吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (3): 888-896.doi: 10.13229/j.cnki.jdxbgxb20180069

轴向往复运动下微槽轴承混合润滑数值模型

王家序1,2( ),倪小康1,2,韩彦峰1,2(

),倪小康1,2,韩彦峰1,2( ),向果1,2,肖科1,2

),向果1,2,肖科1,2

- 1. 重庆大学 机械传动国家重点实验室,重庆 400044

2. 重庆大学 机械工程学院,重庆 400044

Numerical model of mixed lubrication for microgroove bearing considering axial reciprocating motion

Jia⁃xu WANG1,2( ),Xiao⁃kang NI1,2,Yan⁃feng HAN1,2(

),Xiao⁃kang NI1,2,Yan⁃feng HAN1,2( ),Guo XIANG1,2,Ke XIAO1,2

),Guo XIANG1,2,Ke XIAO1,2

- 1. State Key Laboratory of Mechanical Transmissions, Chongqing University, Chongqing 400044, China

2. College of Mechanical Engineering, Chongqing University, Chongqing 400044, China

摘要:

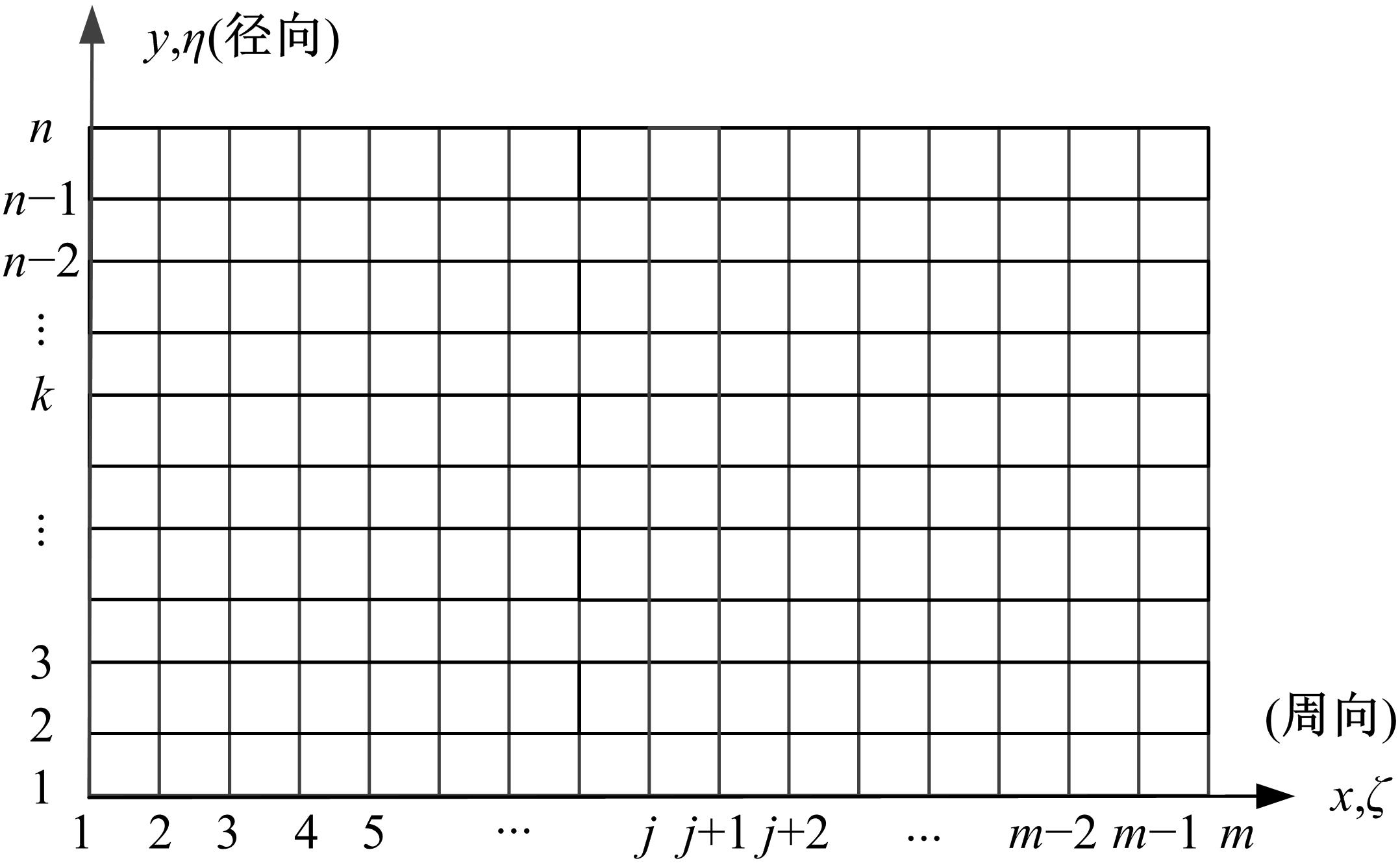

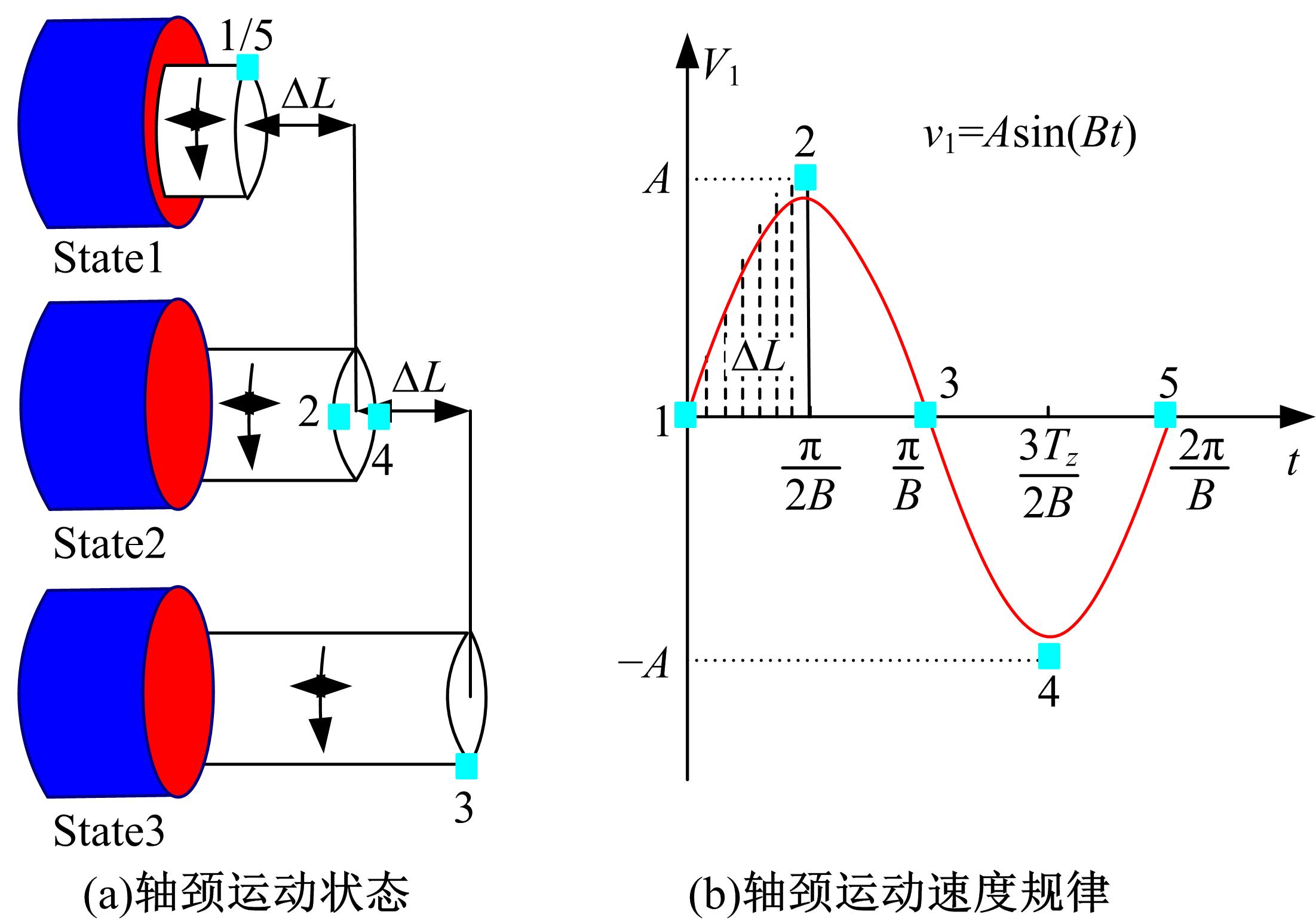

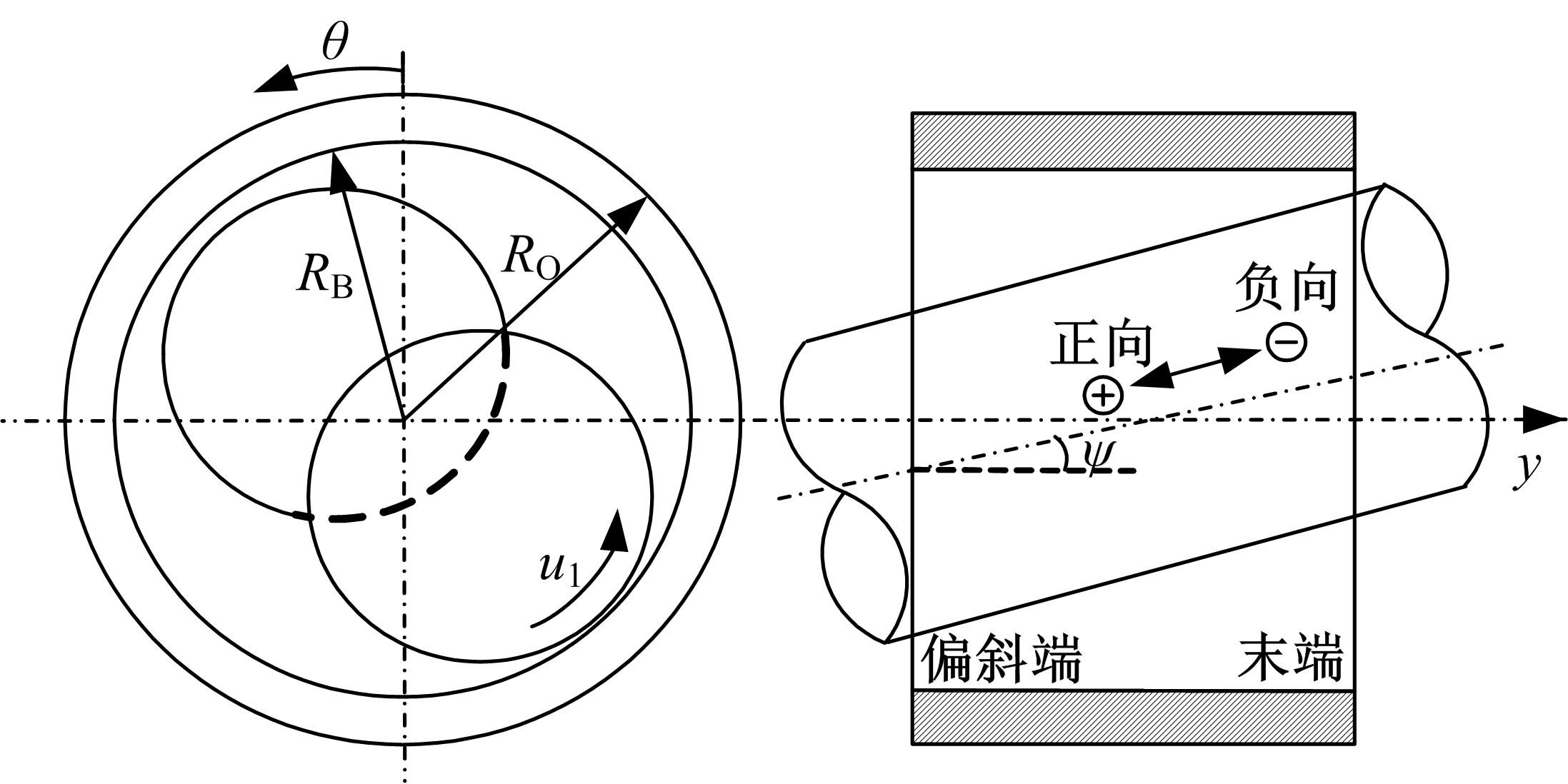

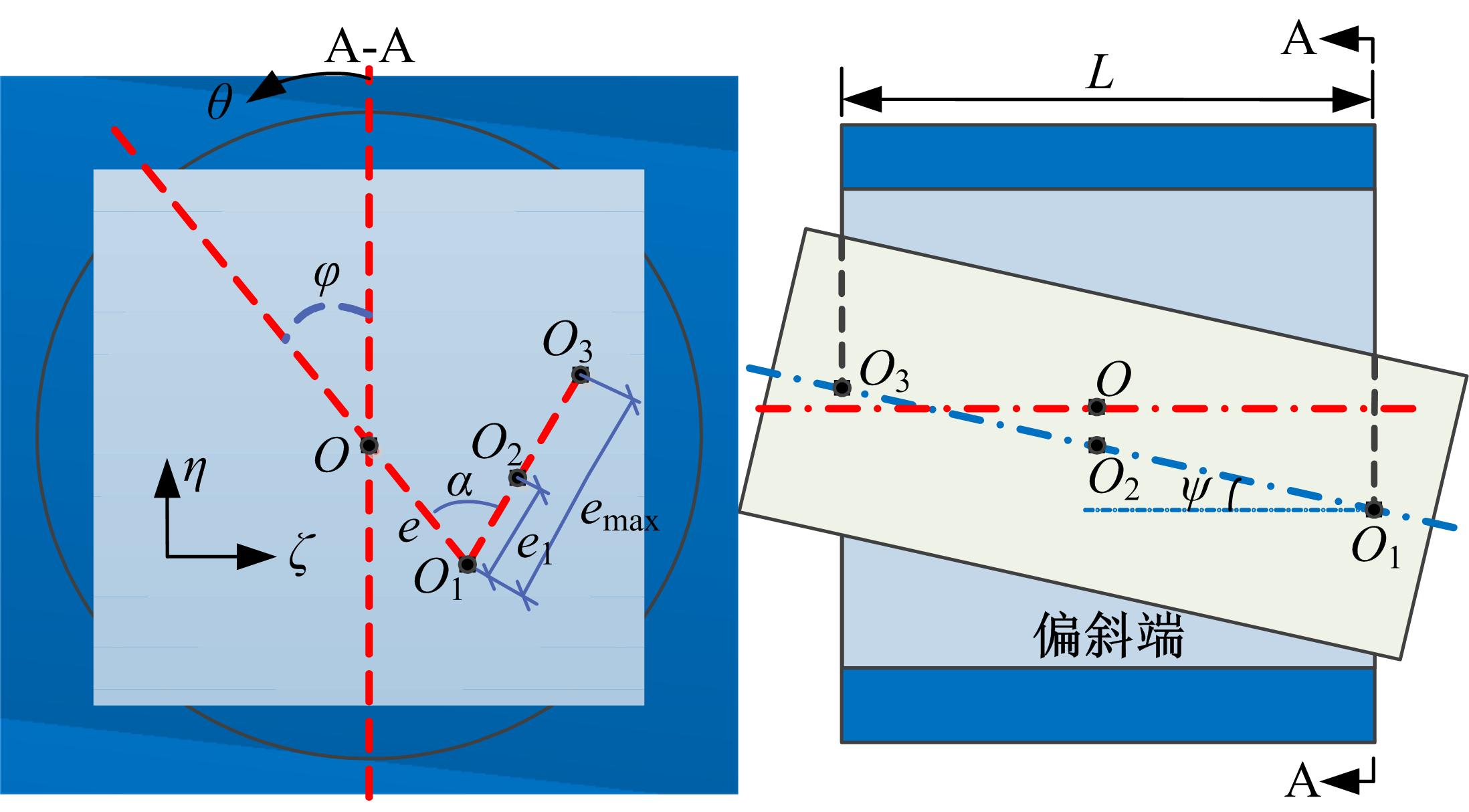

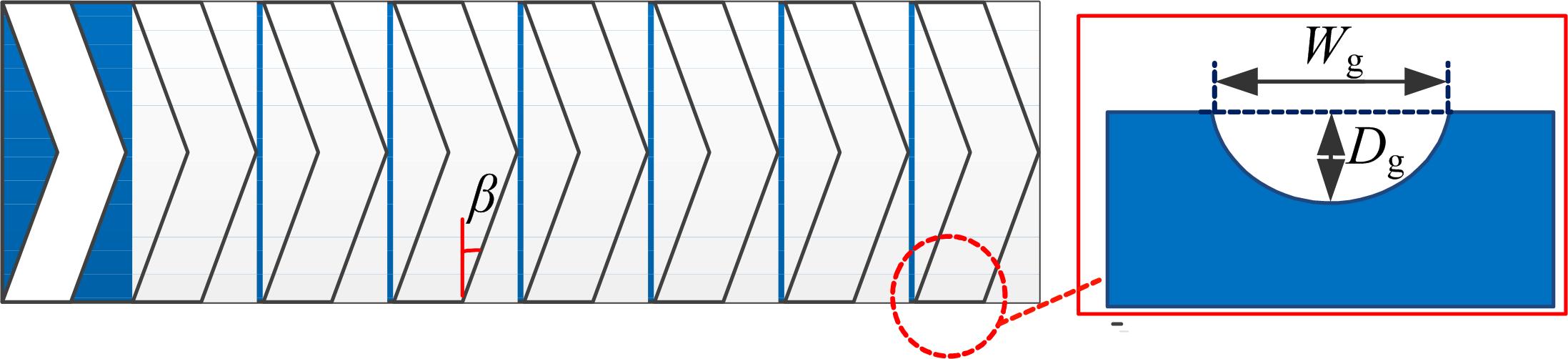

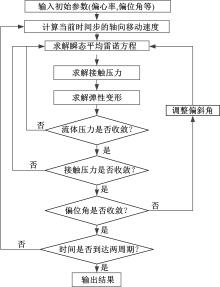

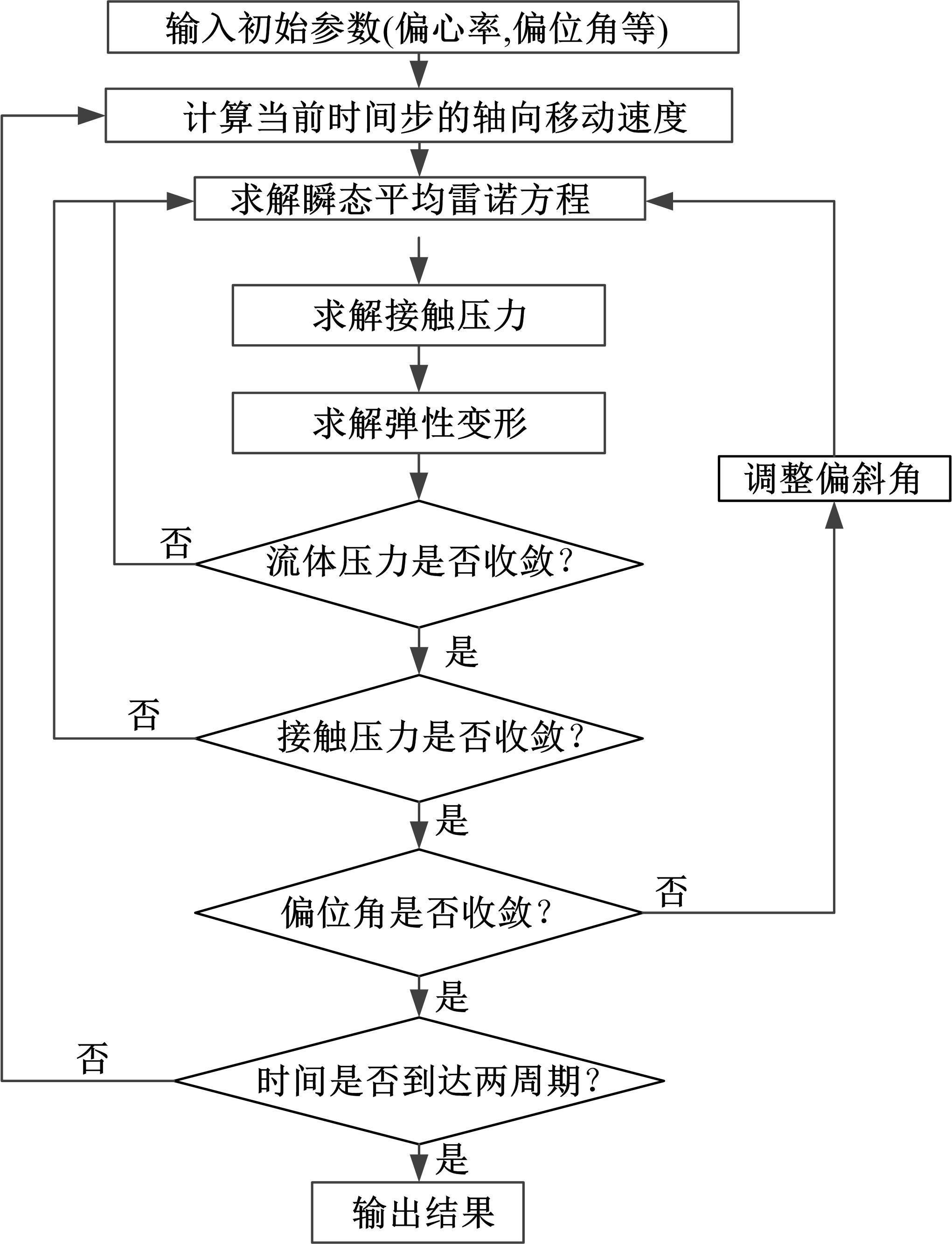

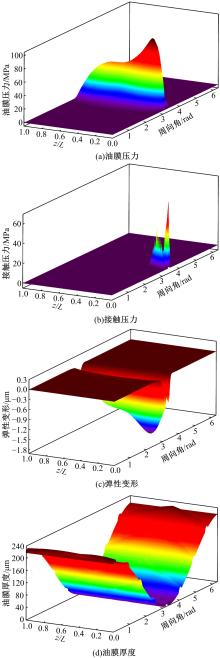

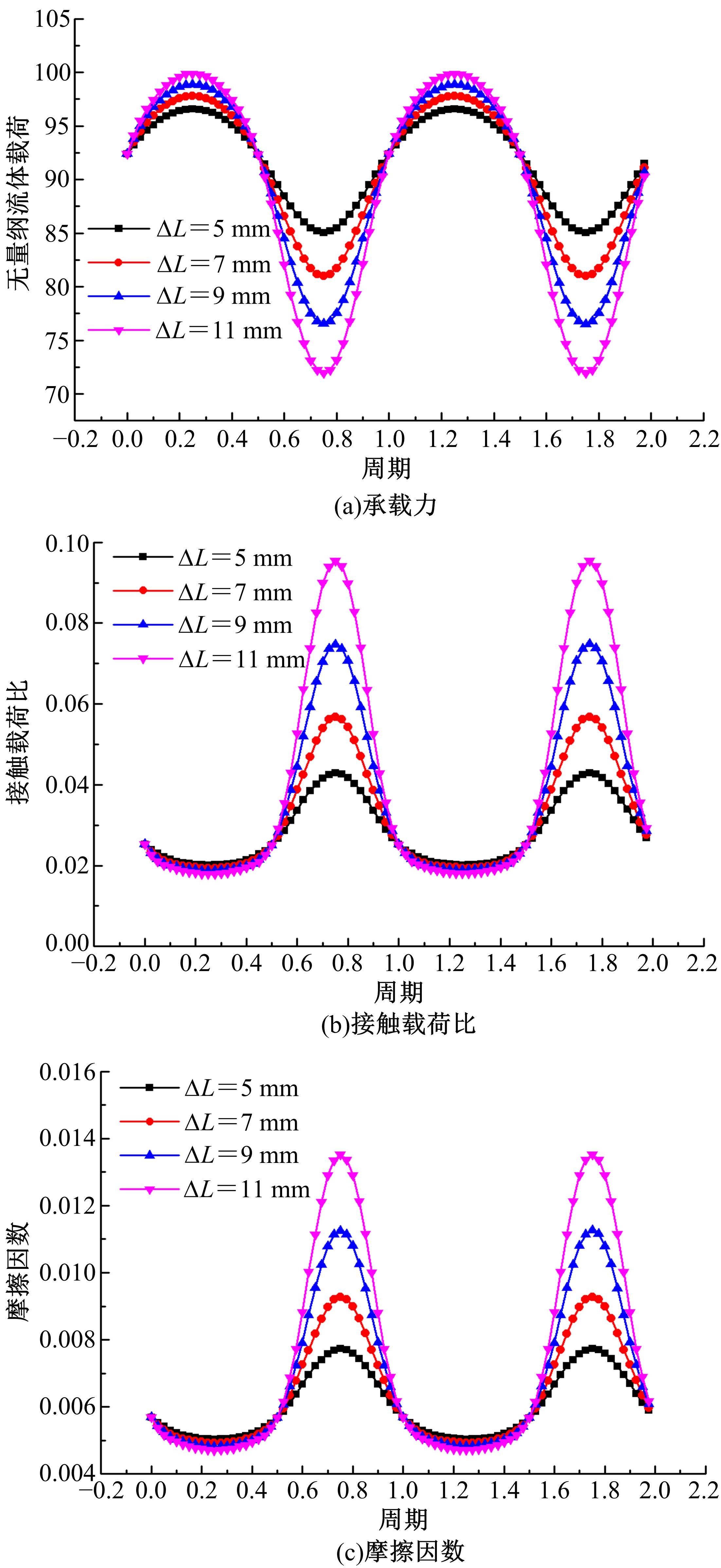

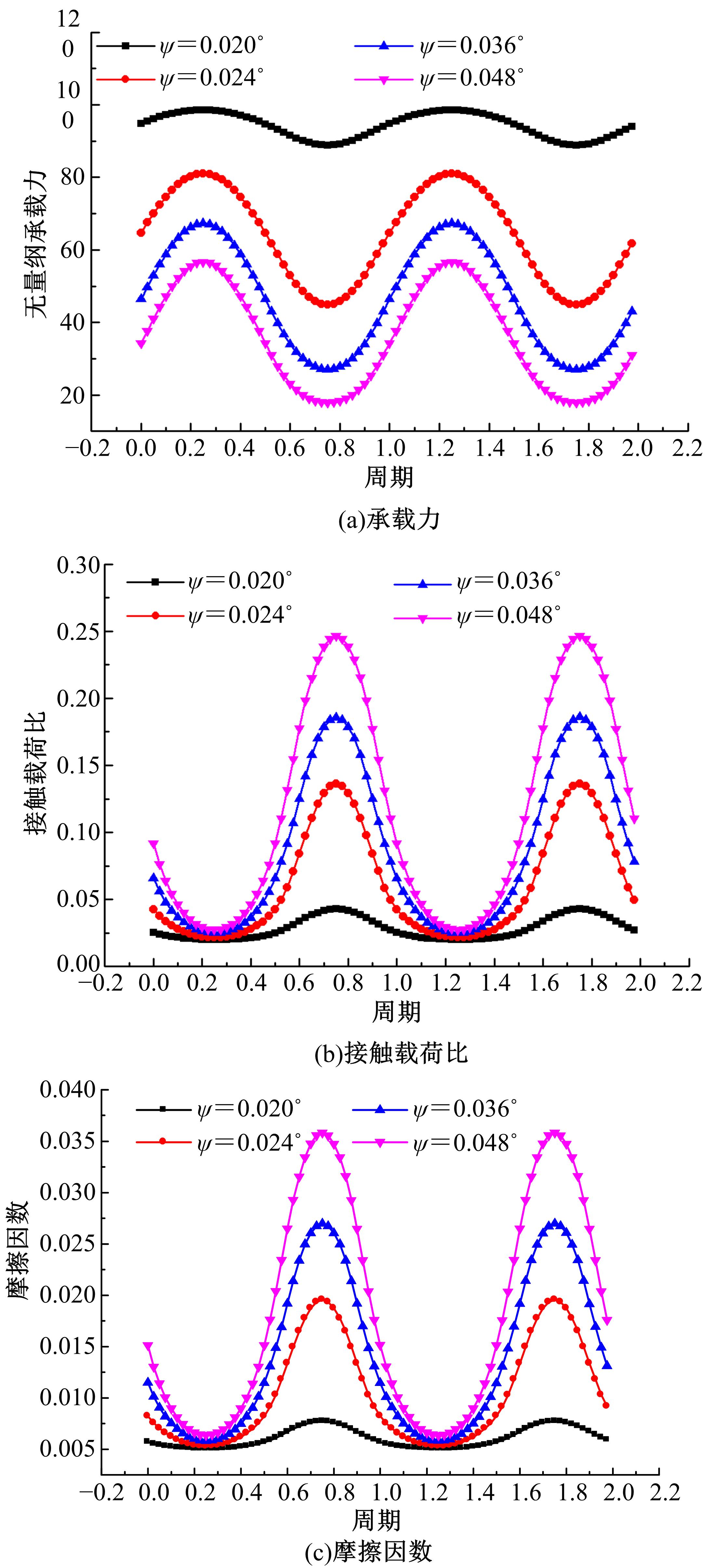

建立了考虑轴向往复运动以及轴颈偏斜的人字槽滑动轴承混合润滑(Mixed?EHL)数值模型。通过瞬态平均雷诺方程求解了考虑表面粗糙度效应的油膜压力,通过影响系数法求得轴瓦内表面弹性变形,而界面接触压力则由Lee?Ren粗糙峰接触模型求得。通过数值模拟得到了承载力、接触载荷比、摩擦因数等参数随时间的变化规律,并研究了往复运动间距及偏斜角对混合润滑性能的影响。研究表明:油膜力与轴向速度呈同相变化,接触载荷与轴向速度呈反相变化;随运动间距的增大,滑动轴承在反向运动历程中的承载能力和润滑性能显著降低;偏斜角增大会降低轴承的混合润滑性能以及承载能力。

中图分类号:

- TH133

| 1 | Smalley A J . Static and dynamic characteristics of the gas⁃lubricated spiral⁃grooved spool bearing for motion in the axial direction[J]. Journal of Tribology,1969,91:104⁃112. |

| 2 | Qiu Z L , Tieu A K . Misalignment effect on the static and dynamic characteristics of hydrodynamic journal bearings[J]. Journal of Tribology,1995,117(4):717⁃723. |

| 3 | Wang Y , Wang Q J , Lin C . A mixed⁃EHL analysis of effects of misalignments and elastic deformations on the performance of a coupled journal⁃thrust bearing system[J]. Tribology International,2006,39(4):281⁃289. |

| 4 | Sharma S C , Phalle V M , Jain S C . Combined influence of wear and misalignment of journal on the performance analysis of three⁃lobe three⁃pocket hybrid journal bearing compensated with capillary restrictor[J]. Journal of Tribology,2012,134(1):011703. |

| 5 | Rao T , Sawicki J T . Stability characteristics of herringbone grooved journal bearings incorporating cavitation effects[J]. Journal of Tribology,2004,126(2):281⁃287. |

| 6 | Lanes R F , Flack R D . Effects of three⁃lobe bearing geometries on flexible rotor stability[J]. ASLE Transactions,1982,25(3):377⁃385. |

| 7 | Usman A , Park C W . Numerical investigation of tribological performance in mixed lubrication of textured piston ring⁃liner conjunction with a non⁃circular cylinder bore[J]. Tribology International,2017,105:148⁃157. |

| 8 | Tang He⁃sheng , Ren Yan , Xiang Jia⁃wei . A novel model for predicting thermoelastohydrodynamic lubrication characteristics of slipper pair in axial piston pump[J]. International Journal of Mechanical Sciences,2017,124/125:109⁃121. |

| 9 | Ma X , Wang Q J , Lu X ,et al . A transient hydrodynamic lubrication model for piston/cylinder interface of variable length[J]. Tribology International,2018,118:227⁃239. |

| 10 | Patir N , Cheng H S . Effect of surface roughness orientation on the central film thickness in EHD contacts[C]∥Proceedings of the Fifth Leeds⁃Lyon Symposium on Tribology, Bury St. Edmunds, UK, 1979:15⁃21. |

| 11 | Shi F H , Wang Q . A mixed⁃TEHD model for journal⁃bearing conformal contacts—part I: model formulation and approximation of heat transfer considering asperity contact[J]. Journal of Tribology,1998,120(2):198⁃205. |

| 12 | Lee S C , Ren N . Behavior of elastic⁃plastic rough surface contacts as affected by surface topography, load, and material hardness[J]. Tribology Transactions,1996,39(1):67⁃74. |

| 13 | Wang Y , Zhang C , Wang Q J , et al . A mixed⁃TEHD analysis and experiment of journal bearings under severe operating conditions[J]. Tribology International,2002,35(6):395⁃407. |

| 14 | Hirs G G . The load capacity and stability characteristics of hydrodynamic grooved journal bearings[J]. Tribology Transactions,1965,8(3):296⁃305. |

| 15 | Wang Q , Shi F H , Lee S C . A mixed⁃TEHD model for journal⁃bearing conformal contact—part II: contact, film thickness, and performance analyses[J]. Journal of Tribology,1998,120(2):206⁃213. |

| [1] | 刘坤,吉硕,孙震源,徐洪伟,刘勇,赵静霞. 多功能坐站辅助型如厕轮椅机械结构设计与优化[J]. 吉林大学学报(工学版), 2019, 49(3): 872-880. |

| [2] | 王兴野,张进秋,李国强,彭志召. 惯性质量对齿轮齿条式作动器阻尼特性的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 881-887. |

| [3] | 毕秋实,王国强,黄婷婷,毛瑞,鲁艳鹏. 基于DEM-FEM耦合的双齿辊破碎机辊齿强度分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1770-1776. |

| [4] | 朱伟,王传伟,顾开荣,沈惠平,许可,汪源. 一种新型张拉整体并联机构刚度及动力学分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1777-1786. |

| [5] | 刘建芳, 王记波, 刘国君, 李新波, 梁实海, 杨志刚. 基于PMMA内嵌三维流道的压电驱动微混合器[J]. 吉林大学学报(工学版), 2018, 48(5): 1500-1507. |

| [6] | 毛宇泽, 王黎钦. 鼠笼支撑一体化结构对薄壁球轴承承载性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1508-1514. |

| [7] | 王涛, 伞晓刚, 高世杰, 王惠先, 王晶, 倪迎雪. 光电跟踪转台垂直轴系动态特性[J]. 吉林大学学报(工学版), 2018, 48(4): 1099-1105. |

| [8] | 贺继林, 陈毅龙, 吴钪, 赵喻明, 汪志杰, 陈志伟. 起重机卷扬系统能量流动分析及势能回收系统实验[J]. 吉林大学学报(工学版), 2018, 48(4): 1106-1113. |

| [9] | 谢传流, 汤方平, 孙丹丹, 张文鹏, 夏烨, 段小汇. 立式混流泵装置压力脉动的模型试验分析[J]. 吉林大学学报(工学版), 2018, 48(4): 1114-1123. |

| [10] | 孙秀荣, 董世民, 王宏博, 李伟成, 孙亮. 整体抽油杆柱在油管内空间屈曲的多段式仿真模型对比[J]. 吉林大学学报(工学版), 2018, 48(4): 1124-1132. |

| [11] | 吉野辰萌, 樊璐璐, 闫磊, 徐涛, 林烨, 郭桂凯. 基于MBNWS算法的假人胸部结构多目标优化设计[J]. 吉林大学学报(工学版), 2018, 48(4): 1133-1139. |

| [12] | 刘坤, 刘勇, 闫建超, 吉硕, 孙震源, 徐洪伟. 基于体外传感检测的人体站起动力学分析[J]. 吉林大学学报(工学版), 2018, 48(4): 1140-1146. |

| [13] | 刘志峰, 赵代红, 王语莫, 浑连明, 赵永胜, 董湘敏. 重载静压转台承载力与油垫温度场分布的关系[J]. 吉林大学学报(工学版), 2018, 48(3): 773-780. |

| [14] | 曹婧华, 孔繁森, 冉彦中, 宋蕊辰. 基于模糊自适应PID控制的空压机背压控制器设计[J]. 吉林大学学报(工学版), 2018, 48(3): 781-786. |

| [15] | 李锐, 张路阳, 刘琳, 武粤元, 陈世嵬. 基于相似理论的三跨桥梁磁流变隔振[J]. 吉林大学学报(工学版), 2018, 48(3): 787-795. |

|