Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (11): 3056-3061.doi: 10.13229/j.cnki.jdxbgxb.20220768

Previous Articles Next Articles

Simulation of ultra-precision machine tool spindle fault diagnosis based on multi-state time series predictive learning

Chao-gang ZHANG1( ),Zhong-lou SHI1,Min LI2

),Zhong-lou SHI1,Min LI2

- 1.Engineering Training Centre,Jianghan University,Wuhan 430056,China

2.Engineering Training and Innovation Practice Center,Wuhan University,Wuhan 430056,China

CLC Number:

- TM464

| 1 | 陈传海, 王成功, 杨兆军, 等. 数控机床可靠性建模研究现状及发展动态分析[J]. 吉林大学学报: 工学版, 2022, 52(2): 253-266. |

| Chen Chuan-hai, Wang Cheng-gong, Yang Zhao-jun, et al. Research status and development trend analysis of reliability modeling of CNC machine tools[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 253-266. | |

| 2 | 赵亮, 雷默涵, 朱星星, 等. 高精度数控机床主轴系统热误差的控制方法[J]. 上海交通大学学报, 2020, 54(11): 1165-1171. |

| Zhao Liang, Lei Mo-han, Zhu Xing-xing, et al. A new thermal error control method for spindle system of high precision computer numerical control machine tools[J]. Journal of Shanghai Jiaotong University, 2020, 54(11): 1165-1171. | |

| 3 | 林伟强. 基于循环神经网络的数控机床故障诊断研究[J]. 机床与液压, 2022, 50(5): 191-196. |

| Lin Wei-qiang. Research on fault diagnosis of NC machine tool based on circulating neural network[J]. Machine Tool & Hydraulics, 2022, 50(5): 191-196. | |

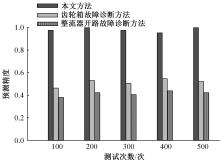

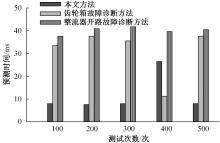

| 4 | 李东东, 赵耀, 赵阳, 等. 基于改进生成对抗网络的风机行星齿轮箱故障诊断方法[J]. 中国电机工程学报, 2021, 41(21): 7496-7507. |

| Li Dong-dong, Zhao Yao, Zhao Yang, et al. Fault diagnosis method of wind turbine planetary gearbox based on improved generative adversarial network[J]. Proceedings of the CSEE, 2021, 41(21): 7496-7507. | |

| 5 | 王英, 王丹, 陈小强, 等. 基于改进谱峭度与电流均值的牵引整流器开路故障诊断方法[J]. 电力自动化设备, 2020, 40(1): 112-118. |

| Wang Ying, Wang Dan, Chen Xiao-qiang, et al. Open circuit fault diagnosis method for traction rectifier based on improved spectral kurtosis and current mean value[J]. Electric Power Automation Equipment, 2020, 40(1): 112-118. | |

| 6 | 史建楠, 邹俊忠, 张见, 等. 基于DMD-LSTM模型的股票价格时间序列预测研究[J]. 计算机应用研究, 2020, 37(3): 662-666. |

| Shi Jian-nan, Zou Jun-zhong, Zhang Jian, et al. Research of stock price prediction based on DMD-LSTM model[J]. Application Research of Computers, 2020, 37(3): 662-666. | |

| 7 | 章子玲, 胡雄, 亓寅, 等. 基于向量投影响应面的数控机床几何误差分配方法[J]. 吉林大学学报: 工学版, 2022, 52(2): 384-391. |

| Zhang Zi-ling, Hu Xiong, Qi Yan, et al. An approach for error allocation of machine tool based on vector projection response surface method[J]. Journal of Jilin University(Engineering and Technology Edition), 2022,52(2): 384-391. | |

| 8 | 崔少华, 李素文, 汪徐德. BP神经网络和SVD算法联合的地震数据去噪方法[J]. 电子测量与仪器学报, 2020, 34(2): 12-19. |

| Cui Shao-hua, Li Su-wen, Wang Xu-de. Joint de-noising method of seismic data via BP neural network and SVD algorithm[J]. Journal of Electronic Measurement and Instrumentation, 2020, 34(2): 12-19. | |

| 9 | 张强, 杨吉斌, 张雄伟, 等. CS-Softmax:一种基于余弦相似性的Softmax损失函数[J]. 计算机研究与发展, 2022, 59(4): 936-949. |

| Zhang Qiang, Yang Ji-bin, Zhang Xiong-wei, et al. CS-Softmax: a cosine similarity-based softmax loss function[J]. Journal of Computer Research and Development, 2022, 59(4): 936-949. | |

| 10 | 孟月波, 石德旺, 刘光辉, 等. 多维度卷积融合的密集不规则文本检测[J]. 光学精密工程, 2021, 29(9): 2210-2221. |

| Meng Yue-bo, Shi De-wang, Liu Guang-hui, et al. Dense irregular text detection based on multi-dimensional convolution fusion[J]. Optics and Precision Engineering, 2021, 29(9): 2210-2221. | |

| 11 | 张峰瑞, 姜谙男, 赵亮, 等. 基于多变量GP-DE模型的隧道变形时间序列预测研究[J]. 现代隧道技术, 2021, 58(1): 109-116. |

| Zhang Feng-rui, Jiang An-nan, Zhao Liang, et al. Study on time series prediction of the tunnel deformation based on the multivariable GP-DE Model[J]. Modern Tunnelling Technology, 2021, 58(1): 109-116. | |

| 12 | 刘新田, 马牧洲, 何佳龙. 基于模糊耦合的机床零件加工精度可靠性预测方法[J]. 吉林大学学报: 工学版, 2022, 52(2): 377-383. |

| Liu Xin-tian, Ma Mu-zhou, He Jia-long. Reliability prediction method of machining precision of machine tool parts based on fuzzy coupling[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 377-383. | |

| 13 | 余孟阳, 杨帆. 信息链接技术下自动化设备现场故障运维仿真[J]. 计算机仿真, 2021, 38(12): 475-479. |

| Yu Meng-yang, Yang Fan. Field failure operation and maintenance simulation of automation equipment based on information link technology[J]. Computer Simulation, 2021, 38(12): 475-479. | |

| 14 | 赵寿生, 汪卫国, 王丰华, 等. 基于统计特征与EMD算法的有载分接开关振动信号去噪[J]. 电工电能新技术, 2020, 39(1): 51-58. |

| Zhao Shou-sheng, Wang Wei-guo, Wang Feng-hua, et al. Denoising method of vibration signal of on-load tap changer based on statistical feature and EMD algorithm[J]. Advanced Technology of Electrical Engineering and Energy, 2020, 39(1): 51-58. | |

| 15 | Li J, Sacchi M D. An l p-space matching pursuit algorithm and its application to robust seismic data denoising via time-domain Radon transforms[J]. Geophysics, 2021, 86(3): 1-90. |

| 16 | Zeng Y, Li J, Wei C, et al. mbDenoise: microbiome data denoising using zero-inflated probabilistic principal components analysis[J]. Genome Biology, 2022, 23(1): 1-29. |

| 17 | 李水利, 周建民, 孙定邦. 自适应MED降噪和EMD分解在注塑机轴承故障诊断中的应用[J]. 塑料科技, 2020, 48(6): 124-128. |

| Li Shui-li, Zhou Jian-min, Sun Ding-bang. Application of adaptive MED noise reduction and EMD decomposition in fault diagnosis of mechanical Bearings[J]. Plastics Science and Technology, 2020, 48(6): 124-128. | |

| 18 | Rakotondramanana A L H, Randrianirina H H R, Randriamiharisoa M A, et al. Contributions of IMFs programs to household financial resilience: financial evolution of households in rural areas—the case of malagasy IMFs[J]. Modern Economy, 2021, 12(12): 1212102. |

| 19 | Shankar V F, Cockle J, et al. IMG-18. Assessment of suspected disease progression using multiparametric 18f-choline pet/mri in childhood and teenage-young adult gliomas[J]. Neuro-Oncology, 2020, 22(3): 358. |

| 20 | Hou S, Guo X. Research on fault location of distribution lines based on the standing wave principle[J]. Processes, 2021, 9(8): 9081436. |

| [1] | Dan-tong OUYANG,Rui SUN,Xin-liang TIAN,Li-ming ZHANG,Ping-ping LIU. Approach for generating minimal fault detectability and isolability set in dynamic system based on partial maximum satisfiability problem [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1163-1173. |

| [2] | Dan-tong OU-YANG,Rui SUN,Xin-liang TIAN,Bo-han GAO. Set blocking⁃based approach to sensor selection in uncertain systems [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 547-554. |

| [3] | Yong-gang CHEN,Ji-ye XU,Hai-yong WANG,Wen-xiang XIONG. Fault diagnosis method of point machine based on adaptive neural fuzzy inference network system [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(11): 3274-3280. |

| [4] | Jie CAO,Jia-lin MA,Dai-lin HUANG,Ping YU. A fault diagnosis method based on multi Markov transition field [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 491-496. |

| [5] | Jin-hua WANG,Jia-wei HU,Jie CAO,Tao HUANG. Multi⁃fault diagnosis of rolling bearing based on adaptive variational modal decomposition and integrated extreme learning machine [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 318-328. |

| [6] | Shao-jiang DONG,Peng ZHU,Xue-wu PEI,Yang LI,Xiao-lin HU. Fault diagnosis of rolling bearing under variable operating conditions based on subdomain adaptation [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 288-295. |

| [7] | Wei LUO,Bo LU,Fei CHEN,Teng MA. Fault diagnosis method of NC turret based on PSO⁃SVM and time sequence [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 392-399. |

| [8] | Fei-yue DENG, LYUHao-yang,Xiao-hui GU,Ru-jiang HAO. Fault diagnosis of high⁃speed train axle bearing based on a lightweight neural network Shuffle⁃SENet [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 474-482. |

| [9] | Long ZHANG,Tian-peng XU,Chao-bing WANG,Jian-yu YI,Can-zhuang ZHEN. Gearbox fault diagnosis baed on convolutional gated recurrent network [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 368-376. |

| [10] | Xiao⁃lei CHEN,Yong⁃feng SUN,Ce LI,Dong⁃mei LIN. Stable anti⁃noise fault diagnosis of rolling bearing based on CNN⁃BiLSTM [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 296-309. |

| [11] | Xian-jun DU,Liang-liang JIA. Fault diagnosis of rolling bearing based on optimized stacked denoising auto encoders [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(12): 2827-2838. |

| [12] | Fei CHEN,Zheng YANG,Zhi-cheng ZHANG,Wei LUO. Fault diagnosis method of rotating machinery for unlabeled data [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2514-2522. |

| [13] | Jie CAO,Zhi-Dong HE,Ping YU,Jin-hua WANG. Bearing fault diagnosis method under unbalanced data distribution [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2523-2531. |

| [14] | Dan-tong OUYANG,Bi-ge ZHANG,Nai-yu TIAN,Li-ming ZHANG. Fail data reduction algorithm combining configuration checking with local search [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2144-2153. |

| [15] | Lao-hu YUAN,Dong-shan LIAN,Liang ZHANG,Yi LIU. Fault diagnosis of key mechanical components of aircraft based on densenet and support vector machine [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1635-1641. |

|