吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (6): 1528-1536.doi: 10.13229/j.cnki.jdxbgxb.20221223

• 车辆工程·机械工程 • 上一篇

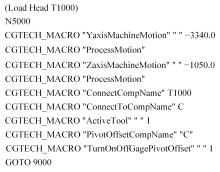

多主轴头数控机床虚拟仿真加工平台的构建方法

- 西安建筑科技大学 机电工程学院,西安 710055

Construction method of virtual simulation machining platform for CNC machine tools with multi-spindle heads

An-jiang CAI( ),Pei-peng WANG,Chen-xi WANG,Ling LI

),Pei-peng WANG,Chen-xi WANG,Ling LI

- School of Mechanical and Electrical Engineering,Xi 'an University of Architecture and Technology,Xi' an 710055,China

摘要:

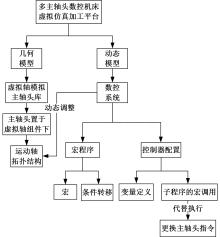

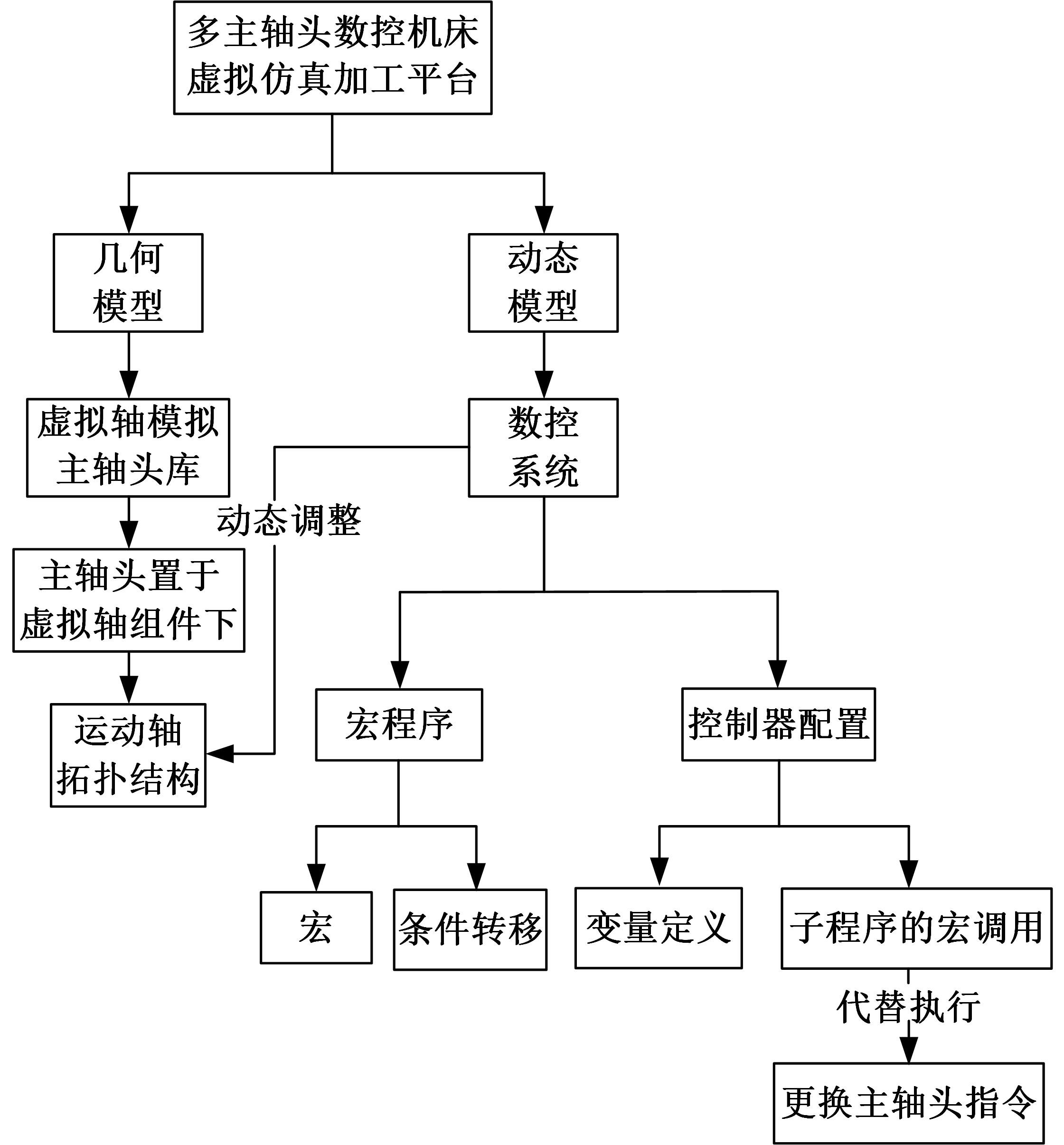

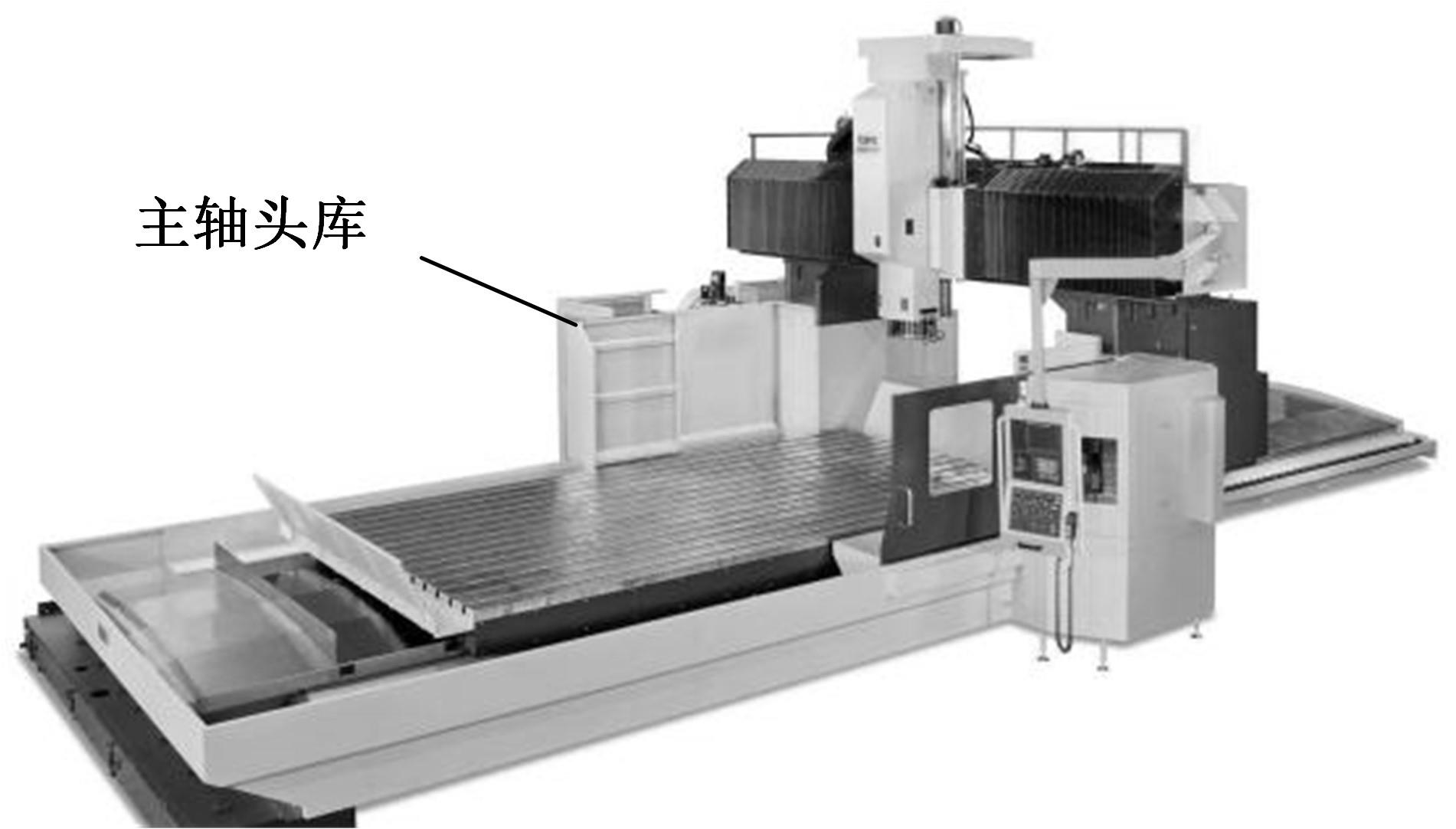

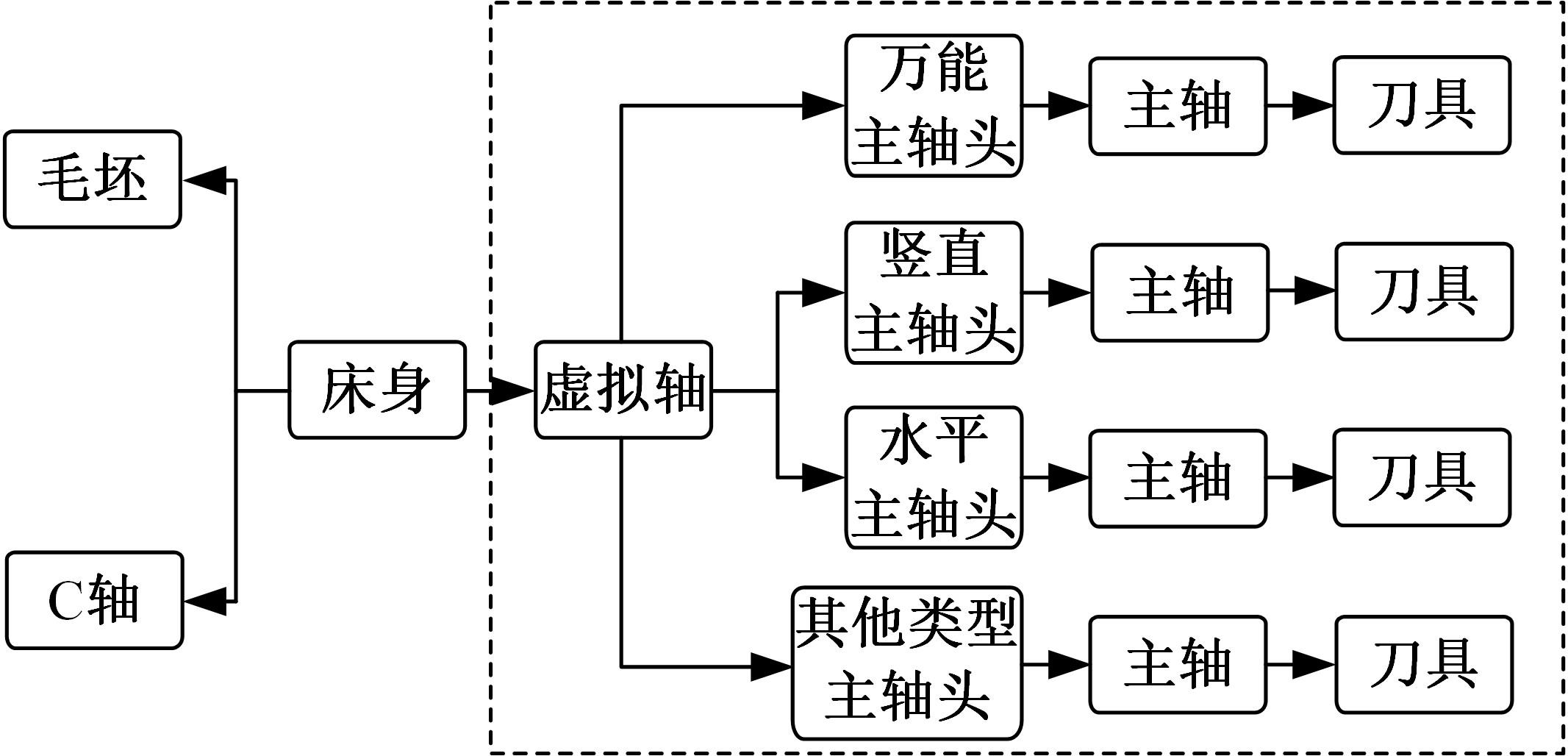

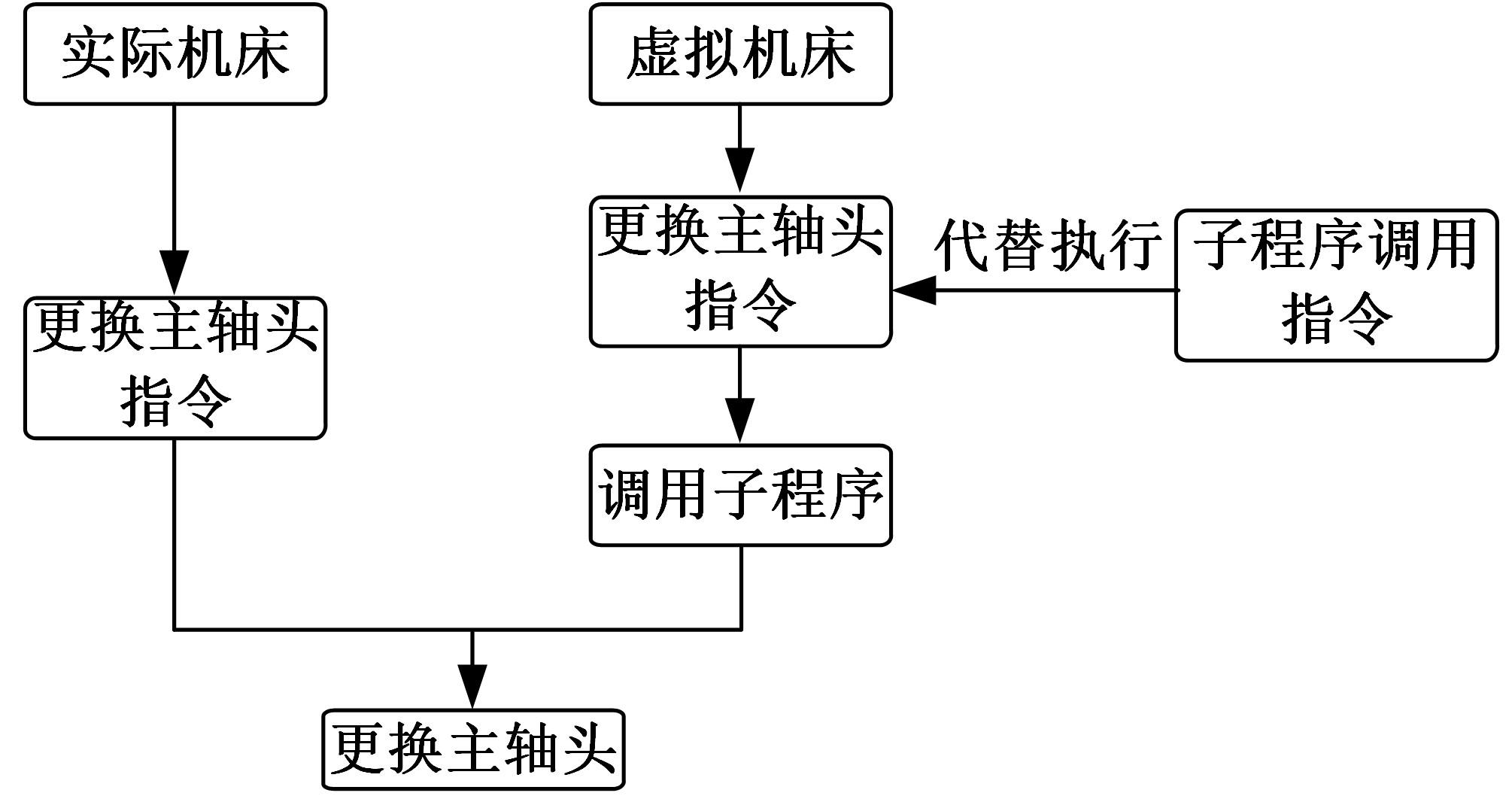

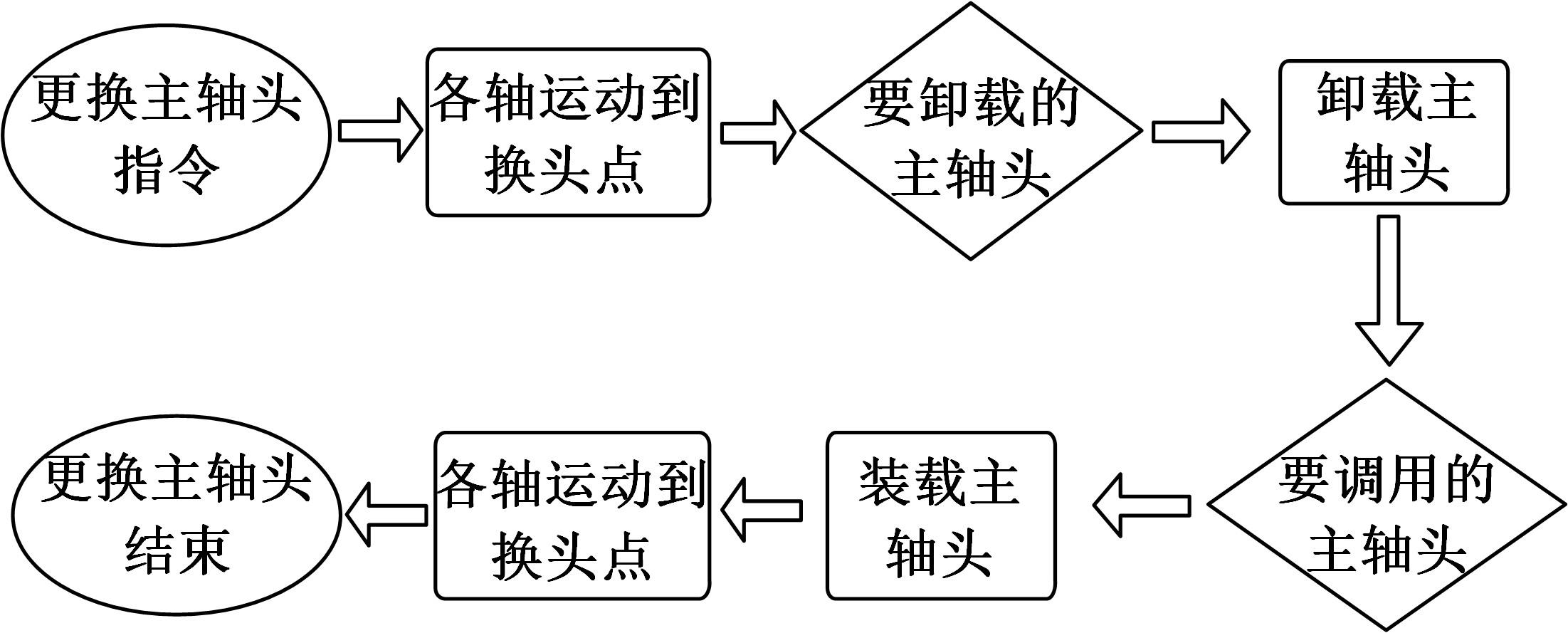

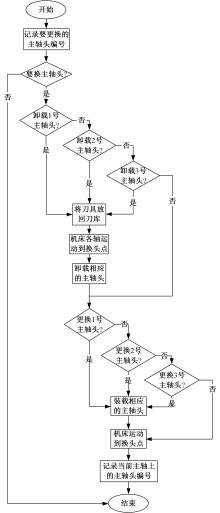

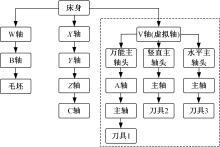

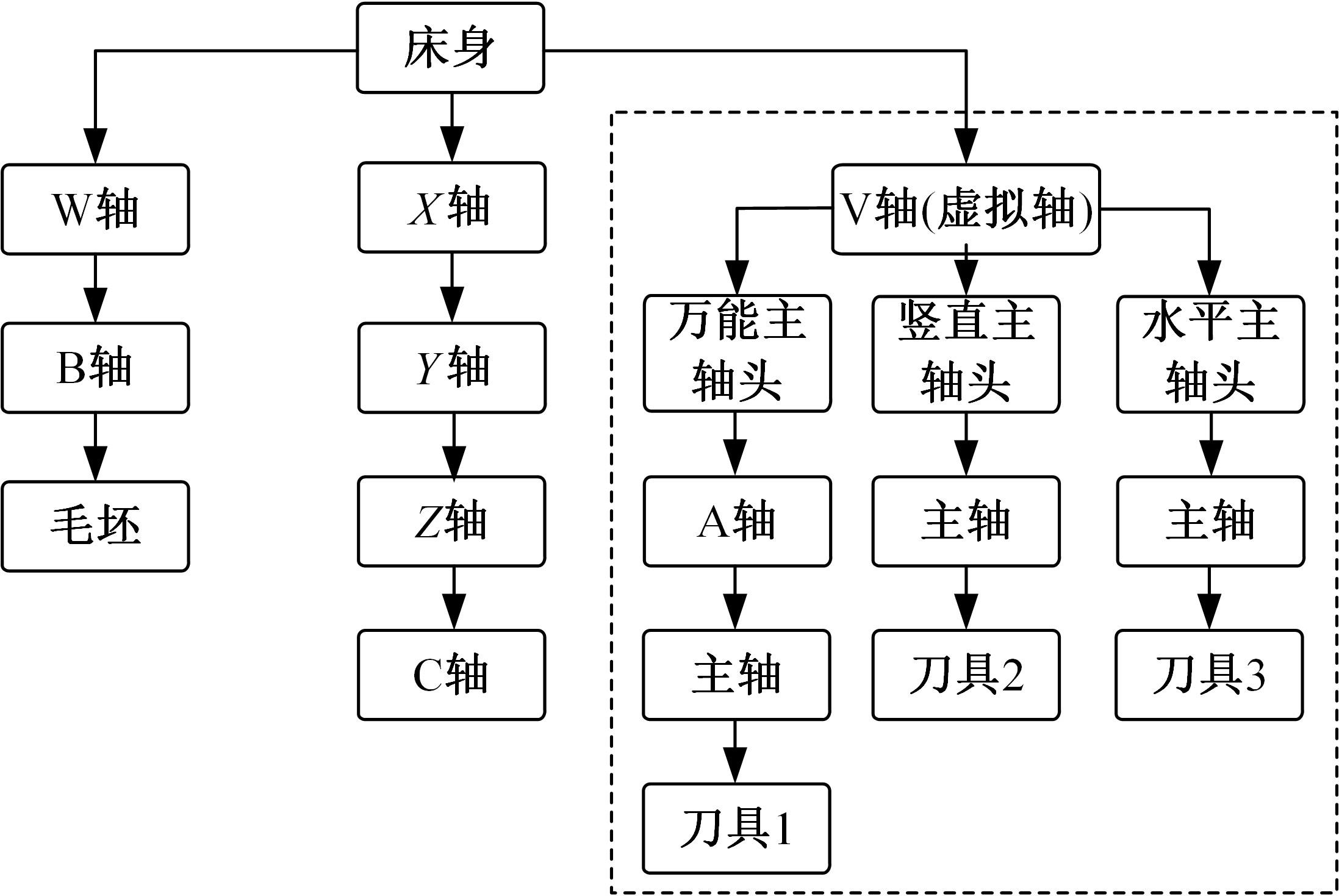

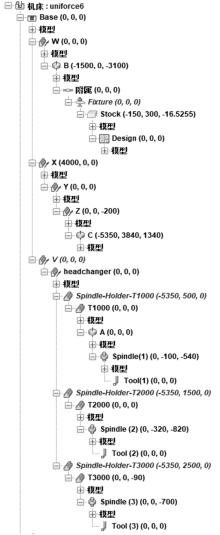

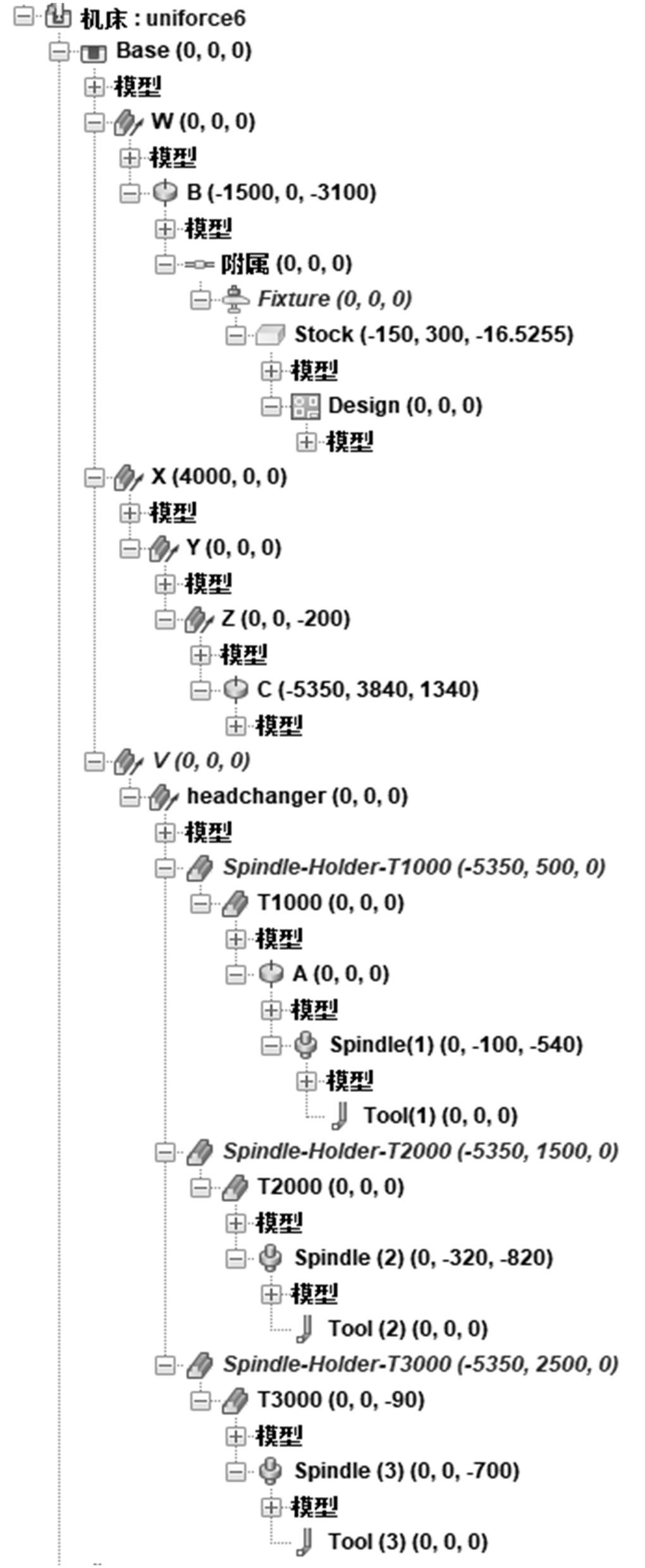

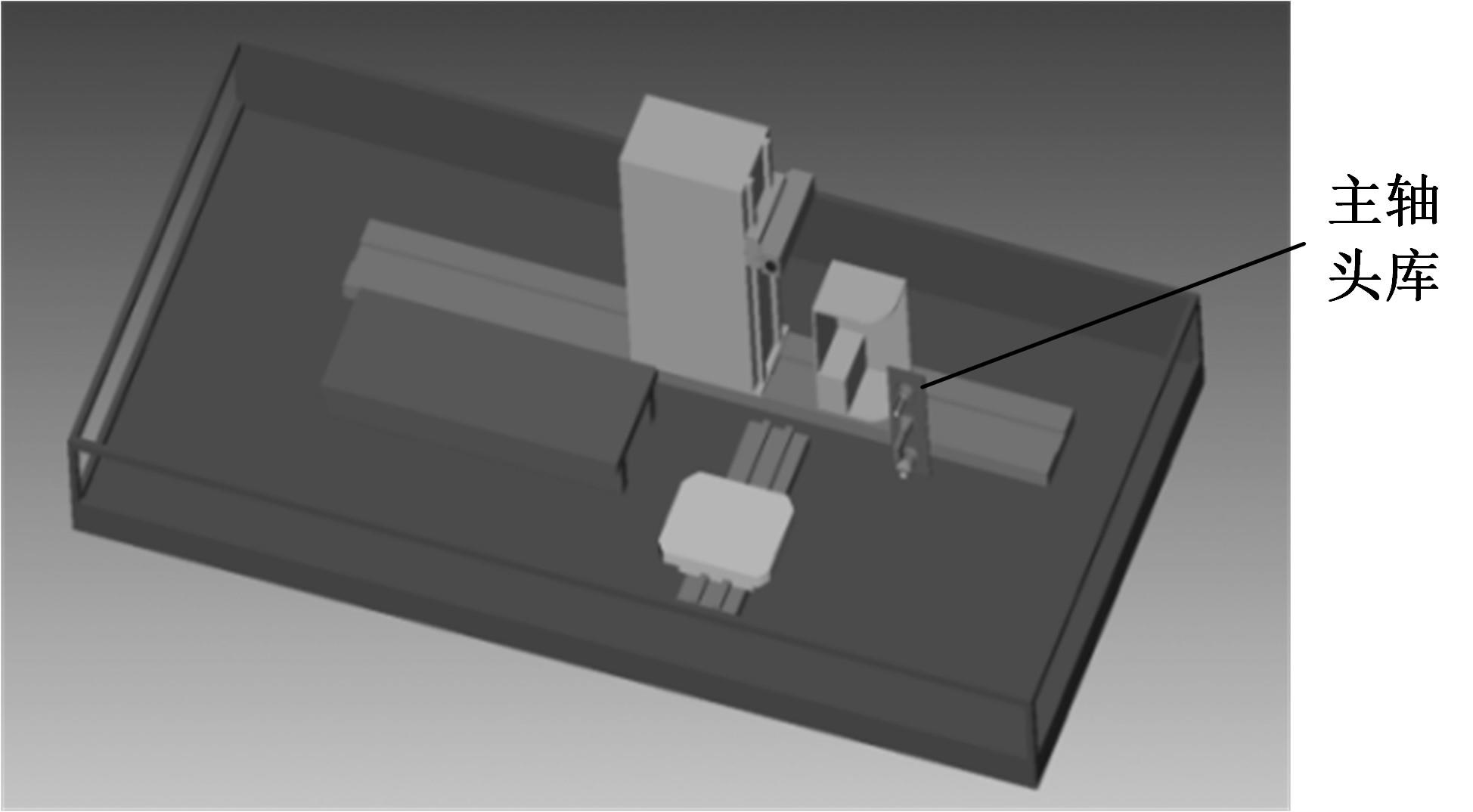

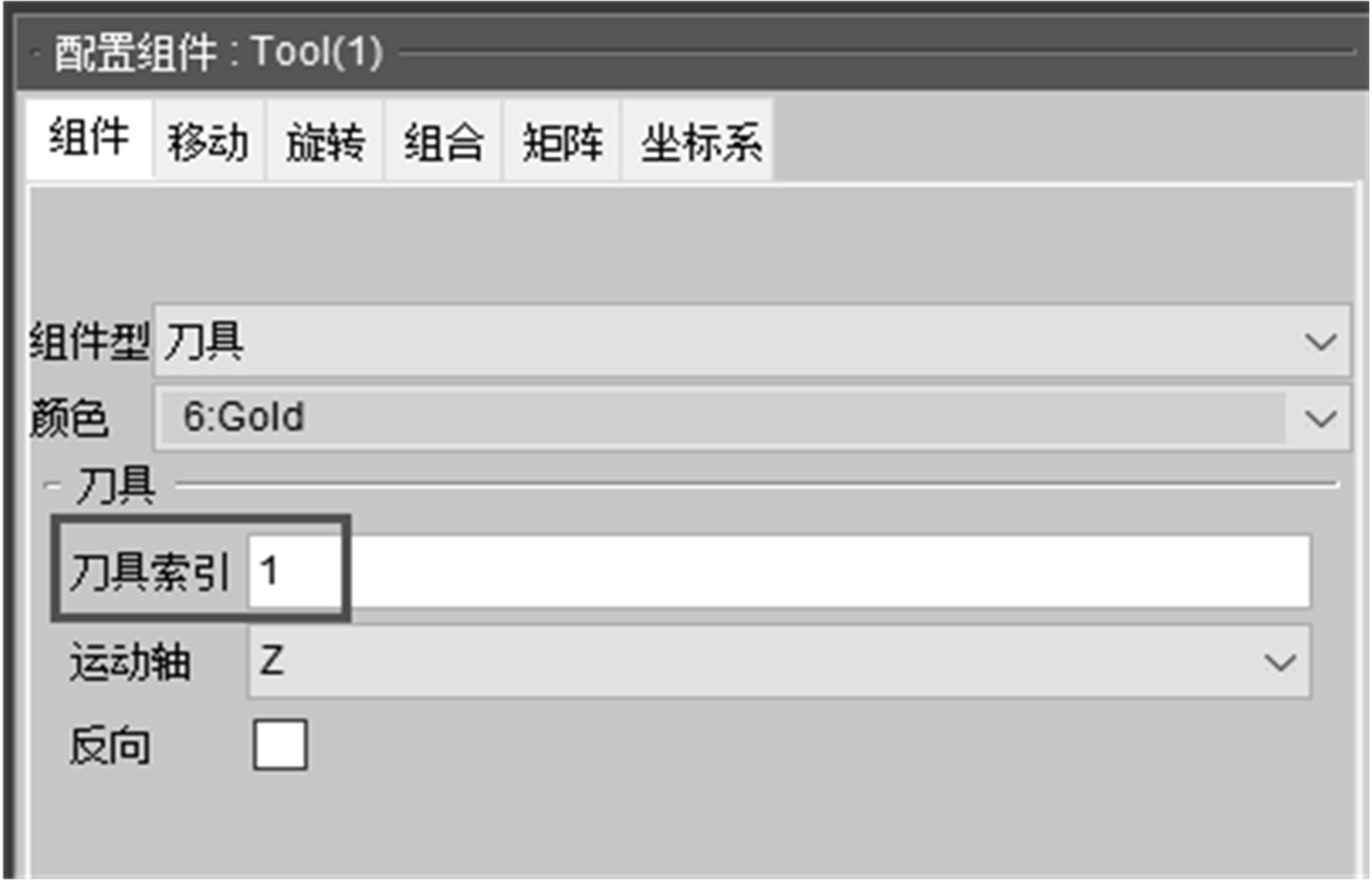

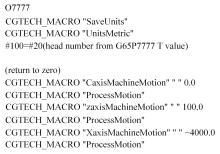

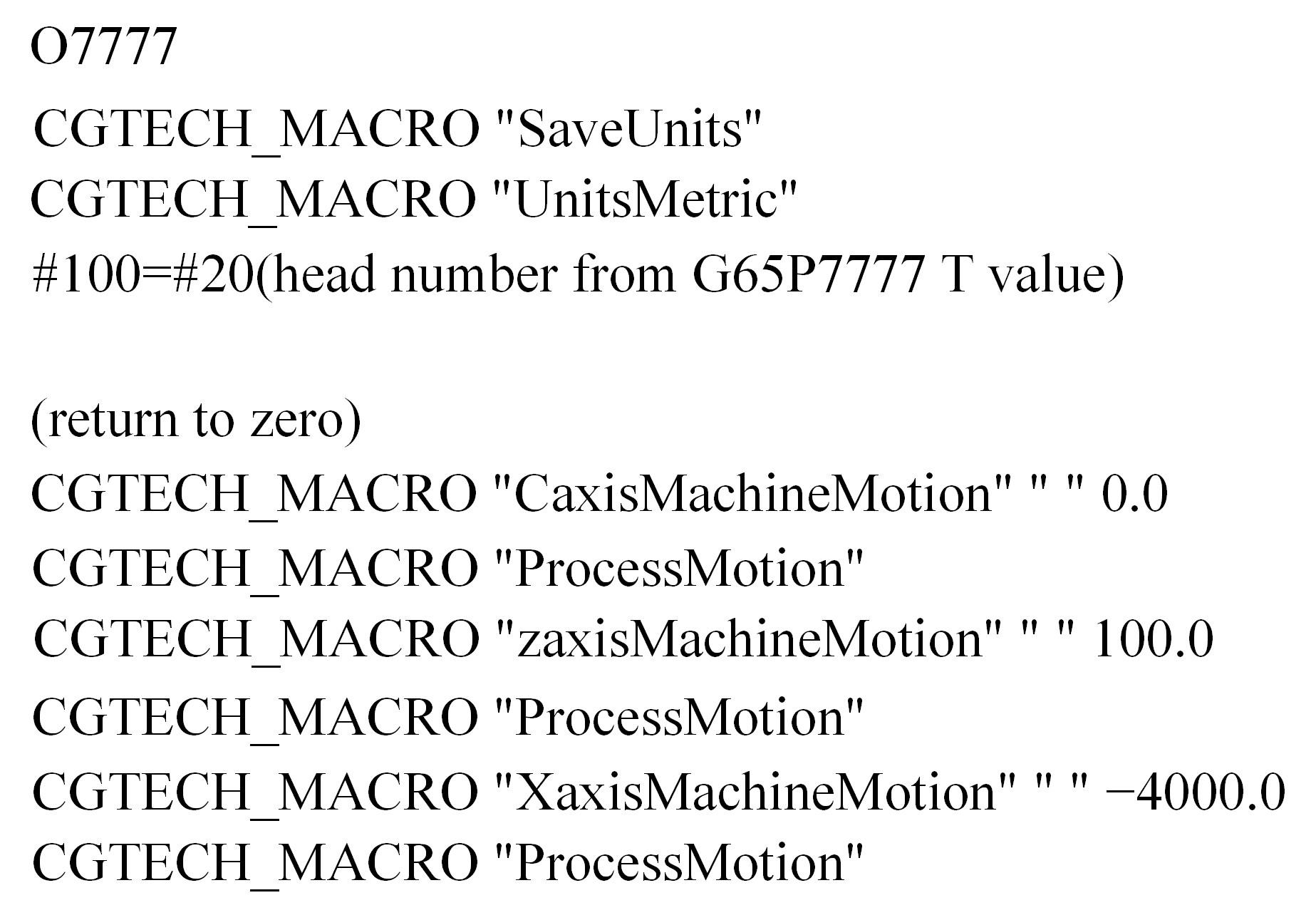

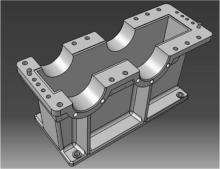

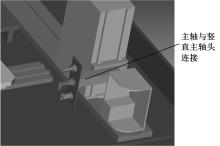

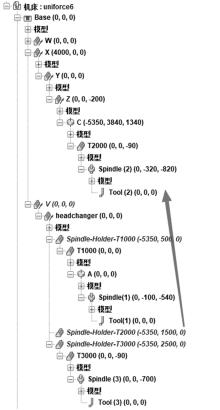

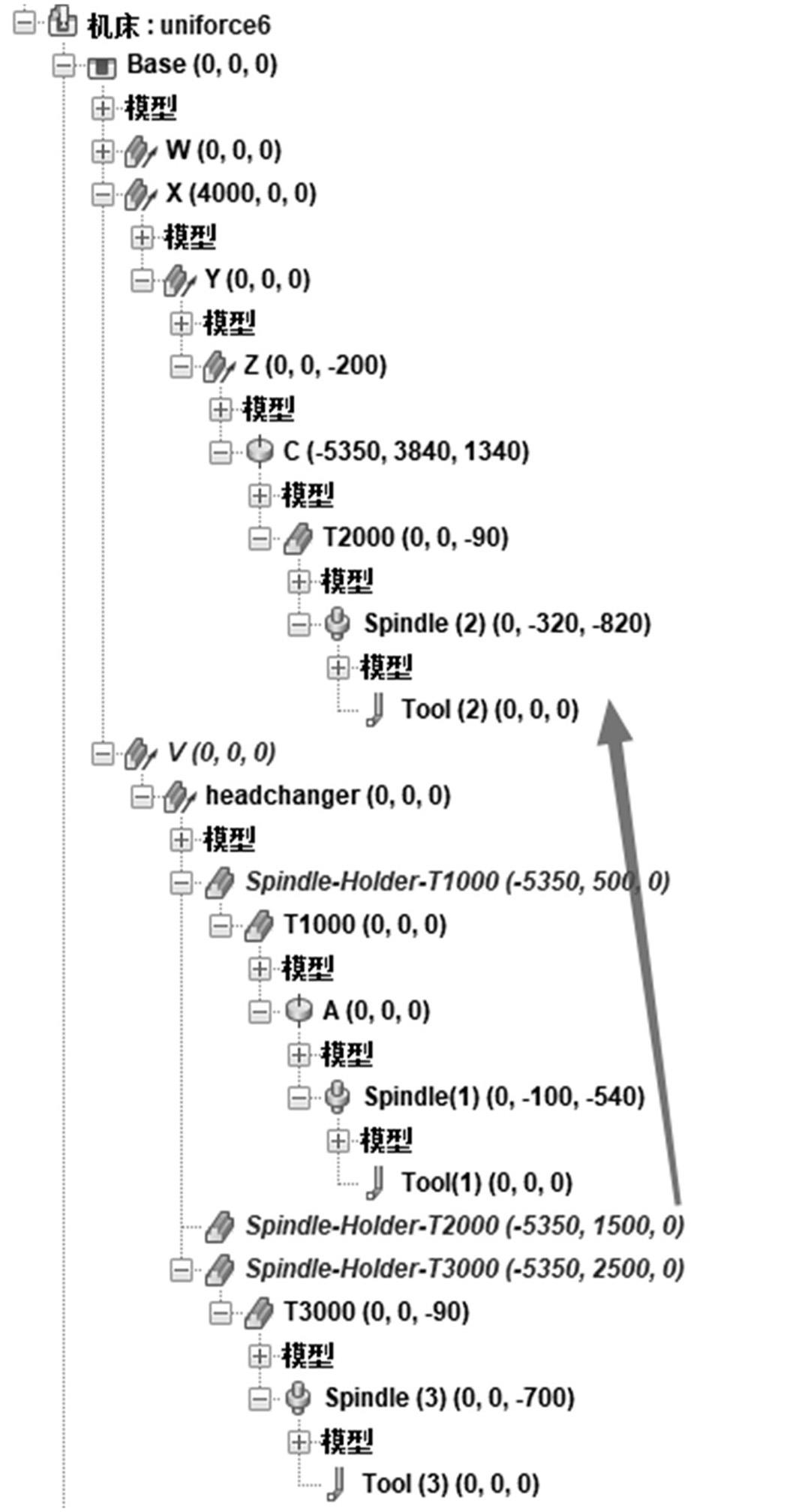

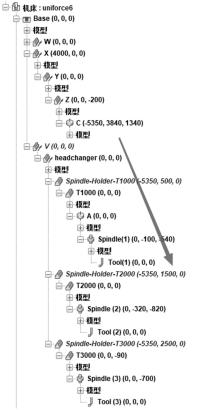

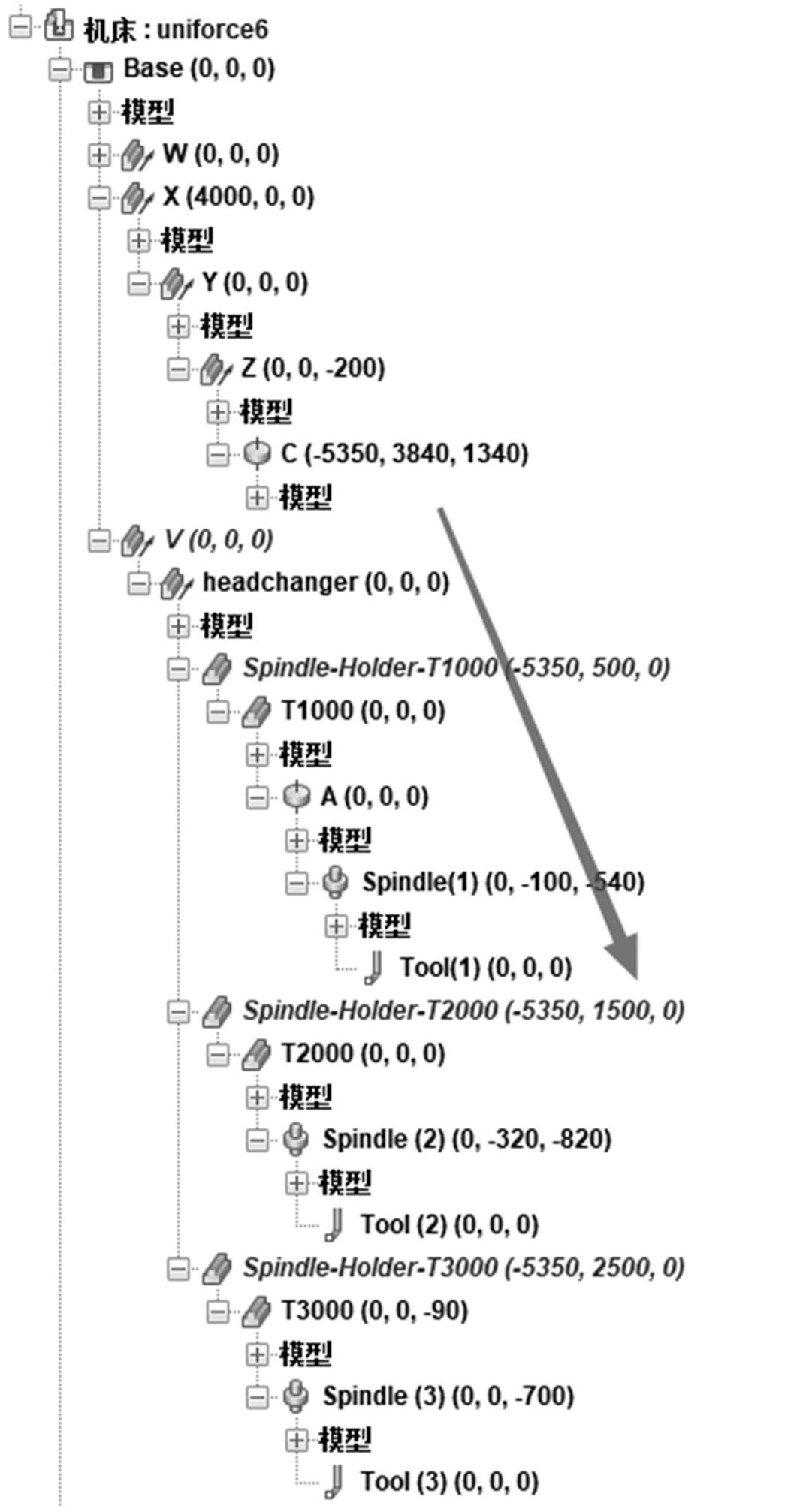

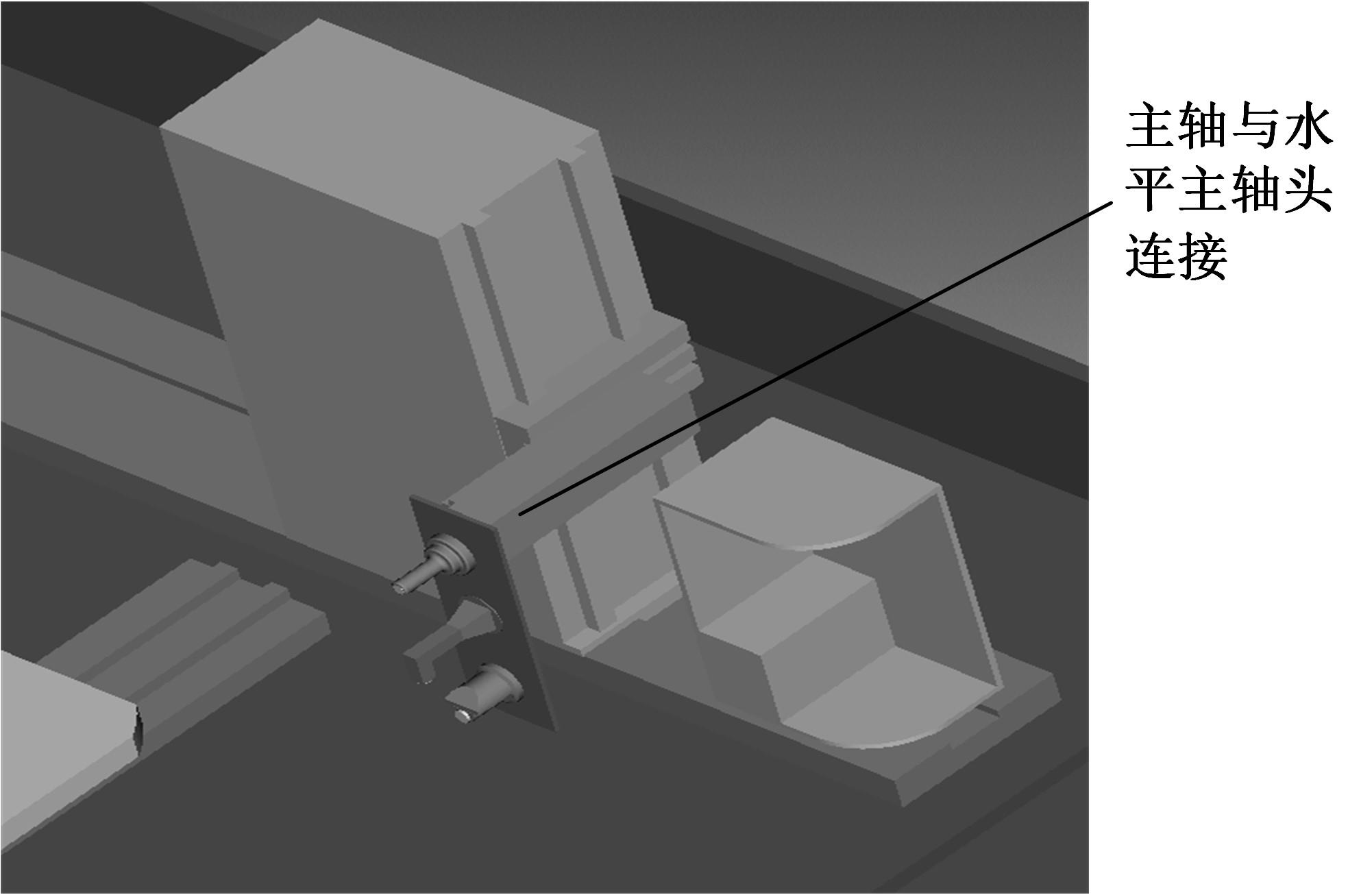

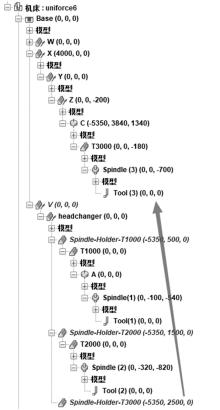

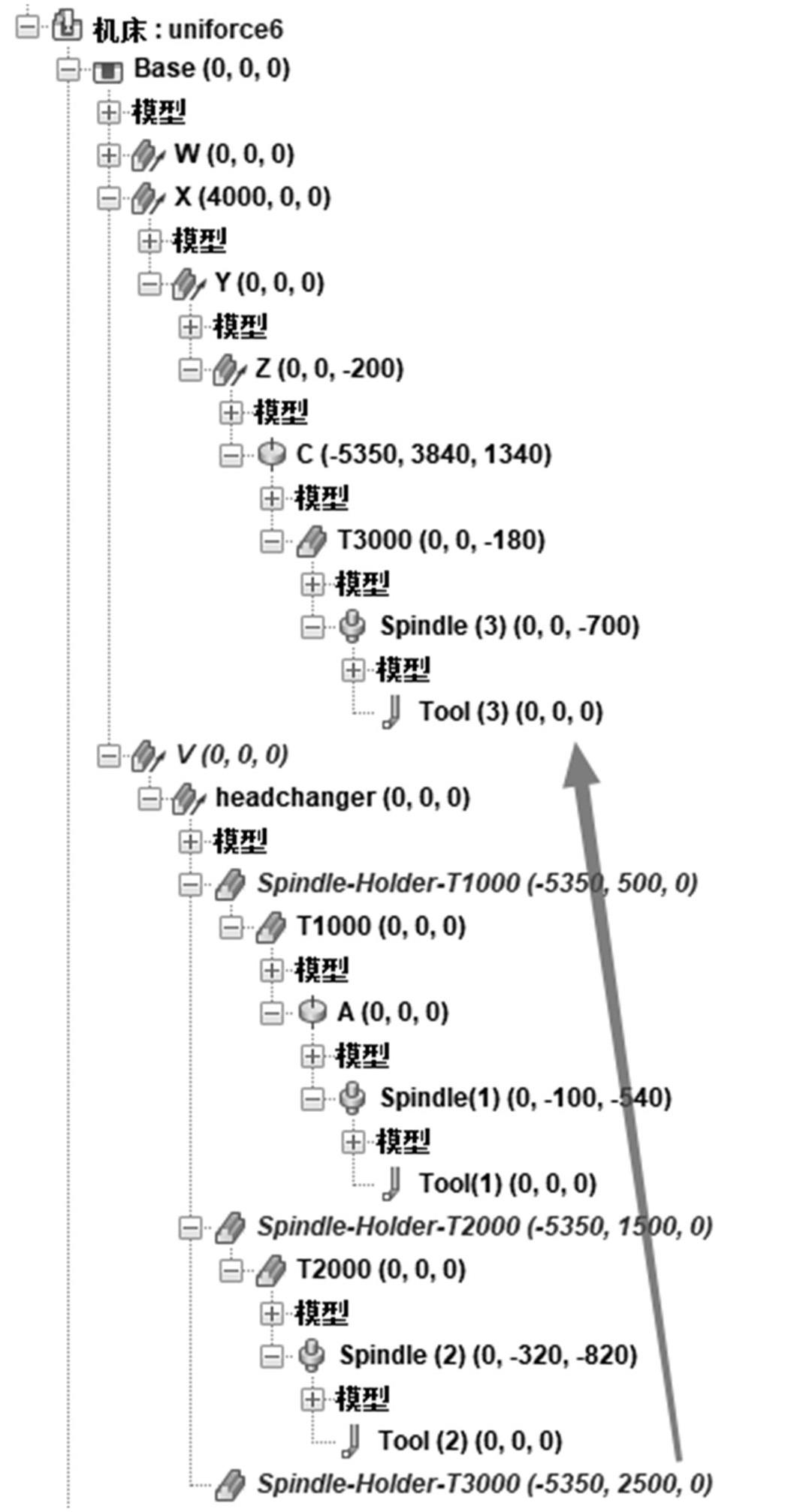

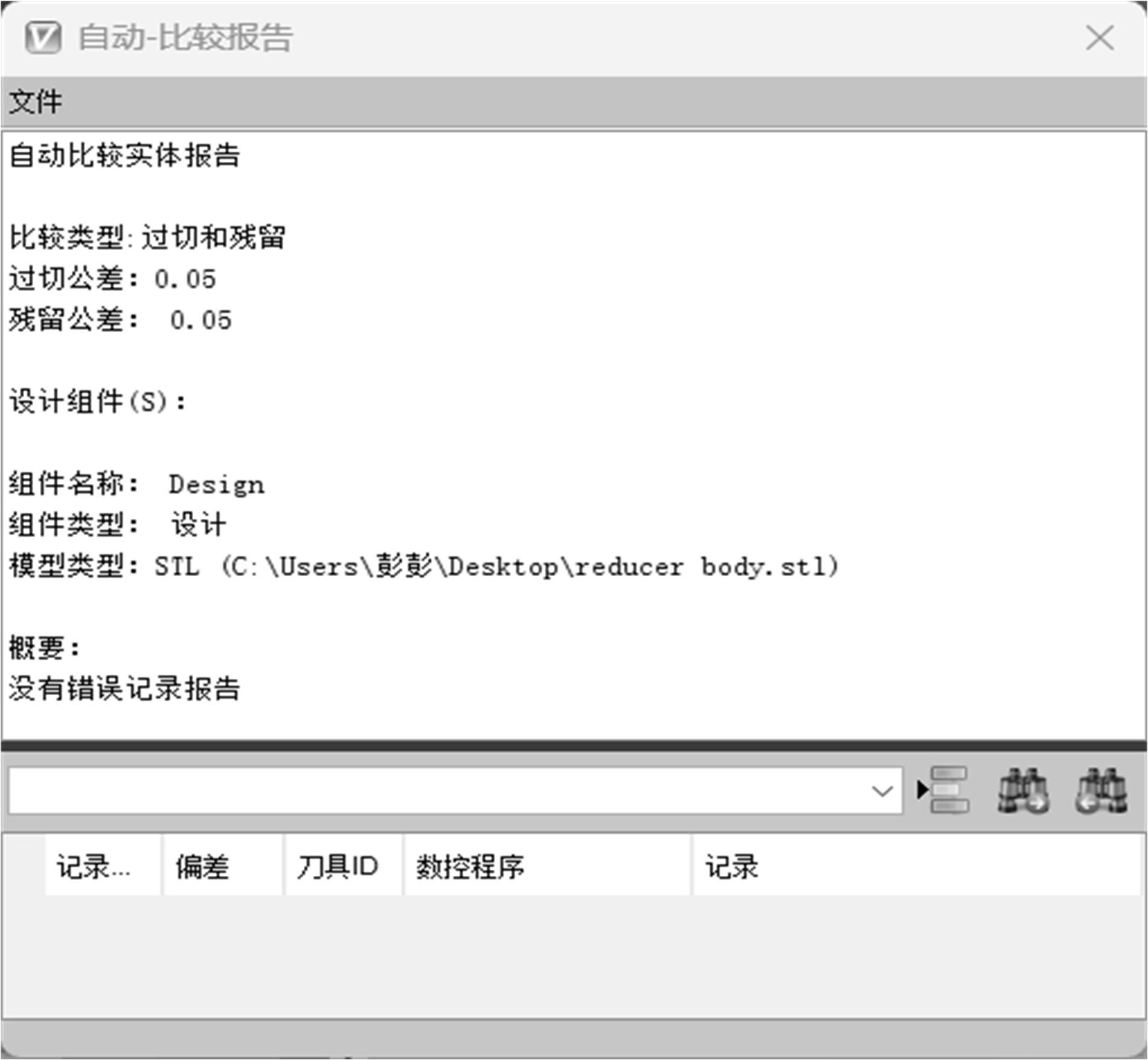

针对目前多主轴头数控机床在虚拟仿真加工过程中无法实现多主轴头切换调用的问题,提出了一种多主轴头数控机床虚拟仿真加工平台的构建方法。首先,根据多主轴头数控机床的多主轴头库创立虚拟轴,构建其各运动轴的拓扑结构,搭建虚拟数控机床的几何模型;其次,利用数控系统的宏和变量等进行二次开发,通过改变虚拟轴中各主轴头组件在虚拟数控机床结构项目树和几何模型中的位置得到宏程序,并通过宏调用指令将此更换主轴头宏程序作为子程序代替执行NC程序中更换主轴头的功能指令,使虚拟数控机床在执行更换主轴头指令时实际执行的是更换主轴头的宏程序,实现了多主轴头数控机床虚拟仿真加工过程中主轴头的动态切换调用;最后,应用该方法构建了UniForce6落地镗铣加工中心的虚拟仿真加工平台,并完成了某箱体零件的仿真加工。结果表明:该虚拟仿真加工平台可实现多个主轴头协同完成加工过程的连续仿真,符合实际加工工况,且在更换主轴头的过程中可检查干涉碰撞情况,进一步提高了多主轴头数控机床虚拟仿真加工的有效性。

中图分类号:

- TG659

| 1 | 胡涞,查俊,朱永生,等.基础装备制造及高档集成数控机床研究进展[J].中国机械工程,2021,32(16):1891-1903. |

| Hu Lai, Zha Jun, Zhu Yong-sheng, et al. Research progress in basic equipment manufacturing and high-grade integrated CNC machine tools[J]. China Mechanical Engineering, 2021,32(16): 1891-1903. | |

| 2 | 崔榕芳,陈蔚芳,潘立剑,等.基于遗传算法的多主轴头加工空行程轨迹规划[J].计算机集成制造系统,2022,28(2):507-517. |

| Cui Rong-fang, Chen Wei-fang, Pan Li-jian, et al. Empty travel trajectory planning of multi-spindle head processing based on genetic algorithm[J]. Computer Integrated Manufacturing System, 2022,28(2): 507-517. | |

| 3 | 吴志清.VERICUT虚拟机床技术在五轴加工中的应用研究[J].机床与液压,2016,44(16):66-68, 76. |

| Wu Zhi-qing. Application of VERICUT virtual machine tool in five axis processing[J]. Machine Tool and Hydraulic Pressure, 2016,44(16): 66-68, 76. | |

| 4 | Yu D Y, Ding Z. Post-processing algorithm of a five-axis machine tool with dual rotary tables based on the TCS method[J]. The International Journal of Advanced Manufacturing Technology, 2019,102(9): 3937-3944. |

| 5 | Chen Y D, Wei H X, Wang T M. Three-dimensional tool radius compensation for a 5-Axis peripheral milling[J]. Advanced Science Letters, 2011, 4(8): 3093-3096. |

| 6 | Tang J Y, Yang X Y. Research on manufacturing method of planing for spur face-gear with 4-axis CNC planer[J]. The International Journal of Advanced Manufacturing Technology, 2016,82(5): 847-858. |

| 7 | Yang J H, Zhang D H, Wu B H, et al. A path planning method for error region grinding of aero-engine blades with free-form surface[J]. The International Journal of Advanced Manufacturing Technology, 2015,81(1): 717-728. |

| 8 | 杨胜群,杨伟群,唐秀梅,等.VERICUT数控加工仿真技术[M].北京:清华大学出版社,2013:103-115. |

| 9 | 唐清春,尹韶辉,王永强,等.非模态回转轴旋转角的优化方法[J].机械工程学报,2018,54(3):178-185. |

| Tang Qing-chun, Yin Shao-hui, Wang Yong-qiang, et al. Optimization method of rotation angle of nonmodal rotary axis[J]. Journal of Mechanical Engineering, 2018,54(3):178-185. | |

| 10 | 韦洪新,王智森,程发武.基于控制分布角的球面螺旋加工法研究[J].现代制造工程,2022,501(6):39-42. |

| Wei Hong-xin, Wang Zhi-sen, Cheng Fa-wu. Study on spherical helix processing method based on control distribution angle[J]. Modern Manufacturing Engineering, 2022,501 (6): 39-42. |

| [1] | 巩亚东,丁明祥,李响,田近民. TC4钛合金材料铣削加工分析及参数优化[J]. 吉林大学学报(工学版), 2024, 54(4): 917-925. |

| [2] | 董长斌,李龙坤,刘永平,裴王鹏. 非圆齿轮传动误差及齿侧间隙的数值模拟与试验[J]. 吉林大学学报(工学版), 2024, 54(4): 865-873. |

| [3] | 吴飞,农皓业,马晨浩. 基于粒子群优化算法⁃长短时记忆模型的刀具磨损预测方法[J]. 吉林大学学报(工学版), 2023, 53(4): 989-997. |

| [4] | 郭静,桂林,侯威,李俊烨,朱志宝,孙立伟. 阀套交叉孔磨粒流精密加工质量分析[J]. 吉林大学学报(工学版), 2023, 53(12): 3367-3378. |

| [5] | 宋林,王立平,吴军,关立文,刘知贵. 基于信息物理融合和数字孪生的可靠性分析[J]. 吉林大学学报(工学版), 2022, 52(2): 439-449. |

| [6] | 宗芳,李宇暄,张慧永,高飞. 一带一路沿线配送中心选址模型[J]. 吉林大学学报(工学版), 2022, 52(11): 2592-2599. |

| [7] | 薛锋,何传磊,黄倩,罗建. 多式轨道交通网络的耦合协调度[J]. 吉林大学学报(工学版), 2021, 51(6): 2040-2050. |

| [8] | 刘永平,董长斌,魏永峭. 椭圆齿轮传动系统齿面接触与动态磨损分析[J]. 吉林大学学报(工学版), 2021, 51(5): 1620-1627. |

| [9] | 李国龙,陶小会,徐凯,李喆裕. 数控机床转台位置相关几何误差的快速测量与辨识[J]. 吉林大学学报(工学版), 2021, 51(2): 458-467. |

| [10] | 董长斌,刘永平,魏永峭,邓海青,许杰. 椭圆齿轮传动系统非线性动态特性分析[J]. 吉林大学学报(工学版), 2020, 50(2): 483-493. |

| [11] | 赵云伟,耿德旭,刘晓敏,刘齐. 气动柔性六足机器人定半径转弯实现方法与稳定性[J]. 吉林大学学报(工学版), 2020, 50(2): 472-482. |

| [12] | 段春争,张方圆,寇文能,魏斌. 高速硬切削表面白层马氏体相变[J]. 吉林大学学报(工学版), 2019, 49(5): 1575-1583. |

| [13] | 罗开玉,邢月华,柴卿锋,吴世凯,尹叶芳,鲁金忠. 激光冲击强化对2Cr13不锈钢腐蚀 疲劳性能的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 850-858. |

| [14] | 马芳武,陈实现,韩露,梁鸿宇,蒲永锋. 金属表面特征与金属⁃塑料直接连接强度的相关性[J]. 吉林大学学报(工学版), 2019, 49(3): 816-821. |

| [15] | 鲁金忠,周婉婷,张圣洋,邵亦锴,王长雨,罗开玉. 激光冲击强化层数对6061⁃T6铝合金抗腐蚀性能的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 842-849. |

|

||