吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (10): 2294-2299.doi: 10.13229/j.cnki.jdxbgxb20210490

• 车辆工程·机械工程 • 上一篇

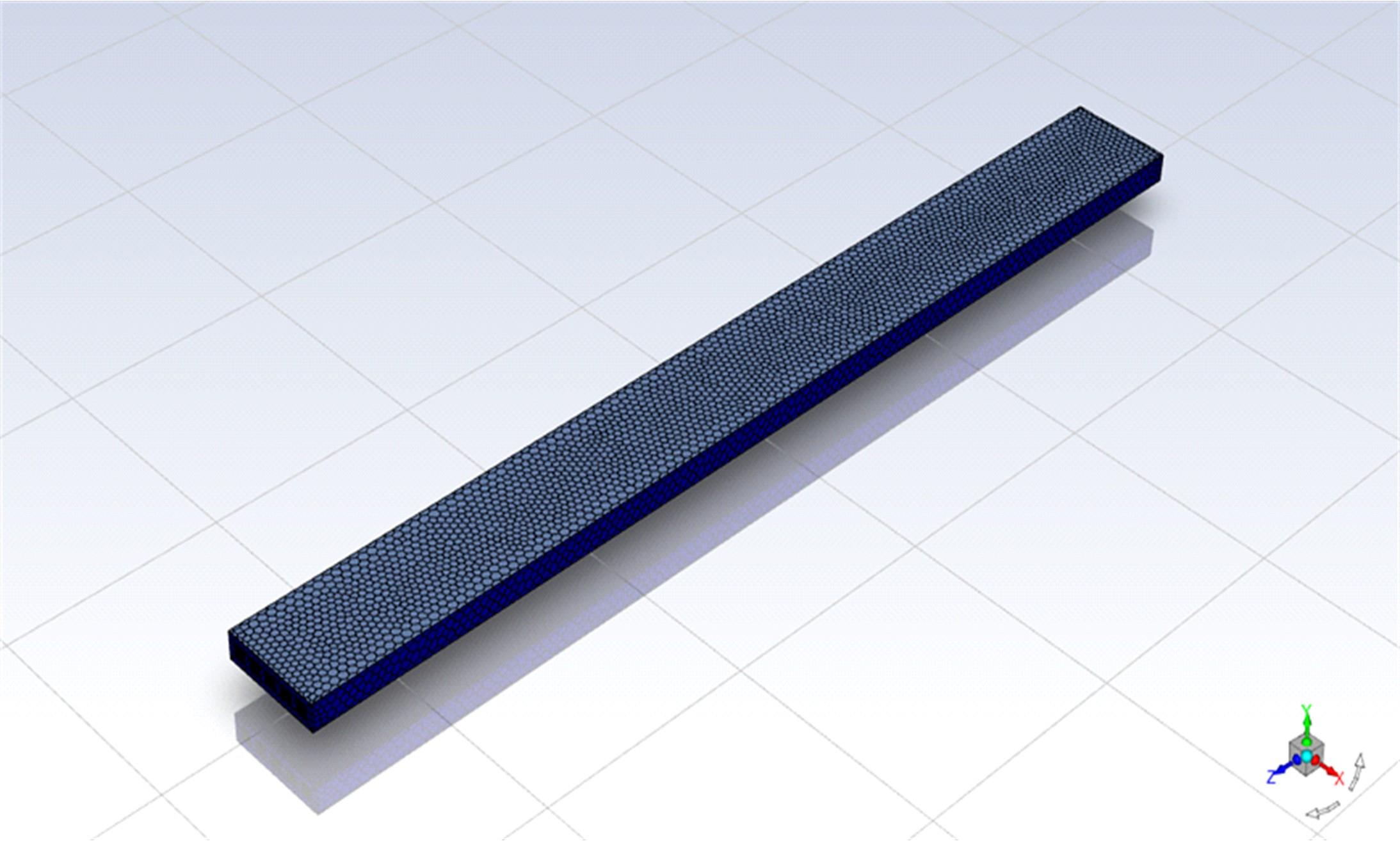

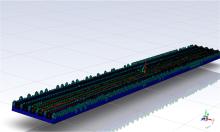

微通道低温换热器流动传热性能

徐振军1( ),王浩1,2,王银成3,张诺2,陈孟1,李清清1

),王浩1,2,王银成3,张诺2,陈孟1,李清清1

- 1.青岛农业大学 建筑工程学院,山东 青岛 266300

2.青岛工学院 机电工程学院,山东 青岛 266300

3.天津商业大学 机械工程学院,天津 300133

Flow heat transfer performance of microchannel low temperature heat exchanger

Zhen-jun XU1( ),Hao WANG1,2,Yin-cheng WANG3,Nuo ZHANG2,Meng CHEN1,Qing-qing LI1

),Hao WANG1,2,Yin-cheng WANG3,Nuo ZHANG2,Meng CHEN1,Qing-qing LI1

- 1.College of Civil Engineering&Architecture,Qingdao Agricultural University,Qingdao 266300,China

2.Mechanical and Electrical Engineering,Qingdao Institute of Technology,Qingdao 266300,China

3.School of Mechanical Engineering,Tianjin University of Commerce,Tianjin 300133,China

摘要:

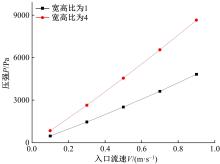

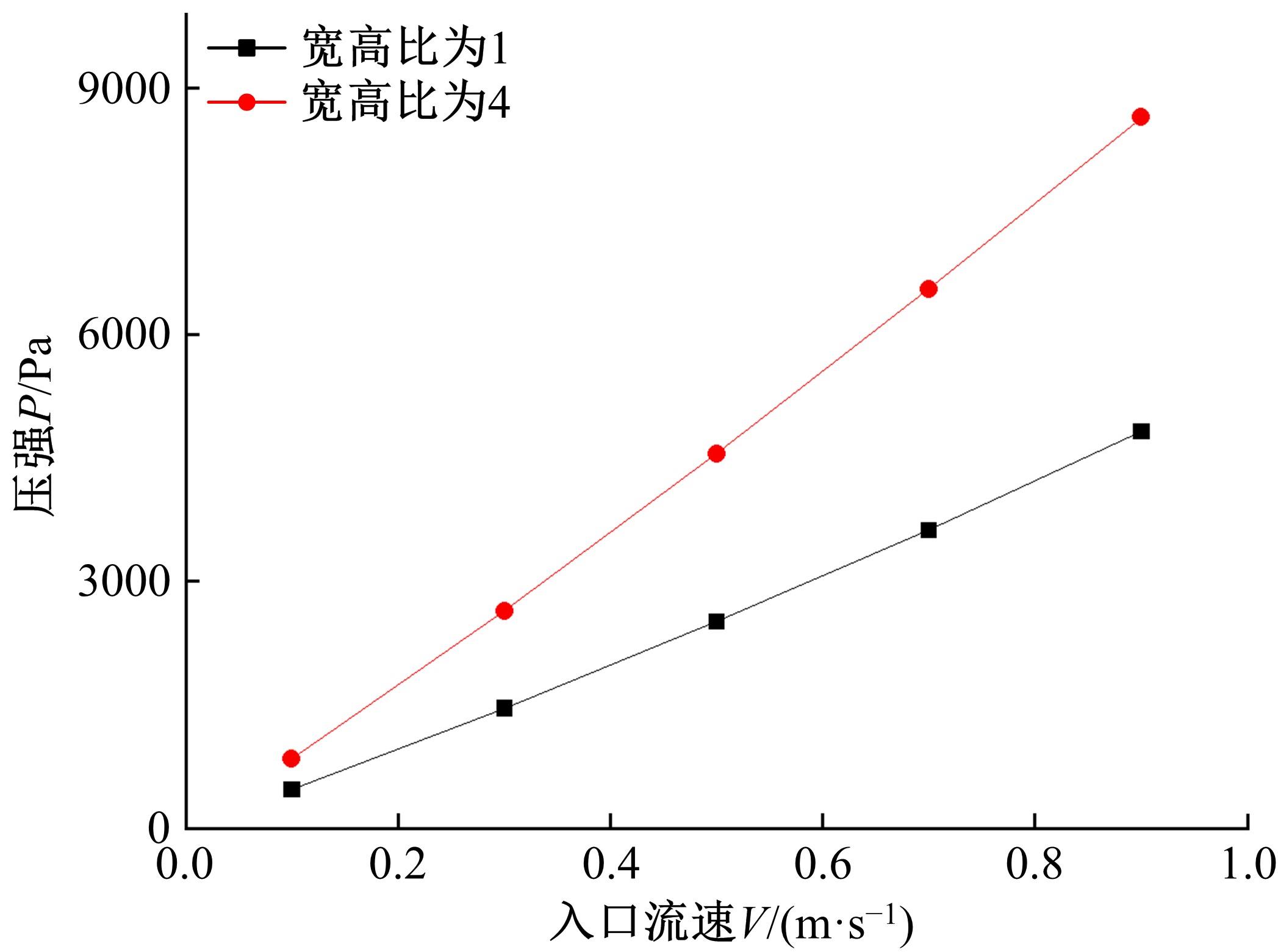

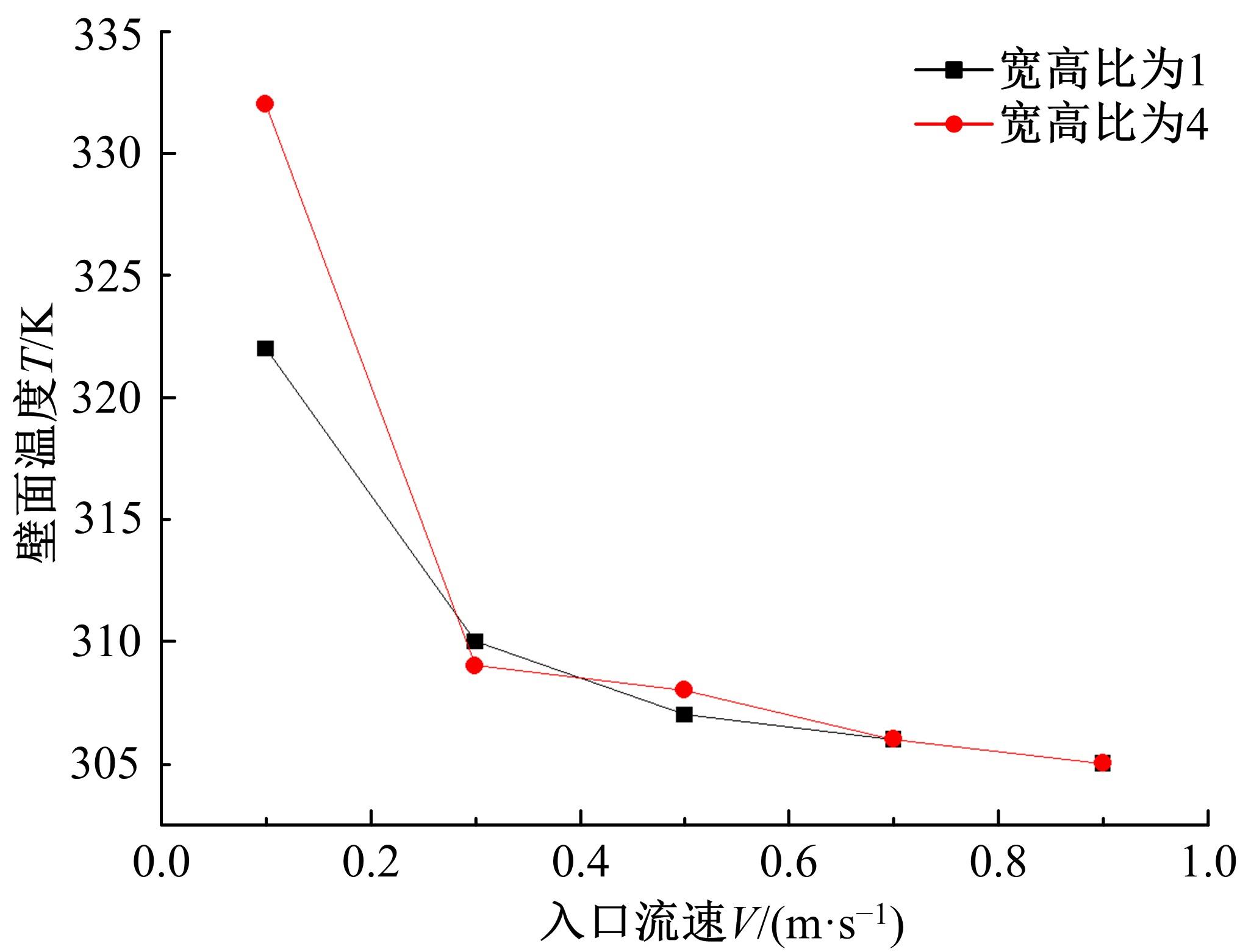

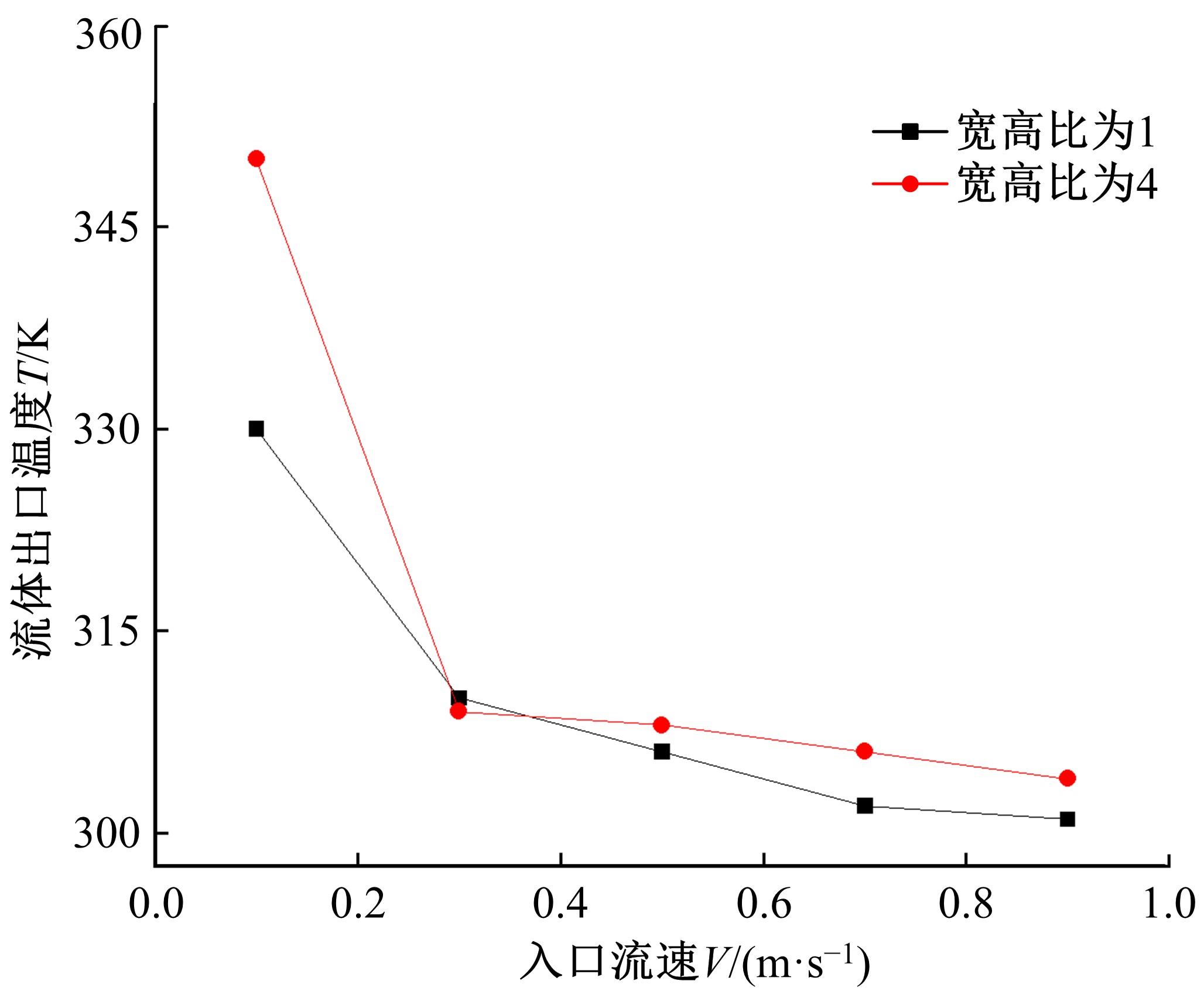

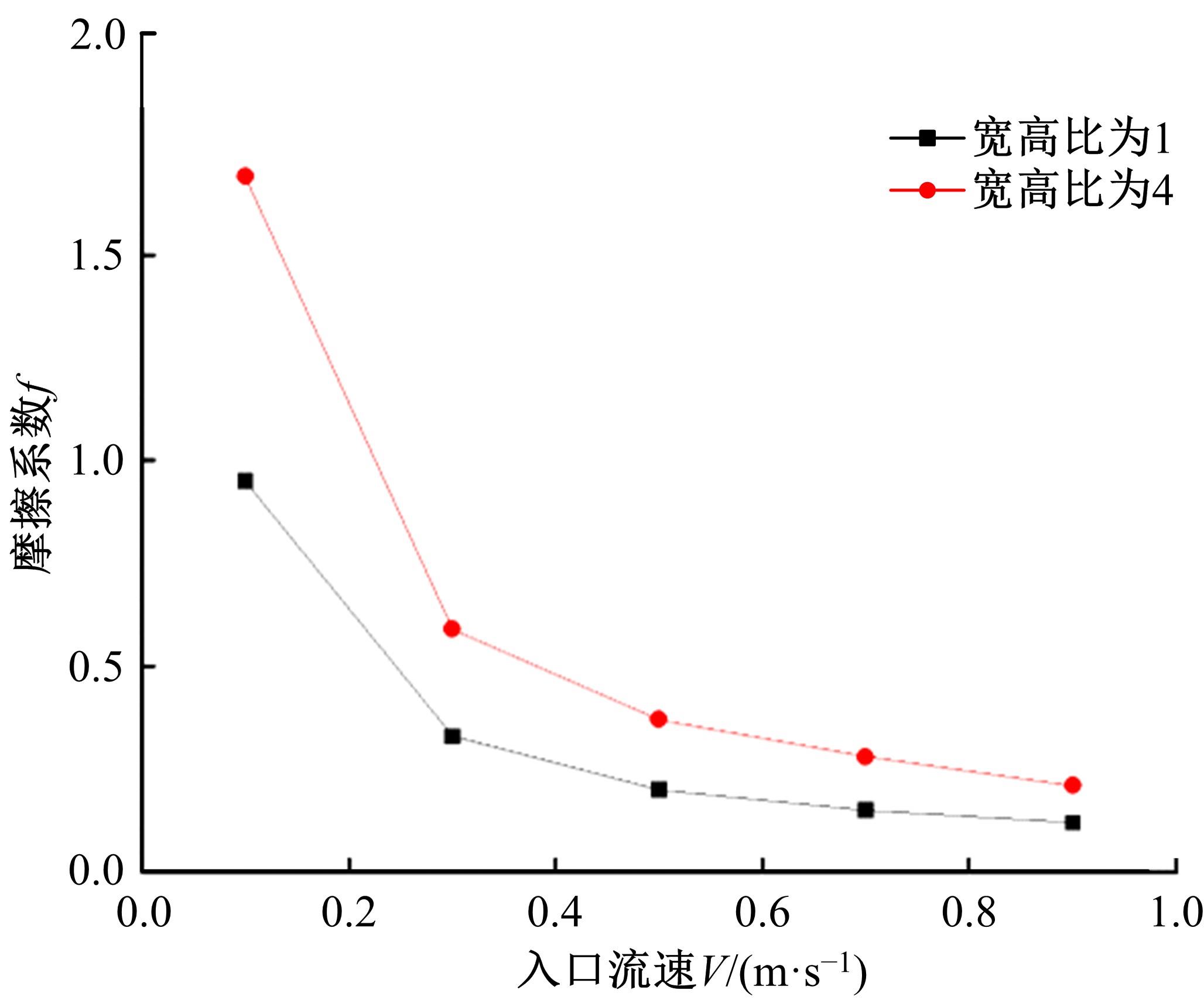

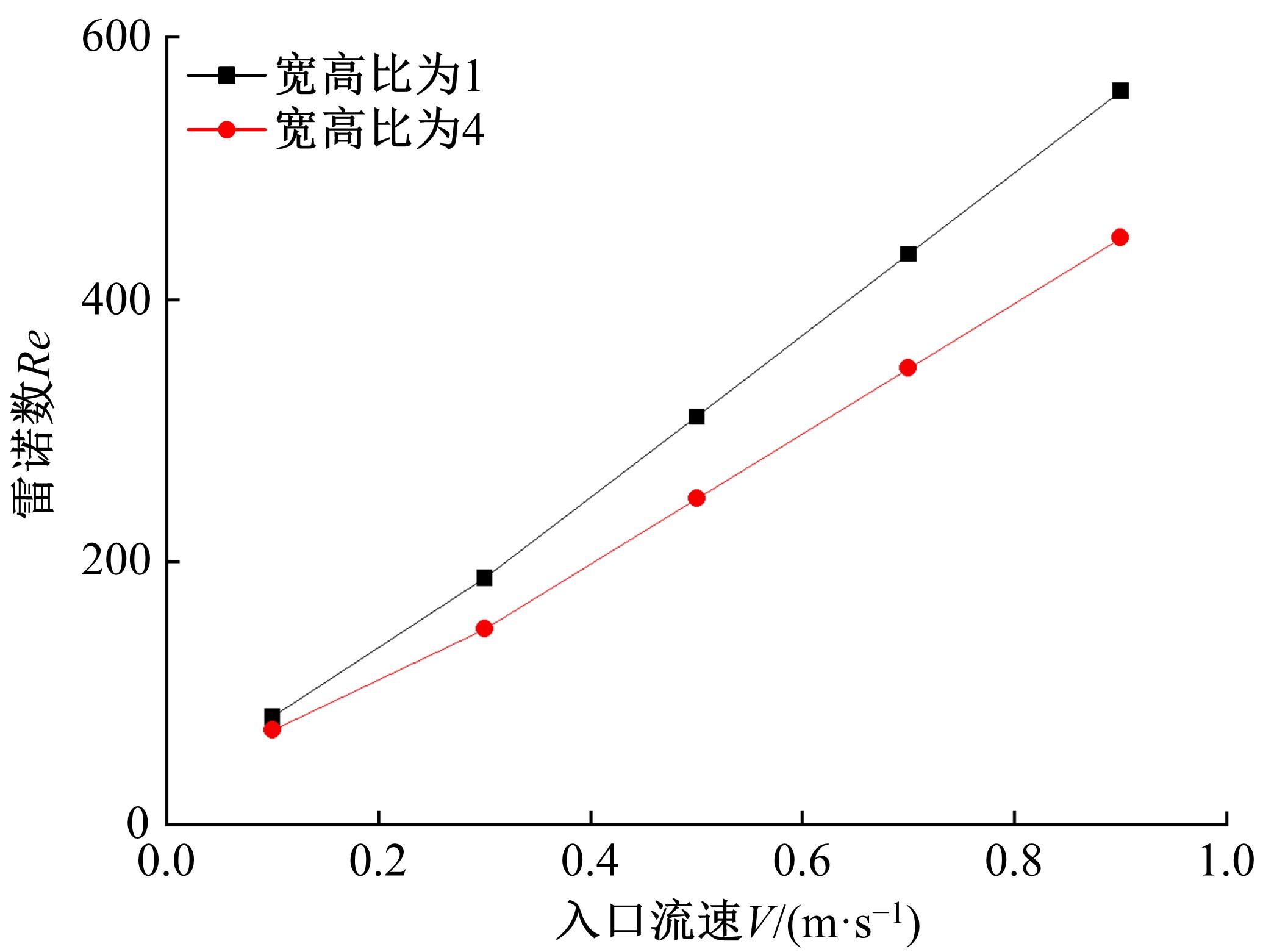

基于微通道换热器占地小、换热效率高等优点和在微电子领域、工业冷藏、电动汽车空调等领域应用广泛的现状,建立了微通道低温换热器的物理模型和数学模型,并对模型进行了求解。针对水力直径小于1 mm的微通道低温换热器的流动换热性能,研究了在改变入口流速以及不同宽高比的情况下,对换热器沿程的阻力压降、壁面温度、通道出口流体温度、摩擦因数的影响。研究结果表明,不同宽高比对以上各种参数都有明显的影响。微通道压降随着流速的增大而增大,而且压降增大趋势逐渐加大。壁面温度、通道流体出口温度、摩擦因数等都随着流速的增大而减小,最后都是趋向于稳定。宽高比为4的通道的参数值比宽高比为1的各项参数值普遍偏大,宽高比对微通道换热器的换热性能有着较大的影响。

中图分类号:

- TB61

| 1 | 梁朋. 矩形微通道内的流动与压降特性研究[D]. 北京:北京交通大学机械与电子控制工程学院, 2017. |

| Liang Peng. The characteristics of flow and pressure drop in rectangular microchannel[D]. Beijing: School of Mechanical, Electronic and Control Engineering,Beijing Jiaotong University, 2017. | |

| 2 | 王剑鹏, 秦四成, 杨立光, 等. 装载机液压系统的传热仿真分析[J].吉林大学学报: 工学版, 2016, 46(1): 153-158. |

| Wang Jian-peng, Qin Si-cheng, Yang Li-guang, et al. Simulation analysis of heat transfer in the hydraulic system of loader[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(1): 153-158. | |

| 3 | 葛洋, 姜未汀. 微通道换热器的研究及应用现状[J]. 化工进展, 2016, 35(): 10-15. |

| Ge Yang, Jiang Wei-ting. The research progress and application of the micro channel heat exchanger[J]. Chemical Industry and Engineering Progess, 2016, 35(Sup.1): 10-15. | |

| 4 | 刘英楠. 微通道换热器的数值模拟[D]. 大连:大连理工大学化工学院, 2016. |

| Liu Ying-nan. The numerical simulation of micro-channel heat exchanger[D]. Dalian:School of Chemical Engineering,Dalian University of Technology, 2016. | |

| 5 | 吴秋瑜. 凹穴型微通道换热器结构设计与性能研究[D]. 广州:华南理工大学机械与汽车工程学院, 2017. |

| Wu Qiu-yu. Structural design and study on performance offlow and heat transfer of complex microchannel heat exchanger with reentrant cavitives[D]. Guangzhou: School of Machanical & Automotive Engineering, South China University of Technology,2017. | |

| 6 | 范凌灏. 矩形微通道内流动传热特性的数值模拟及结构优化[D]. 济南:山东大学能源与动力工程学院, 2020. |

| Fan Ling-hao. Numerical analysis and structural optimization of flow and heat transfer characteristics candidate in rectangular microchannels[D]. Jinan: School of Energy and Power Engineering,Shandong University, 2020. | |

| 7 | 盛伟, 刘鹏鹏, 丁国良. 微通道换热器结霜性能的试验研究[J]. 流体机械, 2017, 45(1): 60-65. |

| Sheng Wei, Liu Peng-peng, Ding Guo-liang. Experimental research on frost performance of microchannel heat exchanger[J]. Fluid Machinery, 2017, 45(1): 60-65. | |

| 8 | 熊通, 晏刚, 樊超超, 等. 微通道换热器两相流分布研究现状与展望[J]. 制冷学报, 2021, 42(1): 23-35. |

| Xiong Tong, Yan Gang, Fan Chao-chao, et al. Review on research status and prospects of two-phase flow distribution in microchannel heat exchanger[J]. Journal of Refrigeration, 2021, 42(1): 23-35. | |

| 9 | 巫江虹, 谢方, 刘超鹏, 等. 电动汽车热泵空调系统微通道换热器适应性研究[J]. 机械工程学报, 2012, 48(14): 141-147. |

| Wu Jiang-hong, Xie Fang, Liu Chao-peng, et al. Adaptability research on micro-channel heat exchanger appued to heat pump air conditioning system for electrical vehicle[J]. Journal of Machanical Engineering, 2012, 48(14): 141-147. | |

| 10 | 张天一. 超临界二氧化碳微通道换热器优化分析研究[D]. 北京:华北电力大学核科学与工程学院, 2021. |

| Zhang Tian-yi. Optimization analysis of supercritical carbon dioxide microchannel heat exchanger[D]. Beijing:School of Nuclear Science and Engineering,North China Electric Power University, 2021. | |

| 11 | 翟玉玲. 复杂结构微通道热沉流动可视化及传热过程热力学分析[D]. 北京:北京工业大学环境与能源学院, 2015. |

| Zhai Yu-ling. Thermodynamic analysis of enhanced heat transfer process in microchannel heat sinks with complex structure[D]. Beijing: School of Environment and Energy,Beijing University of Technology, 2015. | |

| 12 | 白鹏飞, 汤勇, 陆龙生, 等. 以水为工质的铜基微通道热沉的流态可视化与传热特性[J]. 吉林大学学报: 工学版, 2010, 40(4): 959-964. |

| Bai Peng-fei, Tang Yong, Lu Long-sheng, et al. Investigation of flow pattern visualization and heat transfer characteristics on a Cu-base micro-channel heat sink with water coolant[J]. Journal of Jilin University (Engineering and Technology Edition), 2010, 40(4): 959-964. | |

| 13 | 席雷, 徐亮, 高建民, 等. 厚壁矩形带肋通道内蒸汽流动及传热特性[J].吉林大学学报: 工学版, 2018, 48(3): 752-759. |

| Xi Lei, Xu Liang, Gao Jian-min, et al. Flow and heat transfer characteristics of steam in thick-wall rectangular ribbed channel[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(3): 752-759. |

| [1] | 杨子荣,李岩,冀雪峰,刘芳,郝冬. 质子交换膜燃料电池运行工况参数敏感性分析[J]. 吉林大学学报(工学版), 2022, 52(9): 1971-1981. |

| [2] | 徐振军,王浩,赵开元,郝博轶,李清清,王常浩. 复合太阳能的燃气机热泵热力学性能[J]. 吉林大学学报(工学版), 2022, 52(8): 1759-1763. |

| [3] | 赵同宾,吴宜胜,段耀宗,黄震,韩东. RP-3航空煤油的润滑特性和改善措施[J]. 吉林大学学报(工学版), 2022, 52(3): 533-540. |

| [4] | 潘凤文,弓栋梁,高莹,徐明伟,麻斌. 基于锂离子电池线性化模型的电流传感器故障诊断[J]. 吉林大学学报(工学版), 2021, 51(2): 435-441. |

| [5] | 孟育博, 李丕茂, 张幽彤, 王志明. 共轨系统压力波动和多次喷射油量偏差的抑制[J]. 吉林大学学报(工学版), 2018, 48(3): 760-766. |

| [6] | 孙正, 黄钰期, 俞小莉. 径向滑动轴承润滑油膜流动-传热过程仿真[J]. 吉林大学学报(工学版), 2018, 48(3): 744-751. |

| [7] | 孟育博, 张幽彤, 王志明, 张晓晨, 樊利康, 李涛. 压电喷油器压电执行器热-电-机械耦合迟滞特性[J]. 吉林大学学报(工学版), 2018, 48(2): 480-485. |

| [8] | 吴志军, 赵文伯, 张青. 基于热氛围燃烧器的湍流射流起升火焰基础研究进展[J]. 吉林大学学报(工学版), 2016, 46(6): 1881-1891. |

| [9] | 崔金生, 侯绪研, 邓宗全, 潘万竞, 姜生元. 真空颗粒系统有效导热系数测量试验台研制及试验[J]. 吉林大学学报(工学版), 2016, 46(2): 457-464. |

| [10] | 齐子姝, 高青, 刘研, 白莉. 地能利用热泵系统模型计算及其多年运行工况分析[J]. 吉林大学学报(工学版), 2015, 45(6): 1811-1816. |

| [11] | 田桂中, 刘之岭, 周宏根, 宋江超, 朱涛. 家蚕前部丝腺准静态轴向拉伸力学特性[J]. 吉林大学学报(工学版), 2015, 45(3): 872-877. |

| [12] | 解方喜, 于泽洋, 刘思楠, 曹晓峰, 贾贵起, 洪伟. 喷射压力对燃油喷雾和油气混合特性的影响[J]. 吉林大学学报(工学版), 2013, 43(06): 1504-1509. |

| [13] | 孙万臣, 孙士龙, 王晓丹, 李国良, 赖春杰. 燃料挥发性对高压共轨柴油机微粒排放粒度分布的影响[J]. 吉林大学学报(工学版), 2013, 43(03): 619-625. |

| [14] | 齐子姝, 高青, 刘研, 于鸣. 联供模式地下换热器温变及其热泵效能分析[J]. 吉林大学学报(工学版), 2012, 42(02): 339-343. |

| [15] | 白鹏飞,汤勇,陆龙生,唐彪. 以水为工质的铜基微通道热沉的流态可视化与传热特性[J]. 吉林大学学报(工学版), 2010, 40(04): 959-0964. |

|

||