Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (9): 2892-2901.doi: 10.13229/j.cnki.jdxbgxb.20250446

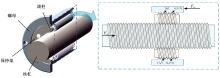

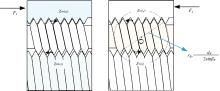

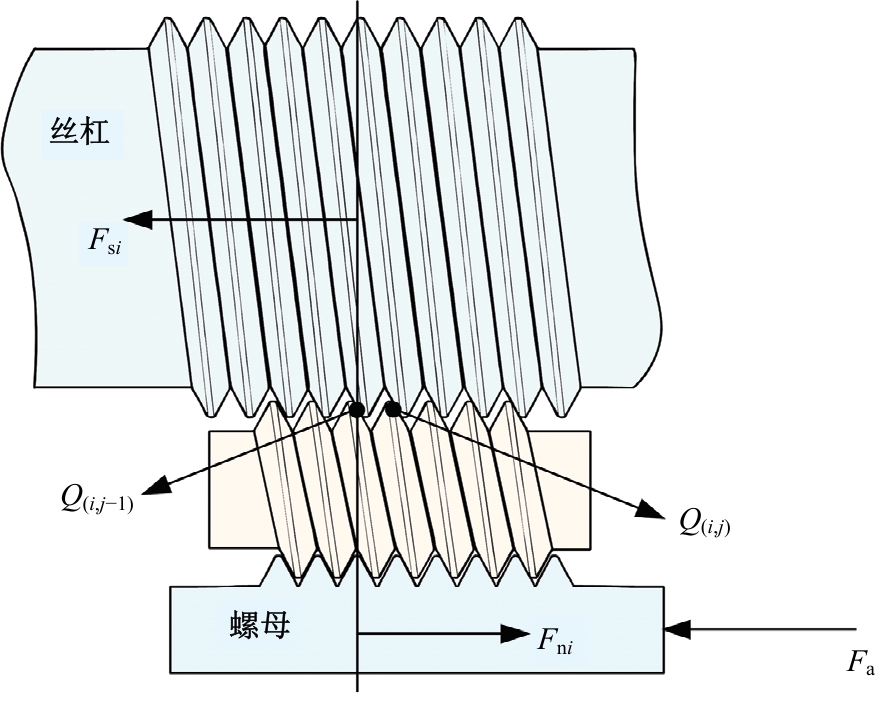

Mechanism analysis and experimental of rolling⁃sliding motion in planetary roller screw

Zhi-feng LIU1,2( ),Wei-ning LI1,Bao-bao QI1,2,3(

),Wei-ning LI1,Bao-bao QI1,2,3( ),Chuan-hai CHEN1,2,3,Wei SHI4,Zhao-jing ZHANG4,Xiao-qing TAN5,Chang-jun WU6

),Chuan-hai CHEN1,2,3,Wei SHI4,Zhao-jing ZHANG4,Xiao-qing TAN5,Chang-jun WU6

- 1.Key Laboratory of CNC Equipment Reliability,Ministry of Education,Jilin University,Changchun 130022,China

2.Jilin Key Laboratory of Advanced Manufacturing and Intelligent Technology for High-end CNC Equipment,Changchun 130022,China

3.Chongqing Research Institute,Jilin University,Chongqing 401120,China

4.Beijing Research Institute of Precise Electro Mechanicals and Controls,Beijing 100076,China

5.Shaanxi Hanjiang Machine Tool Co. ,Hanzhong 723003,China

6.College of Mechanical and Electrical Engineering,Zhengzhou University of Light Industry,Zhengzhou 450002,China

CLC Number:

- TH132.1

| [1] | 吴林萍, 马尚君, 许千斤, 等. 考虑弹性变形的行星滚柱丝杠接触特性[J]. 机械工程学报,2024, 60(5): 130-141. |

| Wu Lin-ping, Ma Shang-jun, Xu Qian-jin, et al. Contact characteristics of planetary roller screw mechanism considering elastic deformation[J]. Journal of Mechanical Engineering, 2024, 60(5): 130-141. | |

| [2] | 王明昊, 汪满新. 一种新型五自由度混联机器人动力学建模与性能评价[J]. 机械工程学报, 2023, 59(9): 63-75. |

| Wang Ming-hao, Wang Man-xin. Dynamic modeling and performance evaluation of a new Five-DOF hybrid robot[J]. Journal of Mechanical Engineering, 2023, 59(9): 63-75. | |

| [3] | 聂建军, 侯军凯, 解晓琳, 等. 新型巡检机器人移动底盘设计及越障性能分析[J]. 吉林大学学报: 工学版,2024, 54(2): 356-364. |

| Nie Jian-jun, Hou Jun-kai, Xie Xiao-lin, et al. Design and obstacle surmounting performance analysis of a novel mobile chassis for inspection robot[J]. Journal of Jilin University (Engineering and Technology Edition), 2024, 54(2): 356-364. | |

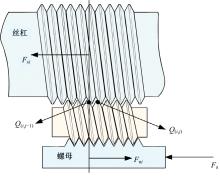

| [4] | 乔冠, 刘更, 马尚君. 行星滚柱丝杠副主曲率计算与接触特性分析[J]. 机械工程学报, 2020, 56(21): 140-148. |

| Qiao Guan, Liu Geng, Ma Shang-jun. Principal curvature calculation and contact characteristics analysis of the planetary roller screw mechanism[J]. Journal of Mechanical Engineering, 2020, 56(21): 140-148. | |

| [5] | 付晓军, 刘更, 马尚君, 等. 行星滚柱丝杠副螺旋曲面啮合机理研究[J]. 机械工程学报,2016, 52(3): 26-33. |

| Fu Xiao-jun, Liu Geng, Ma Shang-jun, et al. Studies on meshing mechanism of helical surfaces in planetary roller screw mechanism[J]. Journal of Mechanical Engineering, 2016, 52(3): 26-33. | |

| [6] | 佟瑞庭, 刘更, 史佑民, 等. 螺纹牙型角对行星滚柱丝杠副接触特性影响研究[J]. 机械设计, 2016, 33(5): 31-34. |

| Tong Rui-ting, Liu Geng, Shi You-min, et al. Studies on the effect of the thread vertex on the contact characteristics of planetary roller screw mechanism[J]. Journal of Machine Design, 2016, 33(5): 31-34. | |

| [7] | 刘阔, 宋磊, 陈虎, 等. 机理驱动的数控机床进给轴时变误差建模和补偿方法[J]. 机械工程学报,2022, 58(3): 251-258. |

| Liu Kuo, Song Lei, Chen Hu. Mechanism-driven method for time-varying error modeling and compensation of cnc machine tool´s feed axes[J]. Journal of Mechanical Engineering, 2022, 58(3): 251-258. | |

| [8] | 马尚君, 刘更, 付晓军, 等. 考虑误差的行星滚柱丝杠副滚柱承载分布[J]. 哈尔滨工业大学学报, 2015, 47(7): 98-102. |

| Ma Shang-jun, Liu Geng, Fu Xiao-jun, et al. Load distribution of rollers considering errors in planetary roller screw mechanism[J]. Journal of Harbin Institute of Technology, 2015, 47(7): 98-102. | |

| [9] | 张文杰, 刘更, 马尚君, 等. 不同安装方式下行星滚柱丝杠副载荷分布研究[J]. 西北工业大学学报,2015, 33(2): 229-236. |

| Zhang Wen-jie, Liu Geng, Ma Shang-jun, et al. Load distribution of planetary roller screw mechanism with different installations[J]. Journal of Northwestern Polytechnical University, 2015, 33(2): 229-236. | |

| [10] | 付晓军, 徐烨, 刘更, 等. 考虑滚柱偏斜的行星滚柱丝杠载荷分布计算方法[J]. 机械工程学报, 2024, 60(13): 247-256. |

| Fu Xiao-jun, Xu Ye, Liu Geng, et al. The calculation method for the load distribution in the planetary roller screw mechanism with the roller deviation[J]. Journal of Mechanical Engineering, 2024, 60(13): 247-256. | |

| [11] | 郭辉, 佟瑞庭, 刘更, 等. 面向行星滚柱丝杠副载荷均布的螺纹牙修形方法[J]. 西北工业大学学报,2018, 36(4): 685-692. |

| Guo Hui, Tong Rui-ting, Liu Geng, et al. Thread modification method for load balance on planetary roller screw mechanism[J]. Journal of Northwestern Polytechnical University, 2018, 36(4): 685-692. | |

| [12] | Abevi F, Daidie A, Chaussumier M, et al. Static load distribution and axial stiffness in a planetary roller screw mechanism[J]. Journal of Mechanical Design, 2016, 138(1):No. 012301. |

| [13] | Abevi F, Daidie A, Chaussumier M, et al. Static analysis of an inverted planetary roller screw mechanism[J].The Journal of Mechanisms and Robotics, 2016, 8(4): No.041020. |

| [14] | Jones M, Velinsky S. Stiffness of the roller screw mechanism by the direct method[J]. Mechanics Based Design of Structures and Machines, 2014, 42(1): 17-34. |

| [15] | Hojjat Y, Agheli M. A comprehensive study on capabilities and limitations of roller-screw with emphasis on slip tendency[J]. Mechanism and Machine Theory, 2009, 44(10): 1887-1899. |

| [16] | Velinsky S, Chu B, Lasky T. Kinematics and efficiency analysis of the planetary roller screw mechanism[J]. Journal of Mechanical Design, 2009, 131(1):No. 011016. |

| [17] | Sandu S, Biboulet N, Nelias D, et al. An efficient method for analyzing the roller screw thread geometry[J]. Mechanism and Machine Theory, 2018, 126: 243-264. |

| [18] | Sandu S, Biboulet N, Nelias D, et al. Analytical prediction of the geometry of contact ellipses and kinematics in a roller screw versus experimental results[J]. Mechanism and Machine Theory, 2019, 131: 115-136. |

| [19] | 马尚君, 刘更, 付晓军, 等. 考虑弹性变形的行星滚柱丝杠副滚滑特性[J]. 东南大学学报: 自然科学版, 2015, 45(3): 461-468. |

| Ma Shang-jun, Liu Geng, Fu Xiao-jun, et al. Rolling-sliding characteristics of planetary roller screw considering elastic deformation[J]. Journal of Southeast University (Natural Science Edition), 2015, 45(3): 461-468. | |

| [20] | Fu X, Liu G, Ma S, et al. A comprehensive contact analysis of planetary roller screw mechanism[J]. Journal of Mechanical Design, 2017, 139(1): No.012302. |

| [1] | Xue-zhong FU,Hou-bing HE,Xu-dong LIU,Jing-zhen LI. Tooth width design of helical face gear with non-orthogonal offset modification integration [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(4): 1207-1214. |

| [2] | Shu-kun WANG,Yu-ze FENG,Jing-ran ZHANG,Xin-ming ZHANG,Long ZHENG. Analysis on decontamination performance of lower lip structure of imitation scavenger [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 392-400. |

| [3] | Yang LIU. Simulation and experiment of elastic roughing for rubber shoe [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2167-2173. |

| [4] | Chen WANG,Te LUO,Qian-qian HUI,Zhong-hao WANG,Fang-fang WANG. Design and verification of electromechanical system for docking and locking of modular flying vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2130-2140. |

| [5] | Yang LIU,Tao JIANG. Interference calculation model of Hooke joint of 6-DOF platform considering installation angle [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1519-1527. |

| [6] | Xiao-dan TAN,Yong-peng WANG,Robert Hall,Tian-shuang XU,Qing-xue HUANG. Haul truck dump body optimization for autonomous shovel loading [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1227-1236. |

| [7] | Bin HU,Yi-quan CAI,Xin LUO,Zi-bin MAO,Jun-wei LI,Meng-yu GUO,Jian WANG. Theory and experiment of high⁃speed seed filling in limited gear⁃shaped side space based on seeds group stress [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 574-588. |

| [8] | Wei SUN,Jun YANG. Finite element modeling and vibration reduction analysis of cylindrical shell structures with equal⁃angle attachment of piezoelectric shunt patches [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 365-374. |

| [9] | Yang LIU. Calculation method of anti-backward-tilting buffer force of luffing jib tower crane [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(10): 2785-2794. |

| [10] | Yang ZHAO,Yang XIAO,Hao SUN,Wen-hao HUO,Song FENG,Yong LIAO. Numerical simulation of micro pitting damage characteristics of lubricated contact gears based on contour integral [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 799-810. |

| [11] | Wei ZHENG,Jian-jun SUN,Chen-bo MA,Qiu-ping YU,Yu-yan ZHANG,Tao NIU. Research status and prospect of automobile wheel hub machining fixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 25-36. |

| [12] | Wei CHEN,Yu-long LEI,Xing-zhong LI,Yao FU,Jian-long HU,Li-guo HOU. Calculation of adhesive wear of involute cylindrical spur gear under low⁃speed conditions [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1628-1634. |

| [13] | Zhen GUO,Hong-ying YU,Zhong-xin HUA,Di ZHAO. Kinematic analysis and simulation of folding process for rigid origami mechanisms [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 66-76. |

| [14] | ZHU Wei,WANG Chuan-wei,GU Kai-rong,SHEN Hui-ping,XU Ke,WANG Yuan. Stiffness and dynamics analysis of a new type of tensegrity parallel mechanism [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1777-1786. |

|

||