Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (5): 1237-1245.doi: 10.13229/j.cnki.jdxbgxb.20220756

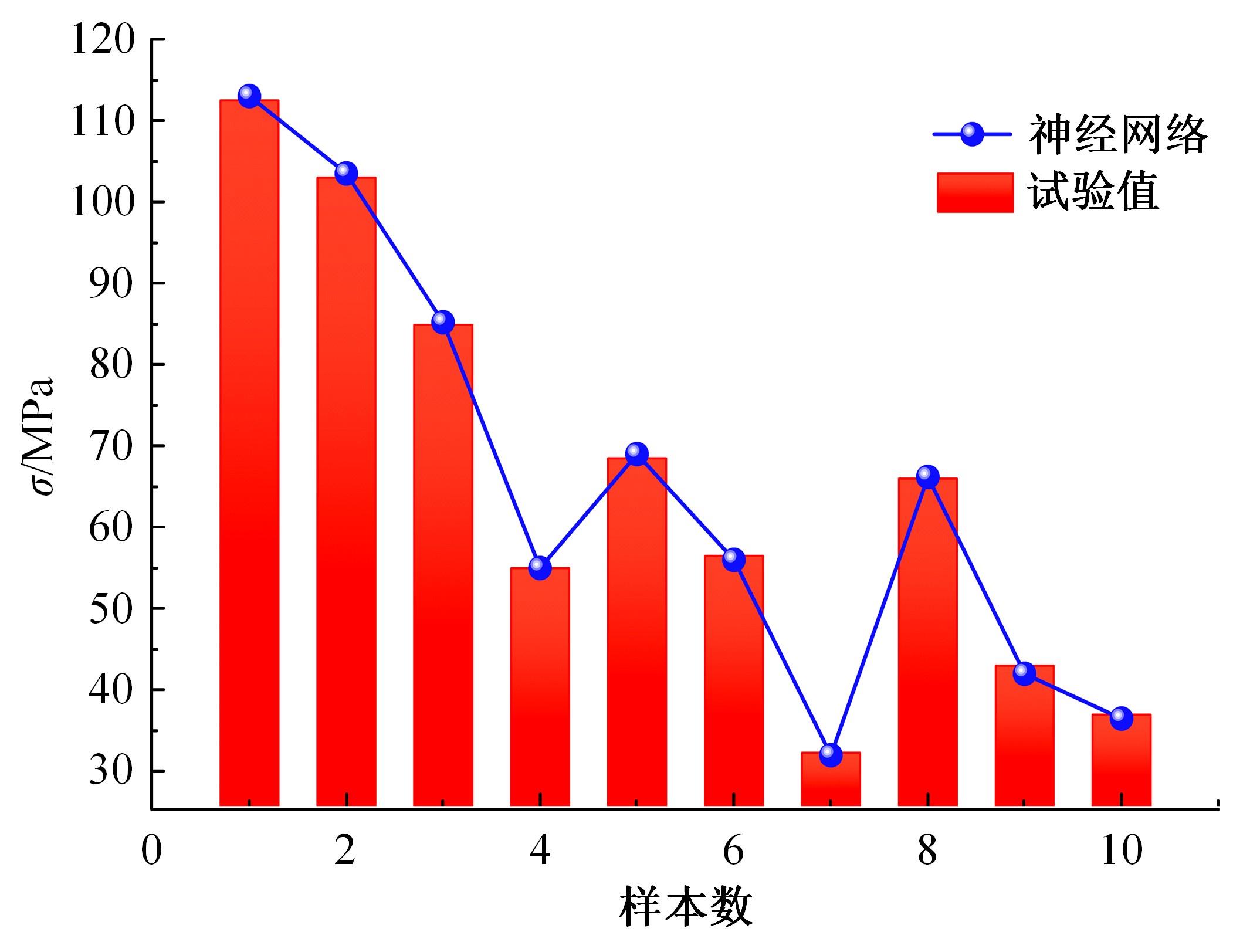

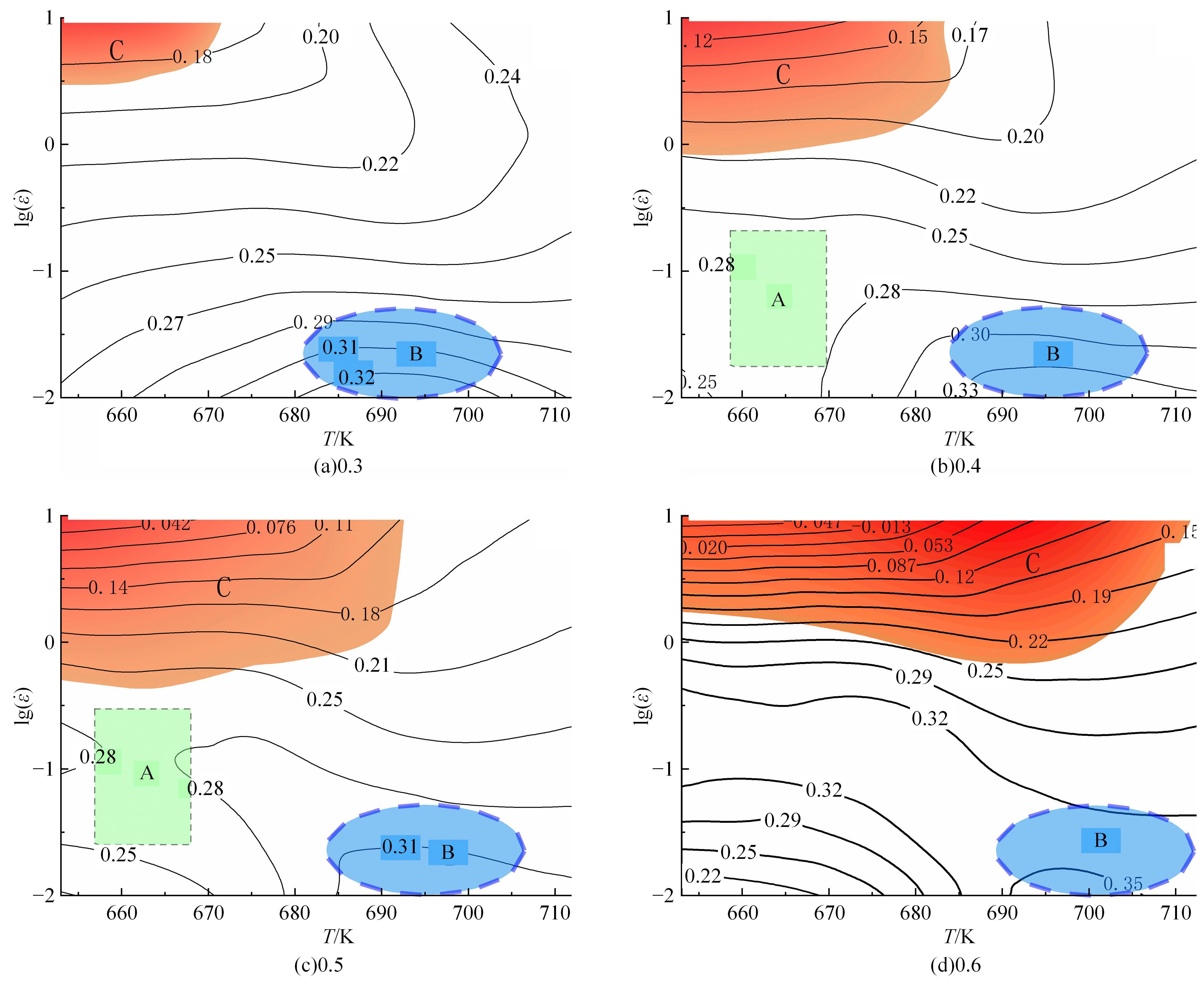

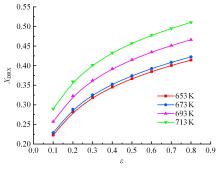

Thermal deformation behavior of graphene nanosheets reinforced 7075Al based on BP neural network and Arrhenius constitutive equation

Shu-mei LOU( ),Yi-ming LI,Xin LI,Peng CHEN,Xue-feng BAI,Bao-jia CHENG

),Yi-ming LI,Xin LI,Peng CHEN,Xue-feng BAI,Bao-jia CHENG

- College of Intelligent Equipment,Shandong University of Science and Technology,Taian 271019,China

CLC Number:

- TG376.2

| 1 | Pérez-Bustamante R, Bolaños-Morales D, Bonilla-Martínez J, et al. Microstructural and hardness behavior of graphene-nanoplatelets/aluminum composites synthesized by mechanical alloying[J]. Journal of Alloys and Compounds, 2014, 615(Sup.1): 5578-5582. |

| 2 | Li De-jun, Feng Yao-rong, Yin Zhi-fu, et al. Hot deformation behavior of an austenitic Fe-20Mn-3Si-3Al transformation induced plasticity steel[J]. Materials and Design, 2011, 34: 713-718. |

| 3 | He Hai-lin, Yi You-pin, Cui Jin-dong, et al. Hot deformation characteristics and processing parameter optimization of 2219 Al alloy using constitutive equation and processing map[J]. Vacuum,2019,160:293-302. |

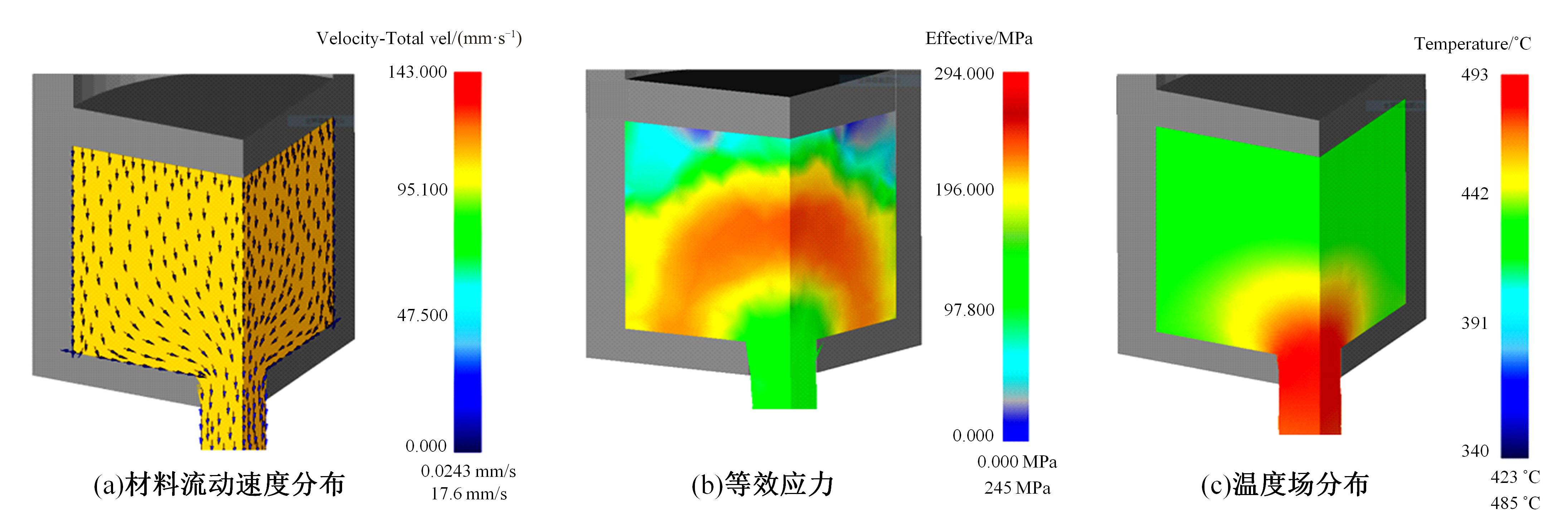

| 4 | Dong Yuan-yuan, Zhang Cun-sheng, Zhao Guo-qun, et al. Constitutive equation and processing maps of an Al-Mg-Si aluminum alloy: determination and application in simulating extrusion process of complex profiles[J]. Materials Design,2016, 92: 983-997. |

| 5 | Ramanathan S, Karthikeyan R, Gupta M. Development of processing maps for Al/SiCp composite using fuzzy logic[J]. Journal of Materials Processing Technology, 2007, 183(1): 104-110. |

| 6 | Senthilkumar V, Balaji A, Narayanasamy R. Analysis of hot deformation behavior of Al 5083-TiC nanocomposite using constitutive and dynamic material models[J]. Materials & Design, 2012, 37: 102-110. |

| 7 | 臧雪柏,管秀君,赵宏伟,等.基于遗传算法的神经网络振动钻削参数优化[J].吉林大学学报:工学版,2002, 32(1): 37-41. |

| Zang Xue-bai, Guan Xiu-jun, Zhao Hong-wei, et al. Optimization of neural network vibration drilling parameter based on genetic algorithm[J]. Journal of Jilin University (Engineering and Technology Edition),2002, 32(1): 37-41. | |

| 8 | 闫楚良,郝云霄,刘克格.基于遗传算法优化的BP神经网络的材料疲劳寿命预测[J].吉林大学学报:工学版,2014,44(6):1710-1715. |

| Yan Chu-liang, Hao Yun-xiao, Liu Ke-ge,et al. Fatigue life prediction of materials based on BP neural networksoptimized by genetic algorithm[J]. Journal of Jilin University (Engineering and Technology Edition), 2014, 44(6): 1710-1715. | |

| 9 | 娄淑梅,张苹苹,冉令伟,等. 石墨烯增强铝基复合材料制备工艺对比与分析[J]. 热加工工艺, 2021, 50(8): 51-54, 58. |

| Lou Shu-mei, Zhang Ping-ping, Ran Ling-wei, et al. Comparison and analysis of preparation technology of graphene reinforced aluminum matrix composites [J]. Hot Working Technology, 2021, 50(8): 51-54, 58. | |

| 10 | Ebrahimi R, Najafizadeh A.A new method for evaluation of friction in bulk metal forming[J]. Journal of Materials Processing Tech, 2004, 152(2): 136-143. |

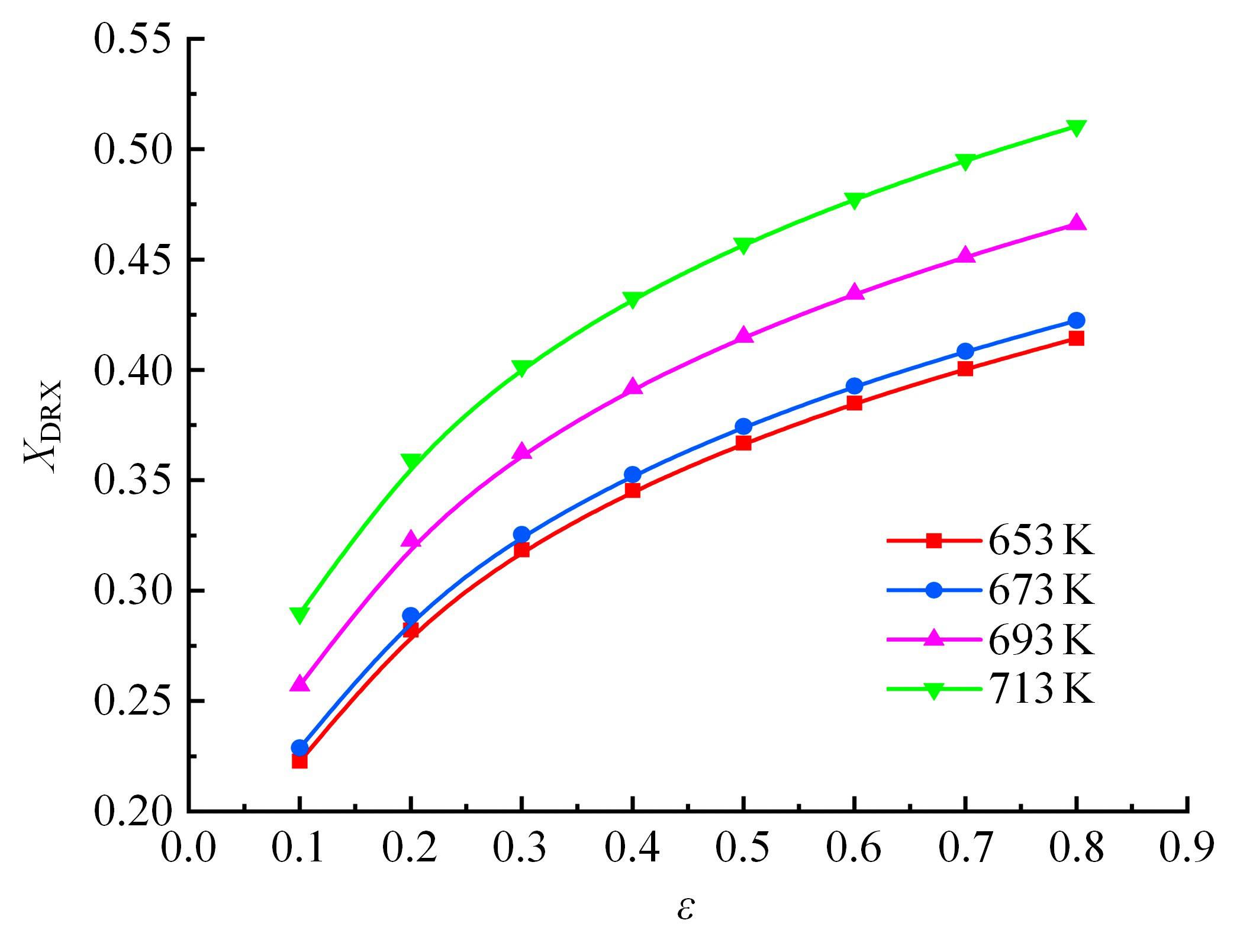

| 11 | Zeng Jian, Wang Feng-hua, Dong Shuai, et al. A new dynamic recrystallization kinetics model of cast-homogenized magnesium alloys[J]. Metallurgical and Materials Transactions A, 2020,52(1):1-16. |

| 12 | Chen Xiao-min, Wen Dong-xu, Zhan Jin-long,et al. Dynamic recrystallization behavior of a typical nickel-based superalloy during hot deformation-scienceDirect[J]. Materials & Design, 2014, 57(5): 568-577. |

| [1] | Qiu ZHAO,Peng CHEN,Yu-wei ZHAO,Ao YU. Overall mechanical performance of jointless bridges with arch structure behind abutment [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 1016-1027. |

| [2] | Yi-gang WANG,Yu-peng WANG,Hao ZHANG,Si-an ZHAO. Identification and analysis of aerodynamic noise sources in the bogie area of high⁃speed trains [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 346-355. |

| [3] | Wei-hua ZHANG,Jia-ming LIU,Li-peng XIE,Heng DING. Lane⁃changing model of autonomous vehicle in weaving area of expressway in intelligent and connected mixed environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 469-477. |

| [4] | Xing WEI,Ya-jie GAO,Zhi-rui KANG,Yu-chen LIU,Jun-ming ZHAO,Lin XIAO. Numerical simulation of residual stress field of stud girth weld in low temperature environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 198-208. |

| [5] | Zhi ZHENG,Pei YUAN,Xuan-hui JIN,Si-si WEI,Bo GENG. Experimental on composite flexible anti⁃collision fender of bridge pier [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2581-2590. |

| [6] | Feng WANG,Shuang-rui LIU,Jia-ying WANG,Jia-ling SONG,Jun WANG,Jiu-peng ZHANG,Xiao-ming HUANG. Size and shape effects of wind drag coefficients for porous structures [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1677-1685. |

| [7] | Chun-li WU,Shi-ming HUANG,Kui LI,Zheng-wei GU,Xiao-ming HUANG,Bing-tao ZHANG,Run-chao YANG. Analysis of pier action effect under flood based on numerical simulation and statistical analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1612-1620. |

| [8] | Zheng-wei GU,Pan ZHANG,Dong-ye LYU,Chun-li WU,Zhong YANG,Guo-jin TAN,Xiao-ming HUANG. Earthquake⁃induced residual displacement analysis of simply supported beam bridge based on numerical simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1711-1718. |

| [9] | Hai-bin WEI,Shuan-ye HAN,Hai-peng BI,Qiong-hui LIU,Zi-peng MA. Intelligent sensing road active ice and snow removal system and experimental technology [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1411-1417. |

| [10] | Jing-fu JIN,Xin-ju DONG,Zhi-cheng JIA,Kang WANG,Lian-bin HE,Meng ZOU,Ying-chun QI. Optimization of the tread plate-spring structure of flexible metal wheel with plate-spring [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 964-972. |

| [11] | Zhuang-zhuang LIU,You-wei ZHANG,Peng-yu JI,Abshir Ismail Yusuf,Lin LI,Ya-zhen HAO. Study on heat transfer characteristics of electric heating snow melting asphalt pavement [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 523-530. |

| [12] | Fang-xi XIE,Shi-jie ZHAO,Zi-sen WANG,Shuang LIU,Xiao-ping LI,Cheng ZHANG. Simulation analysis of influencing factors of flash boiling spray collapse of porous injector [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(12): 3314-3325. |

| [13] | Li-zhao DAI,Liang ZHOU,Xiao-wen YANG,Lei WANG. Meso-scale numerical simulation of interfacial bond behavior of corroded RC beams based on connector element [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(10): 2886-2896. |

| [14] | Xiao-hong LU,Jin-hui QIAO,Yu ZHOU,Chong MA,Guo-chuan SUI,Zhuo SUN. Research progress of temperature field in friction stir welding [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 1-17. |

| [15] | Zhi ZHENG,Bo GENG,Fu-min WANG,Jun-hong DONG,Si-si WEI. Improvement of protective ability for existing low⁃grade concrete guardrail [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1362-1374. |

|

||