Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (11): 3176-3185.doi: 10.13229/j.cnki.jdxbgxb.20211393

Previous Articles Next Articles

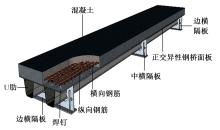

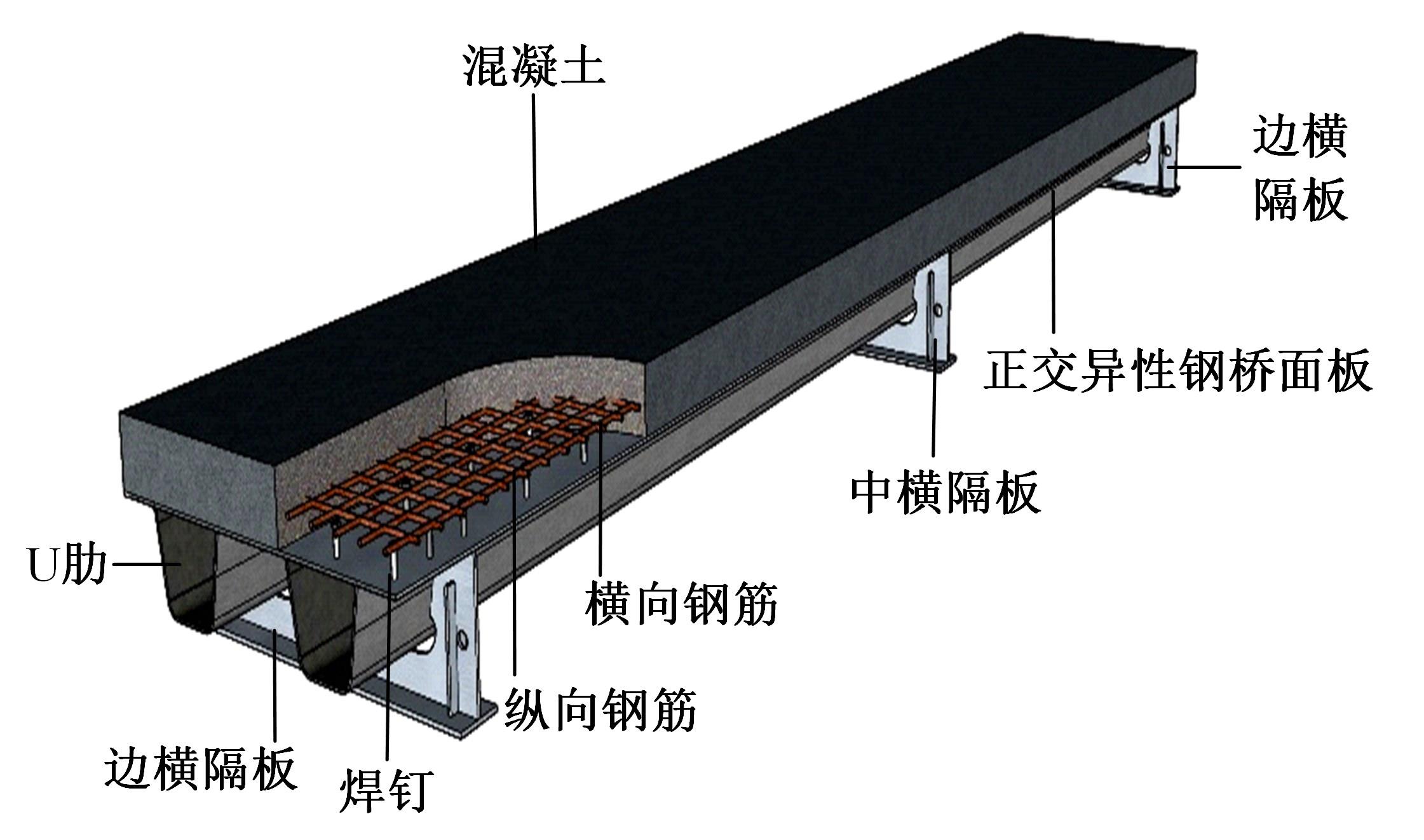

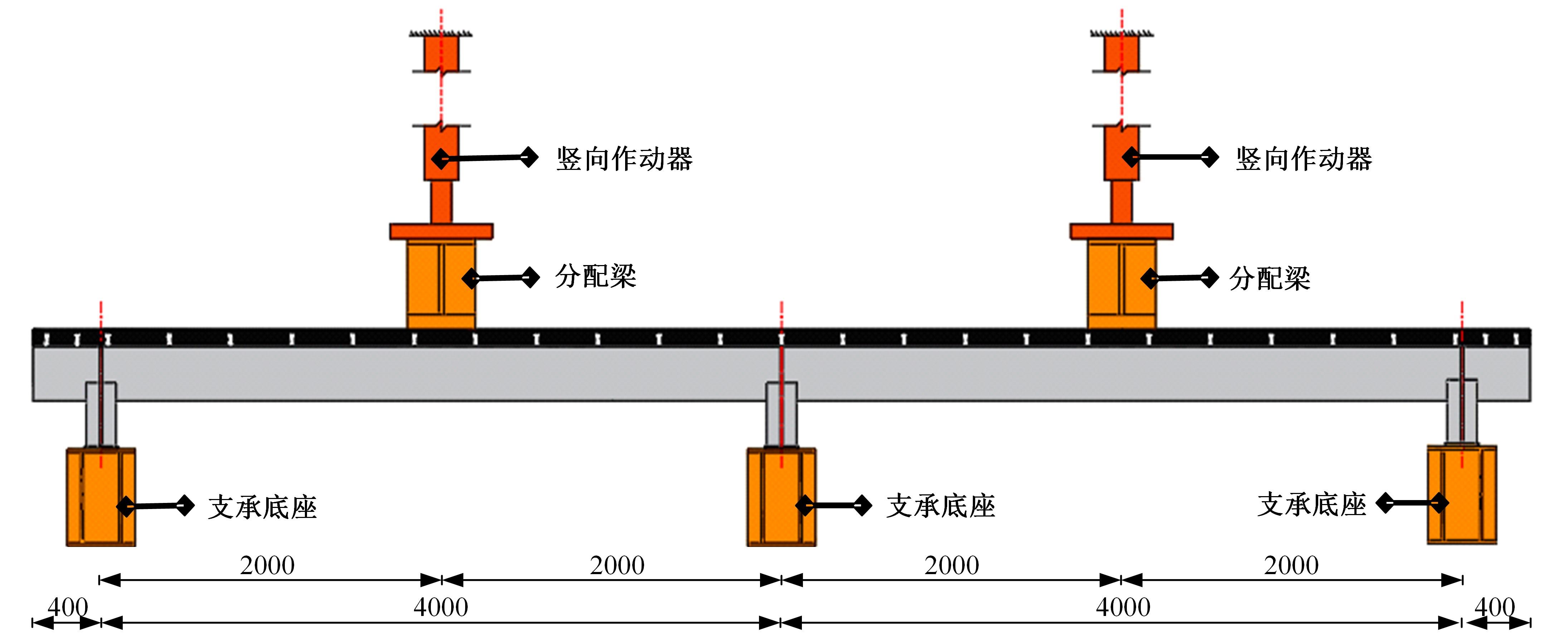

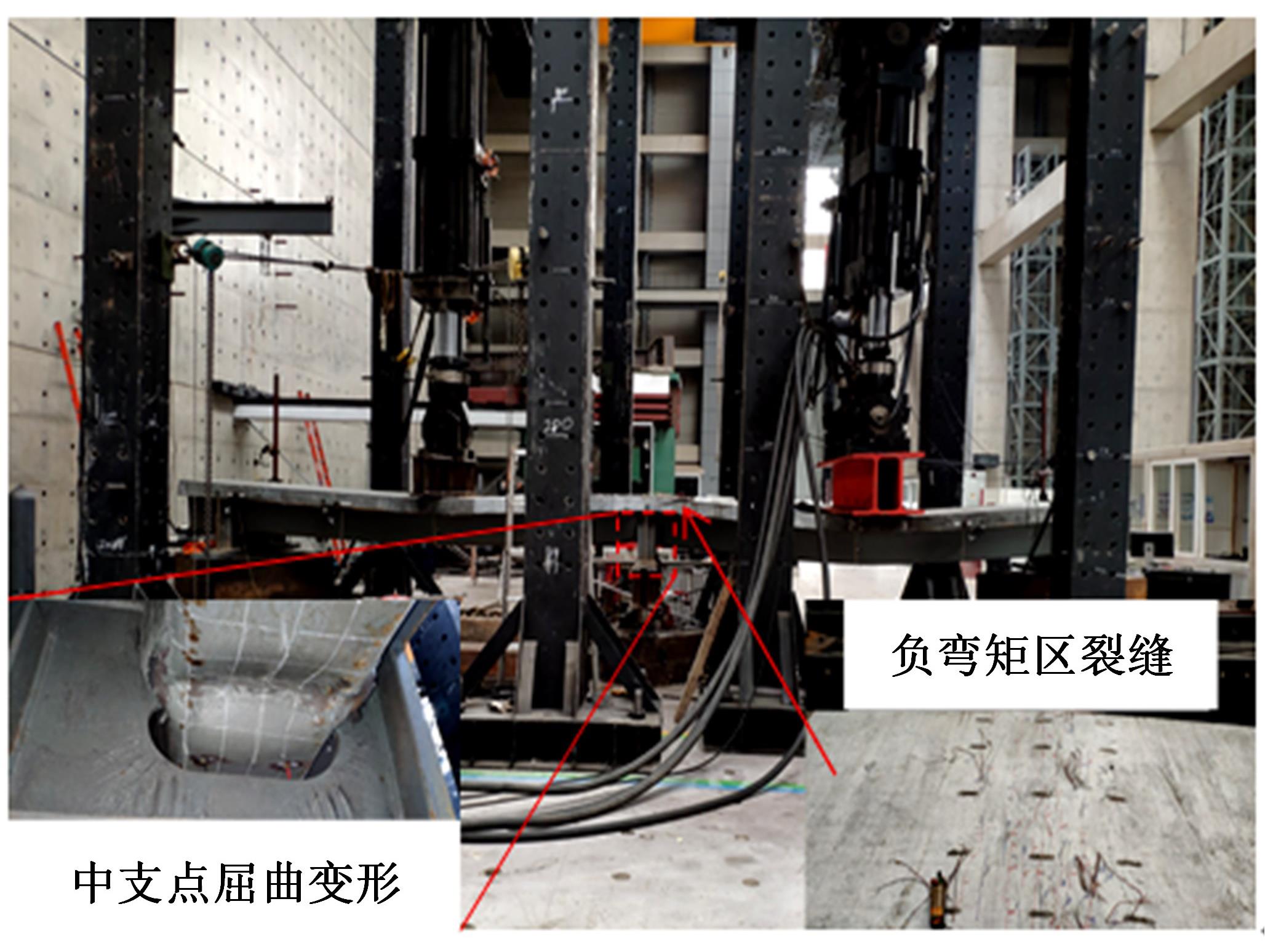

Experimental studies on cracking behavior of steel fiber reinforced concrete slab in negative moment region of orthotropic composite bridge deck

Ming-gen ZENG( ),Yu WU,Qing-tian SU(

),Yu WU,Qing-tian SU( )

)

- College of Civil Engineering,Tongji University,Shanghai 200092,China

CLC Number:

- TU398

| 1 | 杨义东,李涛. 钢-混凝土组合结构桥在日本的发展趋势[J]. 国外桥梁,1998(4):39-42. |

| Yang Yi-dong, Li Tao. The trend of the steel-concrete composite bridge in Japan[J]. World Bridges, 1998(4): 39-42. | |

| 2 | 吴冲. 现代钢桥[M]. 北京:人民交通出版社,2006. |

| 3 | Orta L, Bartlett F M. Reliability analysis of concrete deck overlays[J]. Structural Safety, 2015, 56: 30-38. |

| 4 | Su N Y, Lou L W, Amirkhanian A, et al. Assessment of effective patching material for concrete bridge deck—a review[J]. Construction and Building Materials, 2021, 293: 123520. |

| 5 | Shiotani T, Ohtsu H, Momoki S, et al. Damage evaluation for concrete bridge deck by means of stress wave techniques[J]. Journal of Bridge Engineering, ASCE, 2012, 17(6): 847-856. |

| 6 | 张清华, 卜一之, 李乔. 正交异性钢桥面板疲劳问题的研究进展[J]. 中国公路学报, 2017, 30(3): 14-30, 39. |

| Zhang Qing-hua, Bu Yi-zhi, Li Qiao. Review on fatigue problems of orthotropic steel bridge deck[J]. China Journal of Highway and Transport, 2017, 30(3): 14-30, 39. | |

| 7 | Deng P, Matsumoto T. Determination of dominant degradation mechanisms of RC bridge deck slabs under cyclic moving loads[J]. International Journal of Fatigue, 2018, 112: 328-340. |

| 8 | Liu Y K, Deng L, Zhong W J, et al. A new fatigue reliability analysis method for steel bridges based on peridynamic theory[J]. Engineering Fracture Mechanics, 2020, 236: 107214. |

| 9 | Su Q T, Dai C Y, Jiang X. Bending performance of composite bridge deck with T-shaped ribs[J]. Frontiers of Structural and Civil Engineering, 2019, 13(4): 990-997. |

| 10 | 何亮, 饶志鹏, 凌天清, 等. 大跨径钢桥沥青铺装层裂缝行为研究进展[J]. 公路, 2018, 63(7): 71-81. |

| He Liang, Rao Zhi-peng, Ling Tian-qing, et al. Progress of researches on fracture behavior of long-span steel bridge deck asphalt pavement[J]. Highway, 2018, 63(7): 71-81. | |

| 11 | 王朝辉, 郭瑾, 陈宝, 等. 桥面铺装结构的应用现状与发展[J]. 筑路机械与施工机械化, 2017, 34(12): 42-52. |

| Wang Chao-hui, Guo Jin, Chen Bao, et al. Application status and development of deck pavement structures[J]. Road Machinery & Construction Mechanization, 2017, 34(12): 42-52. | |

| 12 | 程庆国, 徐蕴贤, 卢祖文. 钢纤维混凝土本构理论的研究、工程应用及发展[J]. 中国铁道科学, 1999(2): 3-11. |

| Cheng Qing-guo, Xu Yun-xian, Lu Zu-wen. Research, engineering application and development of steel fiber concrete constitutive theory[J]. China Railway Science, 1999(2): 3-11. | |

| 13 | Smarzewski P. Analysis of failure mechanics in hybrid fibre-reinforced high-performance concrete deep beams with and without openings[J]. Materials, 2018, 12(1): 101-124. |

| 14 | 梁宁慧, 缪庆旭, 刘新荣, 等. 聚丙烯纤维增强混凝土断裂韧度及软化本构曲线确定[J]. 吉林大学学报: 工学版, 2019, 49(4): 1144-1152. |

| Liang Ning-hui, Liao Qing-xu, Liu Xin-rong, et al. Determination of fracture toughness and softening traction-separation law of polypropylene fiber reinforced concrete[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(4): 1144-1152. | |

| 15 |

张春雷, 邵长宇, 苏庆田, 等. 球扁钢肋钢纤维混凝土组合桥面板正弯矩受力性能试验[J/OL]. [2023-08-19]. DOI: 10.13229/j.cnki.jdxbgxb.20220904

doi: 10.13229/j.cnki.jdxbgxb.20220904 |

|

Zhang Chun-lei, Shao Chang-yu, Su Qing-tian. Experimental on positive bending behavior of composite bridge decks with steel-fiber-reinforced concrete and longitudinal bulb-flat ribs[J/OL]. [2023-08-19]. DOI: 10.13229/j.cnki.jdxbgxb.20220904

doi: 10.13229/j.cnki.jdxbgxb.20220904 |

|

| 16 | Gribniak V, Arnautov A K, Norkus A, et al. Experimental investigation of the capacity of steel fibers to ensure the structural integrity of reinforced concrete specimens coated with CFRP sheets[J]. Mechanics of Composite Materials, 2016, 52(3): 401-410. |

| 17 | . 公路钢混组合桥梁设计与施工规范 [S]. |

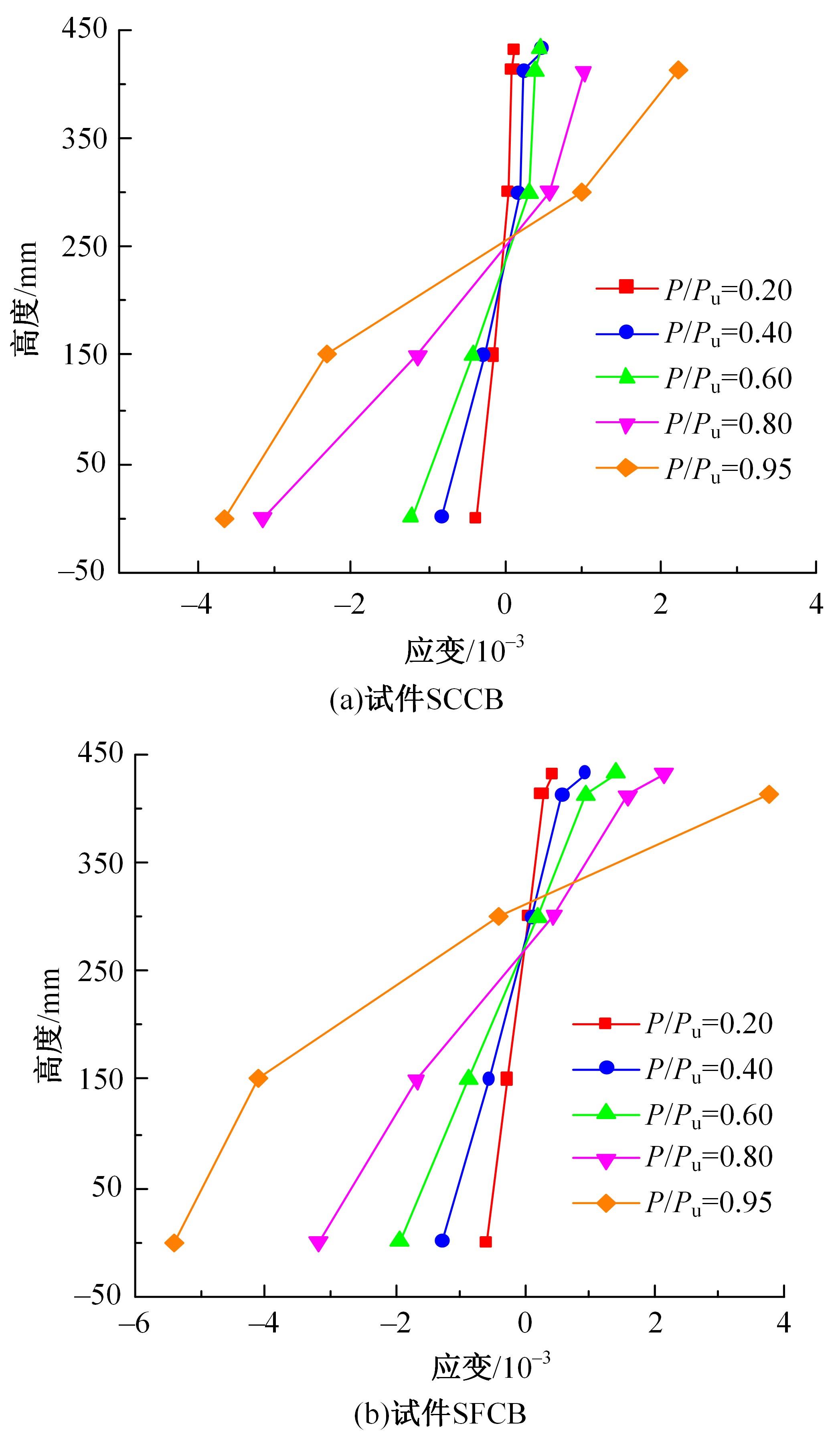

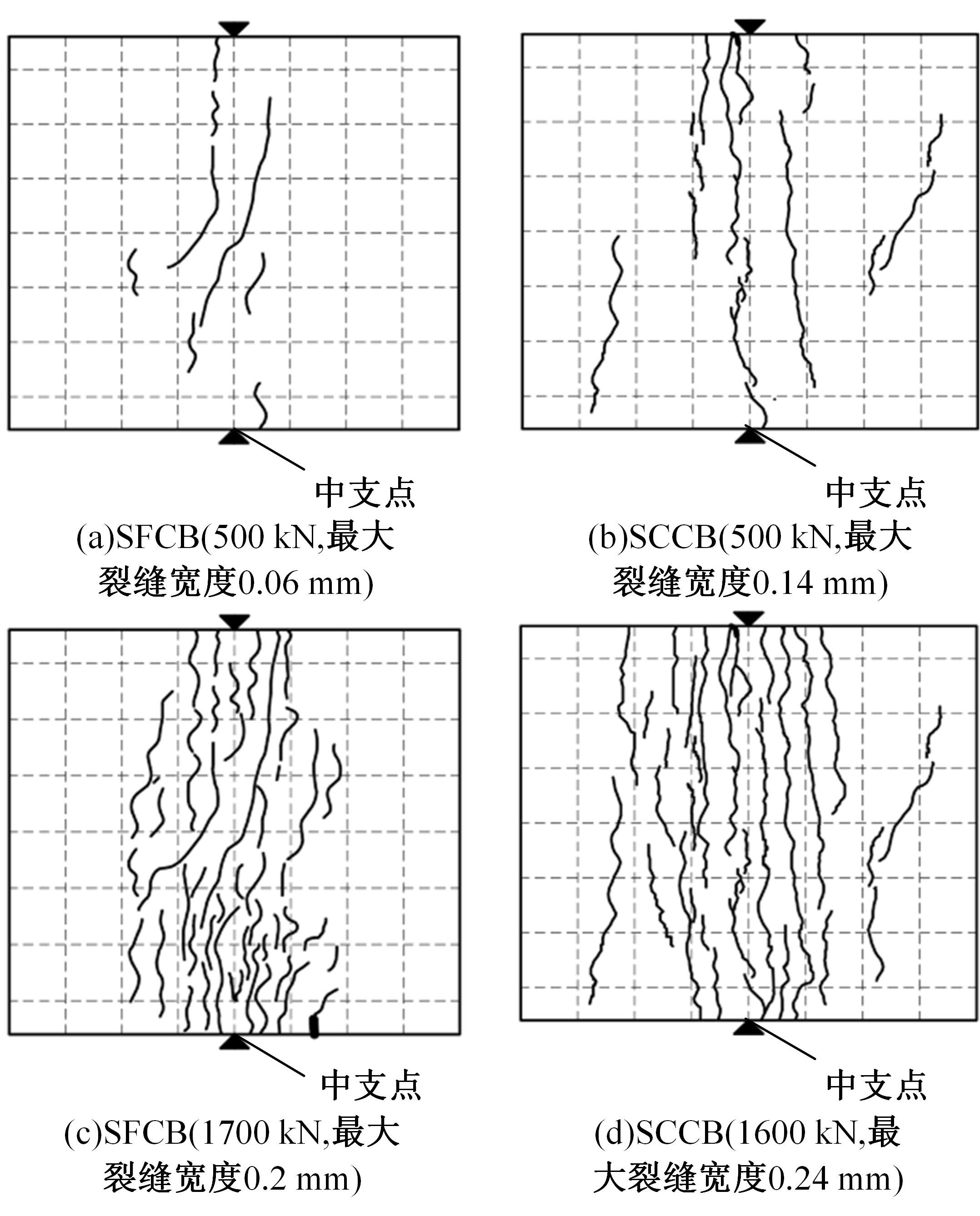

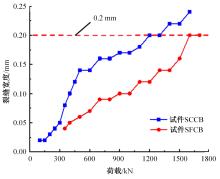

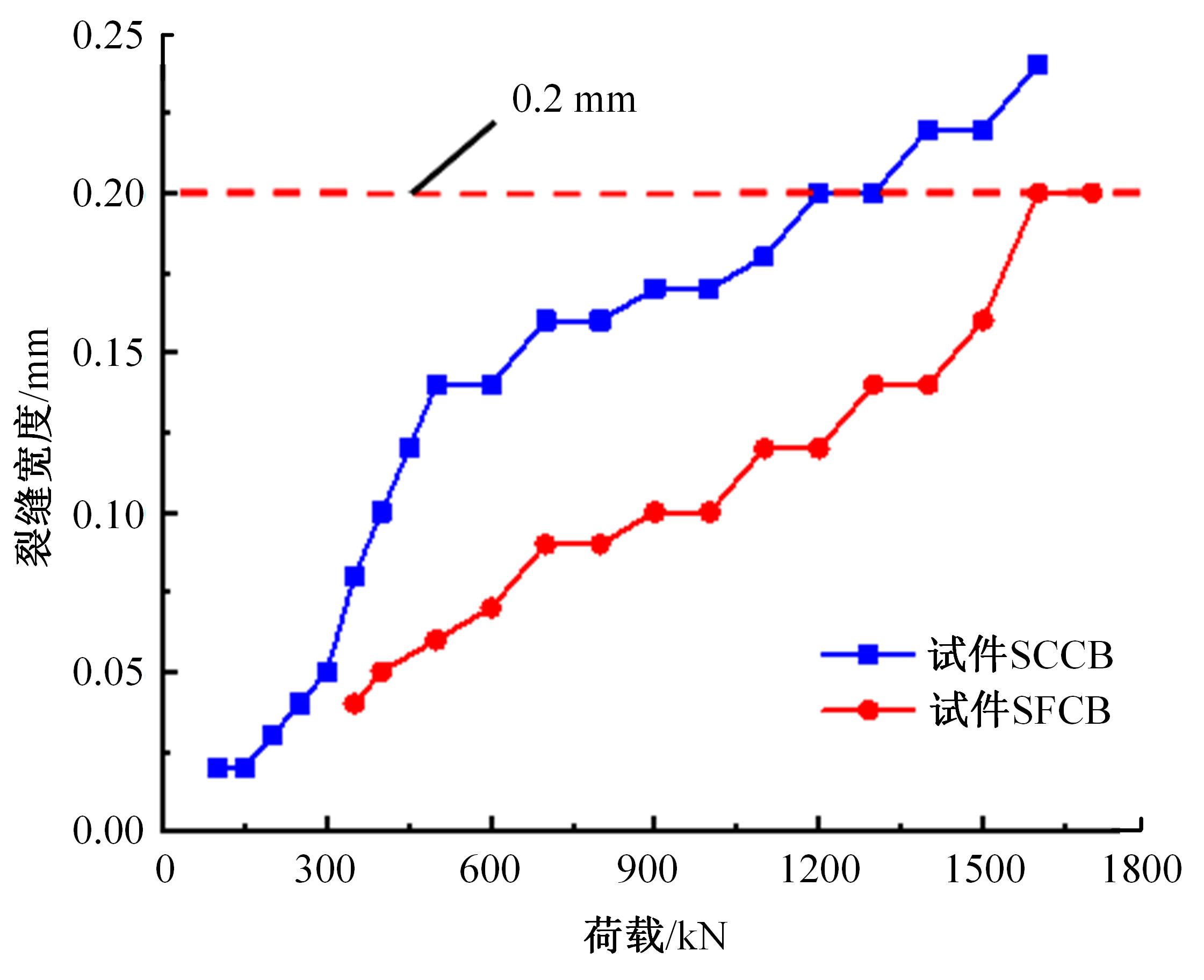

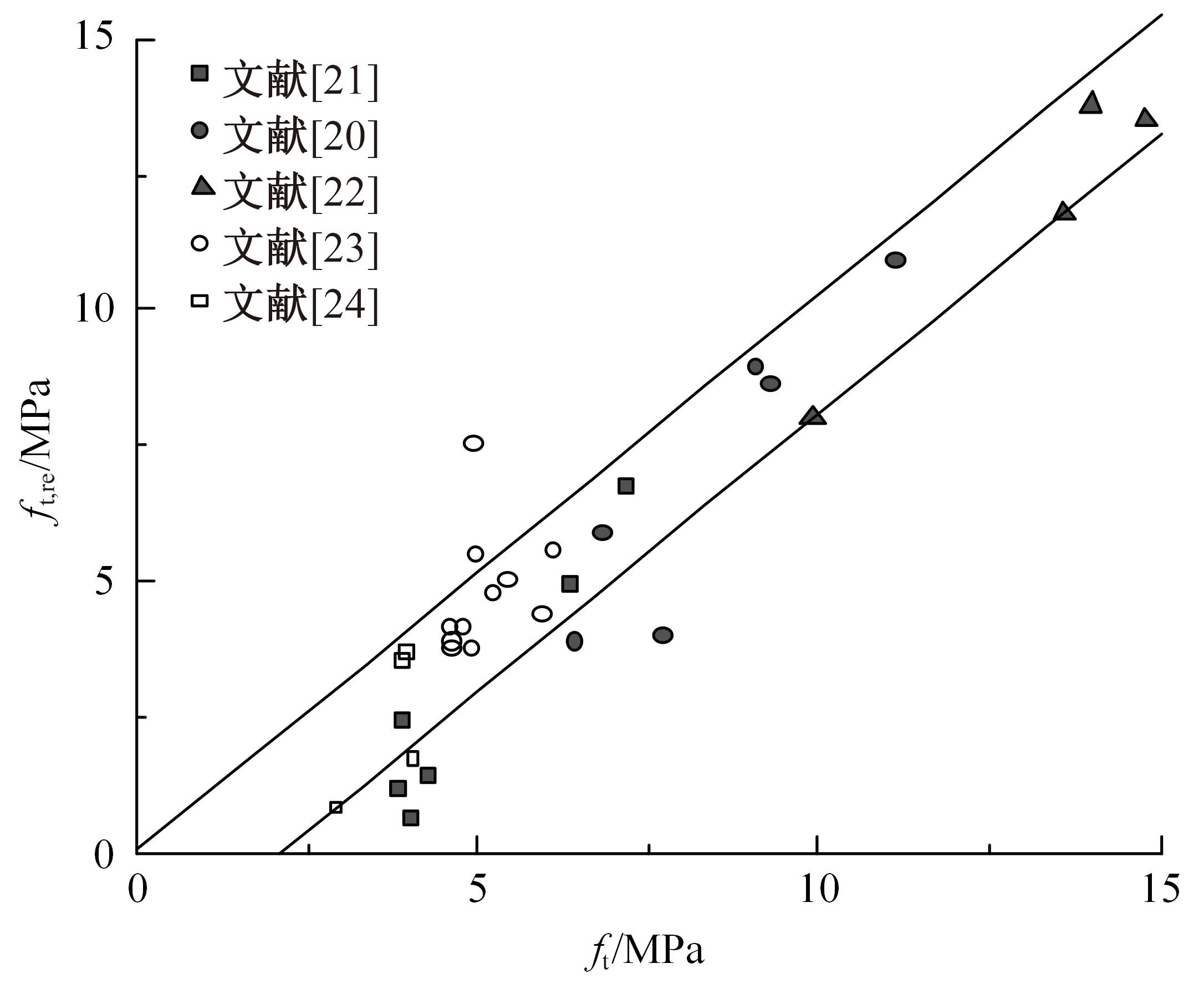

| 18 | 戴昌源, 苏庆田, 冯小毛, 等. 纤维混凝土组合桥面板裂缝宽度计算方法[J]. 同济大学学报: 自然科学版, 2020, 48(6): 788-795. |

| Dai Chang-yuan, Su Qing-tian, Feng Xiao-mao, et al. Crack width calculation method of fiber reinforced concrete composite bridge deck[J]. Journal of Tongji University (Natural Science), 2020, 48(6): 788-795. | |

| 19 | . 钢-混凝土组合桥梁设计规范 [S]. |

| 20 | 高丹盈, 赵亮平, 冯虎, 等. 钢纤维混凝土弯曲韧性及其评价方法[J]. 建筑材料学报, 2014, 17(5): 783-789. |

| Gao Dan-ying, Zhao Liang-ping, Feng Hu, et al. Flexural toughness and its evaluation method of steel fiber reinforced concrete[J]. Journal of Building Materials, 2014, 17(5): 783-789. | |

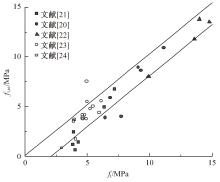

| 21 | Amin A, Foster S J, Muttoni A. Derivation of the σ-w relationship for SFRC from prism bending tests[J]. Structural Concrete, 2015,16(1): 93-105. |

| 22 | Bencardino F, Rizzuti L, Spadea G, et al. Implications of test methodology on post-cracking and fracture behaviour of steel fibre reinforced concrete[J]. Composites Part B: Engineering, 2013, 46: 31-38. |

| 23 | Tiberti G, Minelli F, Plizzari G A, et al. Influence of concrete strength on crack development in SFRC members[J]. Cement and Comcrete Composites, 2014, 45: 176-185. |

| 24 | 陈升平, Hwee Tan Kiang. 反分析法确定钢纤维水泥砂浆拉应力与裂缝张开位移关系[J].工程力学, 2008(4): 165-170. |

| Chen Sheng-ping, Hwee Tan Kiang. Determining the stress-crack opening relationship of sfrm by inverse analysis[J]. Engineering Mechanics, 2008(4): 165-170. |

| [1] | Ran AN,You-zhi WANG. Shear properties of shear stud connectors under combined tension and shear loading [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2554-2562. |

| [2] | Xin-dai ZUO,Jin-quan ZHANG,Shang-chuan ZHAO. Fatigue stiffness degradation and life prediction method of in⁃service concrete T⁃beams [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2563-2572. |

| [3] | Zheng-wei GU,Pan ZHANG,Dong-ye LYU,Chun-li WU,Zhong YANG,Guo-jin TAN,Xiao-ming HUANG. Earthquake⁃induced residual displacement analysis of simply supported beam bridge based on numerical simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1711-1718. |

| [4] | Chun-li WU,Shi-ming HUANG,Kui LI,Zheng-wei GU,Xiao-ming HUANG,Bing-tao ZHANG,Run-chao YANG. Analysis of pier action effect under flood based on numerical simulation and statistical analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1612-1620. |

| [5] | Guo-jin TAN,Qing-wen KONG,Xin HE,Pan ZHANG,Run-chao YANG,Yang-jun CHAO,Zhong YANG. Bridge scour depth identification based on dynamic characteristics and improved particle swarm optimization algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1592-1600. |

| [6] | Hui JIANG,Xin LI,Xiao-yu BAI. Review on development of bridge seismic structural systems: from ductility to resilience [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1550-1565. |

| [7] | Feng WANG,Shuang-rui LIU,Jia-ying WANG,Jia-ling SONG,Jun WANG,Jiu-peng ZHANG,Xiao-ming HUANG. Size and shape effects of wind drag coefficients for porous structures [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1677-1685. |

| [8] | Jun WANG,Jia-wu LI,Feng WANG,Jiu-peng ZHANG,Xiao-ming HUANG. Wind speed distribution in simplified U⁃shaped valley and its effect on buffeting response of long⁃span suspension bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1658-1668. |

| [9] | Hua WANG,Long-lin WANG,Zi-mo ZHANG,Xin HE. Safety early warning technology of continuous rigid frame bridges based on crack width variation [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1650-1657. |

| [10] | Yu FENG,Jian-ming HAO,Feng WANF,Jiu-peng ZHANG,Xiao-ming HUANG. Analysis of transient wind⁃induced response of long⁃span bridge under nonstationary wind field [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1638-1649. |

| [11] | Ye YUAN. Natural frequency analysis of beam bridge structure under temperature and vehicle action [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1702-1710. |

| [12] | Zi-yu LIU,Shi-tong CHEN,Mo-mo ZHI,Xiao-ming HUANG,Zhe-xin CHEN. Ultimate bearing capacity of temporary⁃permanent conversion rush⁃repair steel pier for emergency use [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1601-1611. |

| [13] | Yue ZHANG,Chuan-sen LIU,Fei SONG. Influence of abutment back wall on continuous girder bridge's seismic fragility [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1372-1380. |

| [14] | Shu-wei LAN,Dong-hua ZHOU,Xu CHEN,Nan-ming MO. Practical calculation method for the critical bearing capacity of double column bridge with high piers [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1105-1111. |

| [15] | Qi-kai SUN,Nan ZHANG,Xiao LIU,Zi-ji ZHOU. Dynamic reduction coefficients of steel⁃concrete composite beam based on Timoshenko beam theory [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 488-495. |

|