吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (4): 1197-1206.doi: 10.13229/j.cnki.jdxbgxb.20230677

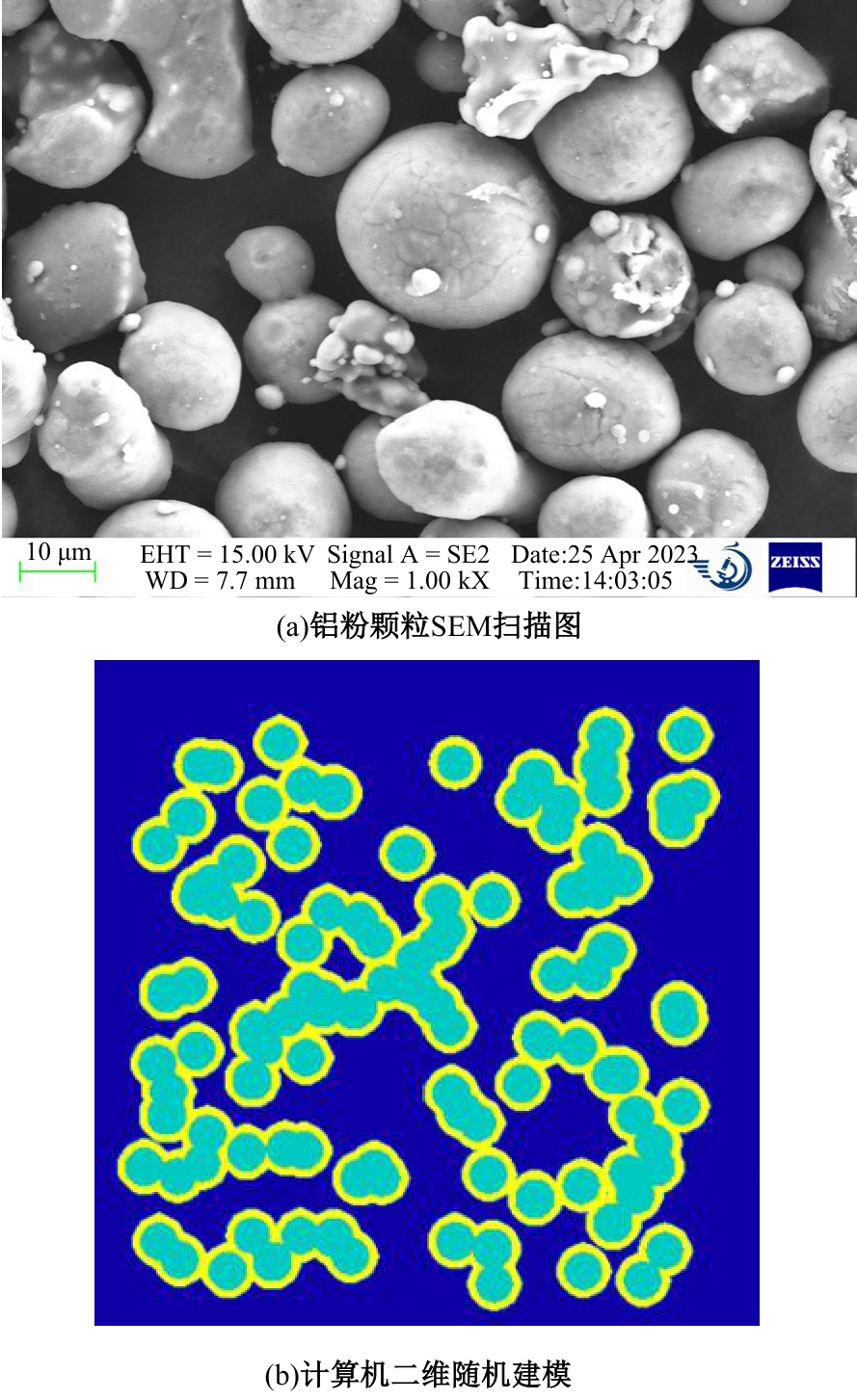

基于格子玻尔兹曼模型的微米级铝颗粒氧化层传热熔化特性

- 1.西安交通大学 能源与动力工程学院,西安 710049

2.西安交通大学 电气绝缘与电力设备国家重点实验室,西安 710049

3.西北核技术研究所,西安 710024

Heat transfer and melting characteristics of micronmeter-sized aluminum particle oxide layers based on lattice Boltzmnn model

Ruo-meng YING1( ),Gao-yi SHANG2,Zhen-chao LIU1(

),Gao-yi SHANG2,Zhen-chao LIU1( ),Deng-wang WANG3,Sheng WANG1

),Deng-wang WANG3,Sheng WANG1

- 1.School of Energy and Power Engineering,Xi'an Jiaotong University,Xi'an 710049,China

2.State Key Laboratory of Electrical Insulation and Power Equipment,School of Energy and Power Engineering,Xi'an Jiaotong University,Xi'an 710049,China

3.Northwest Institute of Nuclear Technology,Xi'an 710024,China

摘要:

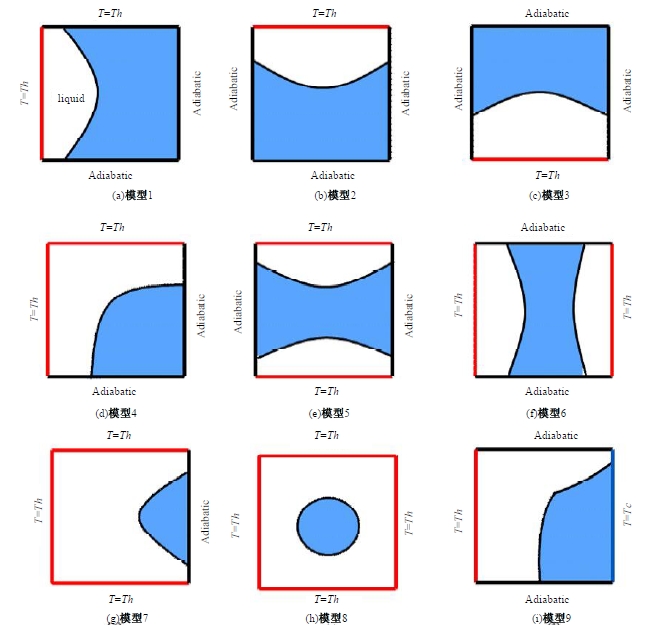

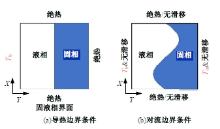

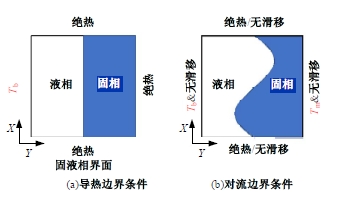

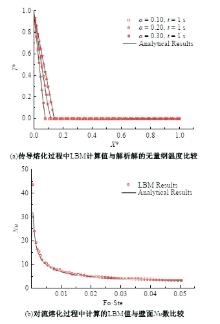

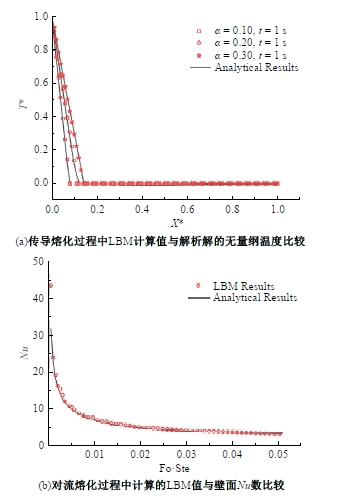

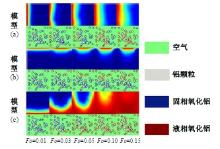

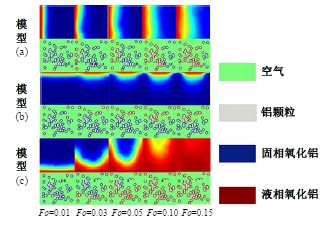

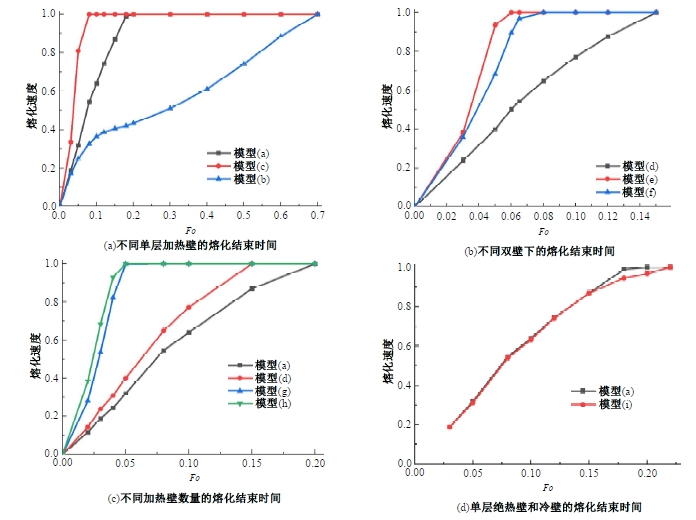

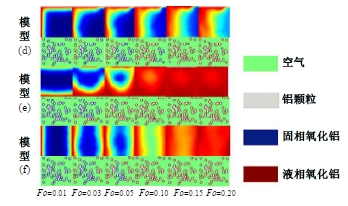

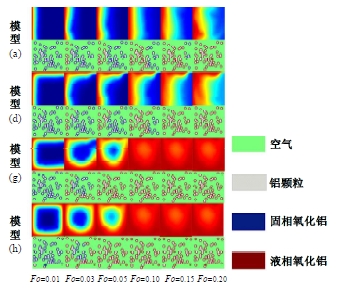

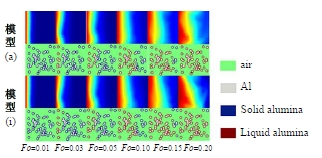

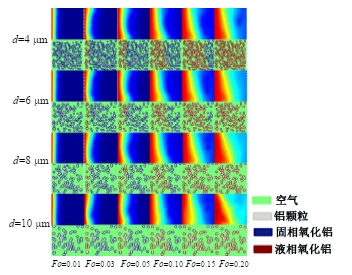

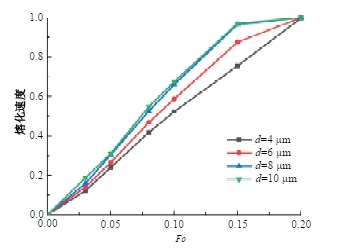

建立了基于焓的二维格子玻尔兹曼模型(LBM),研究了不同边界条件以及不同颗粒粒径下微米级铝颗粒氧化层在熔化过程中的温度分布、平均液相分数和熔化结束时间。结果表明:自然对流浮升力对熔化特性有着显著影响;在单个加热壁加热时,自然对流的浮升力使下壁面加热时的熔化进程最快,上壁面时的最慢;当两个加热壁共同作用时,上下加热壁条件下的熔化最快,与左右加热壁的条件相比,熔化时间缩短了18.05%;随着加热壁的数量增多,熔化效率的提升效果减弱。通过计算发现,与单加热壁相比,双加热壁、三加热壁和四加热壁的熔化效率分别提升了21%、73%和75%。冷壁面的存在使熔化进程变慢,但影响仅存在于熔化进程的后半段。此外,颗粒粒径的增大可以加速熔化,但这一特征也会随着粒径的增大逐渐减弱。

中图分类号:

- TK16

| [1] | 田入园. 复合固体推进剂中Al颗粒燃烧行为数值模拟[D]. 南京: 南京理工大学能源与动力工程学院, 2017. |

| Tian Ru-yuan. Numerical simulation of combustion behavior of aluminum particle in composite solid propellants[D]. Nanjing: School of Energy and Power Engineering, Nanjing University of Science and Technology, 2017. | |

| [2] | 胡松启, 李葆萱. 固体火箭发动机燃烧基础[M]. 西安: 西北工业大学出版社, 2015. |

| [3] | 王克秀. 固体火箭推进剂及燃烧[M]. 北京:国防工业出版社, 1983. |

| [4] | 萨顿·比布拉兹. 火箭发动机基础[M]. 洪鑫, 张宝炯, 等译. 北京: 科学出版社, 2003. |

| [5] | Fang C, Fen L S. Experimental studies on effects of AP content and particle size in NEPE propellant[J]. Journal of Solid Rocket Technology, 2001, 24(3): 47-53. |

| [6] | 唐伟强, 杨荣杰, 李建民, 等. 高铝固体推进剂中氟化物促进铝燃烧研究进展[J]. 固体火箭技术, 2020,43(6): 679-686. |

| Tang Wei-qiang, Yang Rong-jie, Li Jian-min et al. Research progress of fluorides in high aluminum solid propellant to promote aluminum combustion[J]. Solid Rocket Technology, 2020, 43(6): 679-686. | |

| [7] | Jeurgens L P H, Sloof W G, Tichelaar F D, et al. Thermodynamic stability of amorphous oxide films on metals: application to aluminum oxide films on aluminum substrates[J]. Physical Review B, 2000, 62(7): 4707-4719. |

| [8] | Jeurgens L P H, Sloof W G, Tichelaar F D, et al. Structure and morphology of aluminiumoxide films formed by thermal oxidation of aluminium[J]. Thin solid Films, 2002, 418(2): 89-101. |

| [9] | Merzhanov A G, Grigorjev Y M, Galchenko Y A. Aluminum ignition[J]. Combustion and Flame, 1977, 29: 1-14. |

| [10] | Breiter A L, Mal´Tsev V M, Popov E I. Models of metal ignition[J]. Combustion, Explosion and Shock Waves, 1977, 13(4): 475-484. |

| [11] | Ermakov V A, Razdobreev A A, Skorik A I, et a1. Temperature of aluminum particles at the time of ignition and combustion[J]. Combustion, Explosion and Shock Waves, 1982, 18(2): 256-257. |

| [12] | Desjardin P E, Felske J D, Carrara M D. Mechanistic model for aluminum particle ignition and combustion in air[J]. Journal of Propulsion and Power, 2005, 21(3): 478-485. |

| [13] | Yang H, Lee J, Kim K, et a1. Simplified model for single aluminum particle combustion[C]∥The 47th AIAA Aerospace Science Meeting Including, The New Horizons Forum and Aerospace Exposition, Orlando,USA, 2009: 1-9. |

| [14] | Volkov K N. Combustion of Single Aluminum Droplet in Two-phase Flow[M]. Hauppauge: Nova Science, 2011. |

| [15] | Mohammadian S K, Zhang Y. Convection heat transfer with internal heat generation in porous media: implementation of thermal lattice Boltzmann method[J]. Numerical Heat Transfer Part A: Applications, 2019, 76(3): 101-114. |

| [16] | Jourabian M, Darzi A, Akbari O A, et al. The enthalpy-based lattice Boltzmann method(LBM) for simulation of NePCM melting in inclined elliptical annulus[J]. Physica A: Statistical Mechanics and its Applications, 2019, 548: No.123887. |

| [17] | Ghasemi K, Tasnim S, Mahmud S. Shape-stabilized phase change material convective melting by considering porous configuration effects[J]. Journal of Molecular Liquids, 2022, 355: No.118956. |

| [18] | Chen D, Riaz A, Aute V C, et al. A solid–liquid model based on lattice Boltzmann method For phase change material melting with porous media in cylindrical heat exchangers[J]. Applied Thermal Engineering, 2022, 207: No.118080. |

| [19] | He P, Chen L, Mu Y, et al. Lattice Boltzmann method simulation of ice melting process in the gas diffusion layer of fuel cell[J]. International Journal of Heat and Mass Transfer, 2020, 149(2): No.119121. |

| [20] | Eshraghi M, Felicelli S D. An implicit lattice Boltzmann model for heat conduction with phase change[J]. International Journal of Heat and Mass Transfer, 2012, 55(9, 10): 2420-2428. |

| [21] | Zhao C Y, Dai L N, Tang G H, et al. Numerical study of natural convection in porous media (metals) using lattice Boltzmann method(LBM)[J]. International Journal of Heat and Fluid Flow, 2010, 31(5): 925-934. |

| [22] | Jiang Z H, Yang G G, Li S A, et al. Investigation of the ice melting process in a simplified gas diffusion layer of fuel cell by the lattice Boltzmann method[J]. Energy and Fuel, 2022, 36(10): 5403-5414. |

| [23] | Jany P, Bejan A. Scaling theory of melting with natural convection in an enclosure[J]. International Journal of Heat and Mass Transfer, 1988, 31(6): 1221-1235. |

| [1] | 徐振军,张瑞凤,陈嘉祥,张晓慧,密晓光,陈杰,陈林. 回热对低温大质流密度实验系统能耗影响[J]. 吉林大学学报(工学版), 2023, 53(4): 1133-1138. |

| [2] | 杨子荣,李岩,冀雪峰,刘芳,郝冬. 质子交换膜燃料电池运行工况参数敏感性分析[J]. 吉林大学学报(工学版), 2022, 52(9): 1971-1981. |

| [3] | 徐振军,王浩,赵开元,郝博轶,李清清,王常浩. 复合太阳能的燃气机热泵热力学性能[J]. 吉林大学学报(工学版), 2022, 52(8): 1759-1763. |

| [4] | 徐振军,王浩,王银成,张诺,陈孟,李清清. 微通道低温换热器流动传热性能[J]. 吉林大学学报(工学版), 2022, 52(10): 2294-2299. |

| [5] | 兰巍,刘江,辛俐,李婧锡,胡兴军,王靖宇,桑涛. 后视镜造型对侧窗水相分布的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1590-1599. |

| [6] | 孟育博, 李丕茂, 张幽彤, 王志明. 共轨系统压力波动和多次喷射油量偏差的抑制[J]. 吉林大学学报(工学版), 2018, 48(3): 760-766. |

| [7] | 孙正, 黄钰期, 俞小莉. 径向滑动轴承润滑油膜流动-传热过程仿真[J]. 吉林大学学报(工学版), 2018, 48(3): 744-751. |

| [8] | 孟育博, 张幽彤, 王志明, 张晓晨, 樊利康, 李涛. 压电喷油器压电执行器热-电-机械耦合迟滞特性[J]. 吉林大学学报(工学版), 2018, 48(2): 480-485. |

| [9] | 李明达, 隗海林, 门玉琢, 包翠竹. 复杂底部结构下的重型载货汽车气动阻力[J]. 吉林大学学报(工学版), 2017, 47(3): 731-736. |

| [10] | 吴志军, 赵文伯, 张青. 基于热氛围燃烧器的湍流射流起升火焰基础研究进展[J]. 吉林大学学报(工学版), 2016, 46(6): 1881-1891. |

| [11] | 崔金生, 侯绪研, 邓宗全, 潘万竞, 姜生元. 真空颗粒系统有效导热系数测量试验台研制及试验[J]. 吉林大学学报(工学版), 2016, 46(2): 457-464. |

| [12] | 齐子姝, 高青, 刘研, 白莉. 地能利用热泵系统模型计算及其多年运行工况分析[J]. 吉林大学学报(工学版), 2015, 45(6): 1811-1816. |

| [13] | 齐子姝, 高青, 刘研, 于鸣. 联供模式地下换热器温变及其热泵效能分析[J]. 吉林大学学报(工学版), 2012, 42(02): 339-343. |

| [14] | 高印寒,陈王锋,程鹏,李振雷,池俊成,李强 . 旋风分离器两相三维流场仿真 [J]. 吉林大学学报(工学版), 2008, 38(增刊): 85-0089. |

| [15] | 李忠建,郑茂余,王芳 . 有限热容不可逆四热源吸收式制冷机的优化 [J]. 吉林大学学报(工学版), 2008, 38(02): 283-0286. |

|