Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (5): 1331-1337.doi: 10.13229/j.cnki.jdxbgxb.20210880

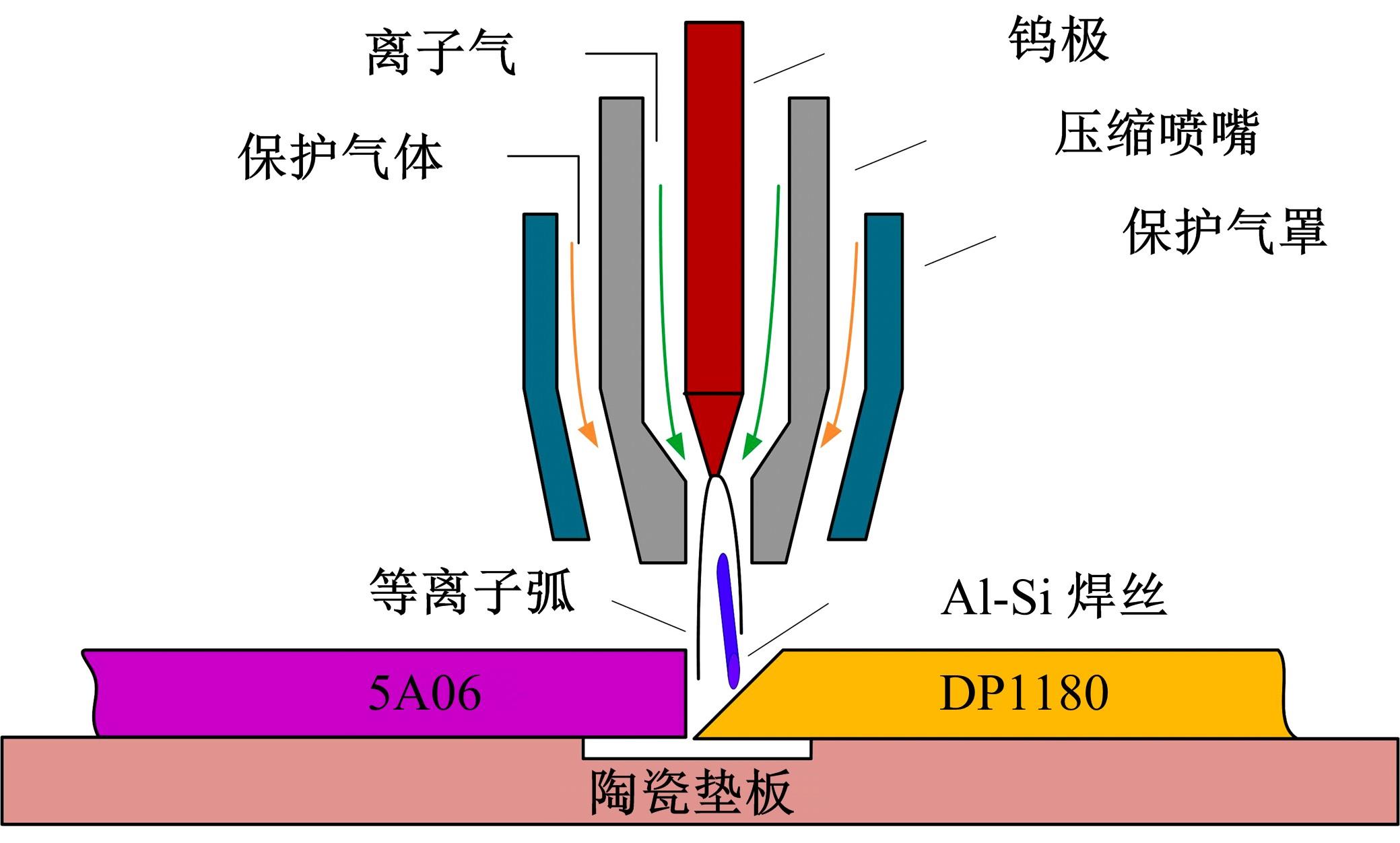

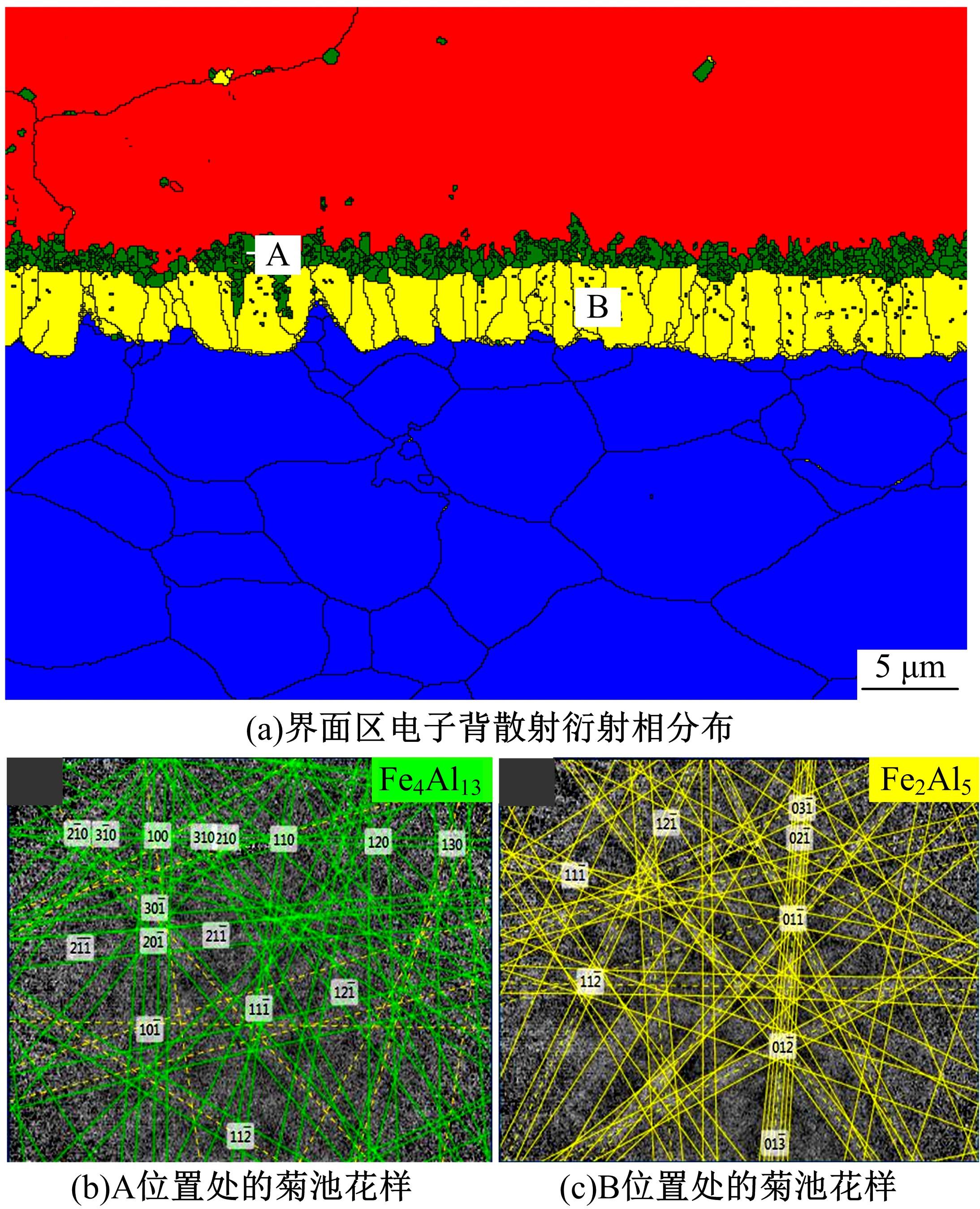

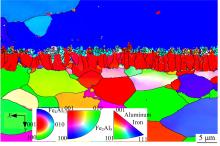

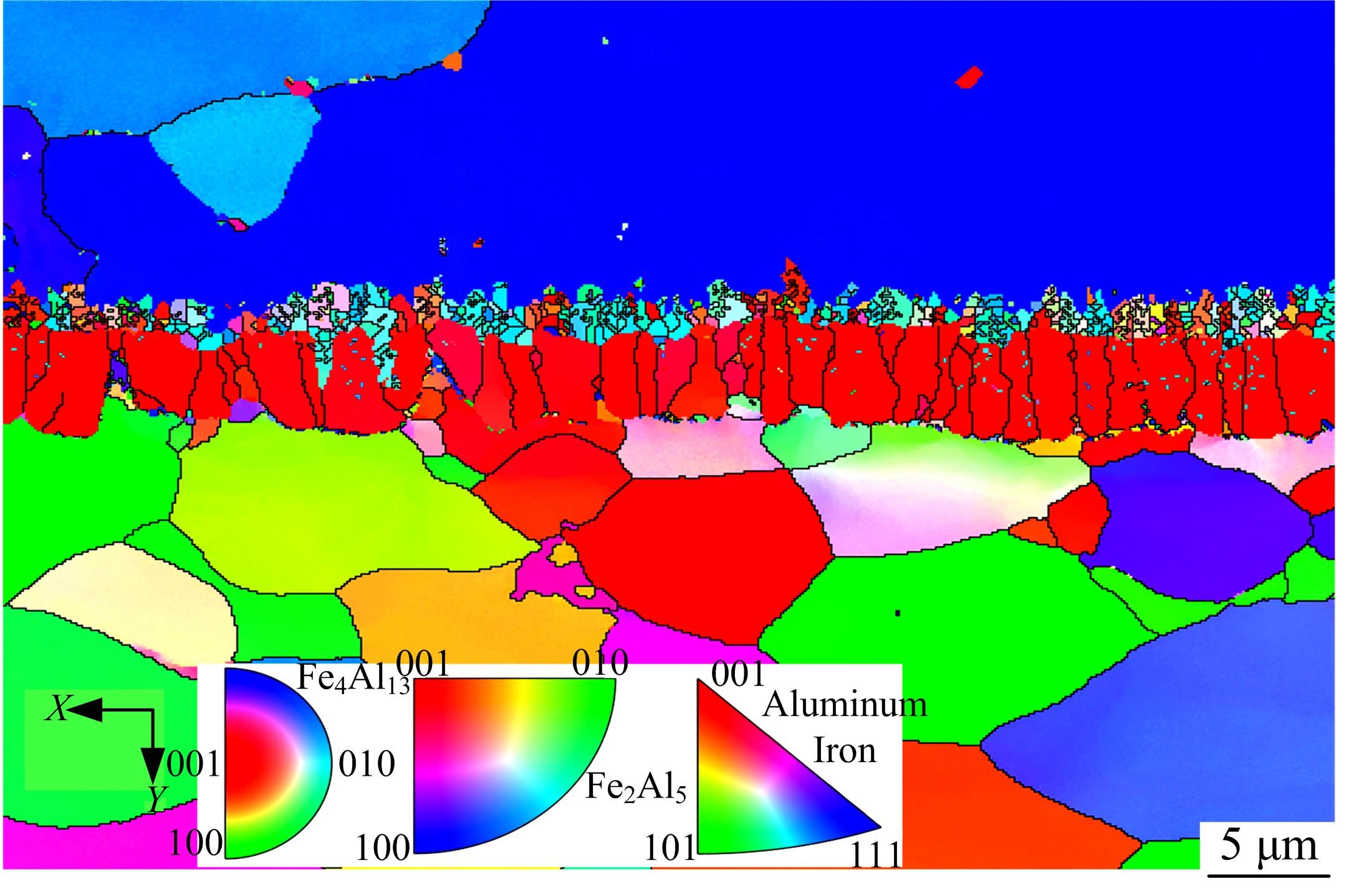

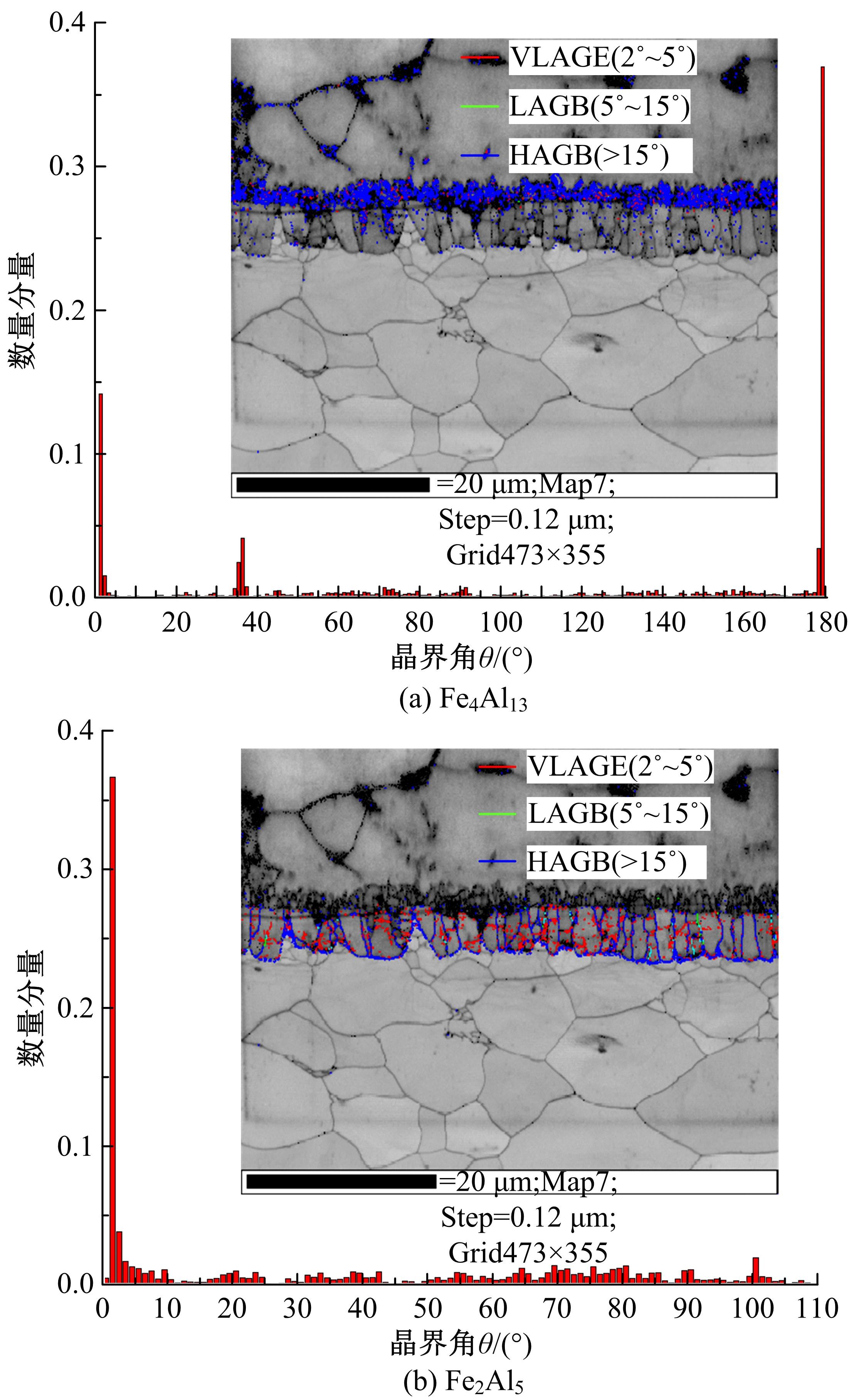

Electron backscattered diffraction analysis on interface of aluminum/steel joints produced by plasma arc welding⁃brazing

Di WU1,2( ),Wen-hua GENG1,3,Hong-mei LI1(

),Wen-hua GENG1,3,Hong-mei LI1( ),Da-qian SUN1

),Da-qian SUN1

- 1.College of Materials Science and Engineering,Jilin University,Changchun 130022,China

2.College of Engineering,Changchun Normal University,Changchun 130031,China

3.Tianjin Branch FAW-VW Automation Limited Company,Tianjin 301599,China

CLC Number:

- TG456.2

| 1 | 马鸣图,王国栋,王登峰,等.汽车轻量化导论[M].北京: 化学工业出版社, 2020. |

| 2 | Kleiner K, Geiger M, Klaus A. Manufacturing of lightweight components by metal forming[J]. CIRP Annals Manufacturing Technology, 2003, 52(2):521-524. |

| 3 | Kin H J, Keoleian G A, Skerlos S J. Economic assessment of greenhouse gas emissions reduction by vehicle light weighting using aluminum and high-strength steel[J]. Industrial Ecolocy, 2011, 15(1):64-80. |

| 4 | Yuan R, Deng S J, Cui H C, et al. Interface characterization and mechanical properties of dual beam laser welding-brazing Al/steel dissimilar metals[J]. Journal of Manufacturing Processes, 2019, 40:37-45. |

| 5 | Oliveira J P, Ponder K, Brizes E, et al. Combining resistance spot welding and friction element welding for dissimilar joining of aluminum to high strengths steels[J]. Journal of Materials Processing Technology, 2019, 273: 116-192. |

| 6 | 黄健康,何翠翠,石玗,等.铝/钢异种金属焊接接头界面Al-Fe金属间化合物生成及其热力学分析[J]. 吉林大学学报: 工学版, 2014, 44(4): 1037-1041. |

| Huang Jian-kang, He Cui-cui, Shi Yu,et al.Thermodynamic analysis of Al-Fe intermetallic compounds formed by dissimilar joining of aluminum and galvanized steel[J]. Journal of Jilin University(Engineering and Technology Edition), 2014, 44(4): 1037-1041. | |

| 7 | 李春玲,樊丁,王斌,等. 5A06铝合金/镀锌钢预置涂粉对接激光熔钎焊组织与性能[J].吉林大学学报:工学版,2016,46(2):516-521. |

| Li Chun-ling, Fan Ding, Wang Bin, et al. 5A06 aluminum alloy and galvanized steel butt welding-brazing by laser with preset filler powder[J]. Journal of Jilin University(Engineering and Technology Edition), 2016, 46(2): 516-521. | |

| 8 | 李亚江,吴娜. 铝/钢异种金属焊接的研究现状[J].焊接, 2010(3): 5-12. |

| Li Ya-jiang, Wu Na. Research status of the aluminum/steel dissimilar metal welding[J]. Welding & Joining, 2010(3): 5-12. | |

| 9 | Song J L, Lin S B, Yang C L, et al. Analysis of intermetallic layer in dissimilar TIG welding-brazing butt joint of aluminium alloy to stainless steel[J]. Science and Technology of Welding and Joining, 2010,15: 213-218. |

| 10 | Song J L, Lin S B, Yang C L. Brazability of dissimilar metals tungsten inert gas butt welding-brazing between aluminum alloy and stainless steel with Al-Cu filler metal[J]. Materials Design, 2010, 31: 2637-2642. |

| 11 | Pouranvari M, Abbasi M. Dissimilar gas tungsten arc weld-brazing of Al/steel using Al-Si filler metal: microstructure and strengthening mechanisms[J]. Journal of Alloys and Compounds, 2018, 749: 121-127. |

| 12 | Geng W H, Wu D, Sun D Q. Microstructures and mechanical properties of plasma arc welded joints of ultra-high strength steel and aluminum alloy using Al-Si and Al-Cu fillers[J]. ISIJ International, 2018, 58(6): 1108-1116. |

| 13 | Wu D, Geng W H, Li H M,et al. Interface characteristics and formation mechanism of plasma arc welding-brazing aluminum alloy/ultrahigh-strength steel joint[J]. Metallurgical Research Technology, 2021, 118(4): 405-415. |

| 14 | 杨平. 电子背散射衍射技术及其应用[M]. 北京: 冶金工业出版社, 2007. |

| 15 | 韦竺施,崔丽,贺定勇,等.钢/铝异种合金激光深熔焊接头界面金属间化合物的EBSD研究[J].材料工程,2018,46(7):113-120. |

| Wei Zhu-shi, Cui Li, He Ding-yong, et al. EBSD investigation of intermetallic compounds at interface of steel/aluminum dissimilar alloy joints produced by laser keyhole welding[J]. Journal of Materials Engineering, 2018, 46(7): 113-120. | |

| 16 | 胡赓祥,蔡珣,戎咏华.材料科学基础[M].第3版.上海: 上海交通大学出版社,2013. |

| 17 | 姚晓红,张林,高文理,等. 时效状态对7A85高强铝合金力学性能和晶间腐蚀性能的影响[J]. 稀有金属材料与工程,2013, 42(12): 2581-2585. |

| Yao Xiao-hong, Zhang Lin, Gao Wen-li, et al. Effect of aging treatment on mechanical and intergranular corrosion properties of 7A85 high strength aluminum alloy[J]. Rare Metal Materials and Engineering, 2013, 42(12): 2581-2585. | |

| 18 | 张翔云,李激光,严玲,等.回火温度对两相区退火海工钢组织和性能的影响[J].材料研究学报,2020,34(11): 113-120. |

| Zhang Xiang-yun, Li Ji-guang, Yan Ling, et al. Effect of tempering temperature on microstructure and properties of intercritical annealing marine steel[J]. Chinese Journal of Materials Research,2020,34(11): 113-120. |

| [1] | Yuan-yuan WANG,Lu SUN,Wei-dong LIU,Jin-shun XUE. Constraint improvement of binocular reconstruction algorithm used to measure pavement three-dimensional texture [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1342-1348. |

| [2] | Jing JIN,Jian-wu DANG,Yang-ping WANG,Dong SHEN. Multi⁃cue particle filter tracking based on fuzzy statistical texture features [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 1111-1120. |

| [3] | Xiao-dong ZHU,Qi-xian ZHANG,Yuan-ning LIU, WU-di,Zu-kang WU,Chao-qun WANG,Xin-long LI. Iris recognition based on multi⁃direction local binary pattern and stable feature [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 650-658. |

| [4] | Jin-guo WANG,Zhi-qiang WANG,Shuai REN,Rui-fang YAN,Kai HUANG,Jin GUO. Effect of Ti addition on microstructure and mechanical properties of ductile iron [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1653-1662. |

| [5] | Yin-bao TIAN,Jun-qi SHEN,Sheng-sun HU,Jian GOU. Effect of EP/EN Balance on droplet transfer and weld formation of Al alloy by VP⁃CMT [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1663-1668. |

| [6] | Wen-biao GONG,Rui ZHU,Xin-zhe QIE,Heng CUI,Ming-yue GONG. Microstructure and properties of 6082 aluminum alloyultra⁃thick plate preparated by friction stir weld [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 512-519. |

| [7] | Jin-guo WANG,Shuai REN,Rui-fang YAN,Kai HUANG,Zhi-qiang WANG. Effect of TiC particles on microstructure and mechanical properties of as cast ductile iron [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 2010-2018. |

| [8] | Yuan-ning LIU,Shuai LIU,Xiao-dong ZHU,Guang HUO,Tong DING,Kuo ZHANG,Xue JIANG,Shu-jun GUO,Qi-xian ZHANG. Iris secondary recognition based on decision particle swarm optimization and stable texture [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1329-1338. |

| [9] | Yu⁃peng LI,Da⁃qian SUN,Wen⁃biao GONG. Temperature fields in bobbin⁃tool friction stir welding for 6082⁃T6 aluminum alloy sheet [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 836-841. |

| [10] | LIU Fu,ZONG Yu-xuan,KANG Bing,ZHANG Yi-meng,LIN Cai-xia,ZHAO Hong-wei. Dorsal hand vein recognition system based on optimized texture features [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1844-1850. |

| [11] | ZHAO Yu-guang, YANG Xue-hui, XU Xiao-feng, ZHANG Yang-yang, NING Yu-heng. Effects of Al-10Sr modifiers with different states, modification temperature and holding time on microstructure of ZL114A alloy [J]. 吉林大学学报(工学版), 2018, 48(1): 212-220. |

| [12] | TANG Hua-guo, MA Xian-feng, ZHAO Wei, LIU Jian-wei, ZHAO Zhen-ye. Synthesis microstructure and thermal properties of high performance bulk Al [J]. 吉林大学学报(工学版), 2017, 47(5): 1542-1547. |

| [13] | LIU Xiao-bo, ZHOU De-kun, ZHAO Yu-guang. Microstructure and mechanical property of Mg2Si/Al composites fabricated by semi-solid extrusion under different isothermal heat treatments [J]. 吉林大学学报(工学版), 2016, 46(5): 1577-1582. |

| [14] | LI Chun-ling, FAN Ding, WANG Bin, YU Shu-rong. 5A06 aluminum alloy and galvanized steel butt welding-brazing by laser with preset filler powder [J]. 吉林大学学报(工学版), 2016, 46(2): 516-521. |

| [15] | ZHANG Jia-tao, ZHAO Yu-guang, TAN Juan. Effect of starting microstructure on refining potency of electro-pulsing on reverse austenite grain [J]. 吉林大学学报(工学版), 2016, 46(1): 193-198. |

|

||