吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (4): 1198-1203.doi: 10.13229/j.cnki.jdxbgxb20200505

• 车辆工程·机械工程 • 上一篇

修正胎体弦轮廓载重子午线轮胎的降噪机理

- 江苏大学 汽车与交通工程学院,江苏 镇江 212013

Noise reduction mechanism of truck radial tire based on modified carcass string contour design

Jian YANG( ),Qi XIA,Hai-chao ZHOU,Guo-lin WANG

),Qi XIA,Hai-chao ZHOU,Guo-lin WANG

- School of Automotive and Traffic Engineering,Jiangsu University,Zhenjiang 212013,China

摘要:

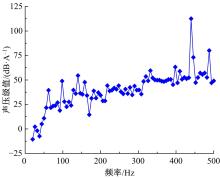

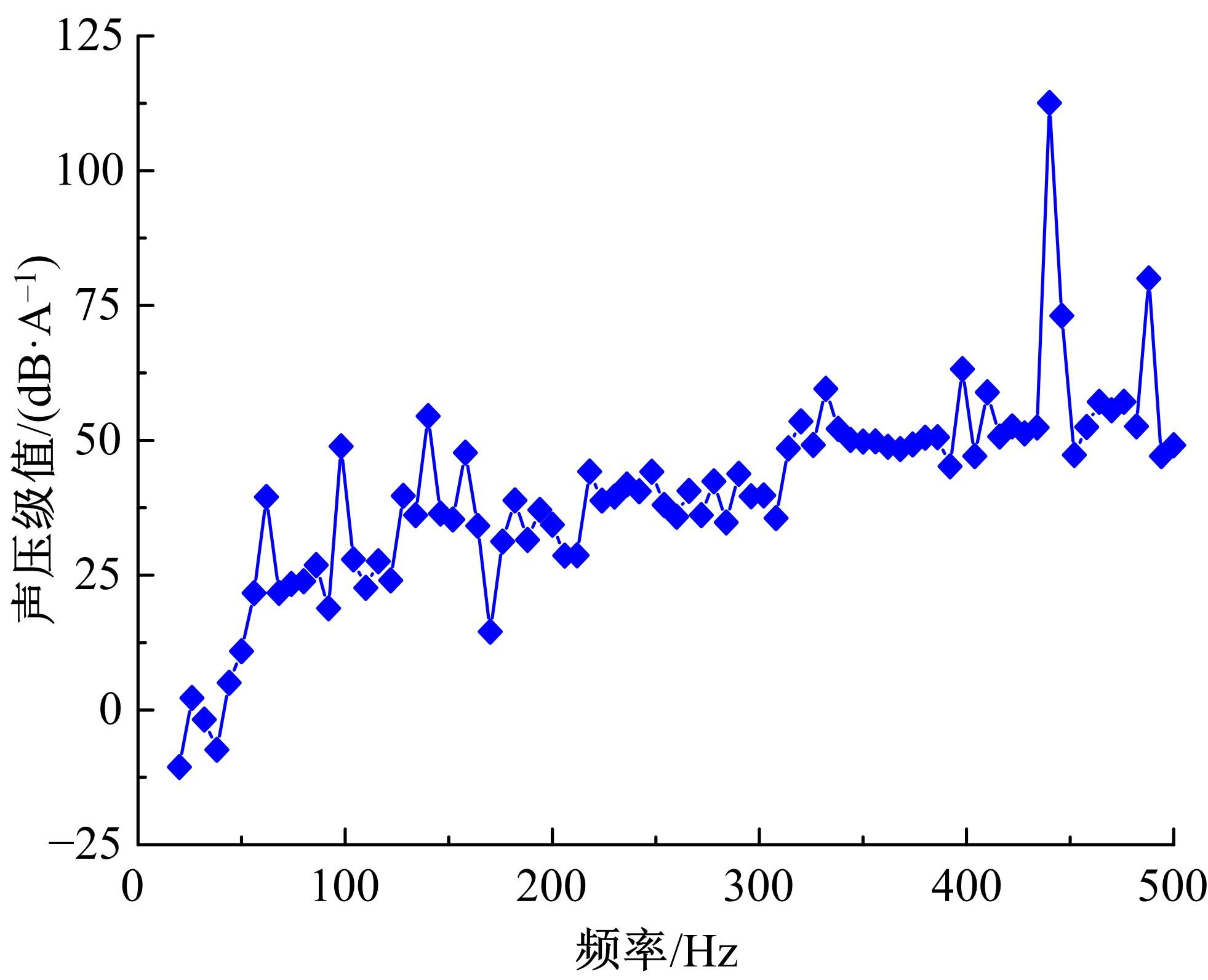

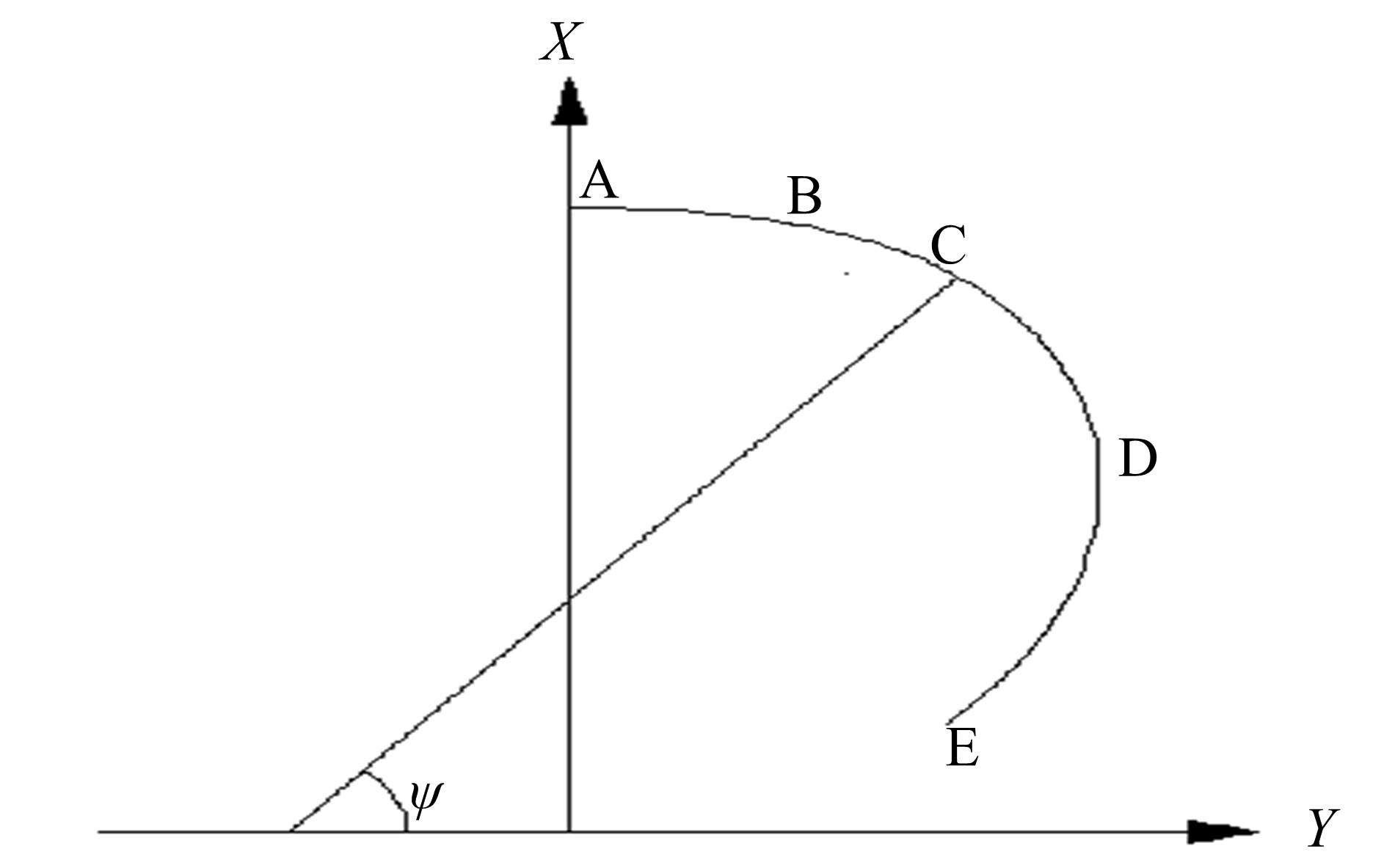

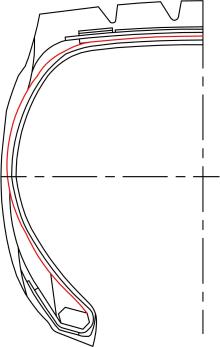

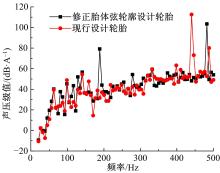

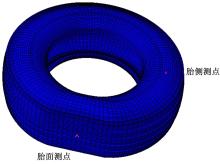

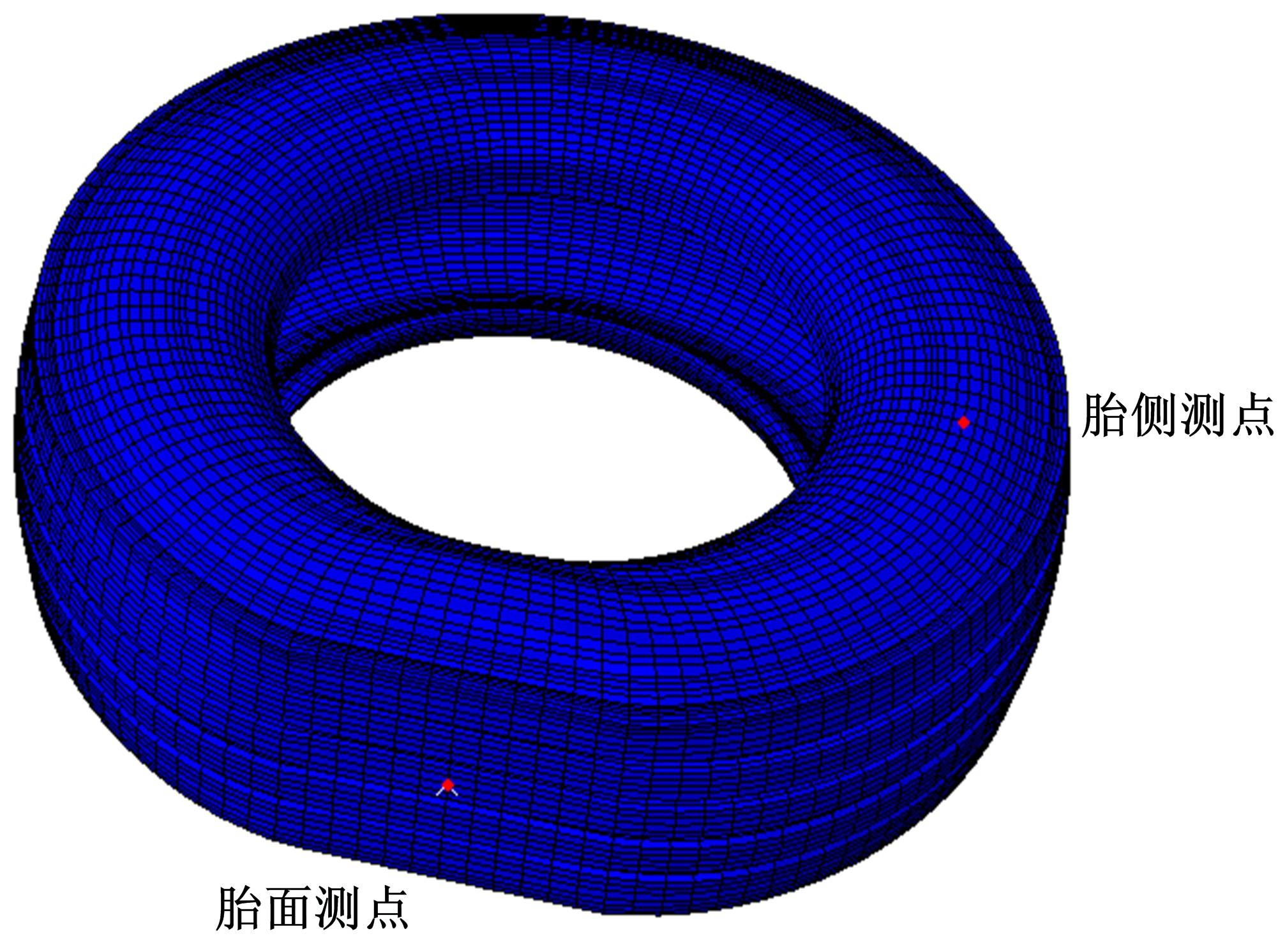

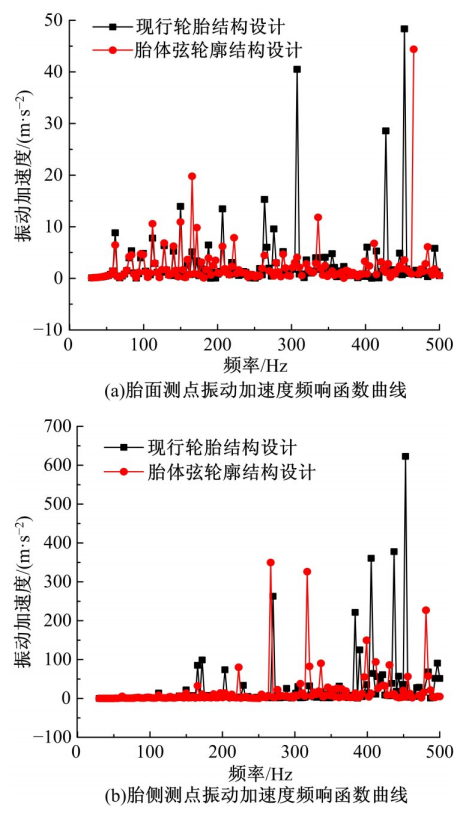

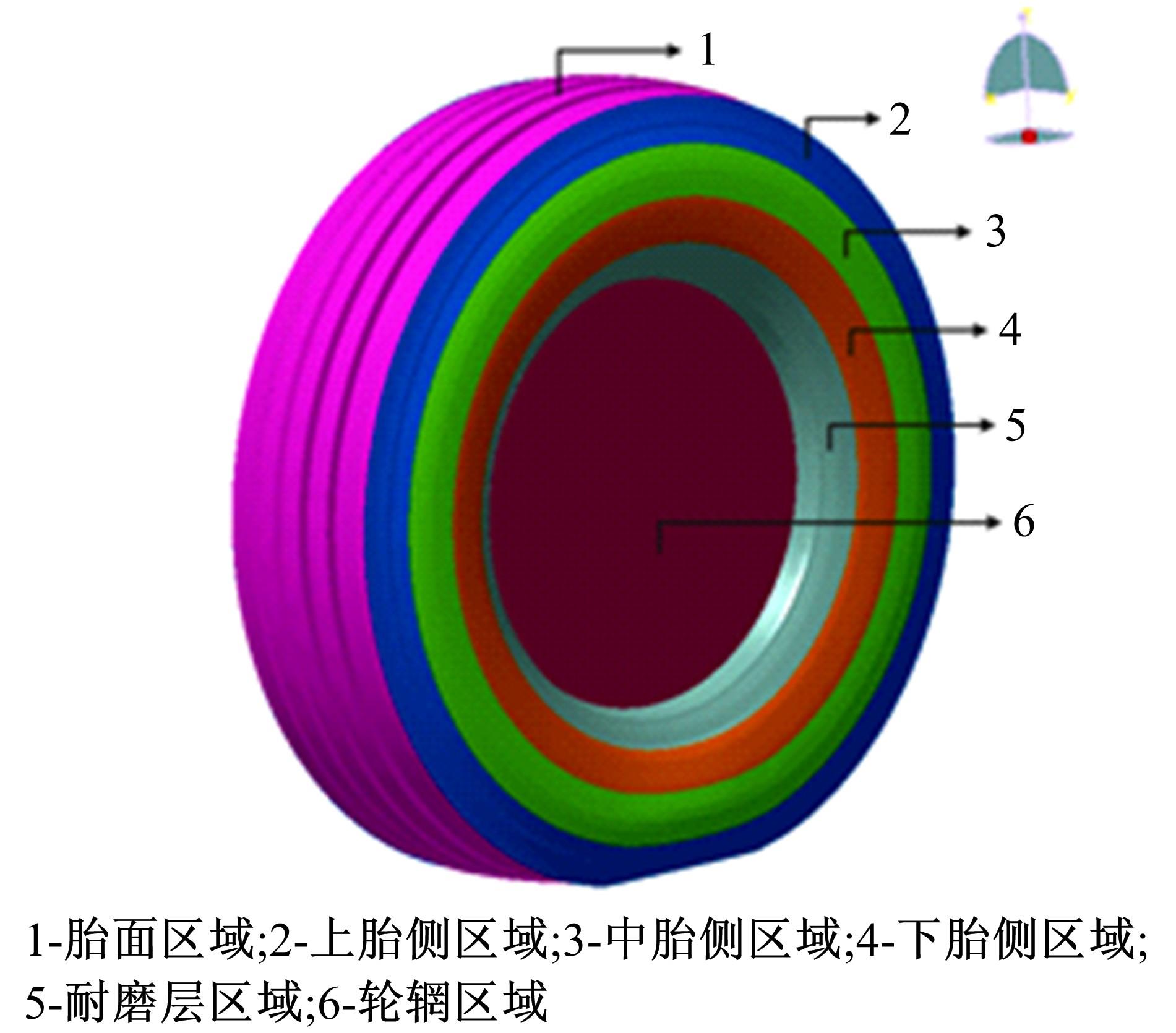

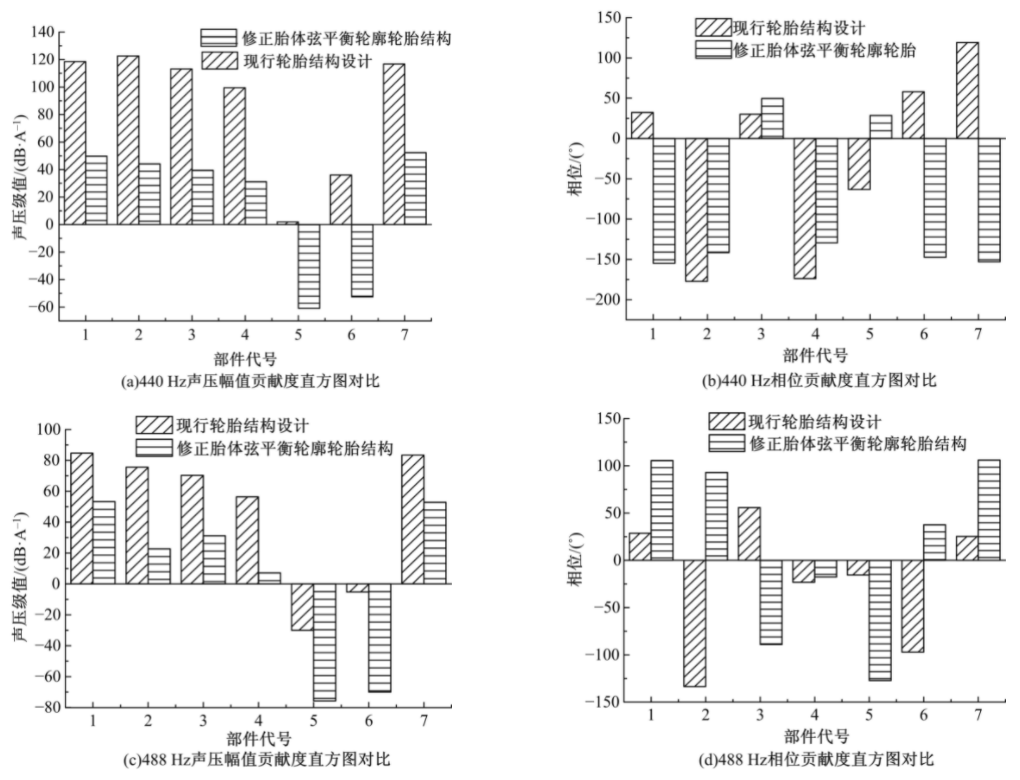

以载重子午线轮胎295/80R22.5为研究对象,结合模态声学传递向量技术和声学边界元法计算滚动轮胎的振动噪声。采用修正胎体弦平衡轮廓设计理论对轮胎的胎体轮廓进行重新设计,并揭示了修正胎体弦轮廓轮胎振动噪声降低的原因。结果表明,修正胎体弦轮廓轮胎胎侧处的质量降低了7.48%,降噪量达1.98 dB,并显著降低了胎面和胎侧处的振动加速度响应,特别是降低了声压峰值对应的440 Hz和488 Hz频率处的振动加速度响应,抑制了胎面和胎侧的振动,进而降低了轮胎的振动噪声。同时,修正胎体弦轮廓轮胎降低了声学正贡献部件胎面和胎侧处的声压幅值贡献,增加了声学负贡献部件的数量,从而实现降低轮胎振动噪声的目的。

中图分类号:

- U463.3

| 1 | Molisani L R, Burdisso R A, Tsihlas D. A coupled tire structure/acoustic cavity model[J]. International Journal of Solids and Structures, 2003, 40(19): 5125-5138. |

| 2 | Kim B S. A study on tire-structure-borne sound[J]. JSME International Journal Series C, 2003, 46(2): 683-691. |

| 3 | 梁晨,赵璠,王国林,等. 基于新非自然平衡轮廓设计的载重子午线轮胎振动辐射噪声的研究[J]. 振动工程学报,2015,28(5):800-808. |

| Liang Chen, Zhao Fan, Wang Guo-lin, et al. Research on radial noise from vibration of load radial tire based on new unnatural balanced contour design[J]. Journal of Vibration Engineering, 2015, 28(5): 800-808. | |

| 4 | 刘占村,李明,刘杰,等. 带束层结构对轿车子午线轮胎接地印痕、径向刚度及噪声的影响[J]. 轮胎工业,2011,31(9):534-536. |

| Liu Zhan-cun, Li Ming, Liu Jie, et al. Influence of belt structure on ground mark, radial stiffness and noise of radial tire [J]. Tire Industry, 2011, 31 (9): 534-536. | |

| 5 | Zhou Hai-chao, Wang Guo-lin, Zhang Ying-wen, et al. Study of the influence of tire belt structure on vibration noise[J]. Recent Patents on Mechanical Engineering, 2017, 10(4): 270-278. |

| 6 | 何敏. 降低胎噪的轮胎消音器[J]. 现代橡胶技术,2012,38(1):33-35. |

| He Min. Tire silencer for reducing tire noise [J]. Advanced Rubber Technology, 2012, 38 (1) : 33-35. | |

| 7 | Mohamed Z, Wang X. A study of tyre cavity resonance and noise reduction using inner trim[J]. Mechanical Systems and Signal Processing, 2015, 50(51): 498-509. |

| 8 | 李牧皛,王瑞乾,温泽峰,等. 喷涂式阻尼车轮振动声辐射特性分析[J]. 噪声与振动控制,2014,34(4):30-34, 38. |

| Li Mu-xiao, Wang Rui-qian, Wen Ze-feng, et al. Analysis on vibration and sound radiation characteristics of sprayed damping wheel[J]. Noise and Vibration Control, 2014, 34(4): 30-34, 38. | |

| 9 | 赵书凯,邓世涛,丁海峰,等. 轮胎噪声影响因素及低噪声轮胎设计方法[J]. 轮胎工业,2014,34(2):76-80. |

| Zhao Shu-kai, Deng Shi-tao, Ding Hai-feng, et al. Influencing factors of tire noise and low noise tire design method [J]. Tire Industry, 2014, 34 (2): 76-80. | |

| 10 | Lafont T, Stelzer R, D'Amico R, et al. Modelling tyre noise in finite element simulations for pass-by noise predictions[J]. Journal of Mechanical Engineering Science, 2019, 233(18): 6398-6408. |

| 11 | Hu Xiao-jun, Liu Xian-dong, Wan Xiao-fei, et al. Experimental analysis of sound field in the tire cavity arising from the acoustic cavity resonance[J]. Applied Acoustics, 2020, 161(1):107172. |

| 12 | 王国林,裴晓朋,周海超,等. 轮胎结构振动声学贡献度分析及降噪方法研究[J]. 振动与冲击,2015, 34(24):53-58. |

| Wang Guo-lin, Pei Xiao-peng, Zhou Hai-chao, et al.Acoustic contribution of tire structure vibration and method for noise reduction [J]. Journal of Vibration and Shock, 2015,34(24):53-58. | |

| 13 | 王国林,任洁雨,杨建,等. 轮胎胎体轮廓设计对侧偏刚度的影响研究[J].机械工程学报, 2015, 51(14): 131-137. |

| Wang Guo-lin, Ren Jie-yu, Yang Jian, et al. Effect study of radial tire contour design to cornering stiffness[J]. Journal of Mechanical Engineering, 2015, 51(14):131-137. |

| [1] | 陈鑫,于贵申,张彪,潘凯旋,杨立飞. 搅拌摩擦点焊接头拉伸-剪切行为的等效建模[J]. 吉林大学学报(工学版), 2021, 51(4): 1190-1197. |

| [2] | 宋大凤,杨丽丽,曾小华,王星琦,梁伟智,杨南南. 基于行驶工况合成的混合动力汽车电池寿命优化[J]. 吉林大学学报(工学版), 2021, 51(3): 781-791. |

| [3] | 张家旭,王欣志,赵健,施正堂. 汽车高速换道避让路径规划及离散滑模跟踪控制[J]. 吉林大学学报(工学版), 2021, 51(3): 1081-1090. |

| [4] | 何仁,赵晓聪,杨奕彬,王建强. 基于驾驶人风险响应机制的人机共驾模型[J]. 吉林大学学报(工学版), 2021, 51(3): 799-809. |

| [5] | 宋强,孙丹婷,章伟. 纯电动车机械式自动变速器换挡非线性建模及控制[J]. 吉林大学学报(工学版), 2021, 51(3): 810-819. |

| [6] | 王波,何洋扬,聂冰冰,许述财,张金换. 底部爆炸条件下车内乘员的腹部损伤[J]. 吉林大学学报(工学版), 2021, 51(3): 792-798. |

| [7] | 庄蔚敏,王鹏跃,高瑞娟,解东旋. 温热成形对AA5754铝合金静态力学性能的影响[J]. 吉林大学学报(工学版), 2021, 51(3): 847-854. |

| [8] | 李寿涛,王蕊,徐靖淳,王德军,田彦涛,于丁力. 一种基于模型预测复合控制的车辆避碰控制方法[J]. 吉林大学学报(工学版), 2021, 51(2): 738-746. |

| [9] | 王伟达,武燕杰,史家磊,李亮. 基于驾驶员意图识别的电子液压制动助力系统控制策略[J]. 吉林大学学报(工学版), 2021, 51(2): 406-413. |

| [10] | 陈国迎,姚军,王鹏,夏其坤. 适用于后轮轮毂驱动车辆的稳定性控制策略[J]. 吉林大学学报(工学版), 2021, 51(2): 397-405. |

| [11] | 马芳武,梁鸿宇,王强,蒲永锋. 双材料负泊松比结构的面内冲击动力学性能[J]. 吉林大学学报(工学版), 2021, 51(1): 114-121. |

| [12] | 吴岛,张立斌,张云翔,单洪颖,单红梅. 基于滑移率辨识的汽车制动时序视觉检测方法[J]. 吉林大学学报(工学版), 2021, 51(1): 206-216. |

| [13] | 张恩慧,何仁,苏卫东. 不同挡板结构对油箱内油液晃动特性的数值分析[J]. 吉林大学学报(工学版), 2021, 51(1): 83-95. |

| [14] | 熊璐,魏琰超,高乐天. 基于惯性测量单元/轮速融合的车辆零速检测方法[J]. 吉林大学学报(工学版), 2021, 51(1): 134-138. |

| [15] | 陈吉清,蓝庆生,兰凤崇,刘照麟. 基于轮胎力预判与拟合的轨迹跟踪控制[J]. 吉林大学学报(工学版), 2020, 50(5): 1565-1573. |

|

||