 159-163. | |

| 35 | Liu W M, Yan Y F, Sun T, et al. Influence of cooling water temperature on ME20M magnesium alloy submerged friction stir welding: a numerical and experimental study[J]. International Journal of Advanced Manufacturing Technology, 2019, 105(12): 5203-5215. |

| 36 | Liu X Q, Yu Y, Yang S L, et al. A modified analytical heat source model for numerical simulation of temperature field in friction stir welding[J]. Advances in Materials Science and Engineering, 2020: 4639382. |

| 37 | 李红克, 史清宇, 赵海燕, 等. 热量自适应搅拌摩擦焊热源模型[J]. 焊接学报, 2006(11): 81-85. |

| Li Hong-ke, Shi Qing-yu, Zhao Hai-yan, et al. Auto-adapting heat source model for numerical analysis of friction stir welding[J]. Transactions of the China Welding Institution, 2006(11): 81-85. | |

| 38 | 安丽, 钱炜, 邹青峰, 等. 2A14-T6铝合金双轴肩搅拌摩擦焊接温度场研究[J]. 热加工工艺, 2015, 44(5): 225-229. |

| An Li, Qian Wei, Zou Qing-feng, et al. Research of temperature field in bobbin tool friction stir welding for 2A14-T6 Aluminum alloy[J]. Hot Working Technology, 2015, 44(5): 225-229. | |

| 39 | 刘震磊, 崔祜涛, 姬书得, 等. 温度峰值影响6061铝/AZ31B镁异种材料FSW接头成形的规律[J]. 焊接学报, 2016, 37(6): 23-26. |

| Liu Zhen-lei, Cui Hu-tao, Ji Shu-de, et al. Effect of peak temperature on formation of 6061 Al/AZ31BMg dissimilar FSW joint[J]. Transactions of the China Welding Institution, 2016, 37(6): 23-26. | |

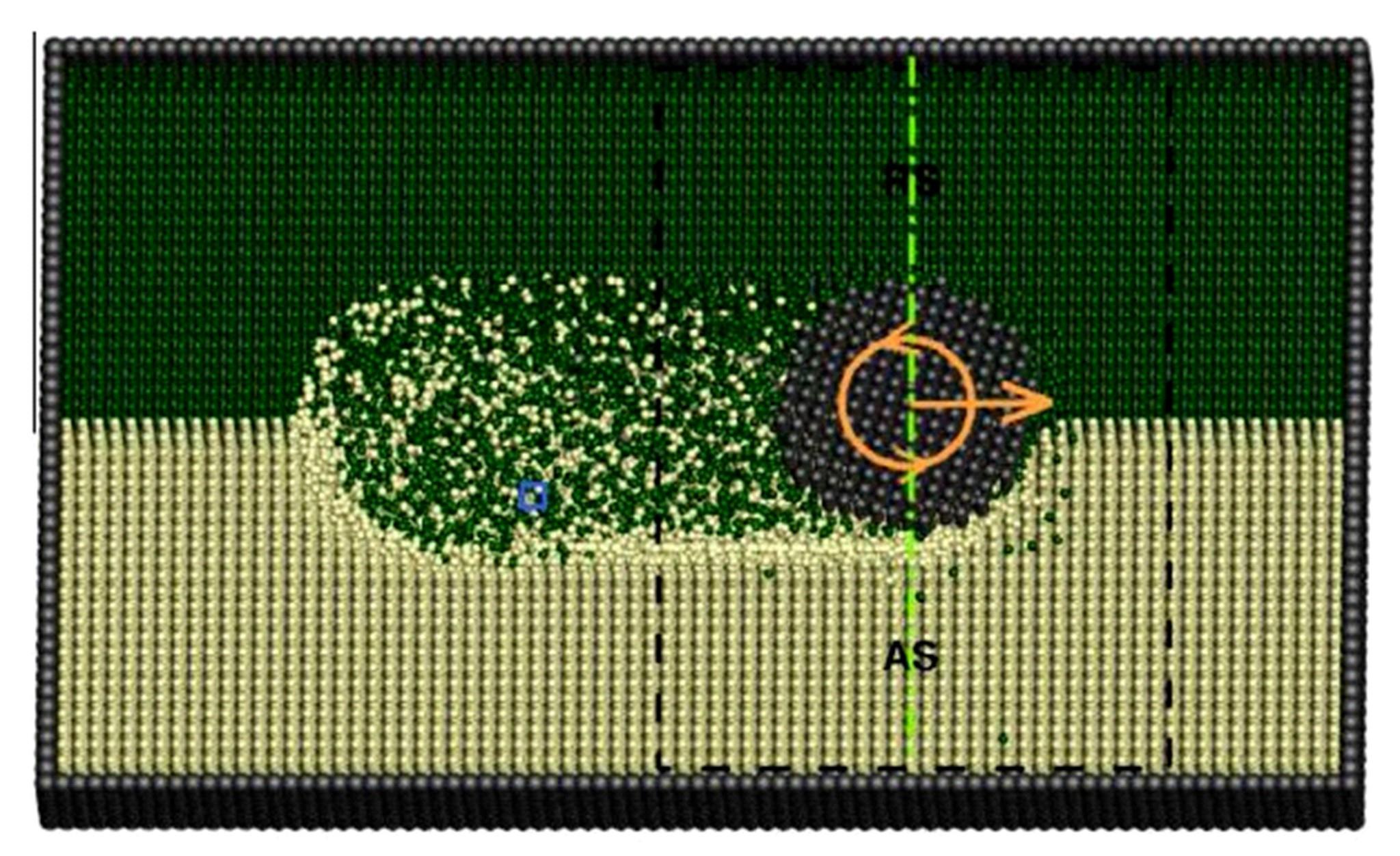

| 40 | 姬书得, 温泉, 吕赞, 等. 激冷影响TC4钛合金FSW残余应力与变形的规律[J]. 中国机械工程, 2016, 27(4): 531-536. |

| Ji Shu-de, Wen Quan, Lv Zan, et al. Effect of Intense cooling on deformation and residual stresses for FSWed TC4 titanium alloy[J]. China Mechanical Engineering, 2016, 27(4): 531-536. | |

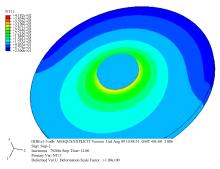

| 41 | 鄢东洋, 史清宇, 吴爱萍, 等. 搅拌摩擦焊接的热力耦合分析模型[J]. 机械工程学报, 2010, 46(16): 106-112. |

| Yan Dong-yang, Shi Qing-yu, Wu Ai-ping, et al. Developmental thermal-mechanical coupled analysis model for friction stir welding[J]. Journal of Mechanical Engineering, 2010, 46(16): 106-112. | |

| 42 | 朱智, 王敏, 张会杰, 等. 高强铝合金薄板搅拌摩擦焊残余应力及变形的热力耦合模拟[J]. 塑性工程学报, 2017, 24(2): 217-222. |

| Zhu Zhi, Wang Min, Zhang Hui-jie, et al. Thermal-mechanical coupled simulation on residual stress and distortion of high-strength aluminum alloy sheet after friction stir welding[J]. Journal of Plasticity Engineering, 2017, 24(2): 217-222. | |

| 43 | 殷鹏飞, 张蓉, 熊江涛, 等. 搅拌摩擦焊准稳态温度场数值模拟[J]. 西北工业大学学报, 2012, 30(4): 622-627. |

| Yin Peng-fei, Zhang Rong, Xiong Jiang-tao, et al. An effective numerical simulation of temperature distribution of friction stir welding in quasi-steady-state[J]. Journal of Northwestern Polytechnical University, 2012, 30(4): 622-627. | |

| 44 | 贺地求, 孙侠, 祝建明. 2024-T4铝合金薄板超声辅助搅拌摩擦焊温度场数值模拟[J]. 热加工工艺, 2014, 43(19): 162-165, 168. |

| He Di-qiu, Sun Xia, Zhu Jian-ming. Numerical simulation on welding temperature field of 2024-T4 aluminum ultrasonic assisted friction stir[J]. Hot Working Technology, 2014, 43(19): 162-165, 168. | |

| 45 | 董平, 窦作勇, 张鹏程. 铝合金搅拌摩擦焊过程热力演变的三维数值模拟[J]. 焊接学报, 2015, 36(4): 71-74. |

| Dong Ping, Dou Zuo-yong, Zhang Peng-cheng. 3D numerical simulation of temperature and stress evolution in friction stir welding of aluminum alloy[J]. Transactions of the China Welding Institution, 2015, 36(4): 71-74. | |

| 46 | Li W Y, Yu M, Li J L, et al. Explicit Finite Element Analysis of the Plunge Stage of Tool in Friction Stir Welding[C]∥Materials Science Forum, 10th International Symposium on Eco-Materials Processing and Design, 2009, 620-622: 233-236. |

| 47 | 李文亚, 余敏, 李京龙. 质量放大因子对搅拌摩擦焊接插入过程的影响[J]. 焊接学报, 2010, 31(2): 1-4. |

| Li Wen-ya, Yu Min, Li Jing-long. Effects of mass scaling factor on the plunge stage of friction stir welding[J]. Transactions of the China Welding Institution, 2010, 31(2): 1-4. | |

| 48 | Buffa G, Hua J, Shivpuri R, et al. A continuum based FEM model for friction stir welding - model development[J]. Materials Science and Engineering A, 2006, 419(1/2): 389-396. |

| 49 | 周明智, 雷党刚, 梁宁, 等. 搅拌摩擦焊三维粘塑性热力耦合有限元数值模拟[J]. 焊接学报, 2010, 31(2): 5-9. |

| Zhou Ming-zhi, Lei Dang-gang, Liang Ning, et al. 3D coupled thermo-mechanical visco-plastic finite element simulation of friction stir welding process[J]. Transactions of the China Welding Institution, 2010, 31(2): 5-9. | |

| 50 | Asadi P, Mahdavinejad R A, Tutunchilar S. Simulation and experimental investigation of FSP of AZ91 magnesium alloy[J]. Materials Science and Engineering A, 2011, 528(21): 6469-6477. |

| 51 | 杜岩峰, 白景彬, 田志杰, 等. 2219铝合金搅拌摩擦焊温度场的三维实体耦合数值模拟[J]. 焊接学报, 2014, 35(8): 57-60. |

| Du Yan-feng, Bai Jing-bin, Tian Zhi-jie, et al. Investigation on three-dimensional real coupling numerical simulation of temperature field of friction stir welding of 2219 aluminum alloy[J]. Transactions of the China Welding Institution, 2014, 35(8): 57-60. | |

| 52 | Šibalić N, Vukčević M, Janjić M, et al. A study on friction stir welding of AlSi1MgMn aluminium alloy plates[J]. Tehnicki Vjesnik, 2016, 23(3): 653-660. |

| 53 | Malik V, Sanjeev N K, Hebbar H S, et al. Finite element simulation of exit hole filling for friction stir spot welding ― a modified technique to apply practically[C]∥The 12th Global Congress on Manufacturing and Management. Procedia Engineering, Vellore, India,2014: 1265-1273. |

| 54 | Jain R, Pal S K, Singh S B. A study on the variation of forces and temperature in a friction stir welding process: a finite element approach[J]. Journal of Manufacturing Processes, 2016, 23: 278-286. |

| 55 | 韩锐, 刘其鹏, 高月华, 等. 型材结构搅拌摩擦焊全热力耦合仿真分析[J]. 塑性工程学报, 2019, 26(4): 293-299. |

| Han Rui, Liu Qi-peng, Gao Yue-hua, et al. Fully coupled thermo-mechanical simulation analysis of friction stir welding for profile structure[J]. Journal of Plasticity Engineering, 2019, 26(4): 293-299. | |

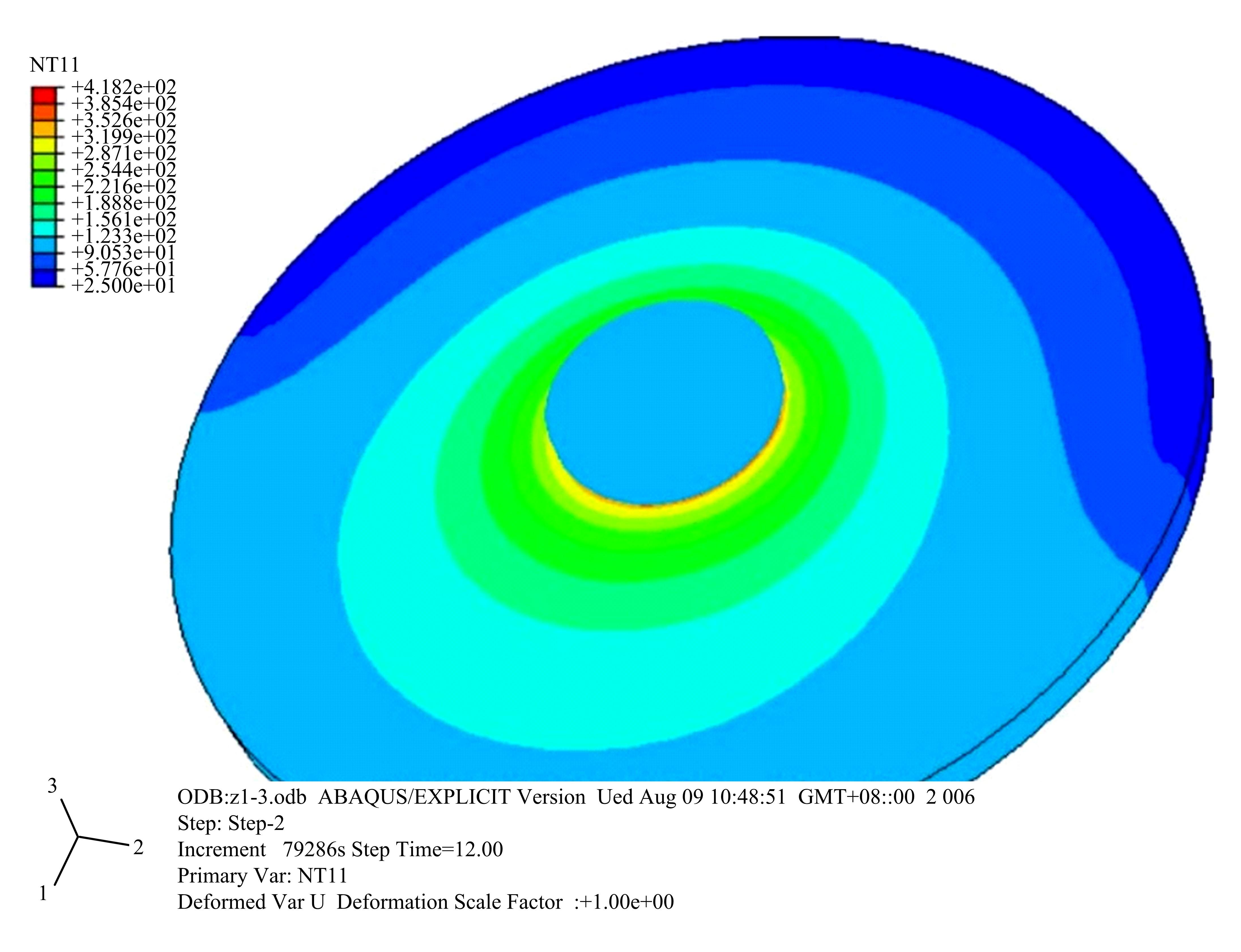

| 56 | Hirt C W, Amsden A A, Cook J L. An arbitrary lagrangian-eulerian computing method for all flow speeds[J]. Journal of Computational Physics, 1974, 14(3): 227-253. |

| 57 | Huerta A, Liu W K. Viscous flow with large free surface motion[J]. Computer Methods in Applied Mechanics and Engineering, 1988, 69(3): 277-324. |

| 58 | Liu W K, Chang H, Chen J S, et al. Arbitrary lagrangian-eulerian petrov-galerkin finite elements for nonlinear continus[J]. Computer Methods in Applied Mechanics and Engineering, 1988, 68(3): 259-310. |

| 59 | Liu W K, Chen J S, Belytschko T, et al. Adaptive ALE finite elements with particular reference to external work rate on frictional interface[J]. Computer Methods in Applied Mechanics and Engineering, 1991, 93(2): 189-216. |

| 60 | Liu W K, Hu Y K, Belytschko T. ALE finite elements with hydrodynamic lubrication for metal forming[J]. Nuclear Engineering and Design, 1992, 138(1): 1-10. |

| 61 | Schmidt H, Hattel J. A local model for the thermomechanical conditions in friction stir welding[J]. Modelling and Simulation in Materials Science and Engineering, 2005, 13(1): 77-93. |

| 62 | Mandal S, Rice J, Elmustafa A A. Experimental and numerical investigation of the plunge stage in friction stir welding[J]. Journal of Materials Processing Technology, 2008, 203(1-3): 411-419. |

| 63 | Zhang Z, Zhang H W. A fully coupled thermo-mechanical model of friction stir welding[J]. International Journal of Advanced Manufacturing Technology, 2008, 37(3/4): 279-293. |

| 64 | 张昭, 刘会杰. 搅拌头形状对搅拌摩擦焊材料变形和温度场的影响[J]. 焊接学报, 2011, 32(3): 5-8. |

| Zhang Zhao, Liu Hui-jie. Effect of pin shapes on material deformation and temperature field in friction stir welding[J]. Transactions of the China Welding Institution, 2011, 32(3): 5-8. | |

| 65 | 张昭, 陈金涛, 王晋宝, 等. 基于仿真的搅拌摩擦焊连接AA2024-T3不同板厚过程对比[J]. 机械工程学报, 2011, 47(18): 23-27. |

| Zhang Zhao, Chen Jin-tao, Wang Jin-bao, et al. Simulation based comparison of friction stir welding of AA2024-T3 plates with different thicknesses[J]. Journal of Mechanical Engineering, 2011, 47(18): 23-27. | |

| 66 | Iordache M, Badulescu C, Niţu E, et al. Numerical simulation of friction stir welding (FSW) process based on ABAQUS environment[C]∥The 6th International Conference on Advanced Materials and Structures. Solid State Phenomena,Timişoara, Romania, 2016, 254: 272-277. |

| 67 | 刘春宁, 郁志凯, 张艳辉, 等. 搅拌针几何形状对搅拌摩擦焊温度场的影响[J]. 焊接技术, 2018, 47(6): 6,73-76. |

| Liu Chun-ning, Yu Zhi-kai, Zhang Yan-hui, et al. Effect of pin shapes on temperature field in friction stir welding[J]. Welding Technology, 2018, 47(6):6,73-76. | |

| 68 | Meyghani B, Awang M B, Momeni M, et al. Development of a finite element model for thermal analysis of friction stir welding (FSW)[C]∥The 11th Curtin University Technology, Science and Engineering International Conference, Sarawak, Malaysia, 2019: No.012101. |

| 69 | Noh W F. CEL: a time-dependent two-space-dimension coupled Eulerian-Lagrangian code[D]. Oakland: University of California, 1963. |

| 70 | Al-Badour F, Merah N, Shuaib A, et al. Coupled eulerian lagrangian finite element modeling of friction stir welding processes[J]. Journal of Materials Processing Technology, 2013, 213(8): 1433-1439. |

| 71 | Al-Badour F, Merah N, Shuaib A, et al. Thermo-mechanical finite element model of friction stir welding of dissimilar alloys[J]. International Journal of Advanced Manufacturing Technology, 2014, 72(5-8): 607-617. |

| 72 | Iordache M, Badulescu C, Iacomi D, et al. Numerical simulation of the friction stir welding process using coupled eulerian lagrangian method[J]. IOP Conference Series: Materials Science and Engineering, 2016, 145(2): 022017. |

| 73 | 马核, 田志杰, 熊林玉, 等. 2A14-T6铝合金搅拌摩擦焊温度场及黏流层数值模拟分析[J]. 航空制造技术, 2018, 61(8): 55-61. |

| Ma He, Tian Zhi-jie, Xiong Lin-yu, et al. Thermal behavior and pre-molten viscousness layer simulation of friction stir welding on 2A14-T6 aluminum alloy[J]. Aviation Welding Technology, 2018, 61(8): 55-61. | |

| 74 | 朱智, 王敏, 张会杰, 等. 基于CEL方法搅拌摩擦焊材料流动及缺陷的模拟[J]. 中国有色金属学报, 2018, 28(2): 294-299. |

| Zhu Zhi, Wang Min, Zhang Hui-jie, et al. Simulation on material flow and defect during friction stir welding based on CEL method[J]. Chinese Journal of Nonferrous Metals, 2018, 28(2): 294-299. | |

| 75 | Wen Q, Li W Y, Gao Y J, et al. Numerical simulation and experimental investigation of band patterns in bobbin tool friction stir welding of aluminum alloy[J]. International Journal of Advanced Manufacturing Technology, 2019, 100(9-12): 2679-2687. |

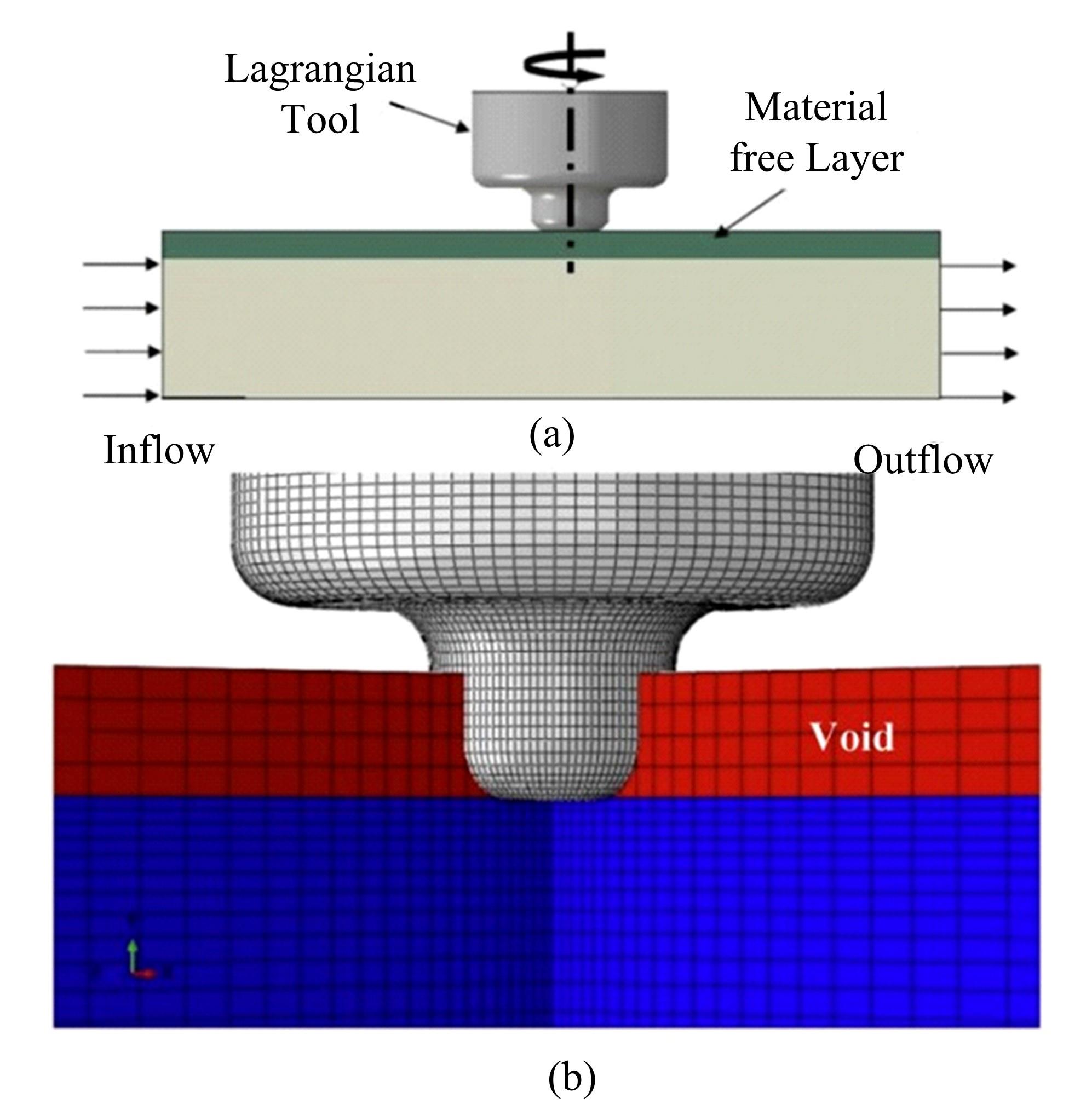

| 76 | Gingold R A, Monaghan J J. Smoothed particle hydrodynamics: theory and application to non-spherical stars[J]. Monthly notices of the royal astronomical society, 1977, 181(3): 375-389. |

| 77 | Tartakovsky A, Grant G, Sun X, et al. Modeling of friction stir welding (FSW) process with smooth particle hydrodynamics (SPH)[C]∥SAE Paper, 2006-01-1394. |

| 78 | Pan W X, Li D S, Tartakovsky A M, et al. A new smoothed particle hydrodynamics non-newtonian model for friction stir welding: process modeling and simulation of microstructure evolution in a magnesium alloy[J]. International Journal of Plasticity, 2013, 48: 189-204. |

| 79 | Sellars C, Tegart W. Hot workability[J]. International Metallurgical Reviewers, 1972, 17: 1-24. |

| 80 | Bagheri B, Abbasi M, Abdolahzadeh A, et al. Numerical analysis of cooling and joining speed effects on friction stir welding by smoothed particle hydrodynamics (SPH)[J]. Archive of Applied Mechanics, 2020, 90(10): 2275-2296. |

| 81 | Bagheri B, Abdollahzadeh A, Abbasi M, et al. Numerical analysis of vibration effect on friction stir welding by smoothed particle hydrodynamics (SPH)[J]. International Journal of Advanced Manufacturing Technology, 2020, 110(1/2): 209-228. |

| 82 | Koshizuka S, Oka Y. Moving-particle semi-implicit method for fragmentation of incompressible fluid[J]. Nuclear Science and Engineering, 1996, 123(3): 421-434 |

| 83 | Yoshikawa G, Miyasaka F, Hirata Y, et al. Development of numerical simulation model for FSW employing particle method[J]. Science and Technology of Welding and Joining, 2012, 17(4): 225-263. |

| 84 | Schmitter D, Zylla I M. Modelling friction stir welding with thermally coupled fluid dynamics [C]//The 2th International Conference on Thermal Process Modelling and Computer, Nancy, France, 2004: 677-680. |

| 85 | 冯天涛, 张晓辉. 三维搅拌摩擦焊接传热与塑性流动分析模型[J]. 焊接学报, 2013, 34(7): 105-108. |

| Feng Tian-tao, Zhang Xiao-hui. Three dimensional model for heat transfer and plastic flow of friction stir welding[J]. Transactions of the China Welding Institution, 2013, 34(7): 105-108. | |

| 86 | 冯莹莹, 赵双, 刘照松, 等. 7075铝合金搅拌摩擦焊模拟与实验研究[J]. 东北大学学报:自然科学版, 2021, 42(3): 340-346. |

| Feng Ying-ying, Zhao Shuang, Liu Zhao-song, et al. Experiment study and simulation for friction stir welding process of 7075 aluminum alloy[J]. Journal of Northeastern University, 2021, 42(3): 340-346. | |

| 87 | Zhai M, Wu C S, Su H. Influence of tool tilt angle on heat transfer and material flow in friction stir welding[J]. Journal of Manufacturing Processes, 2020, 59: 98-112. |

| 88 | Eyvazian A, Hamouda A, Tarlochan F, et al. Simulation and experimental study of underwater dissimilar friction-stir welding between aluminium and steel[J]. Journal of Materials Research and Technology, 2020, 9(3): 3767-3781. |

| 89 | 杨金帅, 刘含莲, 黄传真, 等. 基于Fluent的钢-铝异种金属搅拌摩擦焊数值模拟研究[J]. 焊接技术, 2020, 49(8): 11-15, 105. |

| Yang Jin-shuai, Liu Han-lian, Huang Chuan-zhen, et al. Numerical simulation of friction stir welding between steel and aluminum dissimilar metal based on Fluent[J]. Welding Technology, 2020, 49(8): 11-15, 105. | |

| 90 | Kadian A K, Biswas P. Effect of tool pin profile on the material flow characteristics of AA6061[J]. Journal of Manufacturing Processes, 2017, 26: 382-392. |

| 91 | Yang Z Y, Wang Y L, Domblesky J P, et al. Development of a heat source model for friction stir welding tools considering probe geometry and tool/workpiece interface conditions[J]. International Journal of Advanced Manufacturing Technology, 2021, 114(5/6): 1787-1802. |

| 92 | Su H, Wu C S. Numerical simulation for the optimization of polygonal pin profiles in friction stir welding of aluminum[J]. Acta Metallurgica Sinica (English Letters), 2021, 34(8): 1065-1078. |

| 93 | Andrade D G, Leitão C, Dialami N, et al. Analysis of contact conditions and its influence on strain rate and temperature in friction stir welding[J]. International Journal of Mechanical Sciences, 2021, 191: 106095. |

| 94 | Babu S D D, Sevvel P, Kumar R S. Simulation of heat transfer and analysis of impact of tool pin geometry and tool speed during friction stir welding of AZ80A Mg alloy plates[J]. Journal of Mechanical Science and Technology, 2020, 34(10): 4239-4250. |

| 95 | Mohan R, Jayadeep U B, Manu R. CFD modelling of ultra-high rotational speed micro friction stir welding[J]. Journal of Manufacturing Processes, 2021, 64: 1377-1386. |

| 96 | 赵慧慧, 封小松, 熊艳艳, 等. 铝合金6061高转速无倾角微搅拌摩擦焊温度分布研究[J]. 电焊机, 2014, 44(4): 71-77. |

| Zhao Hui-hui, Feng Xiao-song, Xiong Yan-yan, et al. Study on the temperature distribution of 6061 aluminium alloy micro friction stir welding featured high speed without inclination[J]. Electric Welding Machine, 2014, 44(4): 71-77. | |

| 97 | 王希靖, 郭瑞杰, 阿荣, 等. 搅拌摩擦焊接头的温度检测[J]. 电焊机, 2004, 34(1): 22-23. |

| Wang Xi-jing, Guo Rui-jie, Rong A, et al. Temperature measure for joint of friction stir welding[J]. Electric Welding Machine, 2004, 34(1): 22-23. | |

| 98 | Hwang Y W, Kang Z W, Chiou Y C, et al. Experimental study on temperature distributions within the workpiece during friction stir welding of aluminum alloys[J]. International Journal of Machine Tools and Manufacture, 2008, 48(7): 778-787. |

| 99 | Pires J P, Cota B S, Bracarense A Q, et al. Temperature distribution prediction in 5052 H34 aluminum alloy joints welded by friction stir welding process[J]. Soldagem E Inspecao, 2018, 23(2): 247-263. |

| 100 | 鄢东洋, 史清宇, 吴爱萍, 等. 搅拌摩擦焊接过程的试验测量及分析[J]. 焊接学报, 2010, 31(2): 67-70. |

| Yan Dong-yang, Shi Qing-yu, Wu Ai-ping, et al. Measurement and analysis of friction stir welding process[J]. Transactions of the China Welding Institution, 2010, 31(2): 67-70. | |

| 101 | 芦笙, 贾晓丹, 张春艳, 等. 镁合金搅拌摩擦焊温度场及接头组织形貌特征研究[J]. 材料工程, 2009(): 9-13. |

| Lu Sheng, Jia Xiao-dan, Zhang Chun-yan, et al. Temperature field and microstructure of magnesium alloy fabricated by FSW[J]. Journal of Materials Engineering, 2009(Sup.1): 9-13. | |

| 102 | Lu A, Lu S, Chen S J, et al. Study on the flow field of friction stir welding of AZ31 magnesium alloy based on the temperature variation[C]∥The 12th International Conference on Advanced Materials, Materials Science Forum, Qingdao,China,2014, 789: 282-289. |

| 103 | 李于朋, 孙大千, 宫文彪. 6082-T6铝合金薄板双轴肩搅拌摩擦焊温度场[J]. 吉林大学学报:工学版, 2019, 49(3): 836-841. |

| Li Yu-peng, Sun Da-qian, Gong Wen-biao. Temperature fields in bobbin-tool friction stir welding for 6082-T6 aluminum alloy sheet[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 836-841. | |

| 104 | Maeda M, Liu H, Fujii H, et al. temperature field in the vicinity of FSW-Tool during friction stir welding of aluminium alloys[J]. Welding in the World, 2005, 49(3-4): 69-75. |

| 105 | 周细应, 柯黎明, 刘鸽平, 等. 搅拌摩擦焊的温度分析[J]. 新技术新工艺, 2003, 10: 32-33. |

| Zhou Xi-ying, Ke Li-ming, Liu Ge-ping, et al. Temperature analysise of friction stir welding[J]. New Technology and New Process, 2003, 10: 32-33. | |

| 106 | 苏晓莉, 王快社, 周俊杰. 铝合金搅拌摩擦焊温度场检测[J]. 焊接技术, 2006, 35(1): 12-14, 4. |

| Su Xiao-li, Wang Kuai-she, Zhou Jun-jie. Temperature field measurement of aluminium alloy friction stir welding[J]. Welding Technology, 2006, 35(1): 12-14, 4. | |

| 107 | 王红宾, 白钢, 付春坤, 等. 7050铝合金搅拌摩擦焊接头软化区温度检测[J]. 航空精密制造技术, 2012, 48(4): 39-41. |

| Wang Hong-bin, Bai Gang, Fu Chun-kun, et al. Temperature detection of joint softening area of friction stir welding of 7050 aluminum alloy[J]. Aviation Precision Manufacturing Technology, 2012, 48(4): 39-41. | |

| 108 | 张忠科, 王丽, 王希靖, 等. 10 mm厚LF2铝合金搅拌摩擦焊温度分布及组织分析[J]. 热加工工艺, 2006, 35(19): 8-10. |

| Zhang Zhong-ke, Wang Li, Wang Xi-jing, et al. Analysis on temperature distribution and microstructure of friction stir welding for 10mm LF2 aluminum alloy plate[J]. Hot Working Technology, 2006, 35(19): 8-10. | |

| 109 | Chao Y J, Liu S, Chien C. Friction stir welding of al 6061‐T6 thick plates: part i ‐ experimental analyses of thermal and mechanical phenomena[J]. Journal of the Chinese Institute of Engineers, 2008, 31(5): 757-767. |

| 110 | Shibayanagi T, Mizushima K, Yoshikawa S, et al. Friction stir spot welding of pure aluminum sheet in view of high temperature deformation[J]. Transactions of JWRI, 2011, 40(2): 1-5. |

| 111 | 李敬勇, 赵阳阳, 亢晓亮. 搅拌摩擦焊过程中搅拌头温度场分布特征[J]. 焊接学报, 2014, 35(3): 66-70. |

| Li Jing-yong, Zhao Yang-yang, Kang Xiao-liang. Characteristic of temperature distributions in stirring tools during friction stir welding[J]. Transactions of the China Welding Institution, 2014, 35(3): 66-70. | |

| 112 | 赵阳阳, 李敬勇, 李兴学. 搅拌头材质对搅拌摩擦焊温度场的影响[J]. 航空材料学报, 2014, 34(2): 35-39. |

| Zhao Yang-yang, Li Jing-yong, Li Xing-xue. Influence of stirring tool material on temperature fields of friction stir welding[J]. Journal of Aeronautical Materials, 2014, 34(2): 35-39. | |

| 113 | Fehrenbacher A, Schmale J R, Zinn M R, et al. Measurement of tool-workpiece interface temperature distribution in friction stir welding[J]. Journal of Manufacturing Science and Engineering, 2014, 136(2): No.021009. |

| 114 | Zhai M, Wu C S, Su H. Influence of tool tilt angle on heat transfer and material flow in friction stir welding[J]. Journal of Manufacturing Processes, 2020, 59: 98-112. |

| 115 | 王寒, 王庆霞, 杨建国, 等. 搅拌摩擦焊焊接温度检测系统的研制[J]. 机械设计与制造, 2016(12): 143-145, 149. |

| Wang Han, Wang Qing-xia, Yang Jian-guo, et al. Design and development of temperature detection system for friction stir welding[J]. Machinery Design & Manufacture, 2016(12): 143-145, 149. | |

| 116 | Covington J L, Robison W, Webb B W. Experimental characterization of tool heating during friction stir welding[J]. Trends in Welding Research, 2005: 179-184. |

| 117 | 鲍宏伟, 李京龙, 高大路, 等. 纯铅搅拌摩擦焊接轴肩温度变化规律研究[J]. 电焊机, 2012, 42(2): 54-56. |

| Bao Hong-wei, Li Jing-long, Gao Da-lu, et al. Study on temperature distributions within the shoulder during friction stir welding of pure lead[J]. Electric Welding Machine, 2012, 42(2): 54-56. | |

| 118 | Archimede F, Milena M, Giuseppe P, et al. Similar and dissimilar FSWed Joints in lightweight alloys: heating distribution assessment and IR thermography monitoring for on-line quality control[J]. Key Engineering Materials, 2013, 554-557: 1055-1064. |

| 119 | Lambiase F, Paoletti A, Ilio A D. Forces and temperature variation during friction stir welding of aluminum alloy AA6082-T6[J]. International Journal of Advanced Manufacturing Technology, 2018, 99(1-4): 337-346. |

| 120 | 万心勇, 胡志力, 庞秋, 等. 铝合金高速FSW热输入模型及焊缝峰值温度研究[J]. 稀有金属材料与工程, 2019, 48(6): 1990-1995. |

| Wan Xin-yong, Hu Zhi-li, Pang Qiu, et al. Thermal model and peak temperature in high-travel velocity friction stir welding of aluminum alloy[J]. Rare Metal Materials and Engineering, 2019, 48(6): 1990-1995. | |

| 121 | Sheikh-Ahmad J Y, Ali D S, Deveci S, et al. Friction stir welding of high density polyethylene-Carbon black composite[J]. Journal of Materials Processing Technology, 2019, 264: 402-413. |

| 122 | 张玉存, 崔妍, 付献斌, 等. 搅拌摩擦焊核心区温度在线检测方法[J]. 中国机械工程, 2019, 30(14): 1653-1657. |

| Zhang Yu-cun, Cui Yan, Fu Xian-bin, et al. On-line temperature detection method in core area of friction stir welding[J]. China Mechanical Engineering, 2019, 30(14): 1653-1657. | |

| 123 | Casavola C, Cazzato A, Moramarco V, et al. Temperature field in FSW process: experimental measurement and numerical simulation[C]∥Conference Proceedings of the Society for Experimental Mechanics Series, Garden,USA, 2015: 177-186. |

| 124 | Serio L M, Palumbo D, Galietti U, et al. Monitoring of the friction stir welding process by means of thermography[J]. Nondestructive Testing and Evaluation, 2016, 31(4): 371-383. |

| 125 | Benavides S, Li Y, Murr L E, et al. Low-temperature friction-stir welding of 2024 aluminum[J]. Scripta Materialia, 1999, 41(8): 809-815. |

| 126 | Selvamani S T, Vigneshwar M, Divagar S. Effects of heat transfer on microhardness and microstructure of friction stir welded AA 6061 aluminum alloy[J]. International Journal of Engineering Research in Africa, 2016, 21: 102-109. |

| [1] | 吴迪,耿文华,李洪梅,孙大千. 铝/钢等离子弧熔⁃钎焊接头界面电子背散射衍射分析[J]. 吉林大学学报(工学版), 2023, 53(5): 1331-1337. |

| [2] | 魏海斌,韩栓业,毕海鹏,刘琼辉,马子鹏. 智能感知道路主动除冰雪系统及实验技术[J]. 吉林大学学报(工学版), 2023, 53(5): 1411-1417. |

| [3] | 金敬福,董新桔,贾志成,王康,贺连彬,邹猛,齐迎春. 板簧式弹性金属车轮胎面弹片结构优化[J]. 吉林大学学报(工学版), 2023, 53(4): 964-972. |

| [4] | 刘状壮,张有为,季鹏宇,Abshir Ismail Yusuf,李林,郝亚真. 电热型融雪沥青路面传热特性研究[J]. 吉林大学学报(工学版), 2023, 53(2): 523-530. |

| [5] | 庄蔚敏,王恩铭. 随机壁厚三维实体泡沫铝建模及压缩仿真[J]. 吉林大学学报(工学版), 2022, 52(8): 1777-1785. |

| [6] | 郑植,耿波,王福敏,董俊宏,魏思斯. 既有低等级混凝土护栏防护能力提升[J]. 吉林大学学报(工学版), 2022, 52(6): 1362-1374. |

| [7] | 华琛,牛润新,余彪. 地面车辆机动性评估方法与应用[J]. 吉林大学学报(工学版), 2022, 52(6): 1229-1244. |

| [8] | 郭庆林,刘强,吴春利,李黎丽,李懿明,刘富春. 导电沥青及混合料裂缝局部温度场及愈合效果[J]. 吉林大学学报(工学版), 2022, 52(6): 1386-1393. |

| [9] | 孙健,彭斌,朱兵国. 新型无油涡旋压缩机内部热力学特性和性能测试[J]. 吉林大学学报(工学版), 2022, 52(12): 2778-2787. |

| [10] | 王磊,黄秉汉,丛家慧,回丽,周松,徐永臻. 超声冲击对搅拌摩擦焊缝疲劳性能的影响[J]. 吉林大学学报(工学版), 2022, 52(11): 2542-2548. |

| [11] | 商拥辉,徐林荣,刘维正,蔡雨. 重载铁路改良土和A组填料过渡段的动力特性[J]. 吉林大学学报(工学版), 2021, 51(6): 2128-2136. |

| [12] | 惠迎新,孙晓荣,王红雨,高晨. 预制T梁早期水化热温度效应及梁端开裂机理[J]. 吉林大学学报(工学版), 2021, 51(5): 1734-1741. |

| [13] | 于征磊,陈立新,徐泽洲,信仁龙,马龙,金敬福,张志辉,江山. 基于增材制造的仿生防护结构力学及回复特性分析[J]. 吉林大学学报(工学版), 2021, 51(4): 1540-1547. |

| [14] | 于征磊,信仁龙,陈立新,朱奕凝,张志辉,曹青,金敬福,赵杰亮. 仿蜂窝防护结构的承载特性[J]. 吉林大学学报(工学版), 2021, 51(3): 1140-1145. |

| [15] | 宫亚峰,逄蕴泽,王博,谭国金,毕海鹏. 基于吉林省路况的新型预制装配式箱涵结构的力学性能[J]. 吉林大学学报(工学版), 2021, 51(3): 917-924. |

|

||