Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (11): 3281-3292.doi: 10.13229/j.cnki.jdxbgxb.20220135

Previous Articles Next Articles

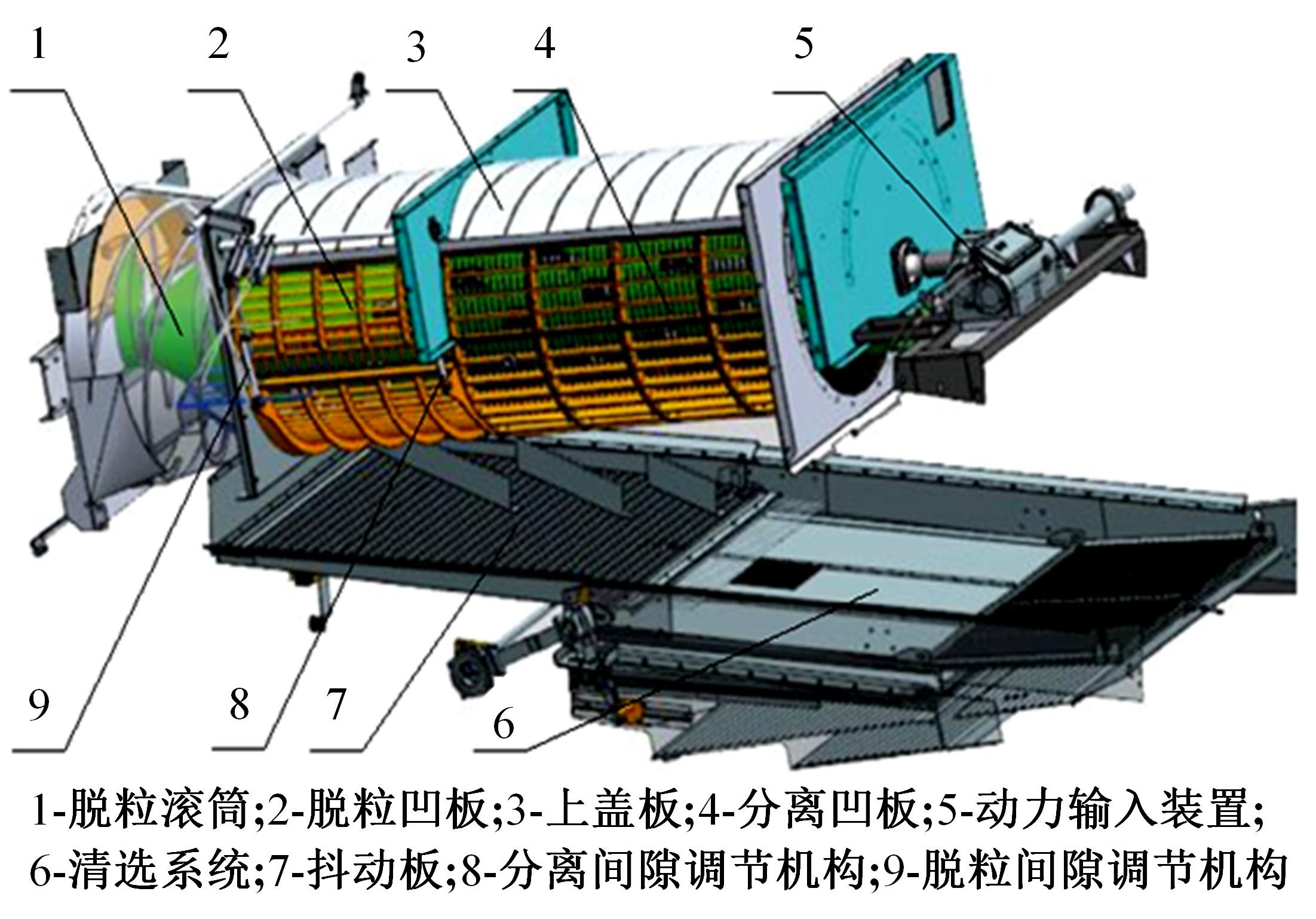

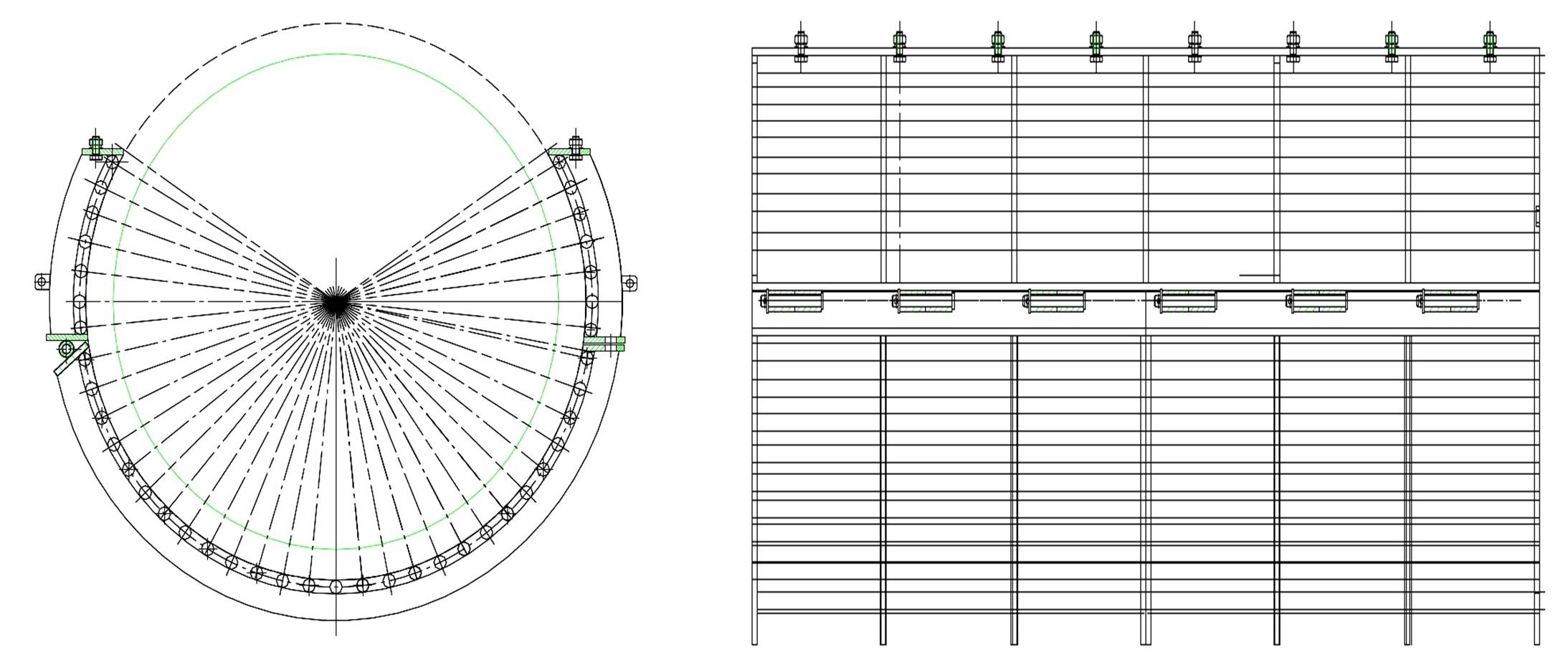

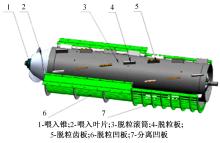

Design and experiment of plate tooth threshing device of corn grain direct harvester

Duan-yang GENG1( ),Yan-cheng SUN1,Zong-yuan WANG1,Qi-huan WANG1,Jia-rui MING1,Hao-lin YANG1,Hai-gang XU2

),Yan-cheng SUN1,Zong-yuan WANG1,Qi-huan WANG1,Jia-rui MING1,Hao-lin YANG1,Hai-gang XU2

- 1.College of Agricultural Engineering and Food Science,Shangdong University of Technology,Zibo 255022,China

2.Shi Feng Group Co. ,Ltd. ,Liaocheng 252899,China

CLC Number:

- S225.5

| 1 | 陈志,郝付平,王锋德,等.中国玉米收获技术与装备发展研究[J].农业机械学报,2012,43(12): 44-50. |

| Chen Zhi, Hao Fu-ping, Wang Feng-de, et al. Research on corn harvesting technology and equipment development in China[J]. Journal of Agricultural Machinery, 2012, 43(12): 44-50. | |

| 2 | 高连兴,李飞,张新伟,等.含水率对种子玉米脱粒性能的影响机理[J].农业机械学报,2011,42(12): 92-96. |

| Gao Lian-xing, Li Fei, Zhang Xin-wei, et al. Mechanism of moisture content affect on corn seed thresin[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(12): 92-96. | |

| 3 | 郝付平, 陈志.国内外玉米收获机械研究现状及思考[J].农机化研究, 2007, 29(10): 206-208. |

| Hao Fu-ping, Chen Zhi. Actuality of domestic and foreign corn harvester[J]. Journal of Agricultural Mechanization Research, 2007, 29(10): 206-208. | |

| 4 | 谢瑞芝, 雷晓鹏, 王克如, 等. 黄淮海夏玉米子粒机械收获研究初报[J]. 作物杂志, 2014(2): 76-79. |

| Xie Rui-zhi, Lei Xiao-peng, Wang Ke-ru, et al. Preliminary report on mechanical harvest of summer maize seeds in Huang Huai Hai[J]. Journal of Crops, 2014(2): 76-79. | |

| 5 | 耿爱军, 杨建宁, 张兆磊, 等. 国内外玉米收获机械发展现状及展望[J].农机化研究,2016,38(4): 251-257. |

| Geng Ai-jun, Yang Jian-ning, Zhang Zhao-lei, et al. Development status and prospect of corn harvester at home and abroad[J]. Agricultural Mechanization Research, 2016, 38(4): 251-257. | |

| 6 | 相茂国.玉米籽粒直收机械适应性研究[D]. 淄博: 山东理工大学农业工程与食品科学学院,2014. |

| Xiang Mao-guo. Study on the adaptability of corn grain harvesting device[D]. Zibo: College of Agriculral Engineering and Food Science, Shandong University of Technology, 2014. | |

| 7 | 雷晓鹏. 黄淮海地区玉米机械收获籽粒可行性研究[D]. 保定: 河北农业大学农学院, 2015. |

| Lei Xiao-peng. Feasibility study on corn mechanical harvest in Huanghuaihai region[D]. Baoding: College of Agronomy, Hebei Agricultural University, 2015. | |

| 8 | 王建廷,李耀明,马征,等.玉米收获机械关键装置结构特点及发展趋势[J].农机化研究, 2019, 41(9): 1-8. |

| Wang Jian-ting, Li Yao-ming, Ma Zheng, et al. Structural characteristics and development trend of key equipment of corn harvesting machinery[J]. Journal of Agricultural Mechanization research, 2019, 41(9): 1-8. | |

| 9 | 王永刚, 张国海, 张恒, 等. 黄淮海地区夏玉米收获现状分析[J].中国农机化学报,2018,39(11): 112-115. |

| Wang Yong-gang, Zhang Guo-hai, Zhang Heng, et al. Analysis on current status of summer maize harvest in Huang-Huai-Hai area[J]. Journal of Chinese Agricultural Mechanization, 2018, 39(11): 112-115. | |

| 10 | 苏媛,刘浩,徐杨,等.轴流式玉米脱粒装置钉齿元件优化与试验[J].农业机械学报,2018,49(): 258-265. |

| Su Yuan, Liu Hao, Xu Yang, et al. Optimization and test of axial flow corn threshing device pin tooth element[J]. Journal of Agricultural Machinery, 2018, 49(Sup.1): 258-265. | |

| 11 | 邸志峰,崔中凯,张华,等.纹杆块与钉齿组合式轴流玉米脱粒滚筒的设计与试验[J].农业工程学报,2018,34(1): 28-34. |

| Di Zhi-feng, Cui Zhong-kai, Zhang Hua, et al. Design and experiment of axial flow corn threshing drum with grain bar block and nail tooth combination[J]. Journal of Agricultural Engineering, 2018, 34(1): 28-34. | |

| 12 | 王志明. 横置差速轴流脱分选系统工作机理及设计研究[D]. 西安: 长安大学工程机械学院, 2017. |

| Wang Zhi-ming. Research on working mechanism and design of transverse differential axial flow separation system[D]. Xi'an: School of Construction Machinery, Chang'an University, 2017. | |

| 13 | 周海玲.玉米果穗物理力学性质研究及脱粒过程仿真分析[D]. 长春: 吉林大学生物与农业工程学院,2013. |

| Zhou Hai-ling. The physical and mechanical property research of corn ears and simulated analysis of corn threshing progress[D]. Changchun: College of Biological and Agricultural Engineering, Jilin University, 2013. | |

| 14 | 高连兴,李飞,张新伟,等.含水率对种子玉米脱粒性能的影响机理[J].农业机械学报, 2011,42(12): 92-96. |

| Gao Lian-xing, Li Fei, Zhang Xin-wei, et al. Mechanism of moisture content affect on corn seed thresing[J]. Transactions ofthe Chinese Society for Agricultural Machinery, 2011, 42(12): 92-96. | |

| 15 | 虞顺成,李耀明,马征,等.玉米籽粒直收中籽粒及穗轴破损形态研究[J].农机化研究,2019,41(10): 208-212. |

| Yu Shun-cheng, Li Yao-ming, Ma Zheng, et al. Study on damage of corn kernel and cob in corn kernel harvesting[J]. Journal of Agricultural Mechanization Research, 2019, 41(10): 208-212. | |

| 16 | 屈哲. 低损伤组合式玉米脱粒分离装置的研究[D]. 北京: 中国农业大学工学院,2018. |

| Qu Zhe.Research on combined maize threshing and separating device with low damade[D]. Beijing: College of Engineering, China Agricultural University, 2018. | |

| 17 | 相茂国,张道林,李春宁,等. 影响玉米脱粒性能的因素分析与研究[J].农机化研究,2015,37(1): 188-191. |

| Xiang Mao-guo, Zhang Dao-lin, Li Chun-ning,et al. Analysis of influence factor on corn threshing performance[J]. Journal of Agricultural Mechanization Research, 2015, 37(1): 188-191. | |

| 18 | 周海玲.玉米果穗物理力学性质研究及脱粒过程仿真分析[D].长春: 吉林大学生物与农业工程学院,2013. |

| Zhou Hai-ling. The physical and mechanical property research of corn ears and simulated analysis of corn threshing progress[D]. Changchun: College of Biological and Agricultural Engineering, Jilin University, 2013. | |

| 19 | 虞顺成.玉米脱粒过程中的籽粒破损试验与分析[D]. 镇江: 江苏大学农业工程学院, 2019. |

| Yu Shun-cheng. Corn kernel damage test and analysis of corn threshing process[D]. Zhenjiang: College of Agricultural Engineering, Jiangsu University, 2019. | |

| 20 | 李心平,熊师,耿令新,等.含水率对玉米果穗抗压特性的影响[J].农业工程学报, 2018, 34(2): 25-31. |

| Li Xin-ping, Xiong Shi, Geng Ling-xin, et al. Effect of moisture content on compressive properties of corn ear[J]. Journal of Agricultural Engineering, 2018, 34(2): 25-31. | |

| 21 | Srivastava A K, Goering C E, Rohrbach R P, et al. Engineering Principles of Agricultural Machines[M]. 2nd ed. Michigan: Michigan State University Press, 1993. |

| 22 | Pužauskas E, Steponavičius D, Jotautienė E, et al. Substantiation of concave crossbar shape for corn ear threshing[J]. Mechanika, 2017, 22(6): 553-561. |

| 23 | Petkevichius S, Shpokas L, Kutzbach H D. Investigation of the maize ear threshing process[J]. Biosystems Engineering, 2008, 99(4): 532-539. |

| 24 | Petkevichius S, Shpokas L, Steponavicius D. Substantiation of technology parameter of wet maize ear threshing[J]. Agronomy Research: Special Issue, 2008, 6: 271-280. |

| 25 | 付君,张屹晨,程超,等.刚柔耦合式小麦脱粒弓齿设计及试验[J].吉林大学学报: 工学版, 2020, 50(2): 730-738. |

| Fu Jun, Zhang Yi-chen, Cheng Chao,et al. Design and experiment of bow tooth of rigid flexible coupling for wheat threshing[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 730-738. | |

| 26 | 钱震杰, 金诚谦, 袁文胜, 等. 柔性脱粒齿杆与谷物含摩擦打击动力学模型[J]. 吉林大学学报: 工学版, 2021, 51(3): 1121-1130. |

| Qian Zhen-jie, Jin Cheng-qian, Yuan Wen-sheng, et al. Frictional impact dynamics model of threshing process between flexible teeth and grains[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 1121-1130. | |

| 27 | 陈美舟, 徐广飞, 王传旭, 等. 纵轴流辊式组合玉米柔性脱粒分离装置设计与试验[J]. 农业机械学报, 2020, 51(10): 123-131. |

| Chen Mei-zhou, Xu Guang-fei, Wang Chuan-xu, et al. Design and experiment of longitudinal axial flow roller combined corn flexible threshing and separation device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(10): 123-131. | |

| 28 | 王占滨, 王振伟, 张银平, 等. 纵轴流柔性锤爪式玉米脱粒装置设计与试验[J]. 农业机械学报, 2020, 51(): 109-117. |

| Wang Zhan-bin, Wang Zhen-wei, Zhang Yin-ping, et al. Design and experiment of longitudinal axial flow flexible hammer claw corn threshing device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(Sup.2): 109-117. | |

| 29 | 耿端阳, 何珂, 王骞, 等. 横轴流式玉米柔性脱粒装置设计与试验[J]. 农业机械学报, 2019, 50(3): 101-108. |

| Geng Duan-yang, He Ke, Wang Qian, et al. Design and experiment of horizontal axial flow corn flexible threshing device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50 (3): 101-108. | |

| 30 | 耿端阳, 谭德蕾, 于兴瑞, 等. 玉米柔性脱粒滚筒脱粒元件设计与试验[J]. 吉林大学学报: 工学版, 2020, 50(5): 1923-1933. |

| Geng Duan-yang, Tan De-lei, Yu Xing-rui, et al. Design and test of corn flexible threshing cylinder element[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1923-1933. | |

| 31 | 中国农业机械化科学研究院.农业机械设计手册(上册)[M]. 北京: 中国农业科学技术出版社,2007. |

| 32 | 赵东元.可靠性工程与应用[M]. 北京: 国防工业出版社, 2009. |

| [1] | Xiao-jun JIN,Yan-xia SUN,Jia-lin YU,Yong CHEN. Weed recognition in vegetable at seedling stage based on deep learning and image processing [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2421-2429. |

| [2] | Yong-shuo WANG,Jian-ming KANG,Qiang-ji PENG,Ying-kai CHEN,Hui-min FANG,Meng-meng NIU,Shao-wei WANG. Design and experiment of obstacle avoidance weeding machine for fruit trees [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2410-2420. |

| [3] | Feng LYU,Nian LI,Zhuang-zhuang FENG,Yang-hang ZHANG. Method of collaborative filtering recommendation of personalized product-service system based on user [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 1935-1942. |

| [4] | Shou-yong XIE,Xiao-liang ZHANG,Fan-yi LIU,Jun LIU,Xiao-liang YUAN,Wei LIU,Peng WANG. Kinetic analysis and experiment of seedling taking and throwing device based on mechanical properties of plug seedlings [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(11): 3293-3304. |

| [5] | Bin WANG,Bing-hui HE,Na LIN,Wei WANG,Tian-yang LI. Tea plantation remote sensing extraction based on random forest feature selection [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1719-1732. |

| [6] | Duan-yang GENG,Yan-cheng SUN,Xiao-dong MU,Guo-dong ZHANG,Hui-xin JIANG,Jun-ke ZHU. Simulation test and optimization of grain breakage of silage maize based on differential roller [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 693-702. |

| [7] | Chang-kai WEN,Bin XIE,Zheng-he SONG,Jian-gang HAN,Qian-wen YANG. Design method of tractor durability accelerated structure test [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 703-715. |

| [8] | Guo-wei WANG,Qing-hui ZHU,Hai-ye YU,Dong-yan HUANG. Silage traceability system based on digital agricultural machinery equipment [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 242-252. |

| [9] | Fang LIANG,De-cheng WANG,Yong YOU,Guang-hui WANG,Yu-bing WANG,Xiao-ming ZHANG,Jin-kui FENG. Design and experiment of root-cutter with fertilization and reseeding compound remediation machine for grassland [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 231-241. |

| [10] | Xin-yan WANG,Quan JIANG,Feng LYU,Zheng-yang YI. Rollover stability of zero turning radius lawn mower based on parametric model [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1908-1918. |

| [11] | Qian CONG,Jin XU,Bo-shuai MA,Xiao-chao ZHANG,Ting-kun CHEN. Design and test of tractor hydraulic suspension system testing device based on virtual simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 754-760. |

| [12] | Chao CHENG,Jun FU,Zhi CHEN,Lu-quan REN. Sieve blocking laws and stripping test of corn grain harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 761-771. |

| [13] | Xue-shen CHEN,Zhu-jian HUANG,Xu MA,Long QI,Gui-jin FANG. Design and test of control system for rice mechanical weeding and seedling-avoiding control [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 386-396. |

| [14] | En-ze LIU,Wen-fu WU. Monochrome fruit growth detection internet architecture based oncomprehensive indicator quality evaluation algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 2019-2026. |

| [15] | Jia⁃hao QIN,Zhen LI,Muneshi MITSUOKA,Eiji INOUE,Zheng⁃he SONG,Zhong⁃xiang ZHU. Significance variation of factorial effects on tractor stability employing scale⁃model⁃based experimental approach [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1236-1245. |

|