Journal of Jilin University(Engineering and Technology Edition) ›› 2018, Vol. 48 ›› Issue (6): 1799-1805.doi: 10.13229/j.cnki.jdxbgxb20170619

Previous Articles Next Articles

Hot deformation behavior of 9%Cr steel contained B and Co elements

GUAN Qing-feng1( ),ZHANG Fu-tao1,PENG Tao1,LYU Peng1(

),ZHANG Fu-tao1,PENG Tao1,LYU Peng1( ),LI Yao-jun2,XU Liang2,DING Zuo-jun2

),LI Yao-jun2,XU Liang2,DING Zuo-jun2

- 1. Materials Science and Engineering,Jiangsu University, Zhenjiang 212013,China

2. Wuxi Parker New Materials Technology Co., Ltd.,Wuxi 214161,China

CLC Number:

- TG144

| [1] |

朱怀沈, 聂义宏, 白亚冠 , 等. 700 ℃先进超超临界汽轮机转子用617合金锻造工艺研究[J]. 锻压技术, 2016,41(9):7-12.

doi: 10.13330/j.issn.1000-3940.2016.09.002 |

|

Zhu Huai-shen, Nie Yi-hong, Bai Ya-guan , et al. Investigation on the hot forging process of alloy 617 A-USC steam turbine rotors at 700 ℃[J]. Forging & Stamping Technology, 2016,41(9):7-12.

doi: 10.13330/j.issn.1000-3940.2016.09.002 |

|

| [2] |

Aghajani A, Somsen C, Eggeler G . On the effect of long-term creep on the microstructure of a 12% chromium tempered martensite ferritic steel[J]. Acta Materialia, 2009,57(17):5093-5106.

doi: 10.1016/j.actamat.2009.07.010 |

| [3] |

Panait C G, Bendick W, Fuchsmann A , et al. Study of the microstructureof the grade 91 steel after more than 100 000 h of creep exposure at 600 ℃[J]. International Journal of Pressure Vessels and Piping, 2010,87(6):326-335.

doi: 10.1016/j.ijpvp.2010.03.017 |

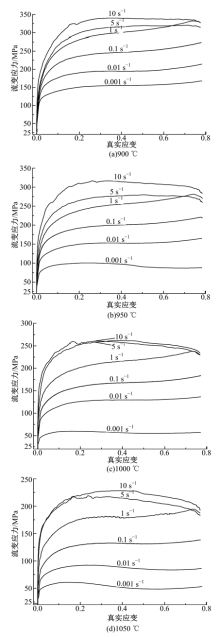

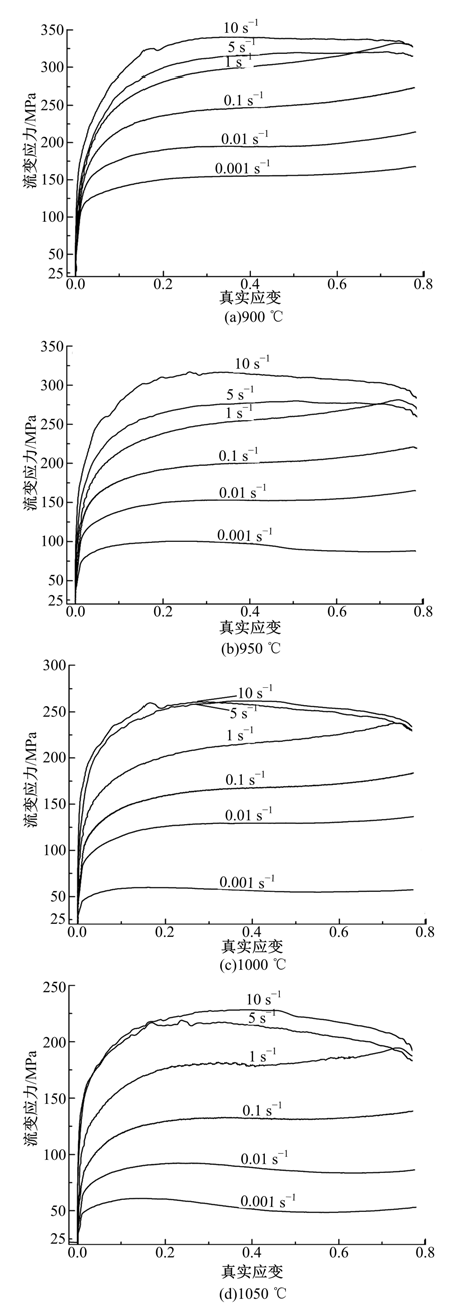

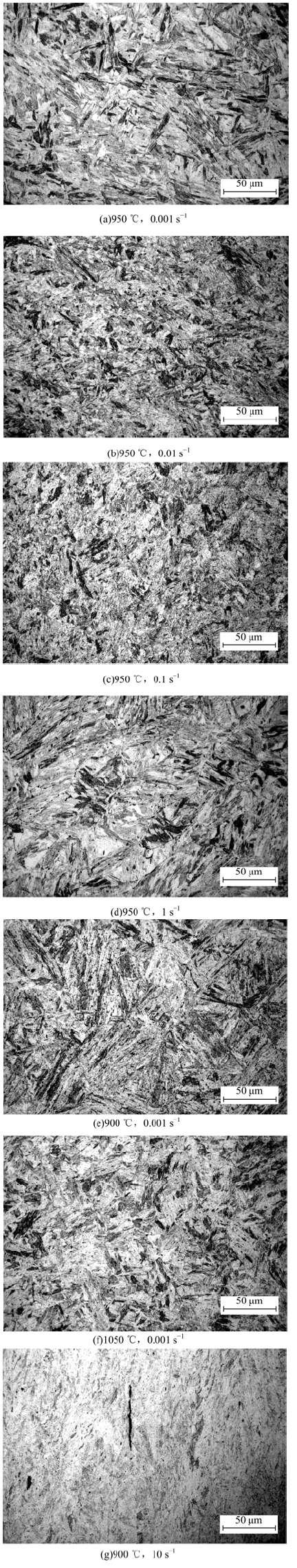

| [4] | 孙述利, 张敏刚, 何文武 , 等. 9%Cr耐热钢的高温热变形机制及组织演变[J]. 材料工程, 2010,12:19-23. |

| Sun Shu-li, Zhang Min-gang, He Wen-wu , et al. Hot deformation mechanism and microstructure evolution of 9%Cr heat resistant steel[J]. Materials Engineering, 2010,12:19-23. | |

| [5] |

曹金荣, 刘正东, 程世长 , 等. T122耐热钢热变形加工图及热成形性[J]. 北京科技大学学报, 2007,29(12):1204-1208.

doi: 10.3321/j.issn:1001-053x.2007.12.007 |

|

Cao Jin-rong, Liu Zheng-dong, Cheng Shi-chang , et al. Processing maps and hot formability of T122 heat resistant steel[J]. Journal of University of Science and Technology Beijing, 2007,29(12):1204-1208.

doi: 10.3321/j.issn:1001-053x.2007.12.007 |

|

| [6] |

Wang Bao-zhong, Fu Wan-tang, Lv Zhi-qing , et al. Study on hot deformation behavior of 12%Cr ultra super critical rotor steel[J]. Materials Science and Engineering:A, 2008,487(1/2):108-113.

doi: 10.1016/j.msea.2007.10.007 |

| [7] |

张萌, 轩福贞 . 汽轮机转子钢蠕变损伤的非线性超声评价[J]. 机械工程学报, 2016,52(2):76-81.

doi: 10.3901/JME.2016.02.076 |

|

Zhang Meng, Xuan Fu-zhen . Creep damage evaluation of steam turbine rotor steel by using the nonlinear ultrasonic technique[J]. Journal of Mechanical Engineering, 2016,52(2):76-81.

doi: 10.3901/JME.2016.02.076 |

|

| [8] |

王欣, 张喜英, 欧阳建国 , 等. FB2转子钢在长期热时效中的组织变化[J]. 一重技术, 2016(1):68-73.

doi: 10.3969/j.issn.1673-3355.2016.01.015 |

|

Wang Xin, Zhang Xi-ying, Ouyang Jian-guo , et al. Evolution of microstructure during long-term aging of FB2 steel used for turbine rotors[J]. CFHI Technology, 2016(1):68-73.

doi: 10.3969/j.issn.1673-3355.2016.01.015 |

|

| [9] |

刘越, 马煜林, 郭浩 , 等. Co、B对新型铁素体耐热钢组织和性能的影响[J]. 材料导报, 2015,29(7):18-23.

doi: 10.11896/j.issn.1005-023X.2015.013.003 |

|

Liu Yue, Ma Yu-lin, Guo Hao , et al. Effects of Co and B on microstructure and properties of modified ferritic heat-resistant steel[J]. Materials Herald, 2015,29(7):18-23.

doi: 10.11896/j.issn.1005-023X.2015.013.003 |

|

| [10] | 尹益辉, 陈裕泽, 彭向和 . 金属力学性能的温升率效应研究概述[J]. 强激光与粒子束, 2006,18(12):1964-1968. |

| Yin Yi-hui, Chen Yu-ze, Peng Xiang-he . Brief overview of effects of temperature rising rate on mechanical properties of metals[J]. High Power Laser and Particle Beam, 2006,18(12):1964-1968. | |

| [11] | Krauss G . Deformation Processing and Structure[M]. Ohio,USA:American Societ for Metal, 1984: 109-230. |

| [12] |

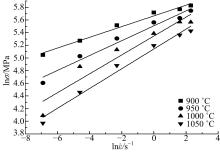

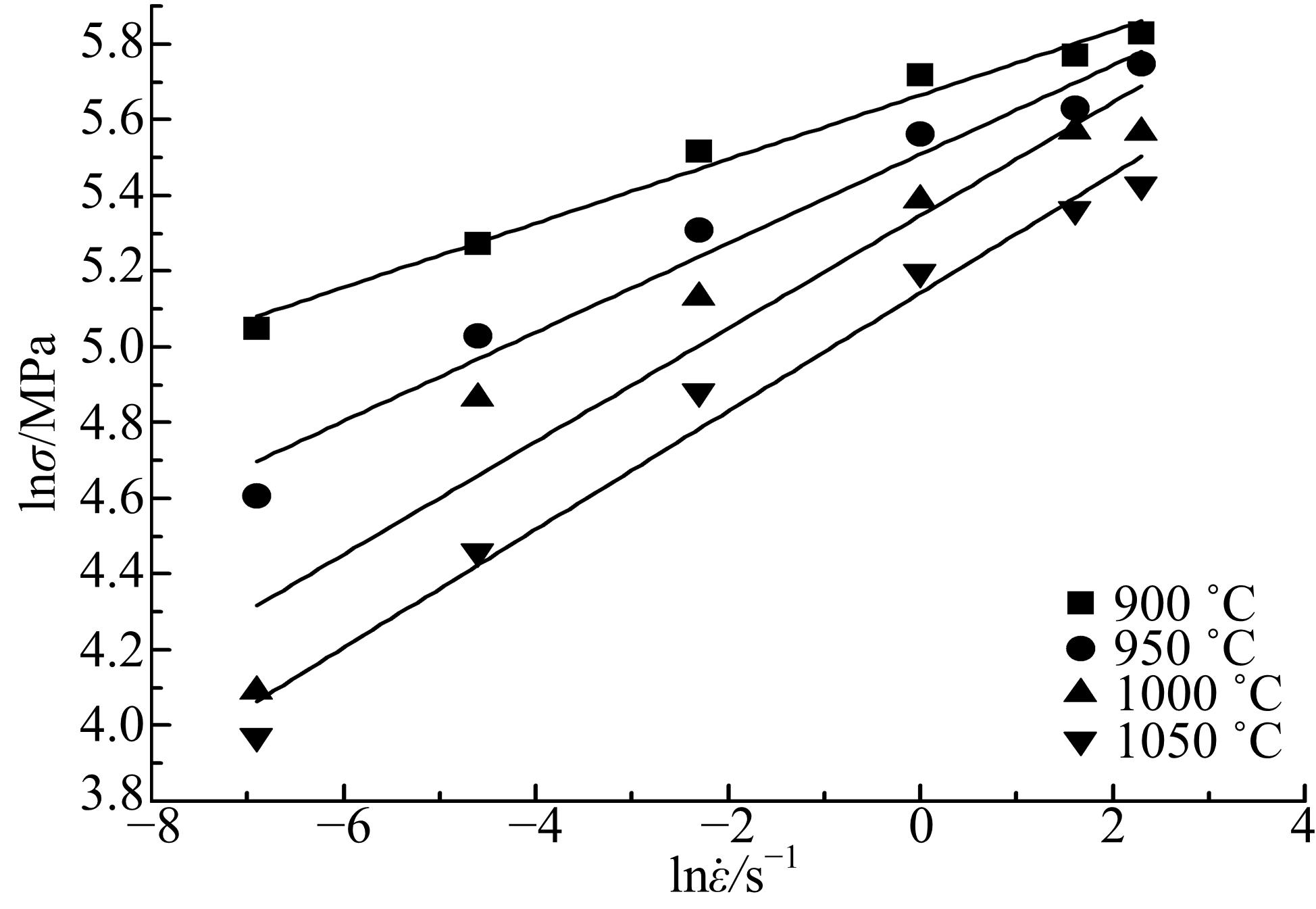

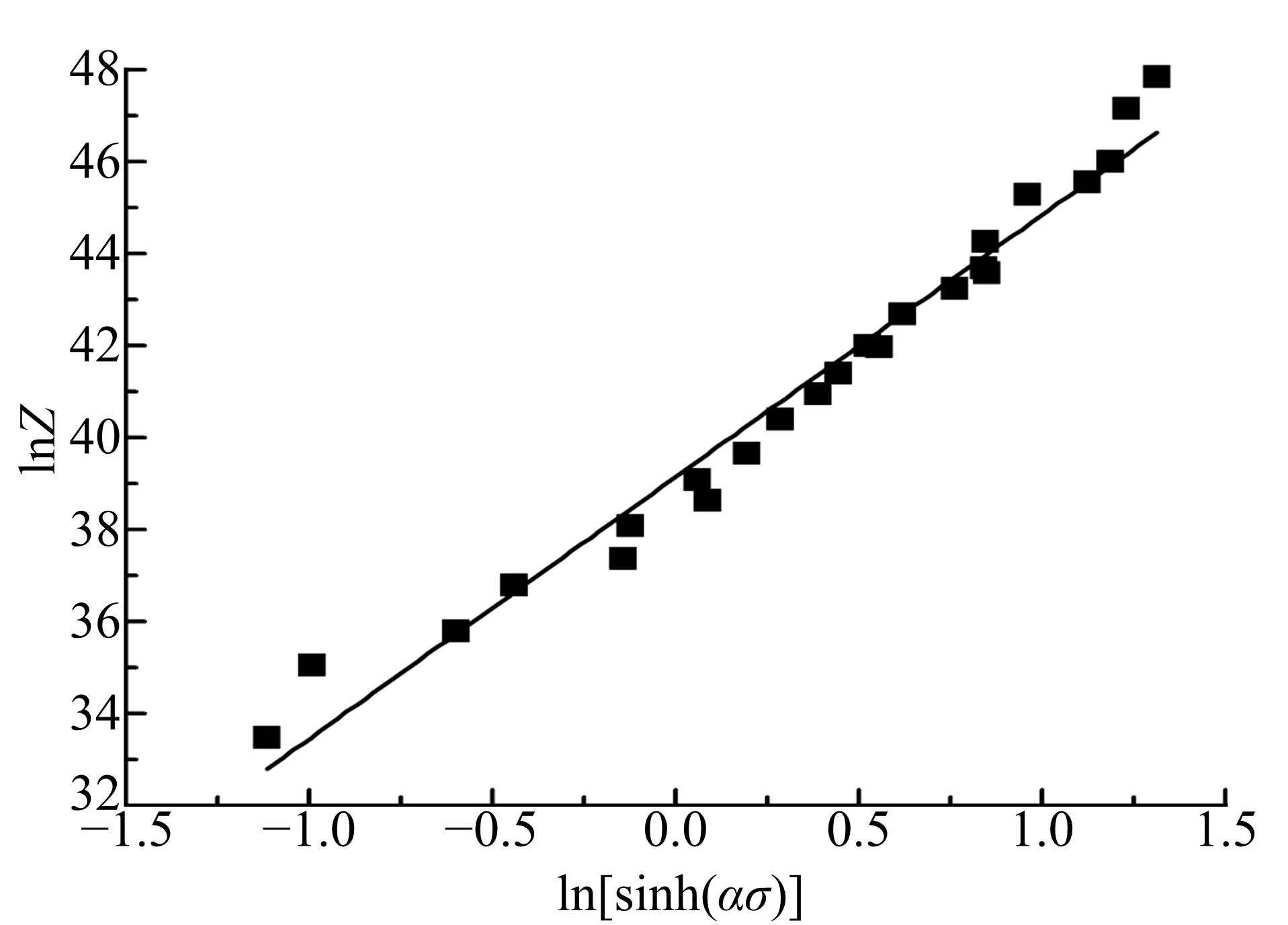

Zener C, Hollomon J H . Effect of strain-rate upon the plastic flow of steel[J]. Journal of Applied Physics, 1944,15(1):22-32.

doi: 10.1063/1.1707363 |

| [13] |

Sellars C M, Mctegart W J . On the mechanism of hot deformation[J]. Acta Metall, 1966,14:1136-1138.

doi: 10.1016/0001-6160(66)90207-0 |

| [14] |

Bruni C, Forcellese A, Gabrielli F . Hot workability and models for flow stress of NIMONIC 115 Ni-base superalloy[J]. Journal of Materials Processing Technology, 2002,125:242-247.

doi: 10.1016/S0924-0136(02)00302-3 |

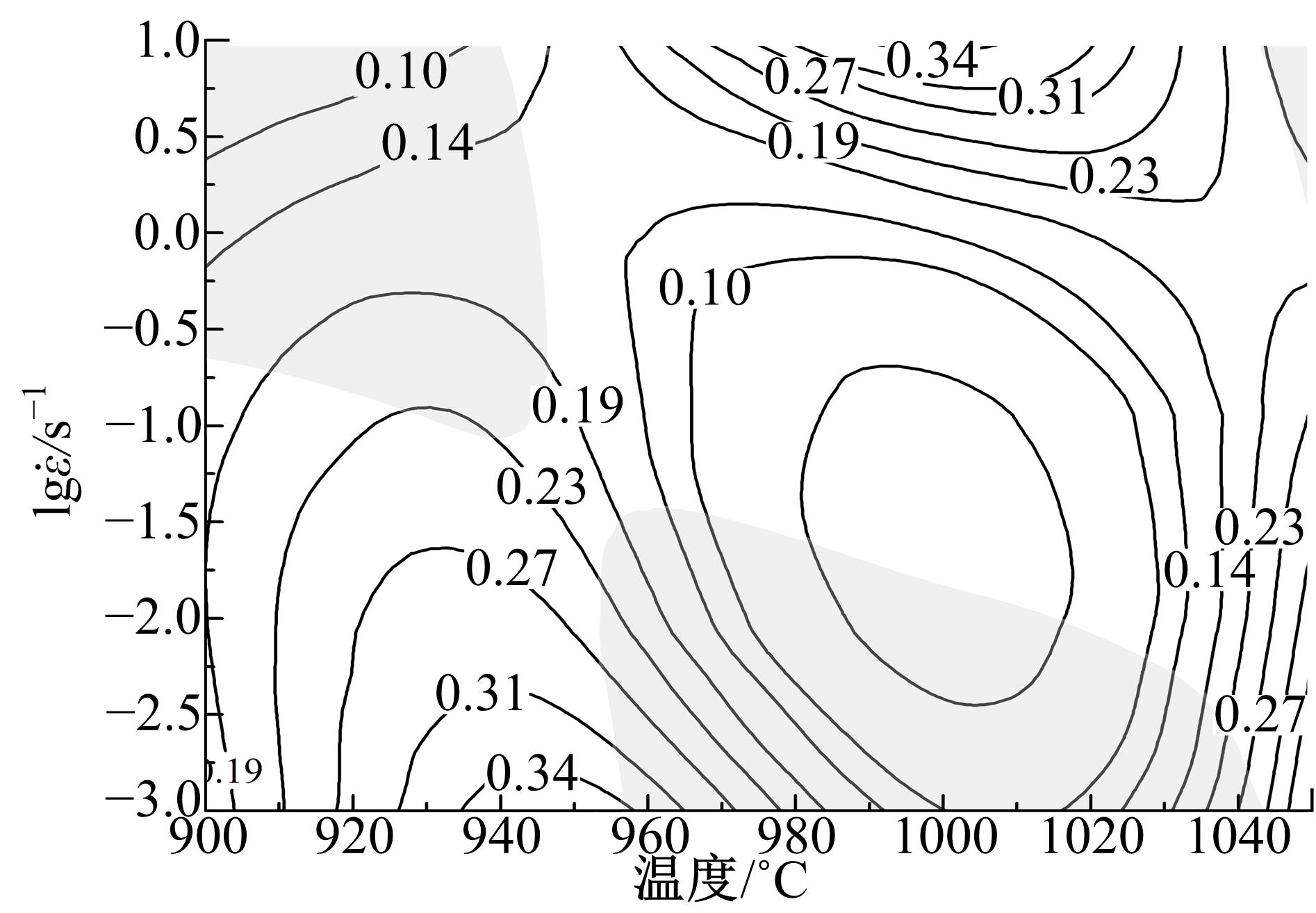

| [15] | 曾卫东, 周义刚, 周军 , 等. 加工图理论研究进展[J]. 稀有金属材料与工程, 2006,35(5):673-677. |

| Zeng Wei-dong, Zhou Yi-gang, Zhou Jun , et al. Recent development of processing map theory[J]. Rare Metal Materials and Engineering, 2006,35(5):673-677. | |

| [16] |

秦芳诚, 李永堂 . 铸辗复合成形法兰坯高温变形行为及加工图[J]. 机械工程学报, 2016,52(4):45-53.

doi: 10.3901/JME.2016.04.045 |

|

Qin Fang-cheng, Li Yong-tang . Deformation behavior at elevated temperature and processing maps of flange blanks on casting-rolling compound forming technology[J]. Journal of Mechanical Engineering, 2016,52(4):45-53.

doi: 10.3901/JME.2016.04.045 |

|

| [17] |

Murty S V S N, Rao B N . On the development of instability criteria during hot working with reference to IN 718[J]. Materials Science and Engineering:A, 1998,254(1/2):76-82.

doi: 10.1016/S0921-5093(98)00764-3 |

| [1] | Yu⁃peng LI,Da⁃qian SUN,Wen⁃biao GONG. Temperature fields in bobbin⁃tool friction stir welding for 6082⁃T6 aluminum alloy sheet [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 836-841. |

| [2] | GUAN Qing-feng, DONG Shu-heng, ZHENG Huan-huan, LI Chen, ZHANG Cong-lin, LV-Peng. Cr surface alloying of 45# steel by high-current pulsed electron beam treatment [J]. 吉林大学学报(工学版), 2018, 48(4): 1161-1168. |

| [3] | ZHAO Yu-guang, YANG Xue-hui, XU Xiao-feng, ZHANG Yang-yang, NING Yu-heng. Effects of Al-10Sr modifiers with different states, modification temperature and holding time on microstructure of ZL114A alloy [J]. 吉林大学学报(工学版), 2018, 48(1): 212-220. |

| [4] | TANG Hua-guo, MA Xian-feng, ZHAO Wei, LIU Jian-wei, ZHAO Zhen-ye. Synthesis microstructure and thermal properties of high performance bulk Al [J]. 吉林大学学报(工学版), 2017, 47(5): 1542-1547. |

| [5] | GUAN Qing-feng, ZHANG Yuan-wang, SUN Xiao, ZHANG Chao-ren, LYU Peng, ZHANG Cong-lin. Surface alloying of Al-W alloy by high current pulsed electron beam treatment [J]. 吉林大学学报(工学版), 2017, 47(4): 1171-1178. |

| [6] | YANG Xiao-hong, HANG Wen-xian, QIN Shao-gang, LIU Yong-bing, LIU Li-ping. Microstructure and wear properties of Co-based composite coatings on H13 steel surface by laser cladding [J]. 吉林大学学报(工学版), 2017, 47(3): 891-899. |

| [7] | GUAN Qing-feng, HUANG Wei, LI Huai-fu, GONG Xiao-hua, ZHANG Cong-lin, LYU Peng. Diffusion alloying of Cu-C induced by high current pulsed electron beam [J]. 吉林大学学报(工学版), 2016, 46(6): 1967-1973. |

| [8] | ZHANG Xue-guang, LIU Chun-guo, ZHENG Yuan, JIANG Zhong-hai, LI Xiang-ji. Forming limit prediction of aluminum alloy based on ductile damage and shear damage [J]. 吉林大学学报(工学版), 2016, 46(5): 1558-1566. |

| [9] | LIU Xiao-bo, ZHOU De-kun, ZHAO Yu-guang. Microstructure and mechanical property of Mg2Si/Al composites fabricated by semi-solid extrusion under different isothermal heat treatments [J]. 吉林大学学报(工学版), 2016, 46(5): 1577-1582. |

| [10] | LIU Li-ping, LIU Yong-bing, JI Lian-feng, CAO Zhan-yi, YANG Xiao-hong. Flow stress behavior of in situ particulate reinforced titanium atrix composite at elevated temperature [J]. 吉林大学学报(工学版), 2016, 46(4): 1197-1201. |

| [11] | LI Chun-ling, FAN Ding, WANG Bin, YU Shu-rong. 5A06 aluminum alloy and galvanized steel butt welding-brazing by laser with preset filler powder [J]. 吉林大学学报(工学版), 2016, 46(2): 516-521. |

| [12] | ZHANG Jia-tao, ZHAO Yu-guang, TAN Juan. Effect of starting microstructure on refining potency of electro-pulsing on reverse austenite grain [J]. 吉林大学学报(工学版), 2016, 46(1): 193-198. |

| [13] | GUAN Qing-feng, LI Yan, HOU Xiu-li, YANG Sheng-zhi, WANG Xiao-tong. Modification of solid solution Mg-Gd-Y-Nd alloy irradiated by high current pulsed electron beam [J]. 吉林大学学报(工学版), 2015, 45(4): 1200-1205. |

| [14] | MA Yun-hai, SHANG Wen-bo, FAN Xue-ying, GAO Zhi-hui, TONG Jin, YAN Zhi-feng, CHANG Zhi-yong. Preparation and degradation of porous β-tricalcium phosphate bioceramic for bone imitaion [J]. 吉林大学学报(工学版), 2015, 45(4): 1367-1374. |

| [15] | DUAN Xing-wang,LIU Jian-sheng. Plasticity at elevated temperature and fracture character of 316LN steel [J]. 吉林大学学报(工学版), 2015, 45(2): 494-500. |

|