吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (4): 1204-1212.doi: 10.13229/j.cnki.jdxbgxb20200372

• 车辆工程·机械工程 • 上一篇

装载机卸载工况动臂油缸回缩现象分析

- 吉林大学 机械与航空航天工程学院,长春 130022

Analysis on retracting phenomenon of boom cylinder of loader under unloading condition

Peng TAN( ),Xin-hui LIU,Wei CHEN(

),Xin-hui LIU,Wei CHEN( ),Bing-wei CAO,Kuo YANG

),Bing-wei CAO,Kuo YANG

- College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

摘要:

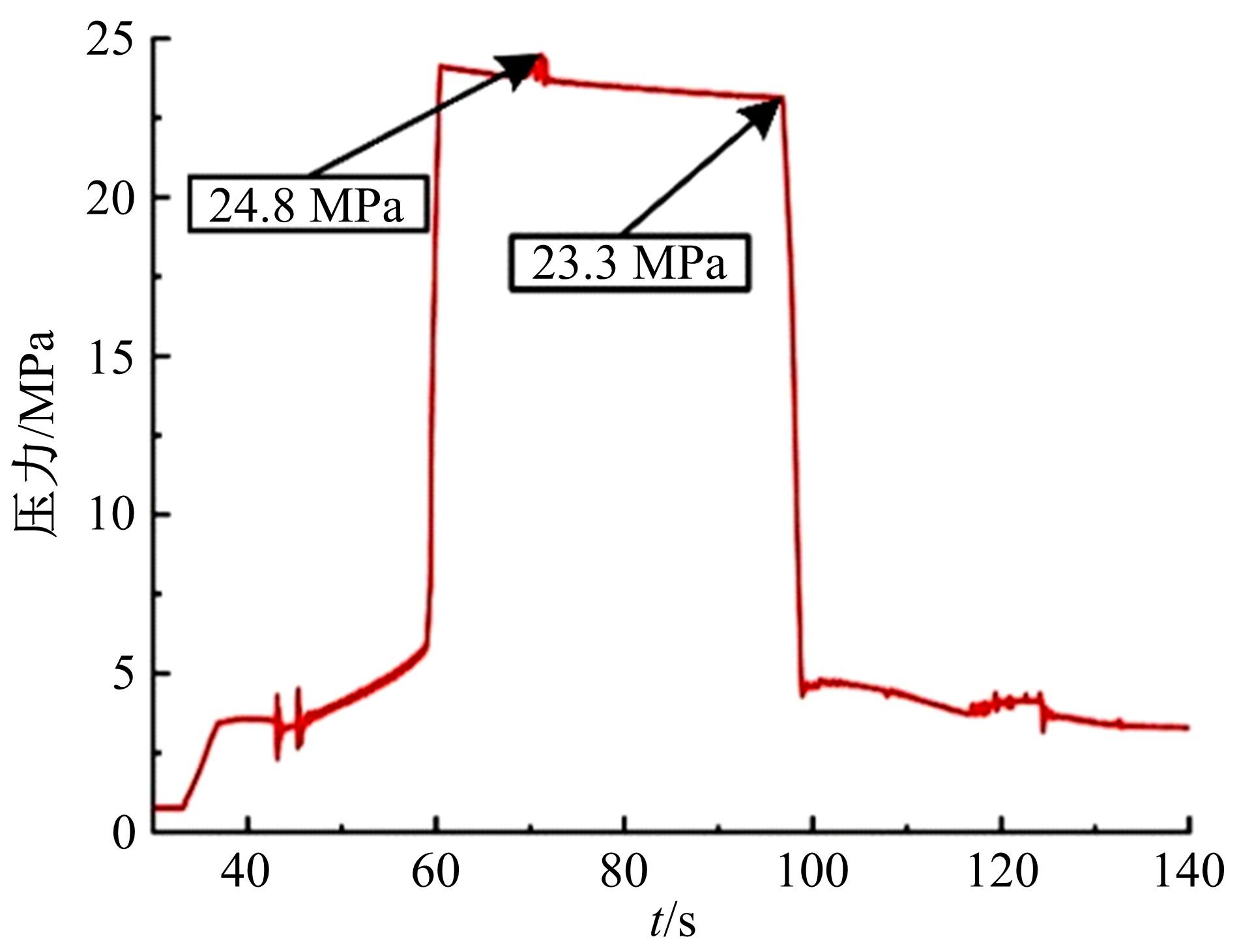

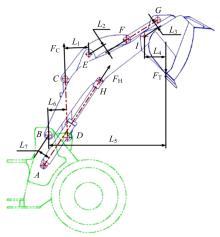

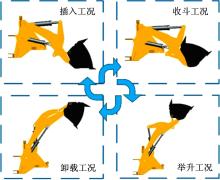

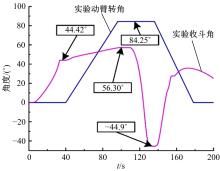

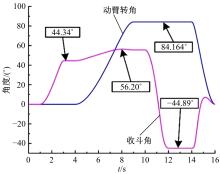

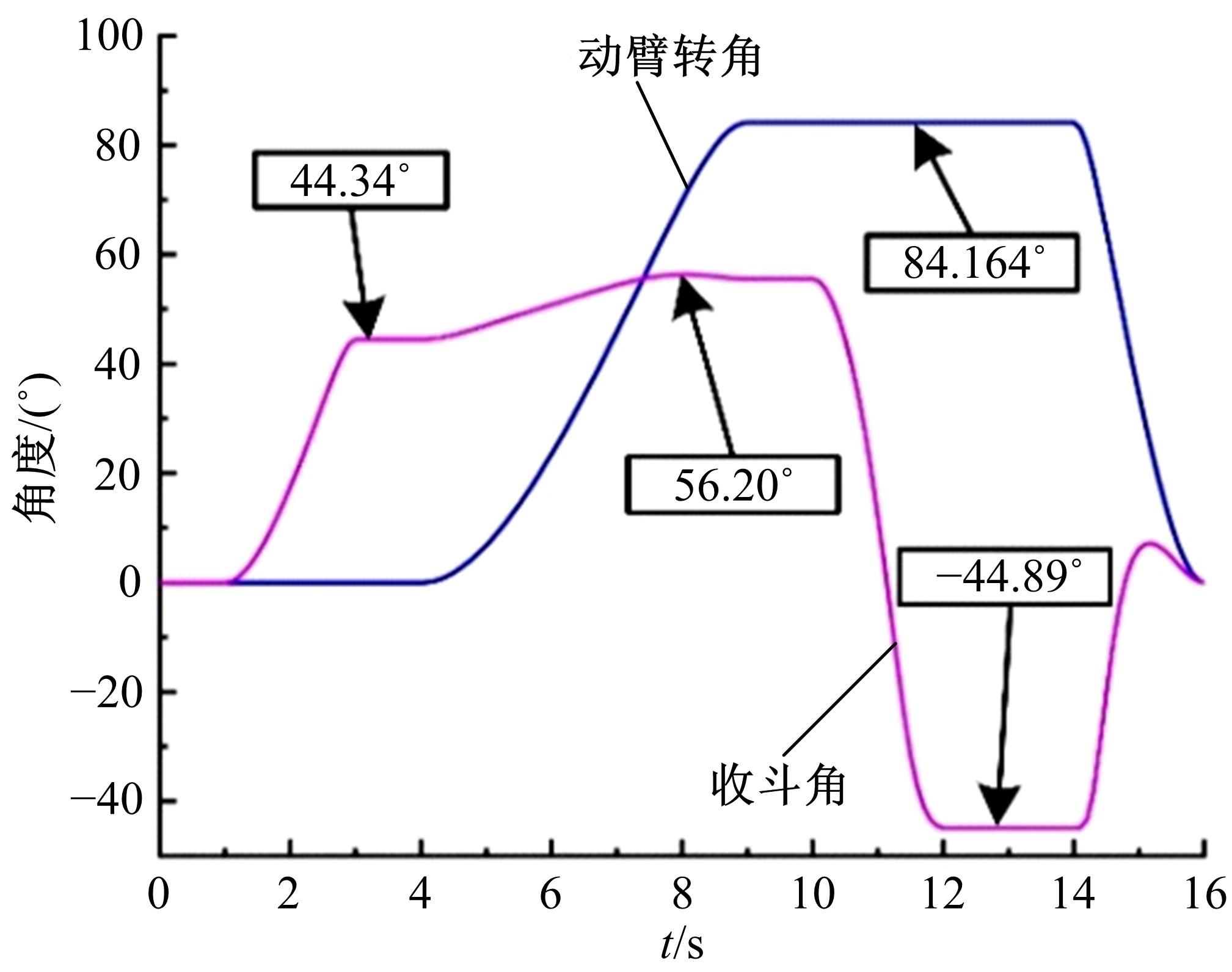

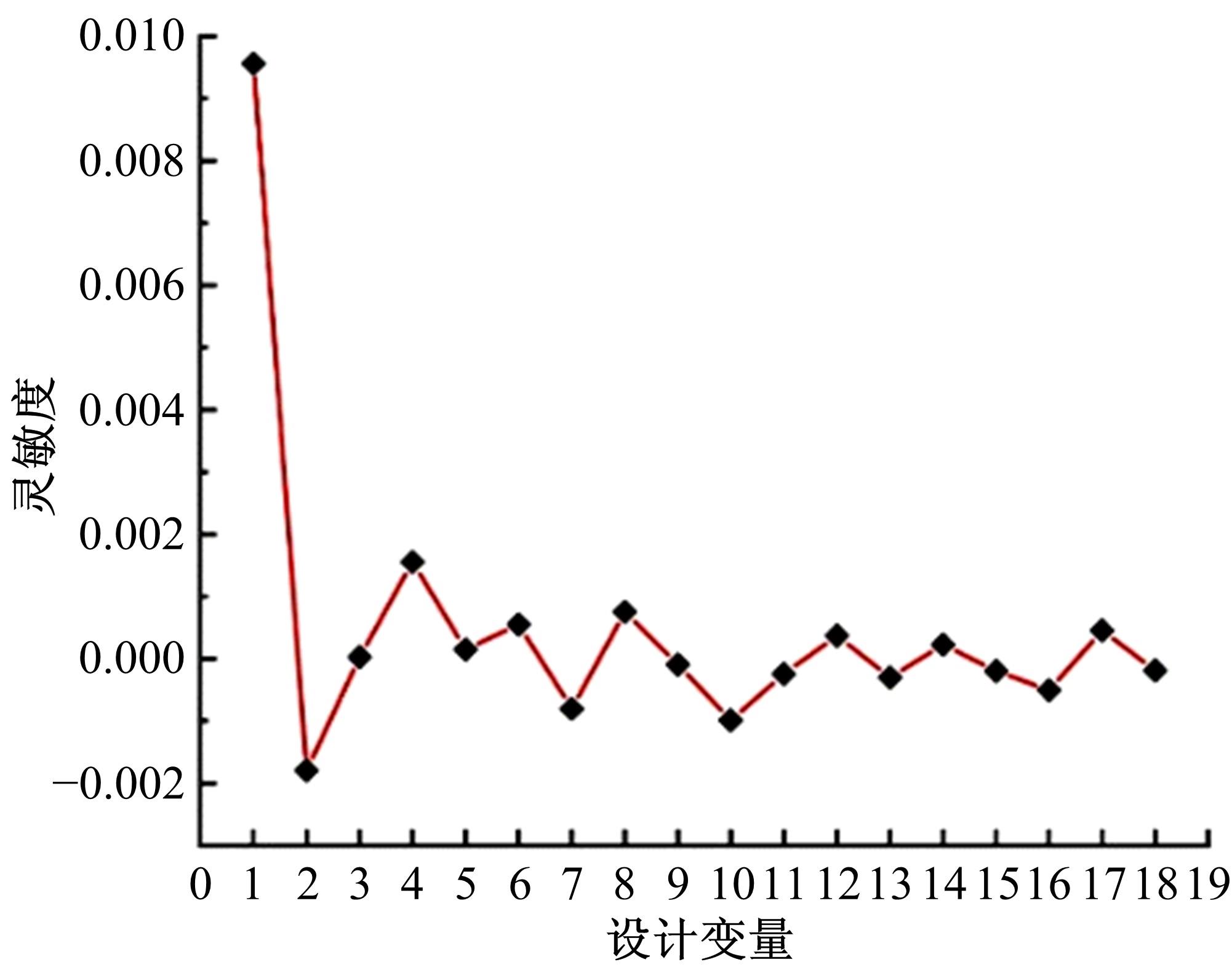

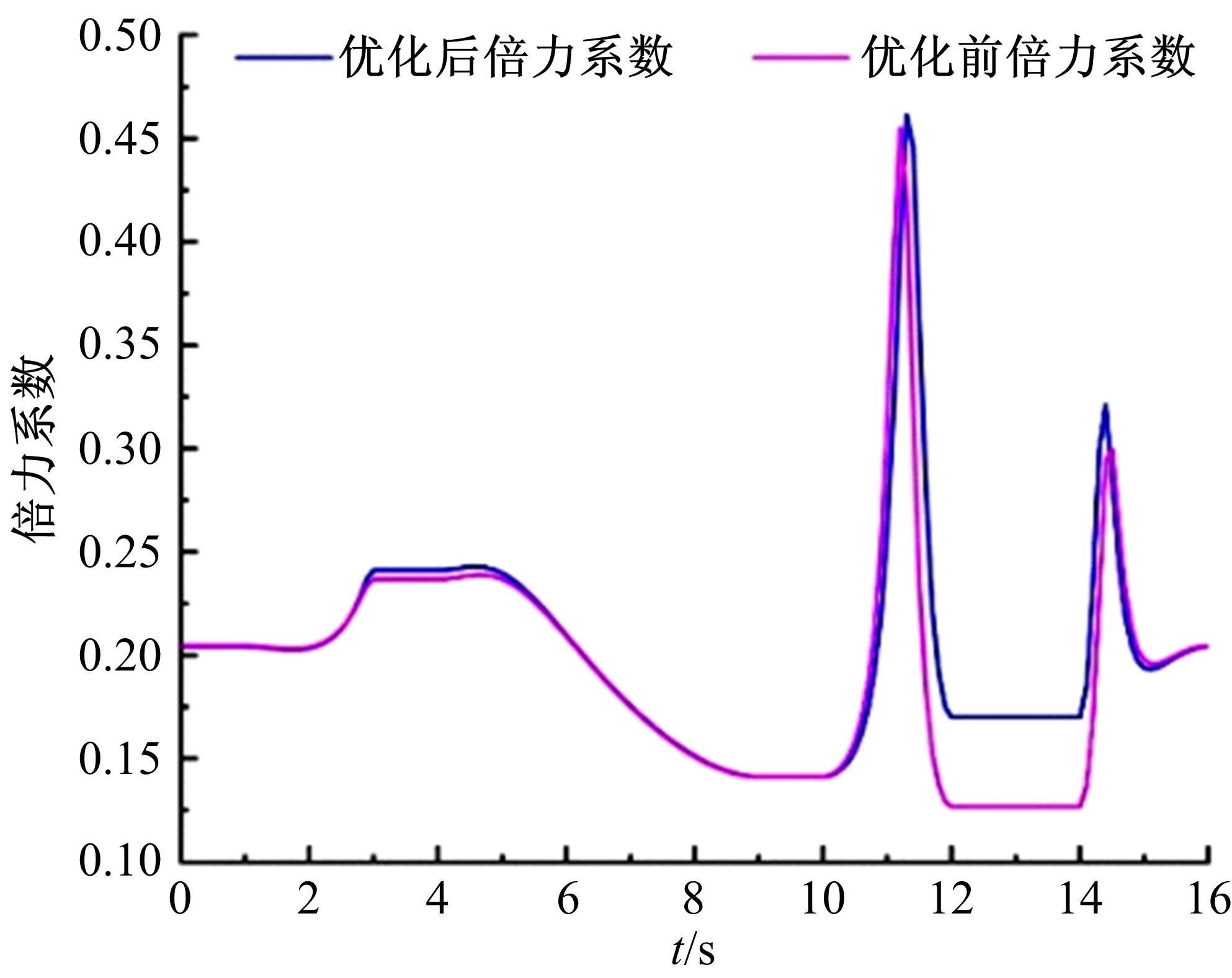

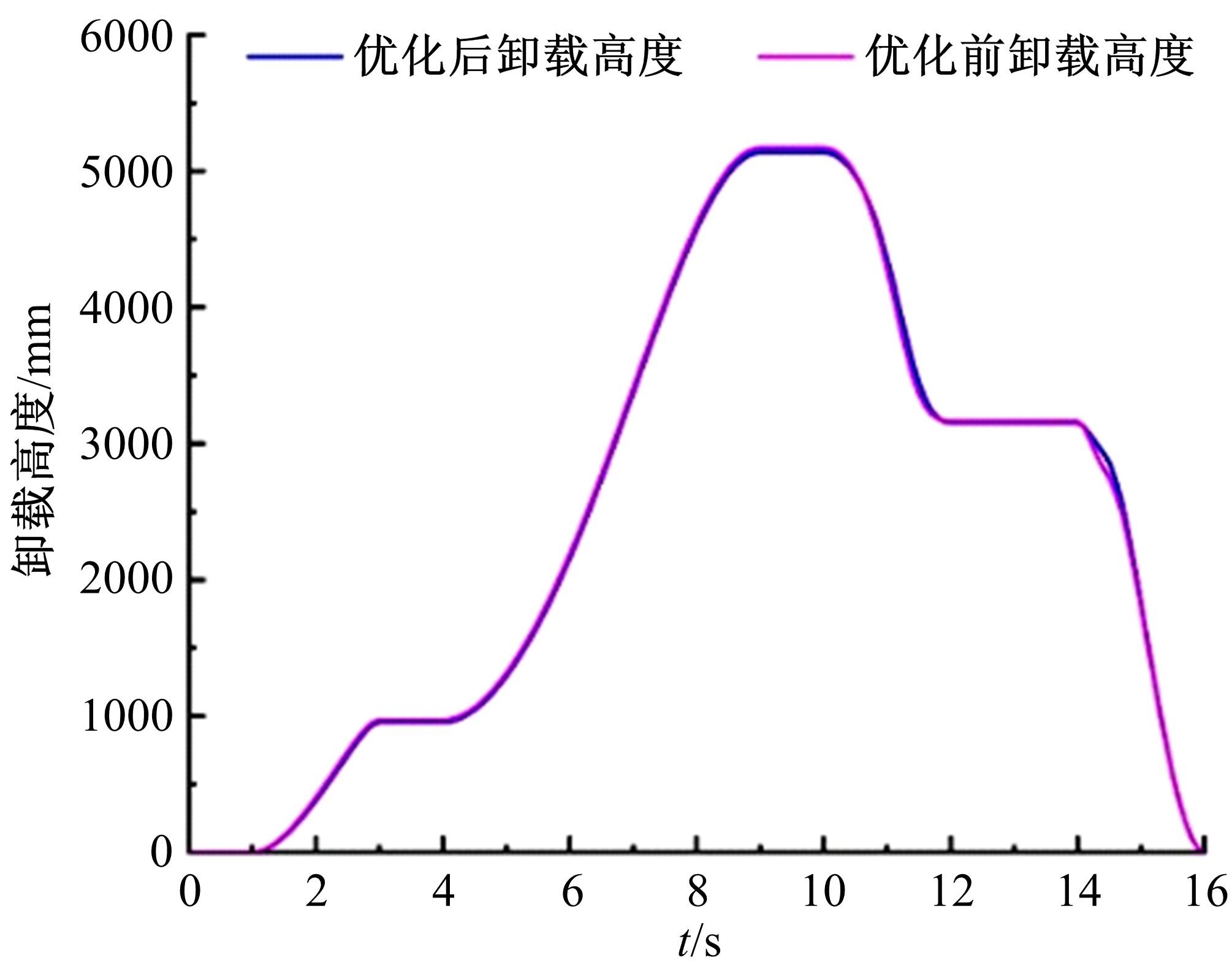

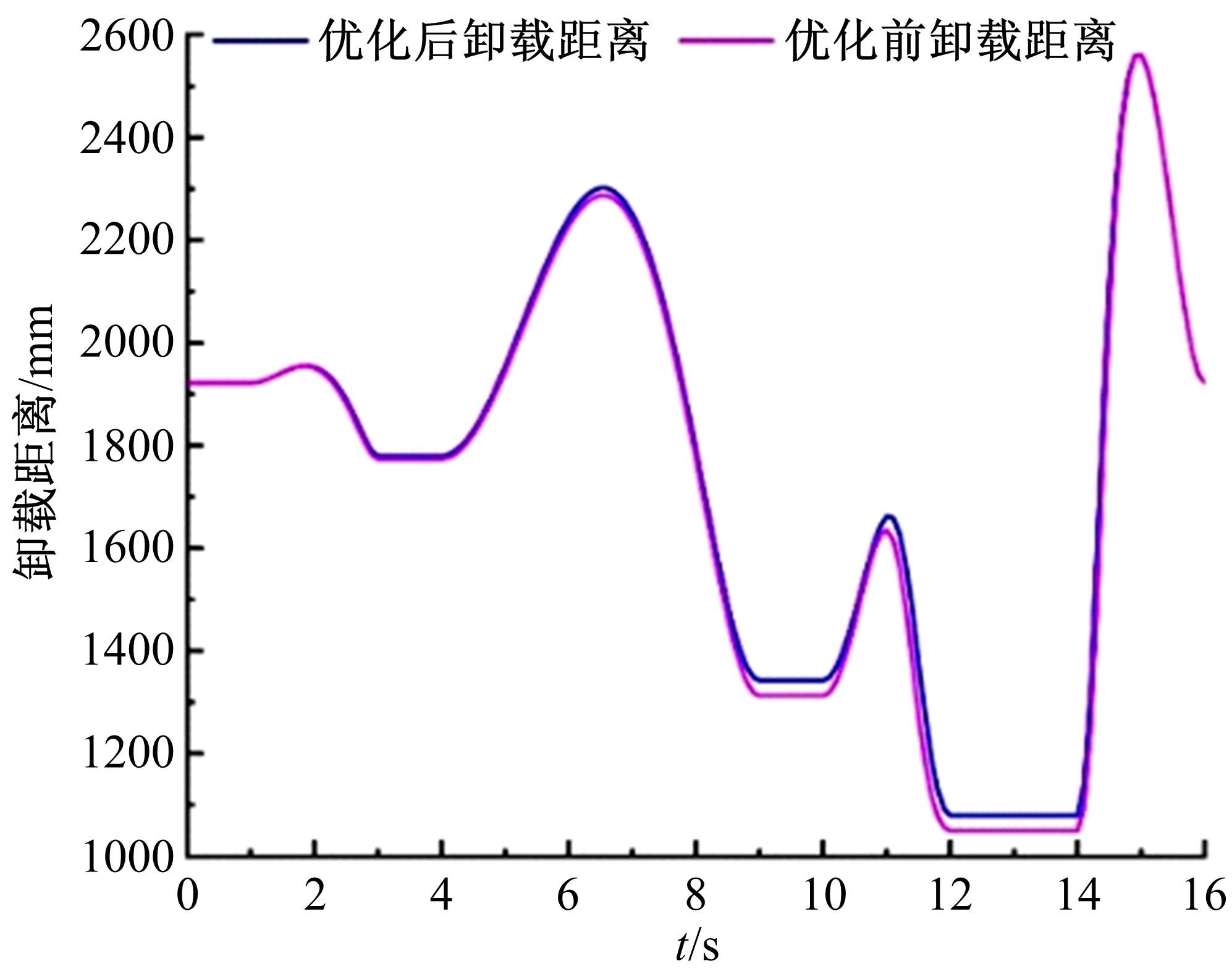

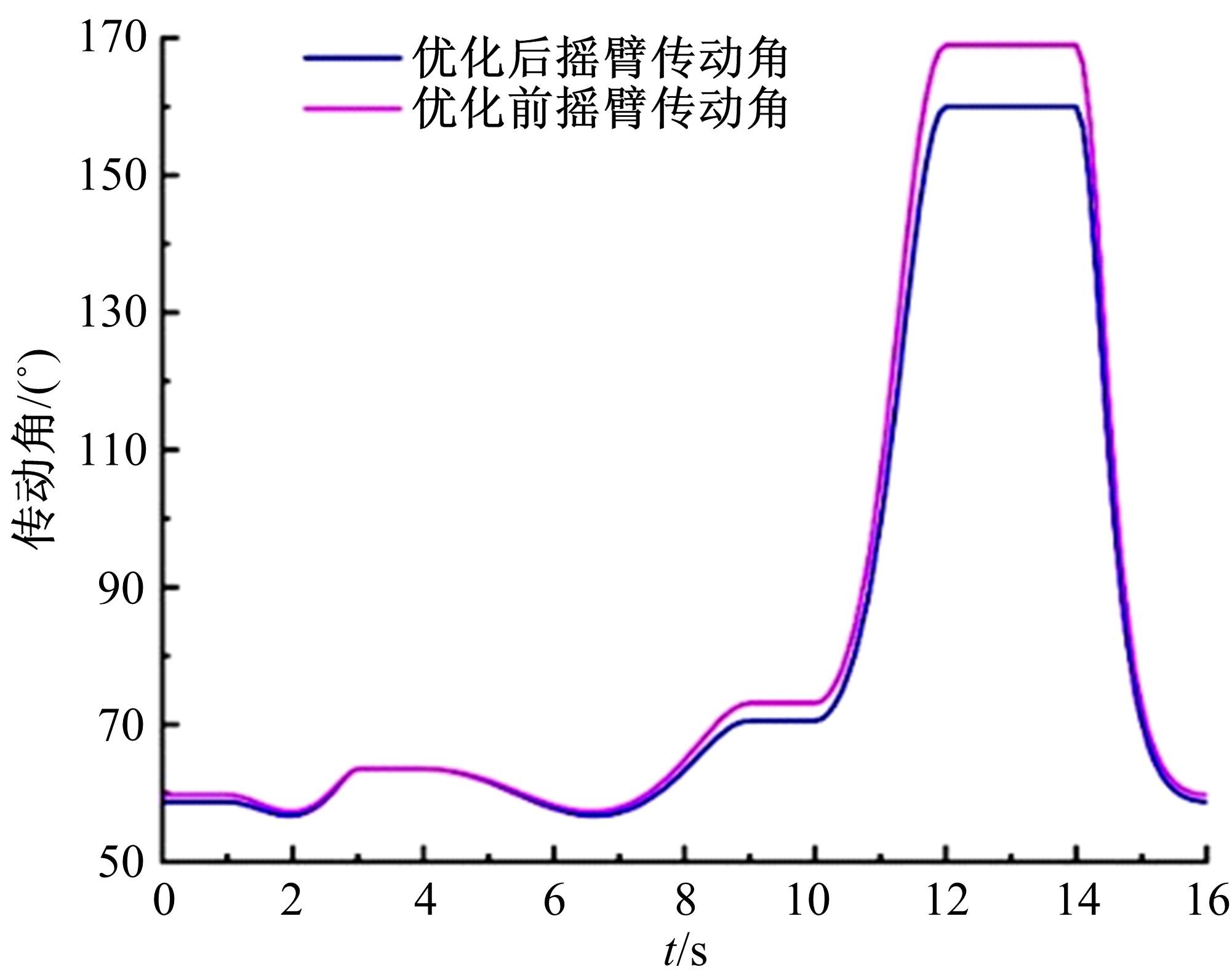

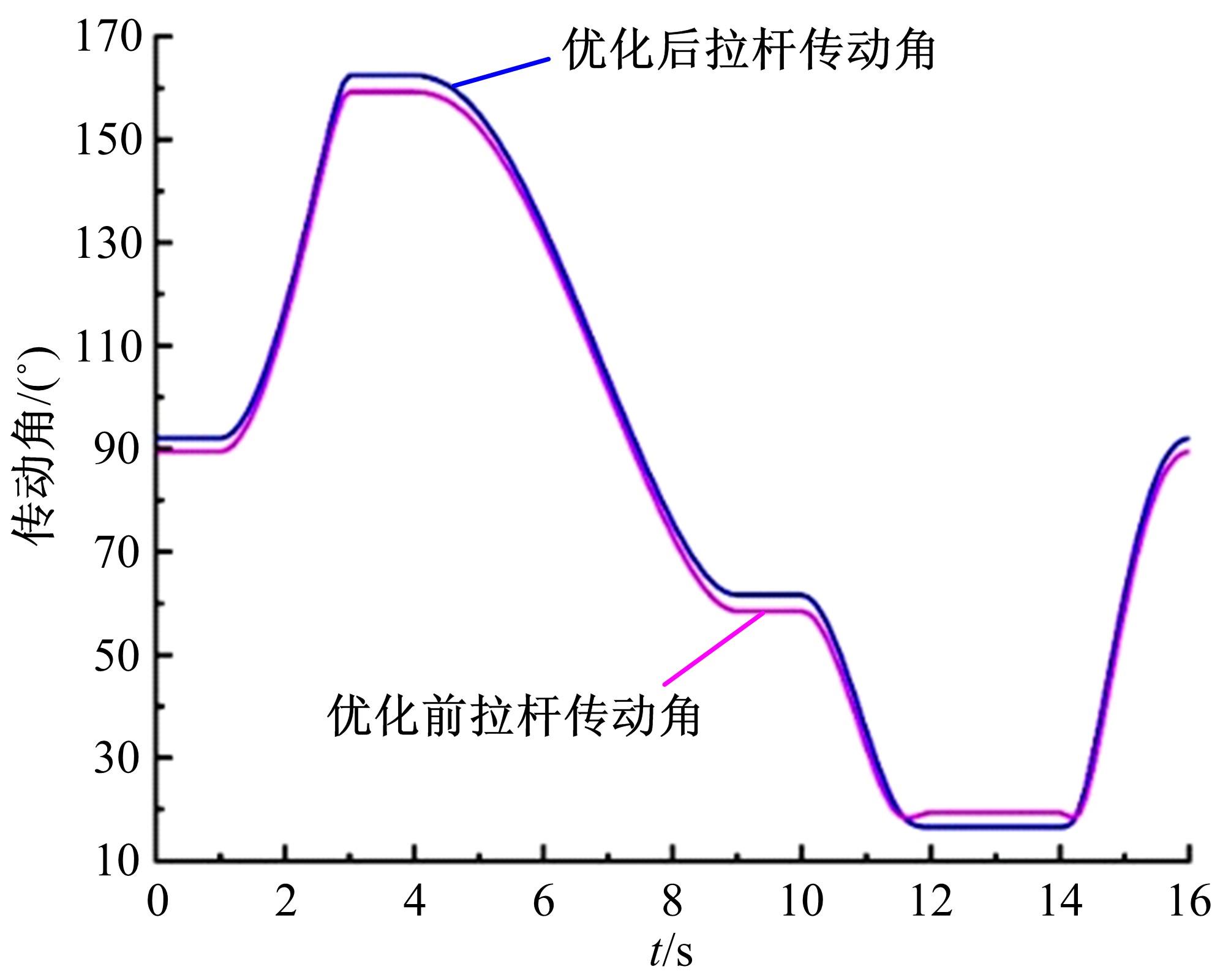

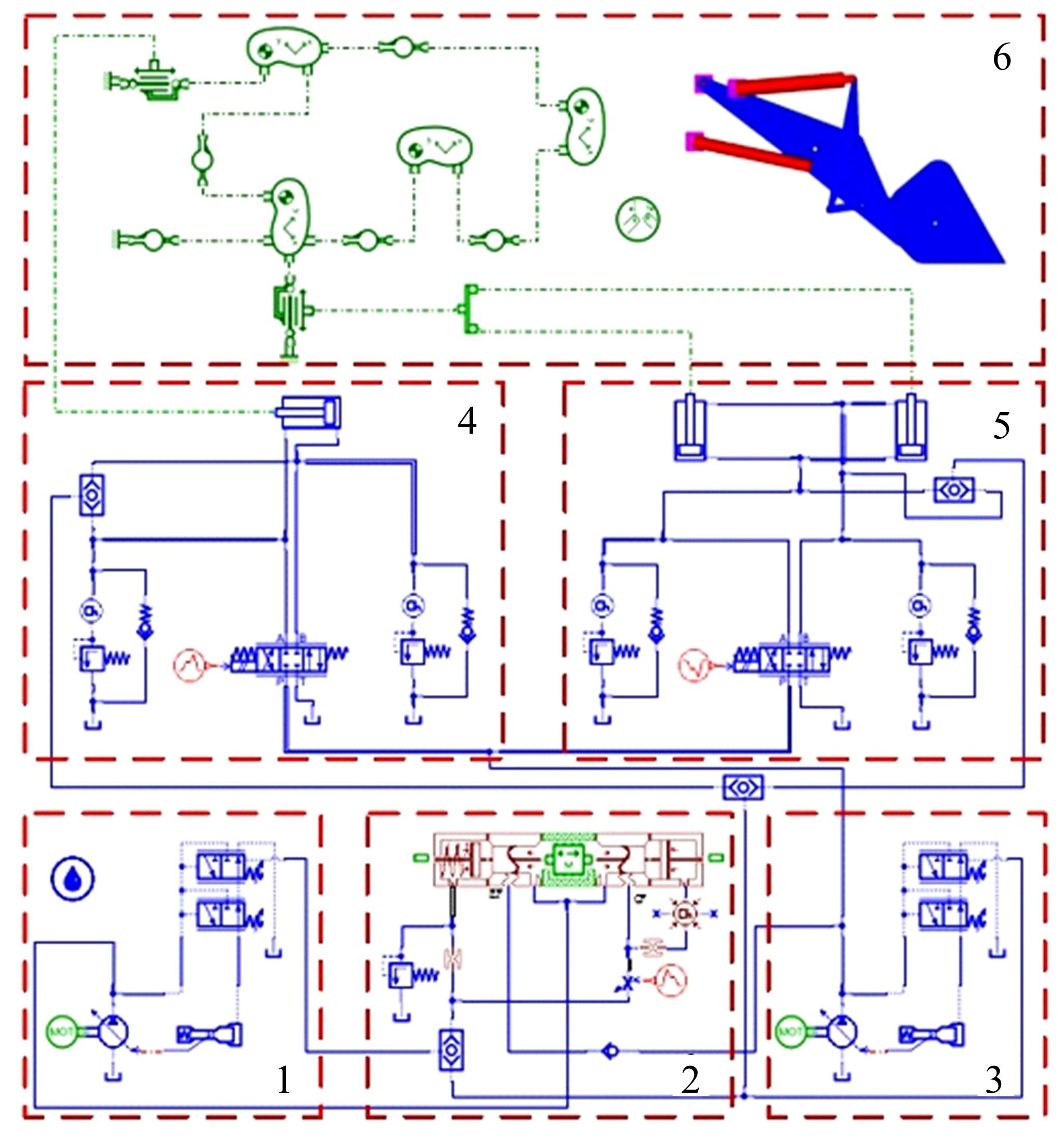

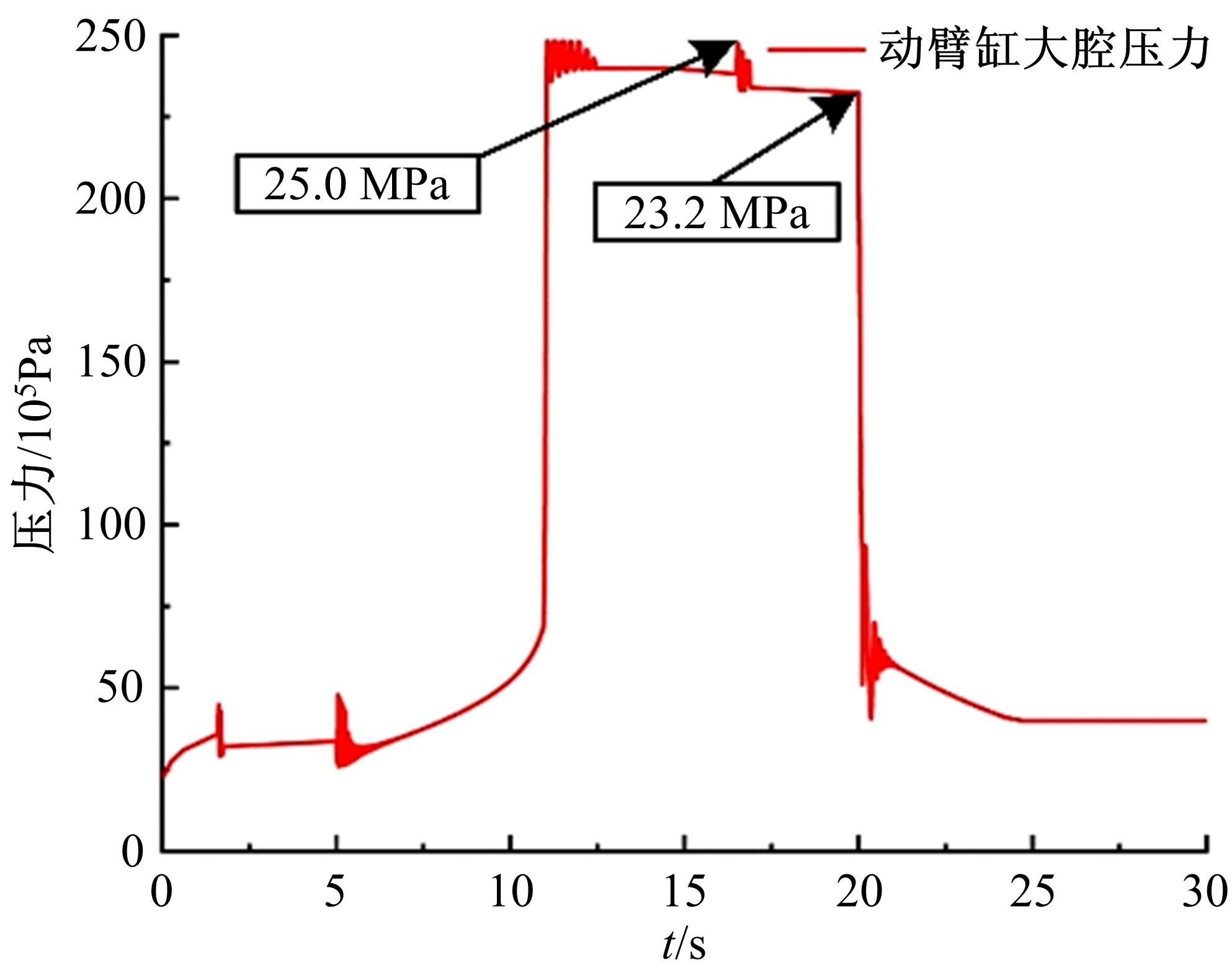

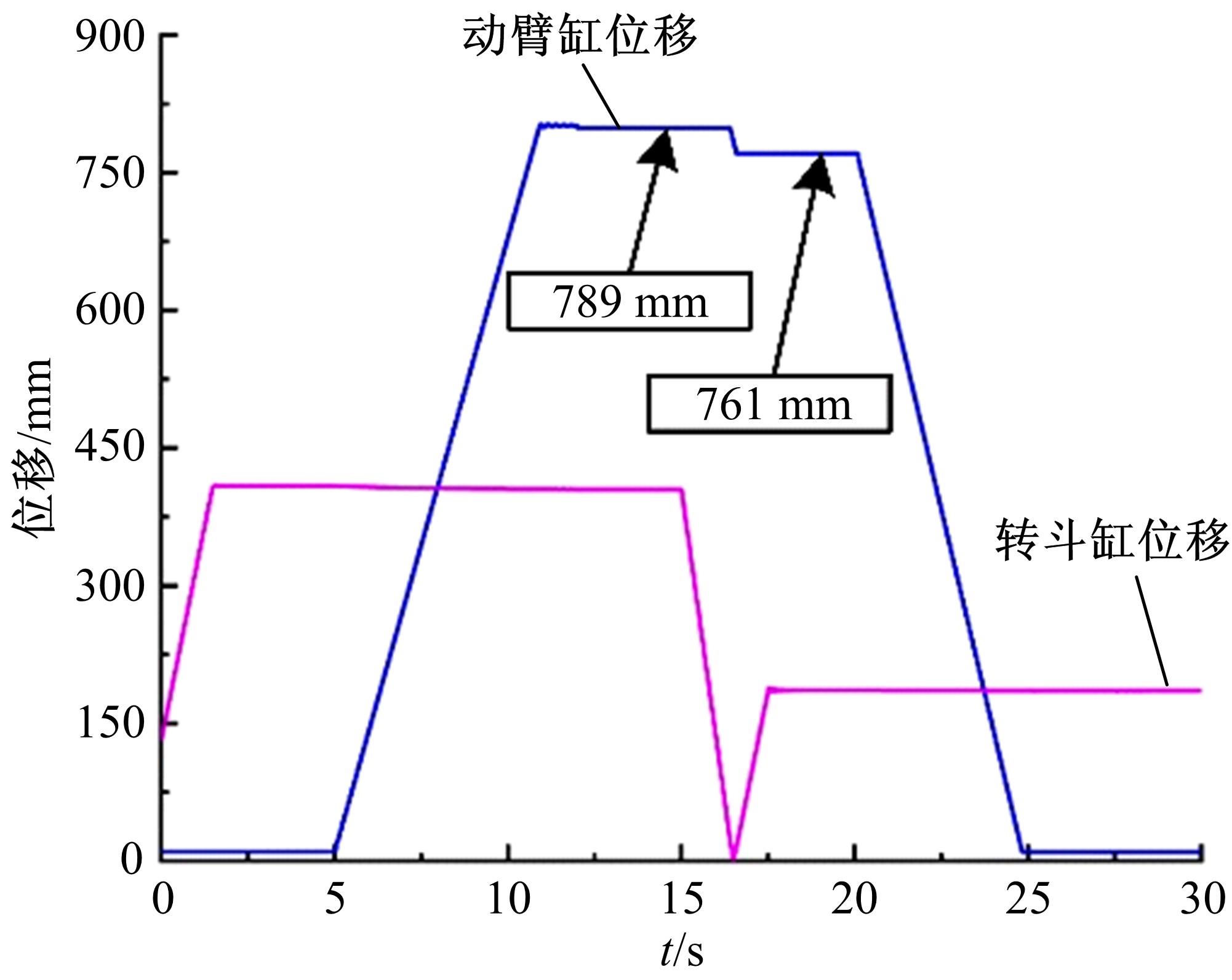

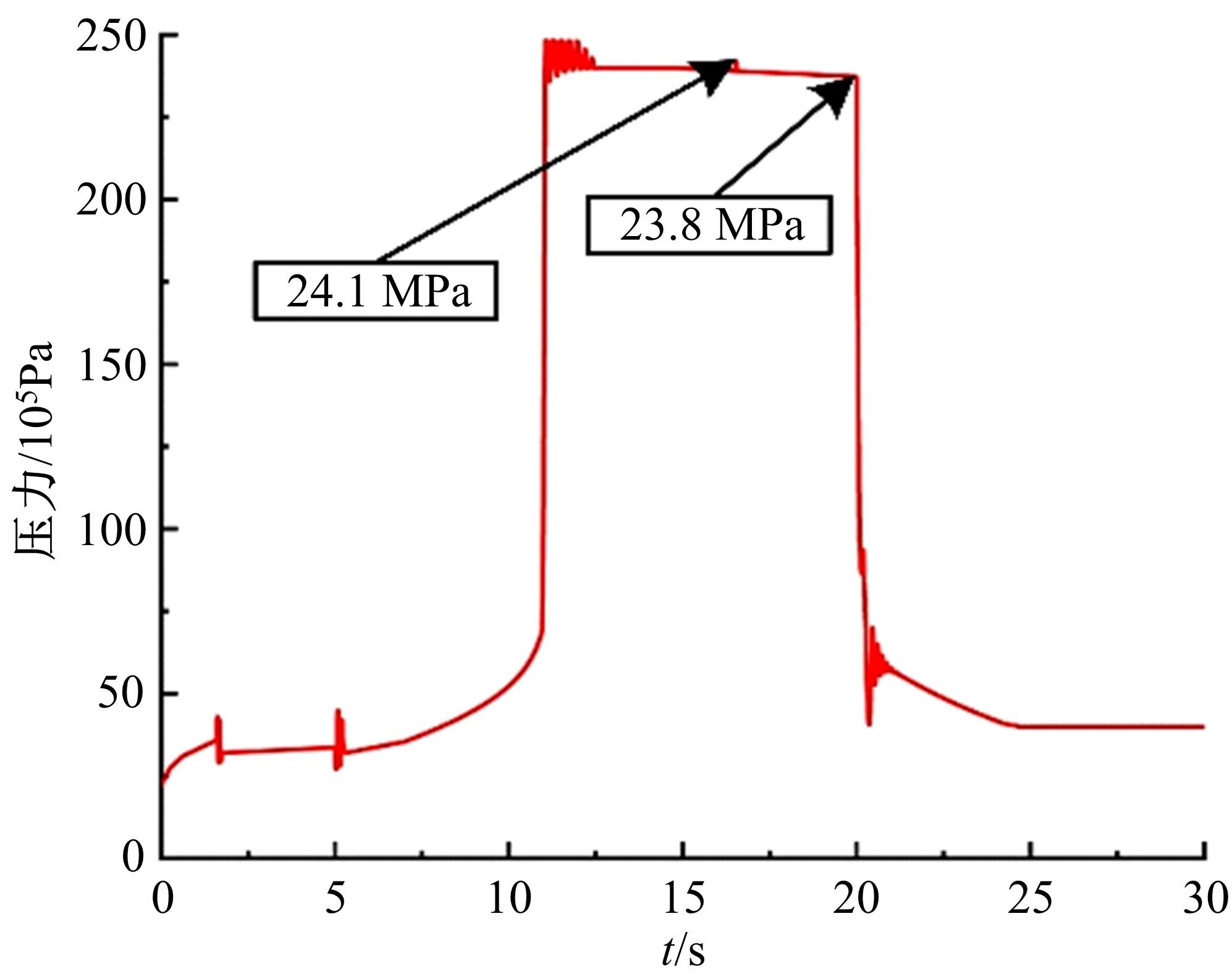

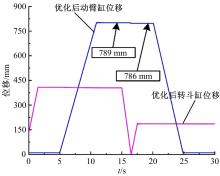

针对装载机在最高位置卸载工况下动臂油缸的回缩现象进行了机理分析,提出一种基于ADAMS优化举升机构倍力系数从而解决动臂油缸回缩的方法。搭建了工作机构运动学ADAMS仿真模型及工作液压系统AMEsim仿真模型,并通过实验验证了仿真模型的正确性。构建目标函数及约束函数后,通过ADAMS寻优得到新的的工作机构铰点坐标。仿真优化结果表明,在满足装载机其他工作性能的前提下,卸载工况举升倍力系数提高了30.8%,动臂油缸回缩量减小了89.3%,为今后工作机构的设计提供了理论基础。

中图分类号:

- TH243

| 1 | 于向军,槐元辉,李学飞,等. 基于克里金和粒子群算法的装载机铲掘轨迹规划[J]. 吉林大学学报:工学版, 2020, 50(2):437-444. |

| Yu Xiang-jun, Huai Yuan-hui, Li Xue-fei, et al. Trajectory planning of loader excavation based on Kriging and particle swarm optimization algorithm[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(2): 437-444. | |

| 2 | 张英爽,王国强,王继新,等.轮式装载机半轴载荷谱编制及疲劳寿命预测[J]. 吉林大学学报:工学版, 2011, 41(6):646-651. |

| Zhang Ying-shuang, Wang Guo-qiang, Wang Ji-xin, et al. Compilation of half axle load spectrum and fatigue life prediction of wheel loader[J]. Journal of Jilin University (Engineering and Technology Edition), 2011, 41 (6): 646-651. | |

| 3 | 杨蓉, 林桂娟. 轮式装载机工作装置仿真设计与强度分析[J]. 南方农机, 2020, 51(1):15-17. |

| Yang Rong, Lin Gui-juan. Simulation design and strength analysis of the working device of the wheel loader [J] .Southern Agricultural Machinery, 2020,51 (1): 15-17. | |

| 4 | Gui Ju, Cai Yuan. Dynamic simulation analysis on loader's working device[J]. Taylor & Francis, 2018, 16(20):1-7. |

| 5 | Wan Yi-pin. Structural strength analysis of the loader working device based on finite element method[C]∥ Proceedings of 3rd International Conference on Engineering Technology and Application,Lisbon, Portugal, 2016:787-792. |

| 6 | Shen Jun-li, Wang Guo-qiang, et al. A comprehensive genetic algorithm for design optimization of Z-bar loader working mechanism[J]. Springer Netherlands, 2013, 27(11): 3381-3394. |

| 7 | 孟凡旺,焦圣德,张光耀,等. 装载机工作装置优化设计研究[J]. 建筑机械化, 2018, 39(2):26-28. |

| Meng Fan-wang, Jiao Sheng-de, Zhang Guang-yao, et al. Research on optimization design of working device of loader[J]. Mechanization of Construction, 2018, 39(2): 26-28. | |

| 8 | 郑德超,刘锋.装载机反转六杆式工作装置的优化设计[J].煤矿机械,2014, 35(10):19-20. |

| Zheng De-chao, Liu Feng. Optimized design of loader reverse six-bar working device[J]. Coal Mine Machinery, 2014, 35(10): 19-20. | |

| 9 | Yang Hua-lin, Zhang Tong-qiang, Gao Gong-ru. Optimization design study of loader working mechanism based on MATLAB complex method[J]. Applied Mechanics and Materials, 2013,397-400:1034-1037. |

| 10 | 戴文跃,梁昊. 装载机工作装置的动力学仿真与综合优化设计[J]. 吉林大学学报:工学版, 2004, 34(4):602-605. |

| Dai Wen-yue, Liang Hao. Dynamic simulation and comprehensive optimization design of loader working device[J]. Journal of Jilin University (Engineering and Technology Edition), 2004,34 (4): 602-605. | |

| 11 | Wu Xiao-ming, Xiao Gui-xiang, Chen Rong. Comprehensive optimum design of working device of loader based on sensitivity[J]. Advance Materials Research,2012(490-495):3027-3031. |

| 12 | He Kong-de. Optimal design of the working device for loader based on virtual prototype technology[C]∥The 3rd International Conference on Mechanical Engineering and Mechanics,Beijing,China,2009:1479-1484. |

| 13 | Huang Cheng-yi. Dynamics modeling and simulation of loader working device under unloading condition[C]∥Proceedings of Joint International Conference on Artificial Intelligence and Engineering Applications, Wuhan, China,2016:492-497. |

| 14 | 宋佰芝. 装载机工作装置现代设计方法研究[D]. 广州:华南理工大学机械与汽车工程学院, 2012. |

| Song Bai-zhi. Research on modern design method of loader working device[D]. Guangzhou: School of Mechanical and Automotive Engineering, South China University of Technology, 2012. | |

| 15 | 黄成毅. 基于Modelica的装载机工作装置仿真研究[D].杭州:杭州电子科技大学机械工程学院,2017. |

| Huang Cheng-yi. Simulation Research on loader working device based on Modelica [D]. Hangzhou: School of Mechanical Engineering, Hangzhou University of Electronic Science and Technology, 2017. | |

| 16 | Han Hui-xian, Cao Xian-li. Analysis of the wheel loader hydraulic hybrid system based on braking energy recovery[J]. Applied Mechanics and Materials,2014, 687:171-174. |

| 17 | Zhang Wei-wei, Zhou Jun, Zhang Yan-liang, et al. Energy-saving analysis in the hydraulic system of loader working device[J]. Inderscience Publishers, 2012, 45(2/3):106-114. |

| 18 | 杨占敏,王智明,张春秋. 轮式装载机[M]. 北京: 化学工业出版社,2006. |

| 19 | Wang Zhi-peng, Xie Xun, Li He, et al. Dynamic simulation and optimization design of the pendulum ring mechanism based on ADAMS[J]. International Journal of Plant Engineering and Management, 2014, 19(3):186-192. |

| 20 | Cui Qun-feng, Li Xu-rong, Wang Jian-zhang. The research of using step function to simulate the step-movement of forklift machine in mechanical engineering based on ADAMS[J]. Advanced Materials Research, 2013, 644:212-215. |

| 21 | 李想,王加森,韩敬虎,等. 基于UG和ADAMS的高仿真咀嚼平台运动学仿真分析[J].现代制造工程,2017(2):35-39. |

| Li Xiang, Wang Jia-sen, Han Jing-hu, et al. Kinematic simulation analysis of high simulation chewing platform based on UG and Adams [J]. Modern Manufacturing Engineering, 2017(2): 35-39. | |

| 22 | Pan Yong-jun, Zhang Chao, Yin Bang-hui, et al. Fuzzy set based multi-objective optimization for eight-rod mechanism via sensitivity analysis[J]. SAGE Publications, 2019, 233(2):333-343. |

| 23 | Li Xing, Chen Ya-zhou. Wheel loader working device optimization design based on the sensitivity analysis[J]. Advanced Materials Research, 2012, 1673:1745-1749. |

| 24 | Yuan Yong-liang. Parametric optimization design of auto-unloading mechanism based on Adams[C]∥MATEC Web of Conferences, Guangzhou,China,2018:175. |

| 25 | Yang Yong, Chen Qian-lin. Modeling and analysis of full hydraulic pressure drive system of the wheel loader based on AMEsim[J]. Applied Mechanics and Materials, 2013, 2658: 261-265. |

| 26 | Wilfrid Marquis-Favre, Eric Bideaux, Serge Scavarda. A planar mechanical library in the AMEsim simulation software. Part II: library composition and illustrative example[J]. Simulation Modelling Practice and Theory, 2005, 14(2):95-111. |

| [1] | 祖象欢,杨传雷,王贺春,王银燕. 船用柴油机废气再循环性能评估及应用[J]. 吉林大学学报(工学版), 2019, 49(3): 805-815. |

| [2] | 贾拓,赵丁选,崔玉鑫. 铰接式装载机倾翻预警方法[J]. 吉林大学学报(工学版), 2018, 48(6): 1762-1769. |

| [3] | 李因武, 吴庆文, 常志勇, 杨成. 基于仿生斗齿的反铲液压挖掘机动臂仿真优化设计[J]. 吉林大学学报(工学版), 2018, 48(3): 821-827. |

| [4] | 张钦国, 秦四成, 杨立光, 马润达, 刘宇飞, 李武. 基于虚拟风洞的装载机动力舱热环境预测分析[J]. 吉林大学学报(工学版), 2016, 46(1): 50-56. |

| [5] | 王继新, 龚大鹏, 张英爽, 邓继业, 沈勇. 利用三参数自动换挡策略的轮式装载机传动系建模与遗传算法优化[J]. 吉林大学学报(工学版), 2011, 41(增刊1): 27-33. |

| [6] | 于向军, 王国强, 王继新, 唐小波, 胡季. 轮式装载机滚翻保护结构动态响应[J]. 吉林大学学报(工学版), 2010, 40(05): 1262-1267. |

| [7] | 王继新;王国强;刘小光;林建荣 . ZL80G装载机倾翻保护结构侧向[J]. 吉林大学学报(工学版), 2006, 36(06): 903-0907. |

|

||