吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (2): 365-374.doi: 10.13229/j.cnki.jdxbgxb.20220416

• 车辆工程·机械工程 • 上一篇

等角贴敷压电分流片圆柱壳有限元建模及减振分析

- 1.东北大学 机械工程与自动化学院,沈阳 110819

2.东北大学 航空动力装备振动及控制教育部重点实验室,沈阳 110819

Finite element modeling and vibration reduction analysis of cylindrical shell structures with equal⁃angle attachment of piezoelectric shunt patches

- 1.School of Mechanical Engineering and Automation,Northeastern University,Shenyang 110819,China

2.Key Laboratory of Vibration and Control for Aerospace Power Equipment,Ministry of Education,Northeastern University,Shenyang 110819,China

摘要:

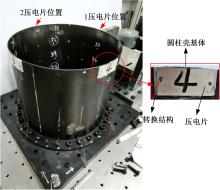

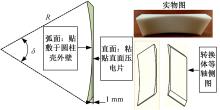

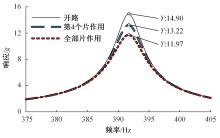

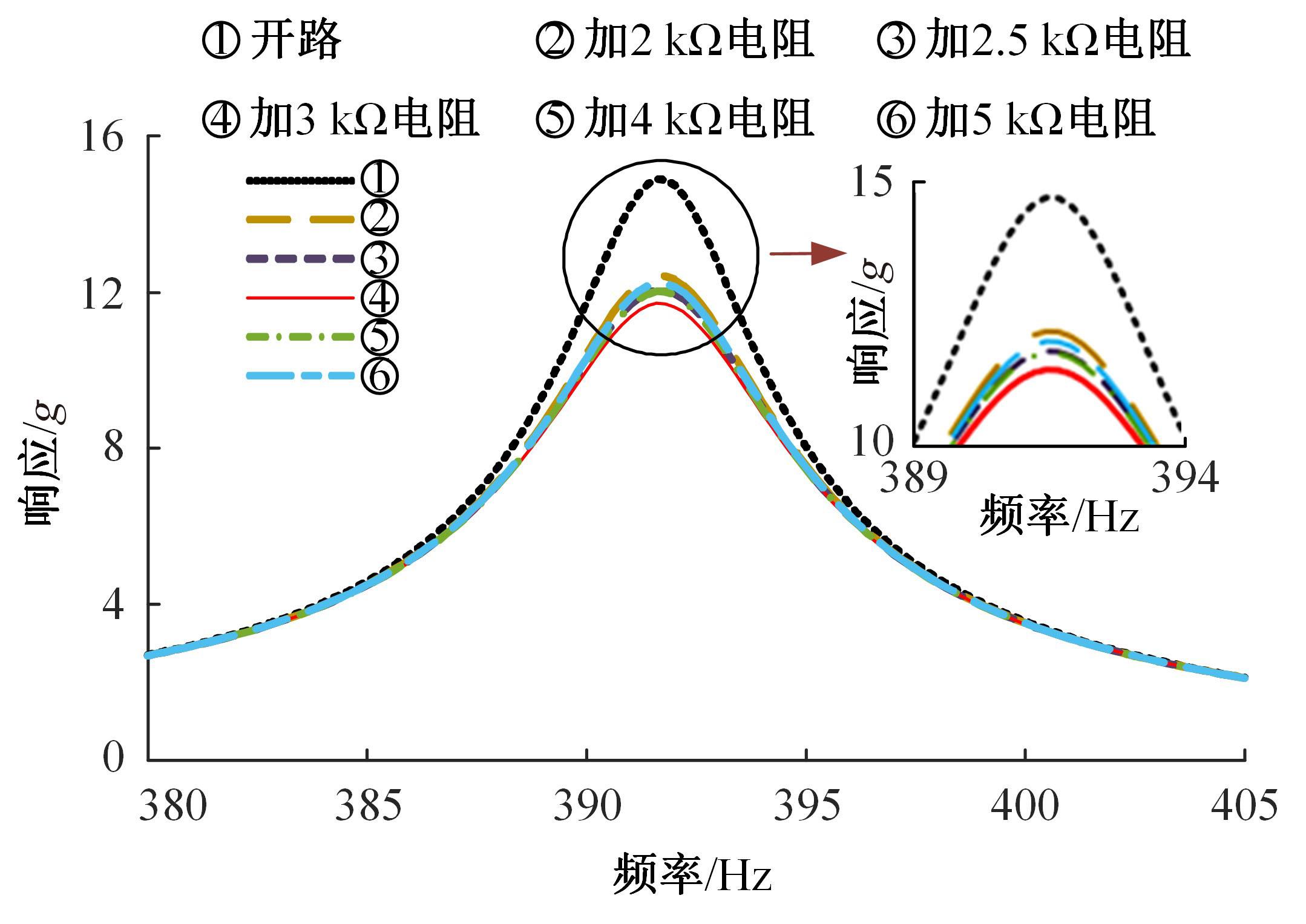

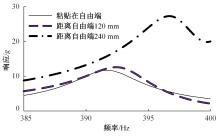

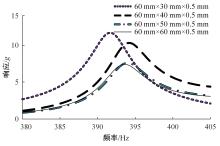

考虑到圆柱壳结构容易出现花瓣型振型的特点,提出了一种等角贴敷多个压电分流片来对其进行振动抑制的方法。基于ANSYS平台,实现圆柱壳与压电片结构耦合,给出了分流电路中电子元件参数输入方法以及和压电片之间的耦合过程。以等角贴敷4个压电分流片圆柱壳为对象进行实例研究,证明了建模方法的合理性以及压电分流阻尼对圆柱壳的减振效果。在此基础上进行参数影响分析,可以发现:对于电阻分流电路存在一个最优电阻值可使减振效果最优;压电片贴敷在变形相对大的区域以及增大尺寸对减振有利。

中图分类号:

- V232.6

| 1 | Du D X, Sun W, Yan X F, et al. Free vibration analysis of rotating thin-walled cylindrical shells with hard coating based on Rayleigh-Ritz method[J]. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, 2021, 235(10): 1170-1186. |

| 2 | Mohammadi F, Sedaghati R. Linear and nonlinear vibration analysis of sandwich cylindrical shell with constrained viscoelastic core layer[J]. International Journal of Mechanical Sciences, 2012, 54(1): 156-171. |

| 3 | 陈中石, 孙伟. 局部贴敷黏弹性阻尼层圆柱壳振动频率与阻尼有限元分析[J]. 航空动力学报, 2020, 35(6): 1176-1185. |

| Chen Zhong-shi, Sun Wei. Finite element analysis of frequency and damping of cylindrical shell partially covered viscoelastic damping layer[J]. Journal of Aerospace Power, 2020, 35(6): 1176-1185. | |

| 4 | 聂斌. 压电结构力学响应的多场耦合稳定节点S-RPIM研究[D].长春:吉林大学机械与航空航天工程学院, 2023. |

| Nie Bin. Research on multi-field coupled stable node-based S-RPIM for mechanical responses of piezoelectric structures[D]. Changchun: School of Mechanical and Aerospace Engineering, Jilin University, 2023. | |

| 5 | 韩也. 压电抑振技术及其在车门振动控制中的应用研究[D]. 长春:吉林大学机械与航空航天工程学院, 2014. |

| Han Ye. Research on the technology of piezoelectric vibration control and its application on vehicle door[D]. Chuangchun: College of Mechanical and Aerospace Engineering, Jilin University, 2014. | |

| 6 | Gripp J, Rade D A. Vibration and noise control using shunted piezoelectric transducers: a review[J]. Mechanical Systems and Signal Processing, 2018, 112: 359-383. |

| 7 | Bo Y, Wang K, Hu Z, et al. Shunt damping vibration control technology: a review[J]. Applied Sciences, 2017, 7(5): 494-526. |

| 8 | Junior V L, Steffen V, Savi M A. Piezoelectric structural vibration control[J]. Dynamics of Smart Systems and Structures, 2016, 12: 289-309. |

| 9 | Kerboua M, Megnounif A, Benguediab M, et al. Vibration control beam using piezoelectric-based smart materials[J]. Composite Structures, 2015, 123: 430-442. |

| 10 | 常道庆, 刘碧龙, 李晓东, 等. 具有压电分流电路薄板的吸声特性Ⅰ.理论分析[J]. 声学学报: 中文版, 2008, 33(2): 131-137. |

| Chang Dao-qing, Liu Bi-long, Li Xiao-dong, et al. Sound absorption characteristics of a thin plate with PZT shunted with passive electrical circuit I.Theoretical analysis[J]. Journal of acoustics(The Chinese version), 2008, 33(2): 131-137. | |

| 11 | Cross C J, Fleeter S. Shunted piezoelectrics for passive control of turbomachine blading flow-induced vibrations[J]. Smart Materials and Structures, 2002, 11(2): 239-248. |

| 12 | Liu J, Li L, Huang X, et al. Dynamic characteristics of the blisk with synchronized switch damping based on negative capacitor[J]. Mechanical Systems and Signal Processing, 2017, 95: 425-445. |

| 13 | Yu H B, Wang K W. Piezoelectric networks for vibration suppression of mistuned bladed disks[J]. Journal of Vibration and Acoustics, 2007, 129(5): 559-566. |

| 14 | Neubauer M, Wallascheck J. Vibration damping with shunted piezoceramics: fundamentals and technical applications[J]. Mechanical Systems and Signal Processing, 2013, 36(1): 36-52. |

| 15 | Bucher O, Fink F, Kreissig V. Steering wheel for a motor vehicle[P]. Germany: |

| 16 | Pernod L, Lossouarn B, Astolfi J A, et al. Vibration damping of marine lifting surfaces with resonant piezoelectric shunts[J]. Journal of Sound and Vibration, 2021, 496:115921. |

| 17 | Araújo A L, Aguilar M J F. Optimal passive shunted damping configurations for noise reduction in sandwich panels[J]. Journal of Vibration and Control, 2020, 26: 1110-1118. |

| 18 | 郭空明, 徐亚兰. Kagome夹心板的多模态压电分流振动控制研究[J]. 振动与冲击, 2017, 36(19): 60-65. |

| Guo Kong-ming, Xu Ya-lan. Multi-mode piezoelectric shunt vibration control of a Kagome sandwich panel[J]. Vibration and Shock, 2017, 36(19): 60-65. | |

| 19 | 陈良, 杜红军, 王刚, 等. 含负电容谐振分流电路的压电声子晶体梁的局域共振带隙与振动衰减[J]. 振动与冲击, 2016, 35(10): 38-43. |

| Chen Liang, Du Hong-jun, Wang Gang, et al. Local resonance band gaps and corresponding vibration attenuations of a piezoelectric phononic beam consisting of negative capacitor based resonant circuits[J]. Vibration and Shock, 2016, 35(10): 38-43. | |

| 20 | Boukraa E, Larbi W, Chaabane M, et al. An Analytical solution for vibration reduction of a thin rectangular plate using shunted piezoelectric patches[J]. Lecture Notes in Mechanical Engineering, 2015, 789: 585-595. |

| 21 | Abdullah Y, Baz A. Brake squeal: a control strategy using shunted piezoelectric pads[J]. Journal of Vibration and Acoustics, 2021, 143(3): 031005. |

| 22 | Dimitris A S. Passively damped laminated piezoelectric shell structures with integrated electric networks[J]. Aiaa Journal, 2000, 38(7): 1260-1268. |

| 23 | Vidoli S, Dell'Isola F. Vibration control in plates by uniformly distributed PZT actuators interconnected via electric networks[J]. European Journal of Mechanics/A Solids, 2001, 20(3): 435-456. |

| 24 | Porfiri M, Dell'Isola F, Mascioli F M F. Circuit analog of a beam and its application to multimodal vibration damping, using piezoelectric transducers[J]. International Journal of Circuit Theory and Applications, 2010, 32(4): 167-198. |

| 25 | Casadei F, Ruzzene M, Dozio L, et al. Broadband vibration control through periodic arrays of resonant shunts:experimental investigation on plates[J]. Smart Materials and Structures, 2010, 19(1): 015002. |

| 26 | Spadoni A, Ruzzene M, Cunefare K. Vibration and wave propagation control of plates with periodic arrays of shunted piezoelectric patches[J]. Journal of Intelligent Material Systems and Structures, 2009, 20(8): 979-990. |

| [1] | 李九一,周丰峻,刘建华,孙云厚,朱精忠,邱明坤. 扭转荷载下螺旋形螺纹连接件的IWAN改进模型[J]. 吉林大学学报(工学版), 2023, 53(5): 1305-1314. |

| [2] | 刘洋. 动臂塔机防后倾缓冲力计算方法[J]. 吉林大学学报(工学版), 2023, 53(10): 2785-2794. |

| [3] | 赵洋,肖洋,孙皓,霍文浩,冯松,廖勇. 基于围道积分的润滑接触齿轮微点蚀损伤特征模拟[J]. 吉林大学学报(工学版), 2022, 52(4): 799-810. |

| [4] | 郑伟,孙见君,马晨波,於秋萍,张玉言,牛韬. 汽车轮毂加工夹具的研究现状及展望[J]. 吉林大学学报(工学版), 2022, 52(1): 25-36. |

| [5] | 陈魏,雷雨龙,李兴忠,付尧,扈建龙,侯利国. 低速工况下渐开线圆柱直齿轮齿面粘着磨损计算[J]. 吉林大学学报(工学版), 2021, 51(5): 1628-1634. |

| [6] | 郭震,于红英,滑忠鑫,赵娣. 刚性折纸机构运动分析及折叠过程仿真[J]. 吉林大学学报(工学版), 2020, 50(1): 66-76. |

| [7] | 朱伟,王传伟,顾开荣,沈惠平,许可,汪源. 一种新型张拉整体并联机构刚度及动力学分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1777-1786. |

| [8] | 毛宇泽, 王黎钦. 鼠笼支撑一体化结构对薄壁球轴承承载性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1508-1514. |

| [9] | 庄晔, 陈禹行, 杨业海, 徐淑芳. 某双筒液阻式减振器外特性建模[J]. 吉林大学学报(工学版), 2016, 46(3): 732-736. |

|

||