吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (6): 1519-1527.doi: 10.13229/j.cnki.jdxbgxb.20230112

• 车辆工程·机械工程 • 上一篇

计及安装角的六自由度平台虎克铰干涉计算模型

- 湖南师范大学 工程与设计学院,长沙 410081

Interference calculation model of Hooke joint of 6-DOF platform considering installation angle

- College of Engineering and Design,Hunan Normal University,Changsha 410081,China

摘要:

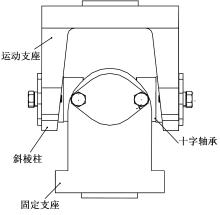

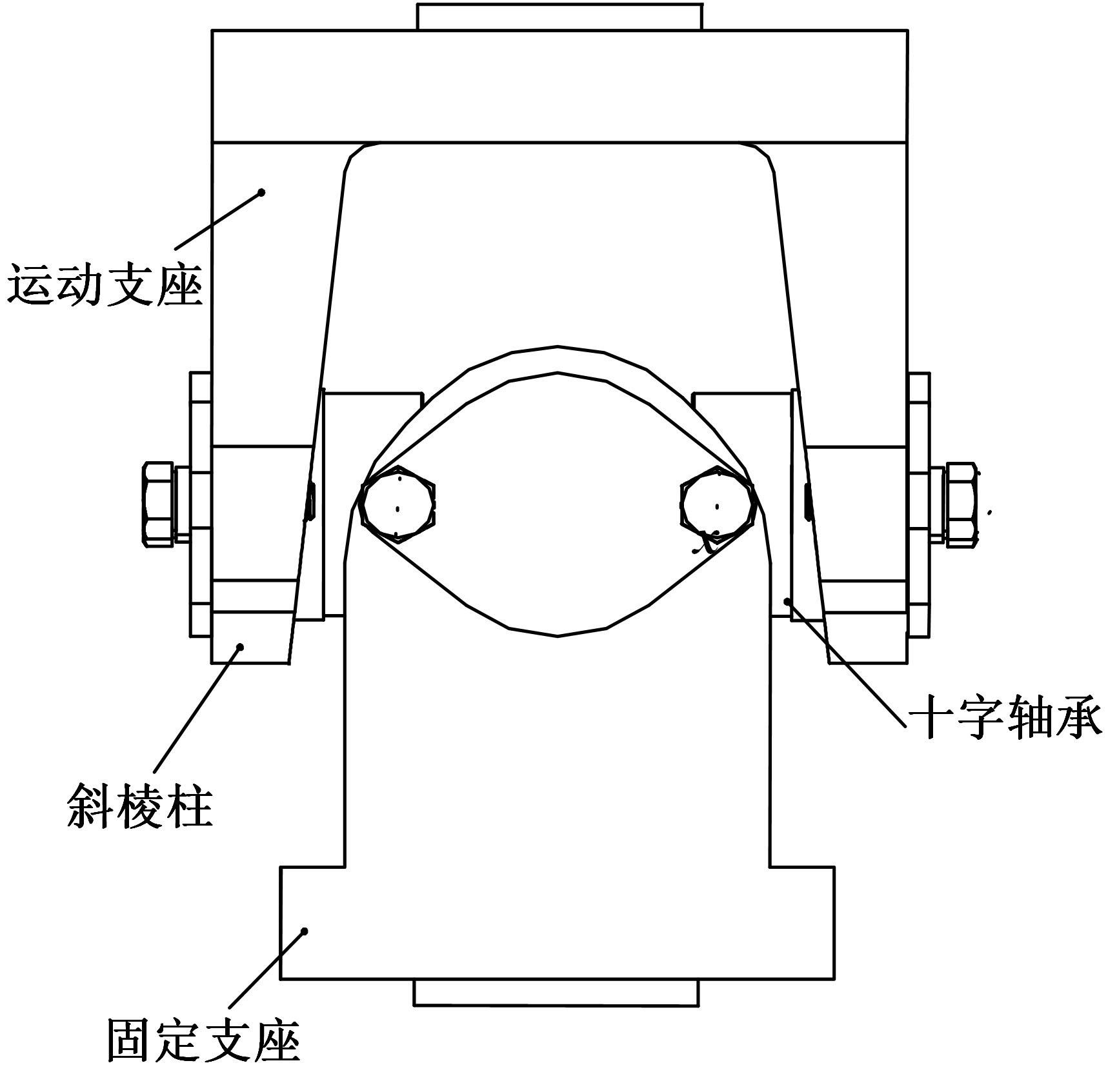

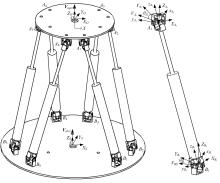

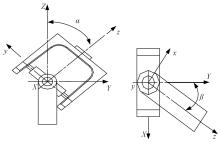

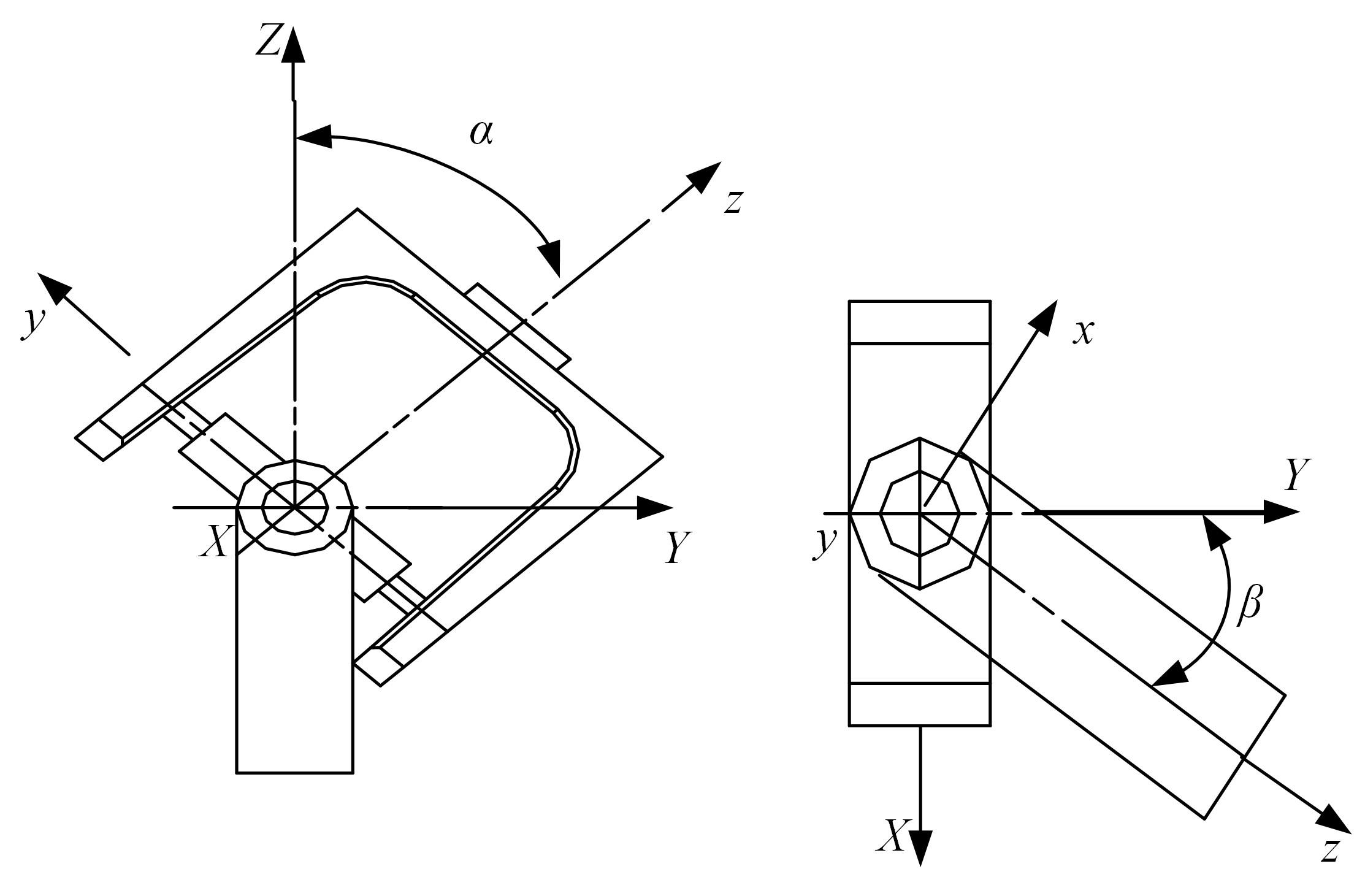

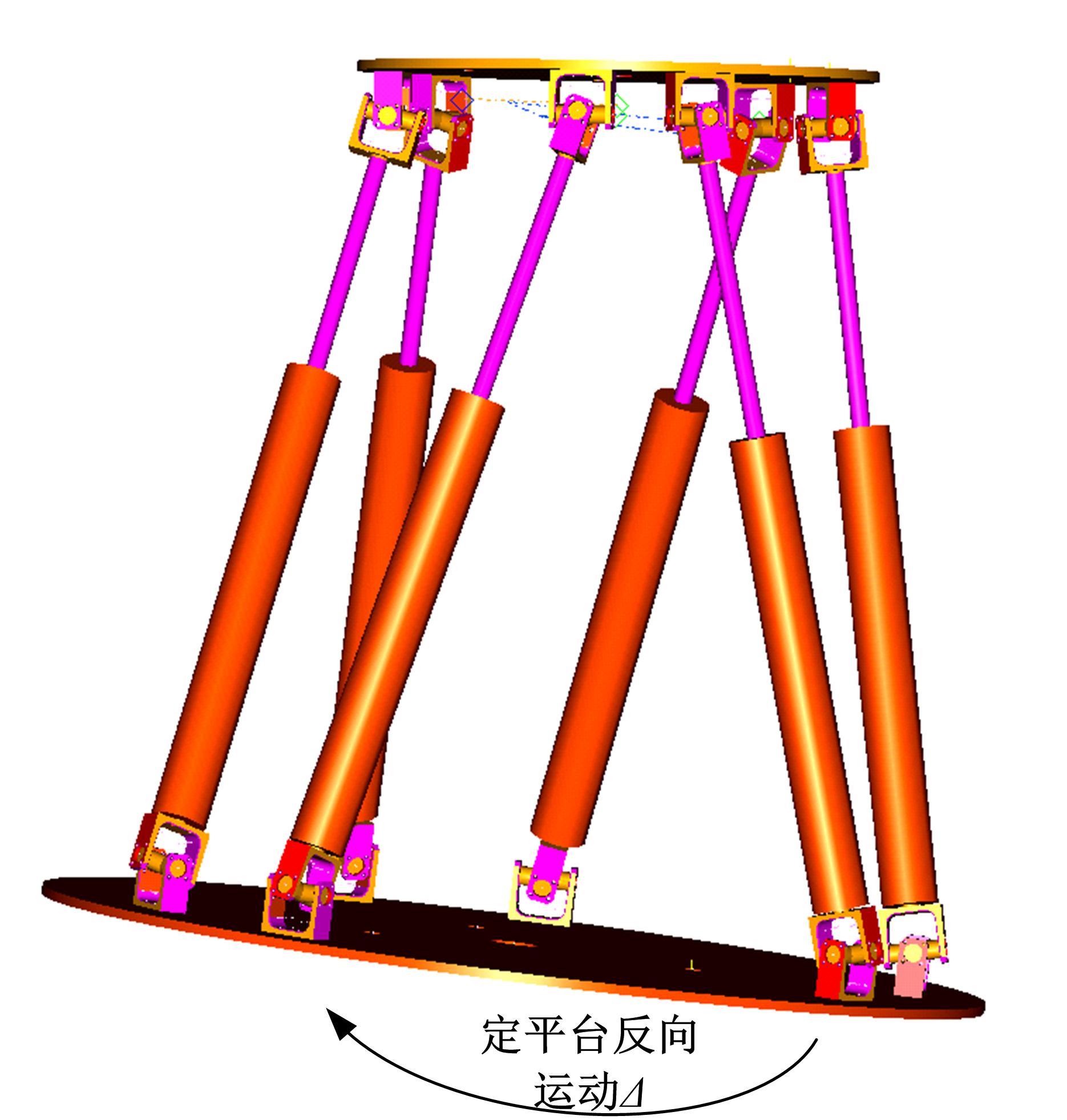

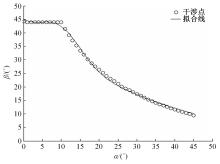

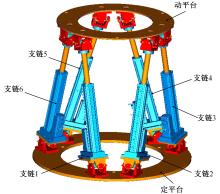

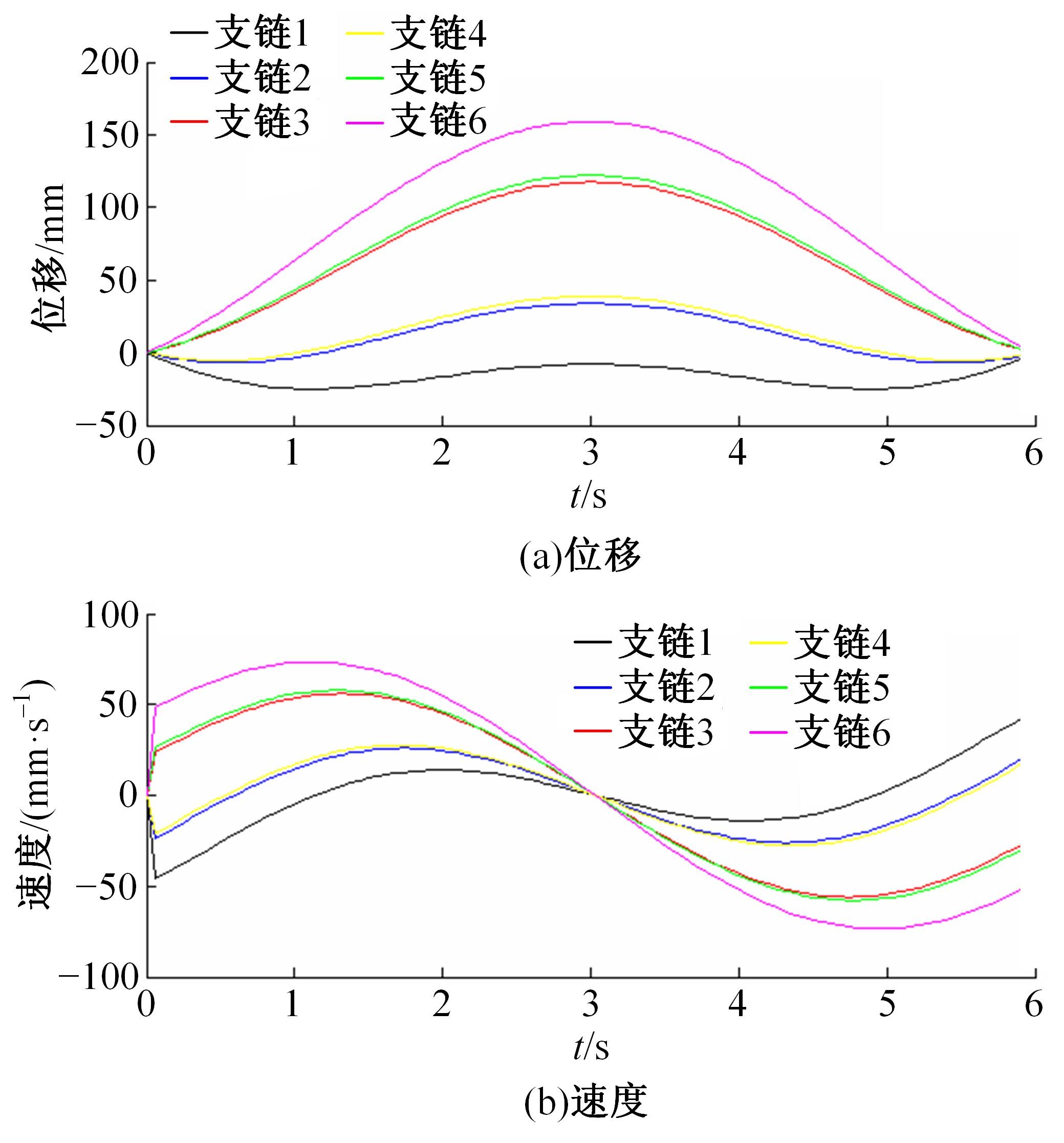

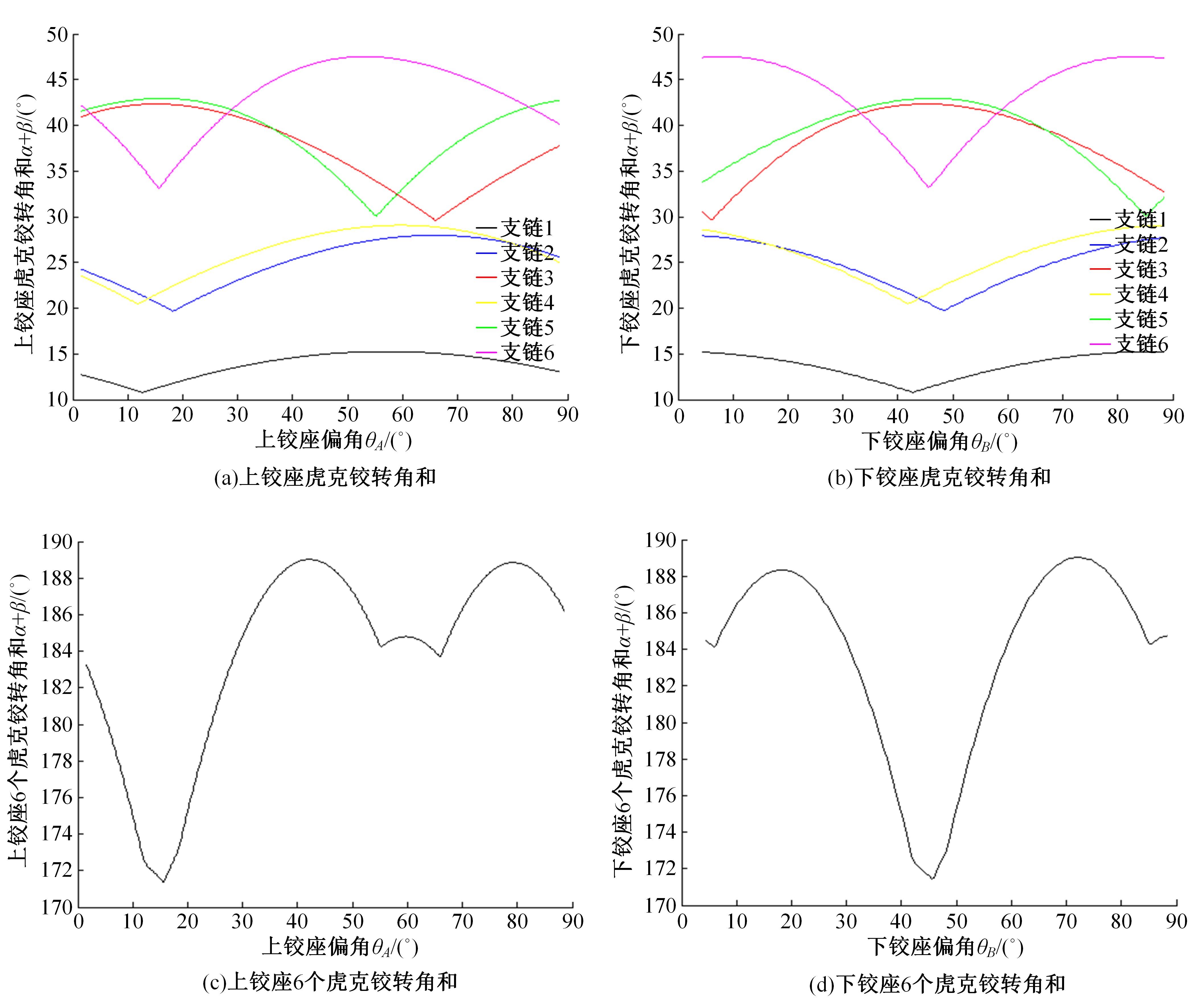

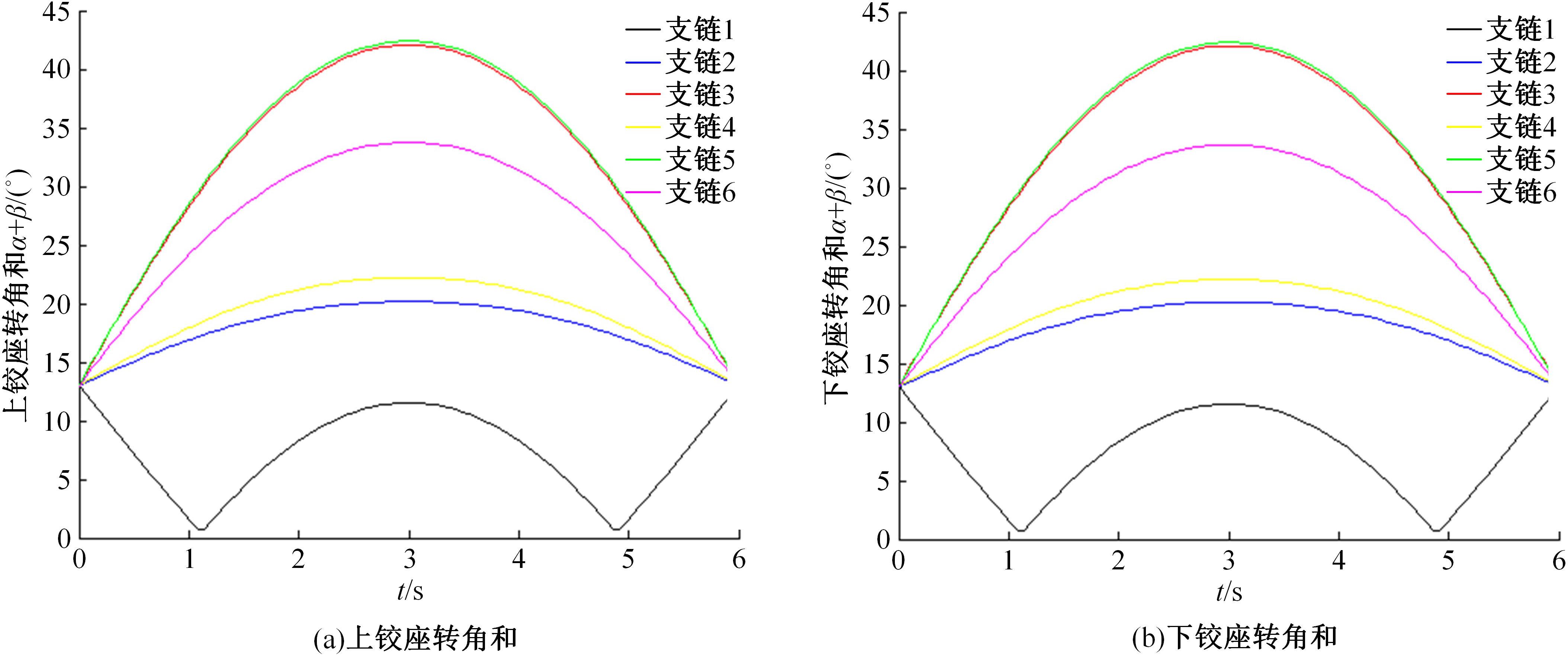

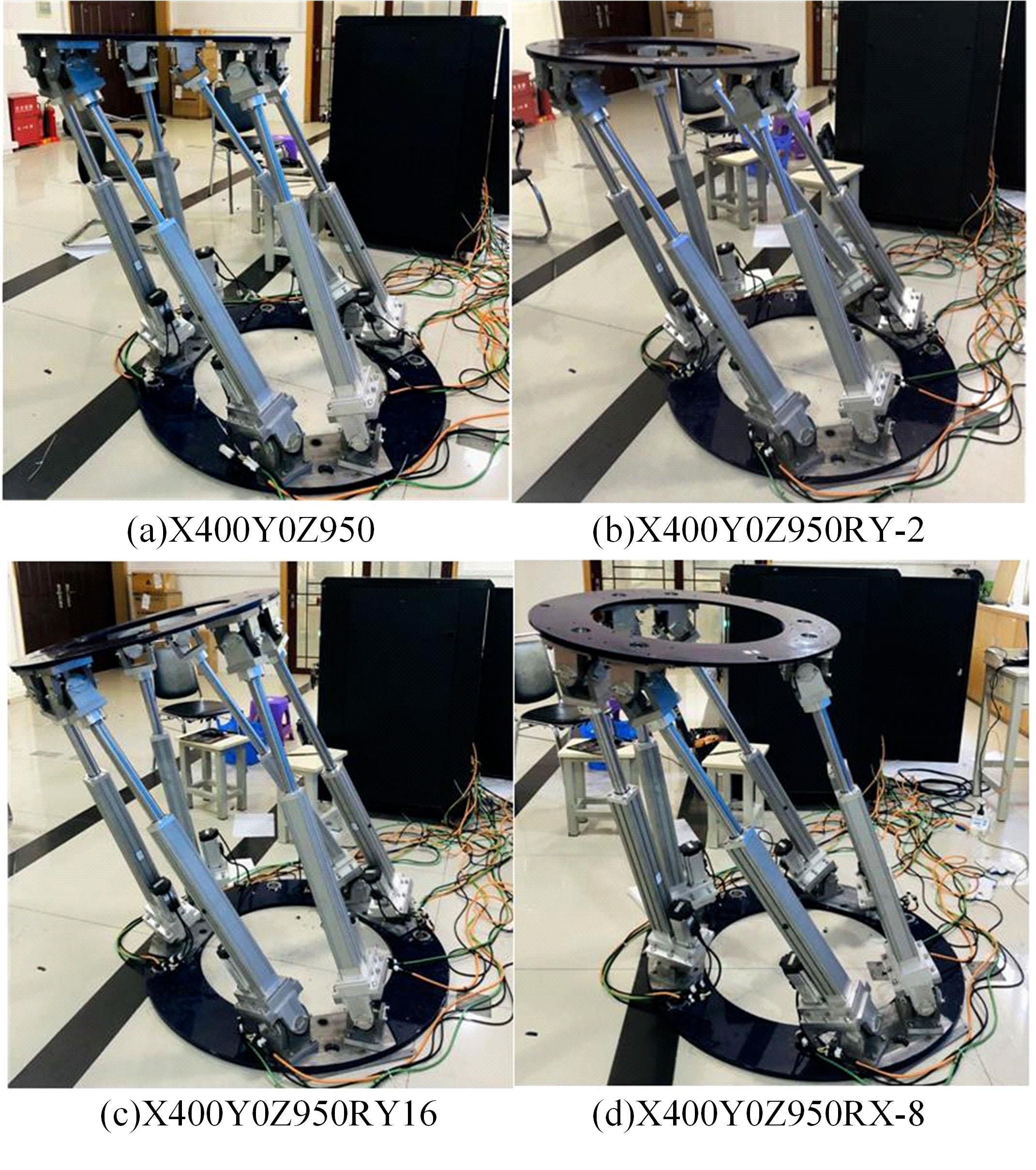

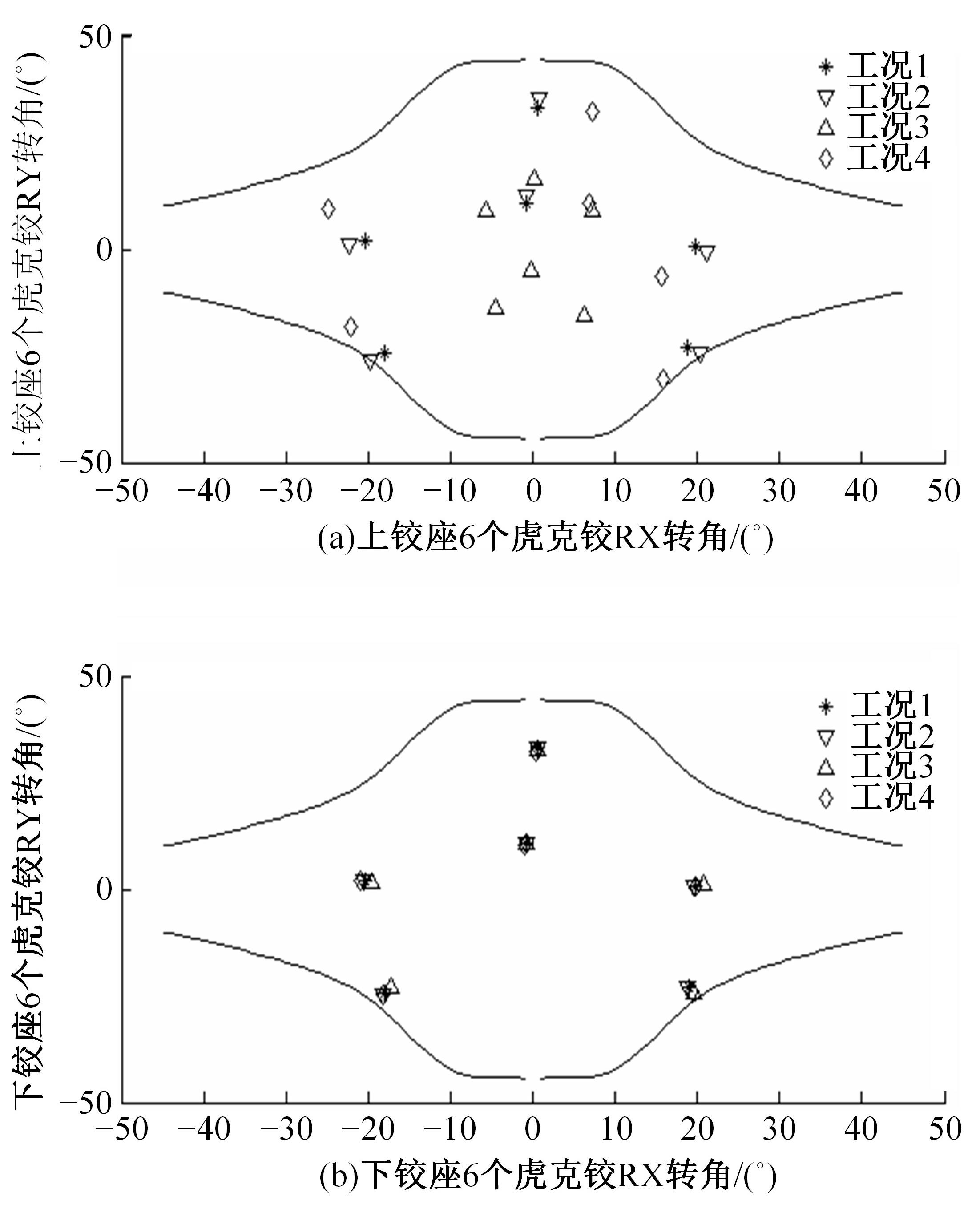

为了拓展六自由度平台的可达空间,提出了计及安装角参数的虎克铰干涉计算方法。根据虎克铰与相邻结构之间的位姿关系,对上、下铰座分别建立了计及安装角的虎克铰转角计算模型。采用仿真法求解了斜棱柱虎克铰的转角范围,拟合了描述虎克铰工作空间的非参数模型,建立了斜棱柱虎克铰干涉判定条件。通过分析动平台平动轨迹,探讨了铰座运动与安装角之间的变化规律。将虎克铰的干涉计算与六自由度平台的运动学反解结合,通过动平台在极限位置的运动试验,验证了虎克铰干涉计算模型在拓展六自由度平台极限位姿中的有效性。

中图分类号:

- TP242

| 1 | Furqan M, Suhaib M, Ahmad N. Studies on Stewart platform manipulator: a review[J]. Journal of Mechanical Science and Technology, 2017, 31(9): 4459-4470. |

| 2 | 丁明, 孟帅, 王书恒, 等. 六自由度波浪补偿平台的神经网络自适应反馈线性化控制[J]. 上海交通大学学报, 2022, 56(2): 165-172. |

| Ding Ming, Meng Shuai, Wang Shu-heng, et al. Neural-netwrok-based adaptive feedback linearization control for 6-DOF wave compensation platform[J].Journal of Shanghai Jiaotong University, 2022, 56(2):165-172. | |

| 3 | Li Z G, Yin Z M. The method of the flaps of C919 Aircraft manufacturing quality control[J]. Journal of Aerospace Science and Technology, 2020,8(1): 19-24. |

| 4 | 刘玉梅, 刘丽, 曹晓宁, 等. 转向架动态模拟试验台避撞模型的构建[J]. 吉林大学学报: 工学版, 2018,48(6): 1661-1668. |

| Liu Yu-mei, Liu Li, Cao Xiao-ning, et al. Construction on collision avoidance model of bogie dynamics imulation test bench[J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1661-1668. | |

| 5 | Chen D, Li S Q, Wang J F, et al. A multi-objective trajectory planning method based on the improved immune clonal selection algorithm[J]. Robotics and Computer Integrated Manufacturing, 2019, 59: 431-442. |

| 6 | 杨超, 叶伟, 陈巧红. 并联机构敏感性分析和多目标优化设计方法[J]. 机械工程学报, 2022, 58(19):229-241. |

| Yang Chao, Ye Wei, Chen Qiao-hong. Sensitivity analysis and multi-objective optimization design of parallel manipulators[J]. Journal of Mechanical Engineering, 2022, 58(19): 229-241. | |

| 7 | Li S Q, Chen D, Wang J F. An optimal singularity-free motion planning method for a 6-DOF parallel manipulator[J]. Industrial Robot: the International Journal of Robotics Research and Application, 2020,48(2): 290-299. |

| 8 | Mahmood A, Aminzadeh M, Menhaj M B, et al. A genearalized method for determing load workspace of spatial parallel mechanism[C]∥International Conference on Control and Automation, Xiamen, China, 2010: 1360-1365. |

| 9 | 程颖, 杨德华, 吴常铖, 等. 新型六自由度微动并联 机构的工作空间分析[J]. 机械科学与技术, 2019, 38(3) : 433-439. |

| Cheng Ying, Yang De-hua, Wu Chang-cheng, et al. Workspace analysis of a novel 6-DOF parallel mechanism with micro displacement[J]. Mechanical Science and Technology for Aerospace Engineering, 2019, 38(3): 433-439. | |

| 10 | Pernkopf F, Husty M L. Workspace analysis of stewart-gouph-type parallel manipulators[J]. Journal of Mechanical Engineering Science, 2006, 220(7): 1019-1032. |

| 11 | 陈晓光, 李超峰, 焦胜海, 等. 双端虎克铰Hexaglide并联机构零姿态工作空间分析[J]. 机械设计与制造, 2020, 11: 266-274. |

| Chen Xiao-guang, Li Chao-feng, Jiao Sheng-hai, et al. Position workspace analysis of the hexaglide parallel mechanism with double-end hooke hinges in kinematic chains[J]. Machinery Design and Manufacture, 2020, 11: 266-274. | |

| 12 | 于晖, 孙立宁, 张秀峰, 等. 虎克铰工作空间研究及其在6-HTRT并联机器人中的应用[J]. 中国机械工程, 2002, 13(21): 1830-1834. |

| Yu Hui, Sun Li-ning, Zhang Xiu-feng, et al. Study on hooke joint and its application in 6-HTRT parallel robot[J]. China Mechanical Engineering, 2002, 13(21) :1830-1834. | |

| 13 | Kong M X, Zhang Y, Sun L N. Analysis of a new workspace of the hexaglide as a motion tank[C]∥International Conference on Mechatronics, Kumamoto,Japan, 2007: 1-6. |

| 14 | 孙立宁, 于凌涛, 杜志江, 等. 并联机器人胡克铰工作空间的研究与应用[J]. 机械工程学报, 2006, 42(8): 120-124. |

| Sun Li-ning, Yu Ling-tao, Du Zhi-jiang, et al. Study and application of workspace on hooke joint in parallel robot[J]. Chinese Journal of Mechanical Engineering, 2006, 42(8): 120-124. |

| [1] | 秦雅琴,钱正富,谢济铭. 协同换道避障模型和轨迹数据驱动的车辆协同避障策略[J]. 吉林大学学报(工学版), 2024, 54(5): 1311-1322. |

| [2] | 谭晓丹,王勇澎,Hall Robert,徐天爽,黄庆学. 面向电铲自主装卸的矿用自卸车斗型优化[J]. 吉林大学学报(工学版), 2024, 54(5): 1227-1236. |

| [3] | 孙伟,杨俊. 等角贴敷压电分流片圆柱壳有限元建模及减振分析[J]. 吉林大学学报(工学版), 2024, 54(2): 365-374. |

| [4] | 胡斌,蔡一全,罗昕,毛自斌,李俊伟,郭孟宇,王剑. 基于种群胁迫的有限齿侧空间高速充种理论与试验[J]. 吉林大学学报(工学版), 2024, 54(2): 574-588. |

| [5] | 杨福增,孙景彬,李亚男,张亚洲,刘志杰. 郁闭果园图传遥控式割草机的设计与性能试验[J]. 吉林大学学报(工学版), 2024, 54(1): 281-293. |

| [6] | 郑皓,余立均,智鹏鹏,汪忠来. 仿生扑翼微型飞行器动态避障策略[J]. 吉林大学学报(工学版), 2023, 53(9): 2732-2740. |

| [7] | 王永烁,康建明,彭强吉,陈英凯,方会敏,牛萌萌,王少伟. 果树株间避障除草机设计与试验[J]. 吉林大学学报(工学版), 2023, 53(8): 2410-2420. |

| [8] | 齐国元,陈浩. 基于观测器的四旋翼控制-抗扰-避障一体化[J]. 吉林大学学报(工学版), 2023, 53(3): 810-822. |

| [9] | 刘春晖,王思长,郑策,陈秀连,郝春蕾. 基于深度学习的室内导航机器人避障规划算法[J]. 吉林大学学报(工学版), 2023, 53(12): 3558-3564. |

| [10] | 刘洋. 动臂塔机防后倾缓冲力计算方法[J]. 吉林大学学报(工学版), 2023, 53(10): 2785-2794. |

| [11] | 赵洋,肖洋,孙皓,霍文浩,冯松,廖勇. 基于围道积分的润滑接触齿轮微点蚀损伤特征模拟[J]. 吉林大学学报(工学版), 2022, 52(4): 799-810. |

| [12] | 郑伟,孙见君,马晨波,於秋萍,张玉言,牛韬. 汽车轮毂加工夹具的研究现状及展望[J]. 吉林大学学报(工学版), 2022, 52(1): 25-36. |

| [13] | 陈魏,雷雨龙,李兴忠,付尧,扈建龙,侯利国. 低速工况下渐开线圆柱直齿轮齿面粘着磨损计算[J]. 吉林大学学报(工学版), 2021, 51(5): 1628-1634. |

| [14] | 郭震,于红英,滑忠鑫,赵娣. 刚性折纸机构运动分析及折叠过程仿真[J]. 吉林大学学报(工学版), 2020, 50(1): 66-76. |

| [15] | 朱伟,王传伟,顾开荣,沈惠平,许可,汪源. 一种新型张拉整体并联机构刚度及动力学分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1777-1786. |

|

||