Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (1): 105-115.doi: 10.13229/j.cnki.jdxbgxb.20230215

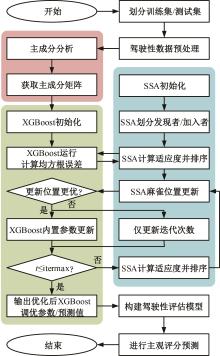

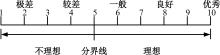

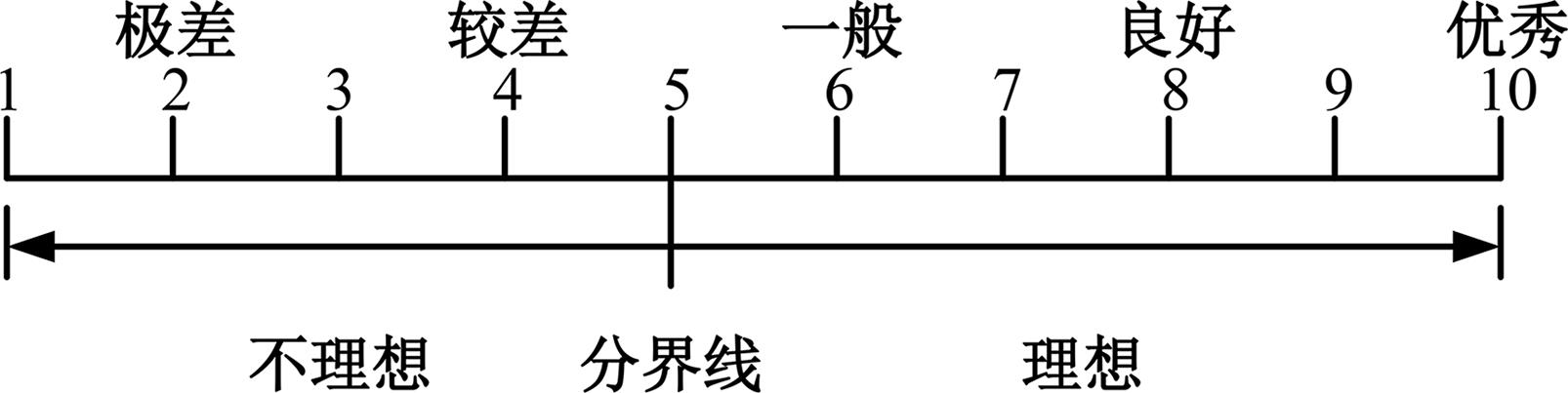

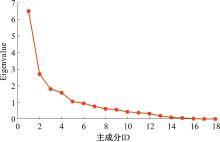

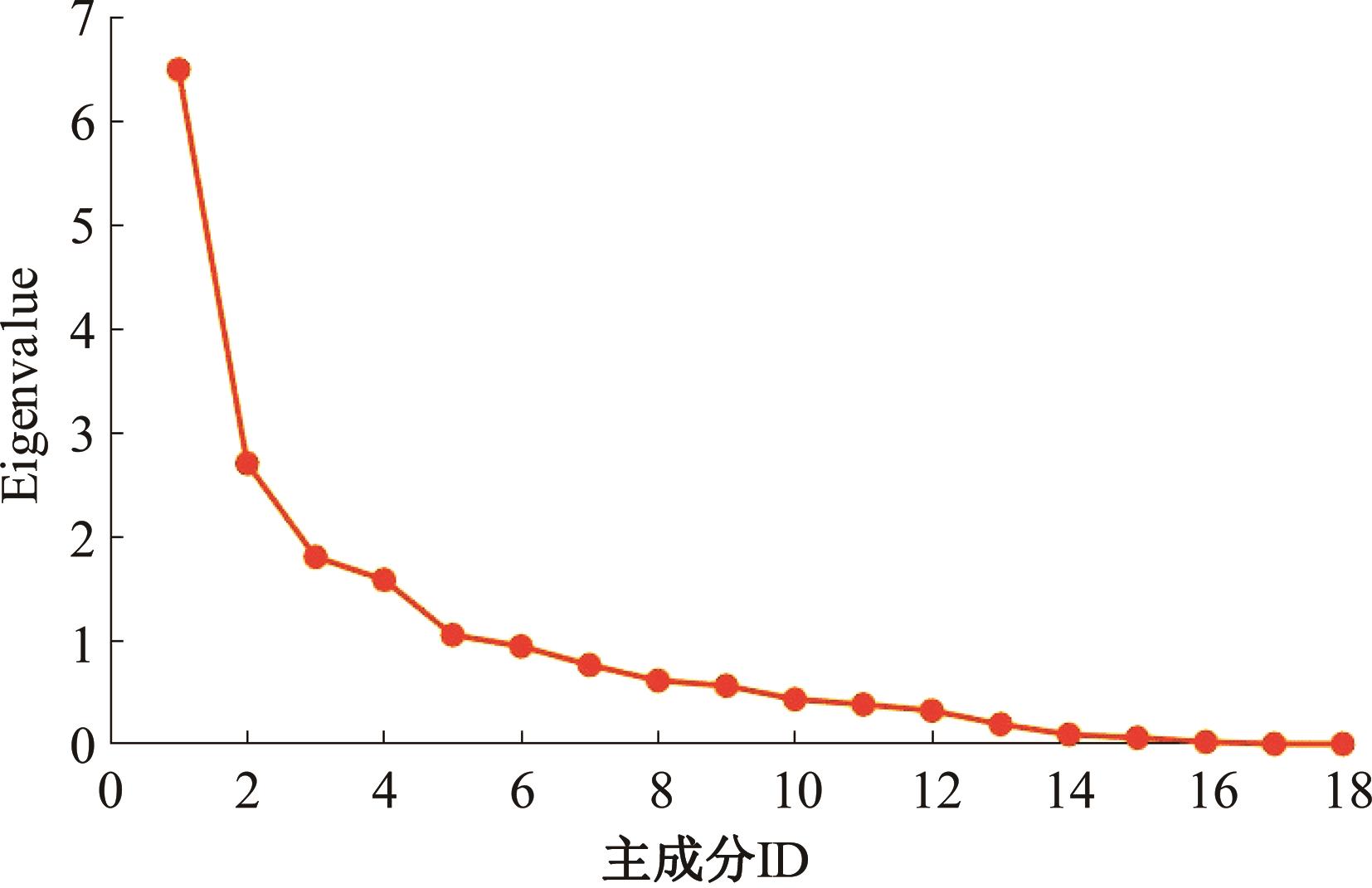

Drivability evaluation model based on PCA-SSA-XGBoost

Fei WU( ),Peng-cheng WANG,Kang YANG

),Peng-cheng WANG,Kang YANG

- School of Mechanical & Electrical Engineering,Wuhan University of Technology,Wuhan 430070,China

CLC Number:

- U461

| 1 | Zhou W, Guo X, Pei X, et al. Research on objective drivability evaluation with multi-source information fusion for passenger car[C]∥SAE Papers,2020-01-1044. |

| 2 | Koch Andreas, Brauer Jonas, Falkenstein Jens.Drivability optimization of electric vehicle drivetrains for brake blending maneuvers[J].World Electric Vehicle Journal,2022, 13(209): No.13110209. |

| 3 | Shin C W, Kim H, Kim M K, et al. Development of an evaluation method for quantitative driveability in heavy-duty vehicles[J].Journal of Mechanical Science and Technology,2014, 28(5): 1615-1621. |

| 4 | Chang Woo Shin, Choi Jongdae,Suk Won Cha, et al. An objective method of driveability evaluation using a simulation model for hybrid electric vehicles[J].International Journal of Precision Engineering and Manufacturing,2014, 15(2): 219-226. |

| 5 | 宋世欣,张元侠,刘科,等.双离合器自动变速器控制品质评价指标分析[J].汽车工程,2015,37(8): 925-930, 958 |

| Song Shi-xin, Zhang Yuan-xia, Liu Ke, et al. Analysis of control quality evaluation index of dual clutch automatic transmission[J]. Automobile Engineering,2015,37(8): 925-930, 958 | |

| 6 | Chandrasekaran K, Rao N, Palraj S,et al. Objective drivability evaluation on compact SUV and comparison with subjective drivability[C]∥SAE Paper, 2017-26-0153, 2017. |

| 7 | 黄伟,刘海江,童荣辉,等.车辆驾驶性评估方法在蠕行工况中的应用[J].哈尔滨工业大学学报,2018,50(7): 126-130. |

| Huang Wei, Liu Hai-jiang, Tong Rong-hui,et al. Application of vehicle driveability evaluation method in creep driving condition[J]. Journal of Harbin Institute of Technology, 2018,50(7): 126-130. | |

| 8 | 刘海江,徐新胜,李敏.双离合自动变速器车辆换挡品质模糊综合评价[J].哈尔滨工业大学学报,2020,52(7): 43-51. |

| Liu Hai-jiang, Xu Xin-sheng, Li Min. Fuzzy comprehensive evaluation of shifting quality of dual clutch Automatic transmission vehicles[J]. Journal of Harbin Institute of Technology,2022,52(7): 43-51. | |

| 9 | Huang Xin-cheng.A fuzzy evaluation method for the drivability of new energy vehicles based on similarity[J].Journal of Physics: Conference Series,2022, 2218(1): No.012066. |

| 10 | Schoeggl Peter, Ramschak Erich.Vehicle driveability assessment using neural networks for development, calibration and quality tests[J].SAE Transactions,2000,109: 1052-1061. |

| 11 | 张建国. 基于神经网络的AMT换档品质评价方法研究[D]. 长春:吉林大学汽车工程学院, 2007. |

| Zhang Jian-guo. Research on the evaluation method of AMT shift quality based on neural network[D]. Changchun: College of Automotive Engineering, Jilin University,2007. | |

| 12 | 孙贤安,吴光强.双离合器式自动变速器车辆换挡品质评价系统[J].机械工程学报,2011(8): 146-151. |

| Sun Xian-an, Wu Guang-qiang. Shift quality evaluation system of dual clutch automatic transmission vehicle[J]. Journal of Mechanical Engineering,2011(8): 146-151. | |

| 13 | 王叶,陶刚,李德晴,等.综合传动换挡品质的误差逆传播神经网络评价方法[J].兵工学报,2014(4): 495-500. |

| Wang Ye, Tao Gang, Li De-qing,et al. An error back propagation neural network evaluation method for shift quality of integrated transmission[J]. Armaments Engineering Journal,2014(4): 495-500. | |

| 14 | 孙坚.驾驶性评价及其仿真方法研究[D].长春: 吉林大学交通学院,2017. |

| Sun Jian. Research on drivability Evaluation and Simulation method[D]. Changchun: College of Transpotation, Jilin University,2017. | |

| 15 | Huang W, Liu H J, Ma Y F, et al.Drivability evaluation model using principal component analysis and optimized extreme learning machine[J]. Journal of Vibration & Control,2019,25(16): 2274-2281. |

| 16 | 刘海江,邢证.基于粗糙集理论的双离合器自动变速器车辆换挡品质评价指标约简[J].哈尔滨工业大学学报,2021,53(7): 164-170. |

| Liu Hai-jiang, Xing Zheng. Reduction of shift quality evaluation index of dual clutch automatic transmission vehicle based on rough set theory[J]. Journal of Harbin Institute of Technology,2021,53(7): 164-170. | |

| 17 | 莫易敏,胡恒,王骏,等.基于神经网络的车辆急加速工况驾驶性评价研究[J].汽车技术,2021,(4): 12-18. |

| Mo Yi-min, Hu Heng, Wang Jun, et al. Research on driving evaluation of vehicle under rapid acceleration condition based on neural network[J]. Automobile Technology,2021(4): 12-18. | |

| 18 | 刘洪波,雷雨龙,张建国,等.双离合器式自动变速器换档品质评价与优化[J].吉林大学学报:工学版,2012,42(6): 1360-1365. |

| Liu Hong-bo, Lei Yu-long, Zhang Jian-guo, et al. Evaluation and optimization of shift quality of dual clutch automatic transmission[J]. Journal of Jilin University(Engineering and Technology Edition), 2012,42(6): 1360-1365. | |

| 19 | 王鑫.基于主客观数据的整车驾驶性评价方法研究[D].重庆:重庆大学汽车工程学院,2019. |

| Wang Xin. Research on vehicle driveability evaluation method based on subjective and objective data[D]. Chongqing: College of Vehicle Engineering, Chongqing University,2019. | |

| 20 | 付尧.基于客观评价的双离合器自动变速器换挡控制技术研究[D].长春:吉林大学汽车工程学院,2015. |

| Fu Yao. Research on shifting control technology of dual clutch automatic transmission based on objective evaluation[D]. Changchun: College of Automotive Engineering,Jilin University,2015. | |

| 21 | Heusch C, Guse D, Dorscheidt F,et al.Analysis of drivability influence on tailpipe emissions in early stages of a vehicle development program by means of engine-in-the-loop test benches[C]//SAE Paper,2020-01-0373. |

| 22 | Tatas Lauritz,Maximilian Kurt Wick, Birmes Georg.Objectified drivability analysis and evaluation of deceleration maneuvers for electric vehicles[J].SAE International Journal of Engines,2021,14(3): 387-403. |

| 23 | 李岩,张久鹏,陈子璇,等.基于PCA-PSO-SVM的沥青路面使用性能评价[J].吉林大学学报:工学版,2023,53(6):1729-1735. |

| Li Yan, Zhang Jiu-peng, Chen Zi-xuan, et al. Performance evaluation of asphalt pavement based on PCA-PSO-SVM[J]. Journal of Jilin University(Engineering and Technology Edition),2023,53(6):1729-1735. | |

| 24 | 刘兴涛,刘晓剑,武骥,等.基于曲线压缩与XGBoost算法的锂离子电池SOH估计[J/OL].[2023-03-03].. |

| [1] | Shi-jun SONG,Min FAN. Design of big data anomaly detection model based on random forest algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2659-2665. |

| [2] | Yan LI,Jiu-peng ZHANG,Zi-xuan CHEN,Guo-jing HUANG,Pei WANG. Evaluation of asphalt pavement performance based on PCA⁃PSO⁃SVM [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1729-1735. |

| [3] | Yong-fei ZHANG,Tao CHEN. Design of communication data classification algorithm based on fuzzy segmentation of time series [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(11): 3268-3273. |

| [4] | Lin JIANG,Li YANG,Wen-jun ZHANG,Qiong-yu ZHANG,Yan-xia WU. Detection and processing algorithm of slope point cloud in obstacle detection [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(11): 3221-3228. |

| [5] | Qiang GUO,Ming-song LI,Kai ZHOU. Multi⁃mode radar signal sorting based on potential distance graph and improved cloud model [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1904-1911. |

| [6] | Xing-tao LIU,Xiao-jian LIU,Ji WU,Yao HE,Xin-tian LIU. State of health estimation method for lithium⁃ion battery based on curve compression and extreme gradient boosting [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1273-1280. |

| [7] | Zhen CAO,Lu-yao CUI,Bin LEI,Jing-yi WANG,Shuang-sheng CAO. Feature dimensionality reduction and random forest method in intelligent diagnosis of rolling bearings for urban rail trains [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2287-2293. |

| [8] | Hong-xue LI,Shi-wu LI,Wen-cai SUN,Wei LI,Meng-zhu GUO. Driving cycle construction of heavy semi⁃trailers carrying hazardous cargos [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1700-1707. |

| [9] | Li-qun WU,Liang-liang ZHANG. Health detection of bridge structures based on data mining technology [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 565-571. |

| [10] | Ting YAN,Lin YANG,Liang CHEN. AMT shift actuator adaptive intelligent control strategy [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1441-1450. |

| [11] | LIU Zhe, XU Tao, SONG Yu-qing, XU Chun-yan. Image fusion technology based on NSCT and robust principal component analysis model with similar information [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1614-1620. |

| [12] | ZHANG Man, SHI Shu-ming. Analysis of state transition characteristics for typical vehicle driving cycles [J]. 吉林大学学报(工学版), 2018, 48(4): 1008-1015. |

| [13] | GENG Qing-tian, YU Fan-hua, WANG Yu-ting, GAO Qi-kun. New algorithm for vehicle type detection based on feature fusion [J]. 吉林大学学报(工学版), 2018, 48(3): 929-935. |

| [14] | SU Chang, FU Li-ming, WEI Jun, LI Shuo, HUANG Lei, CAO Yue. Design method in exterior color based Kansei engineering and principal component analysis [J]. 吉林大学学报(工学版), 2016, 46(5): 1414-1419. |

| [15] | MA Shuang, ZHOU Chang-jiu, ZHANG Lian-dong, HONG Wei, TIAN Yan-tao. Twist-lock online recognition based on improved incremental PCA by Kinect [J]. 吉林大学学报(工学版), 2016, 46(3): 890-896. |

|

||