Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (3): 836-841.doi: 10.13229/j.cnki.jdxbgxb20180202

Previous Articles Next Articles

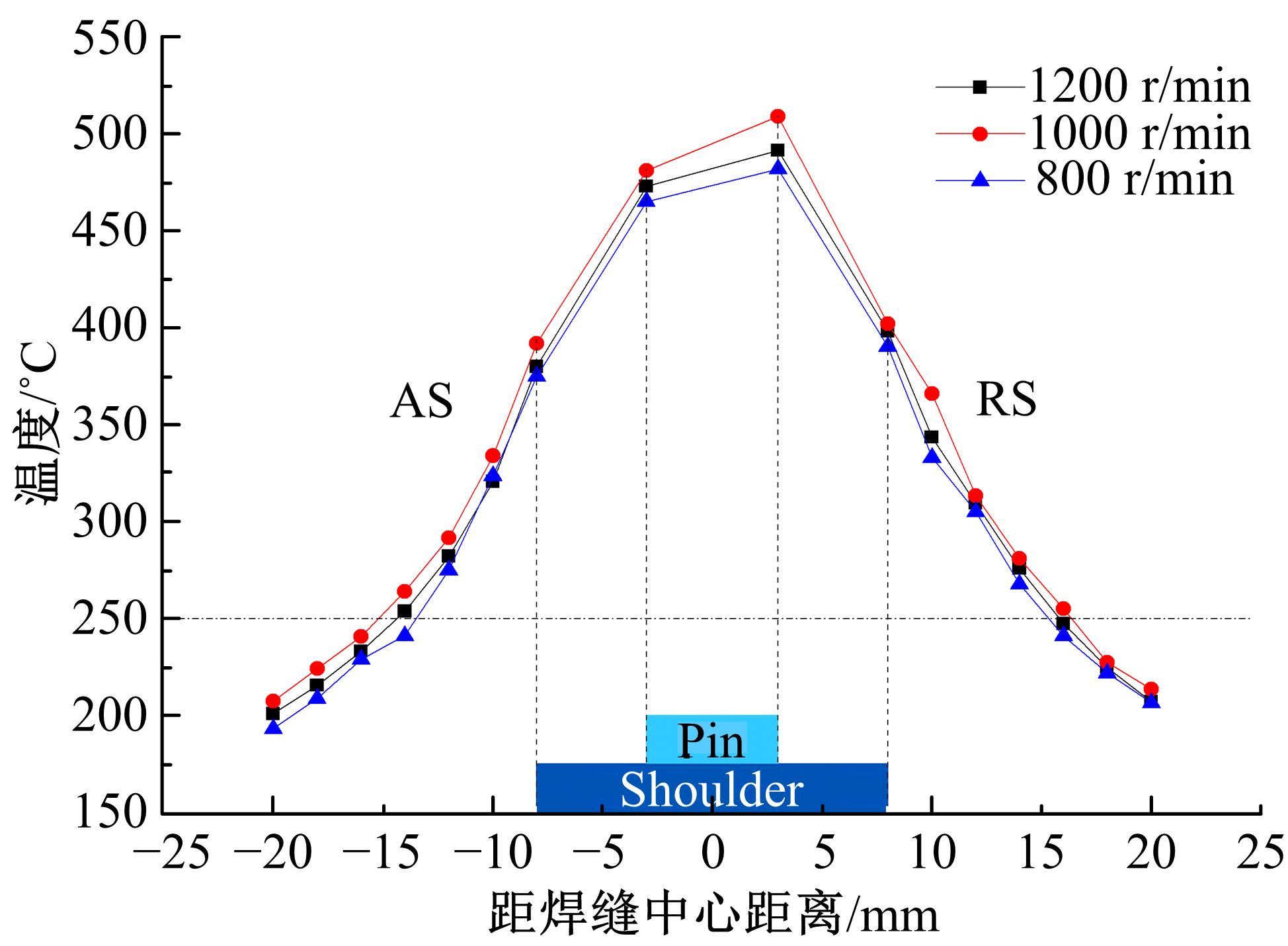

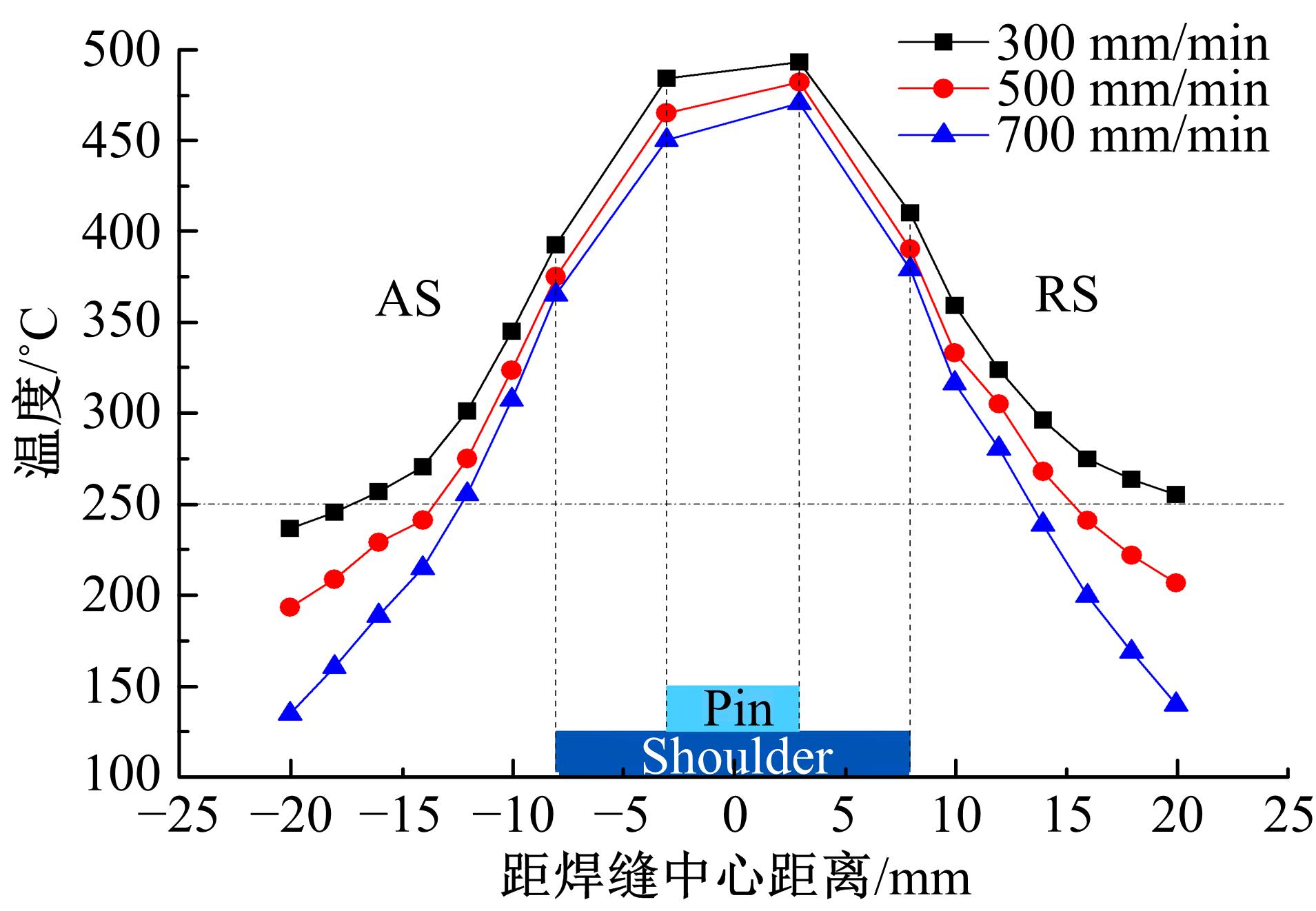

Temperature fields in bobbin⁃tool friction stir welding for 6082⁃T6 aluminum alloy sheet

Yu⁃peng LI1,2,3( ),Da⁃qian SUN1,2,Wen⁃biao GONG3

),Da⁃qian SUN1,2,Wen⁃biao GONG3

- 1. School of Materials Science and Engineering, Jilin University, Changchun 130022, China

2. Key Laboratory of Automobile Materials, Ministry of Education, Jilin University, Changchun 130022, China

3. School of Materials Science and Engineering, Changchun University of Technology, Changchun 130012, China

CLC Number:

- TG456.9

| 1 | ThomasW M, NicholasE D, NeedhamJ C, et al. Improvements relating of friction welding[P]. PCT/GB1992/002203,1992⁃11⁃27. |

| 2 | 温泉,李文亚,王非凡, 等. 双轴肩搅拌摩擦焊接方法研究进展[J]. 航空制造技术,2017(12):16⁃23. |

| WenQuan,LiWen⁃ya,WangFei⁃fan,et al. Research progress on bobbin tool friction stir welding[J]. Aeronautical Manufacturing Technology,2017(12):16⁃23. | |

| 3 | LiuH J,HouJ C, GuoH. Effect of welding speed on microstructure and mechanical properties of self⁃reacting friction stir welded 6061⁃T6 aluminum alloy[J]. Materials & Design,2013(50):872⁃878. |

| 4 | 赵秋颖,吴志生,刘翠荣,等. 铝合金搅拌摩擦焊研究现状[J]. 焊接技术,2016(1):1⁃5. |

| ZhaoQiu⁃ying,WuZhi⁃sheng,LiuCui⁃rong, et al. Research status about friction stir welding of aluminum alloy[J]. Welding Technology,2016(1):1⁃5. | |

| 5 | 刘杰,邓刚,韩凤武,等. 双轴肩搅拌摩擦焊技术在铝合金车体制造中的应用发展[J].焊接,2015(1):17⁃20. |

| LiuJie, DengGang, HanFeng⁃wu, et al. The application and development of the friction stir welding technology in the manufacture of aluminum alloy body[J]. Welding & Jointing,2015(1):17⁃20. | |

| 6 | ThreadgillP L, LeonardA J, ShercliffH R, et al. Friction stir welding of aluminum alloys[J]. International Materials Reviews,2009,54(2):49⁃93. |

| 7 | SongM, KovacevicR. Thermal modeling of friction stir welding in a moving coordinate system and its validation[J]. International Journal of Machine Tools and Manufacture,2003,43(6):605⁃615. |

| 8 | SongM, KovacevicR. Numerical and experimental study of the heat transfer process in friction stir welding[J]. Proceedings of the Institution of Mechanical Engineers Part B:Journal of Engineering Manufacture,2003,217(1):73⁃85. |

| 9 | OerteltG, BabuS S,DabidS A, et al. Effect of thermal cycling on friction stir welds of 2195 aluminum alloy[J]. Welding Journal,2001,80(3):71⁃79. |

| 10 | HilgertJ, SchmidtH N B, SantosJ F, et al. Thermal models for bobbin tool friction stir welding[J]. Jounral of Materials Processing Technology,2011,211(2):197⁃204. |

| 11 | TangW, GuoX, McClureJ C, et al. Heat input and temperature distribution in friction stir welding[J]. Journal of Materials Processing and Manufacturing Science,1998,7(2):163⁃172. |

| 12 | HwangY M, KangZ W, ChiouY C, et al. Experimental study on temperature distributions within the workpiece during friction stir welding of aluminum alloys[J]. International Journal of Machine Tools and Manufacture,2008,48(7):778⁃787. |

| 13 | 张骁,王敏,张会杰,等. 2A14铝合金双轴肩搅拌摩擦焊的温度场模拟与测定[J]. 焊接,2015(9):16⁃19. |

| ZhangXiao, WangMin, ZhangHui⁃jie, et al. Simulation and test of bobbin tool friction stir welding temperature feld of 2A14 aluminum alloy[J]. Welding & Joining,2015(9):16⁃19. | |

| 14 | ChenShun⁃jin, LiHao,LuSheng, et al. Temperature measurement and control of bobbin tool friction stir welding[J]. The International Journal of Advanced Manufacturing Technology,2016,86(1⁃4):337⁃346. |

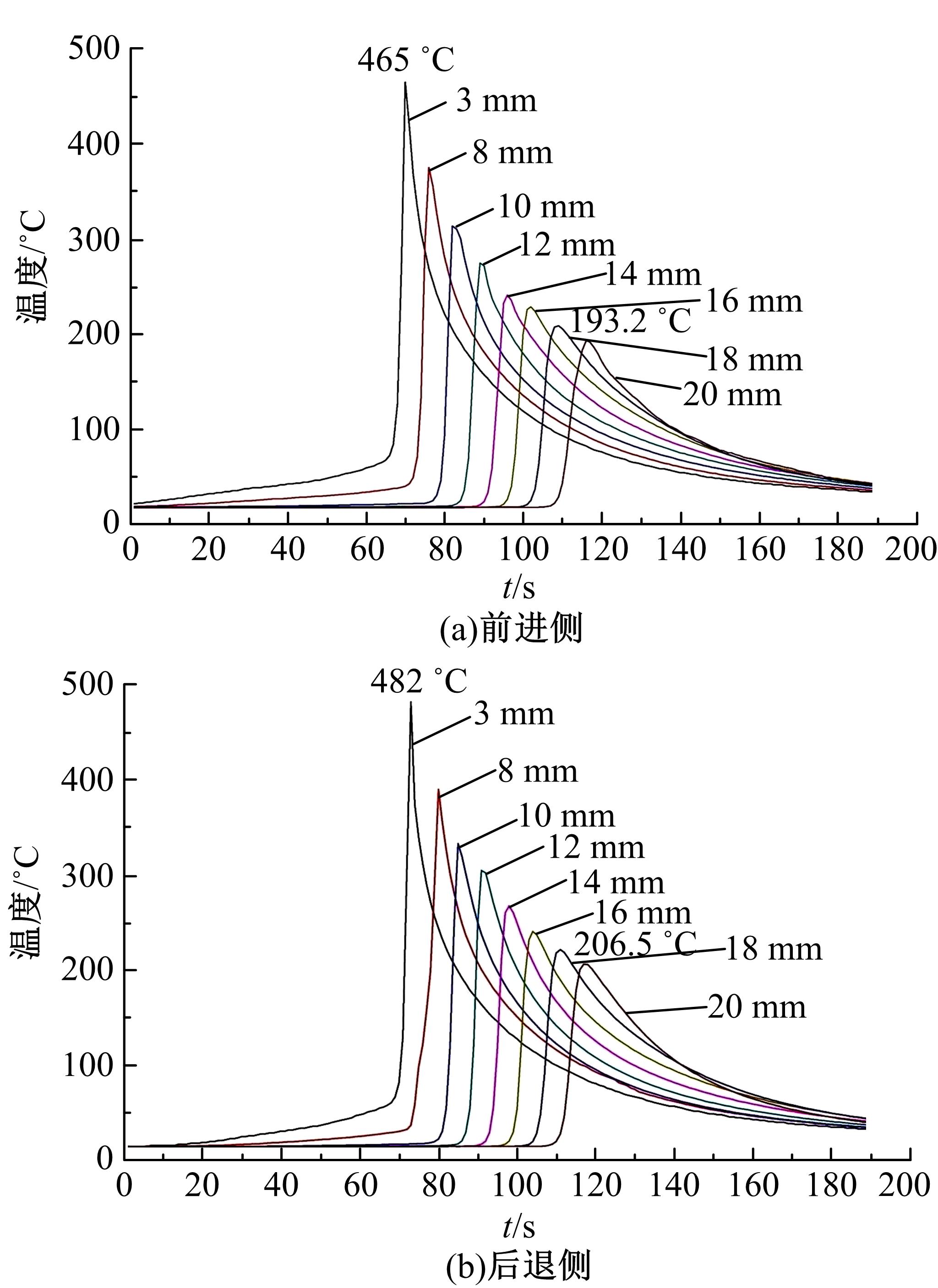

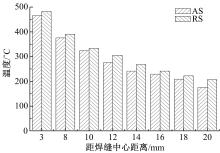

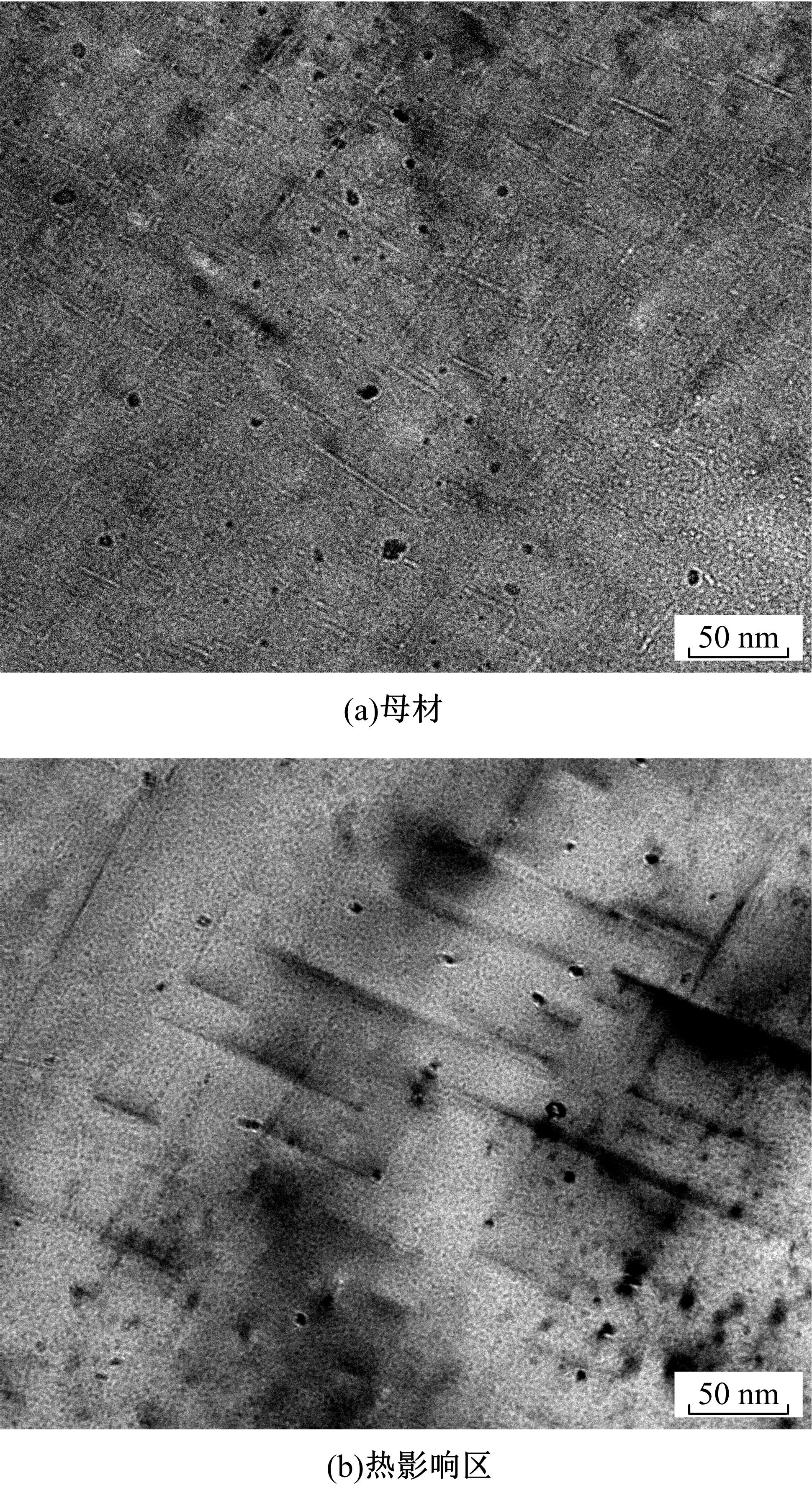

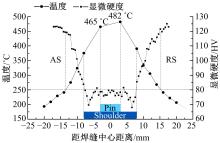

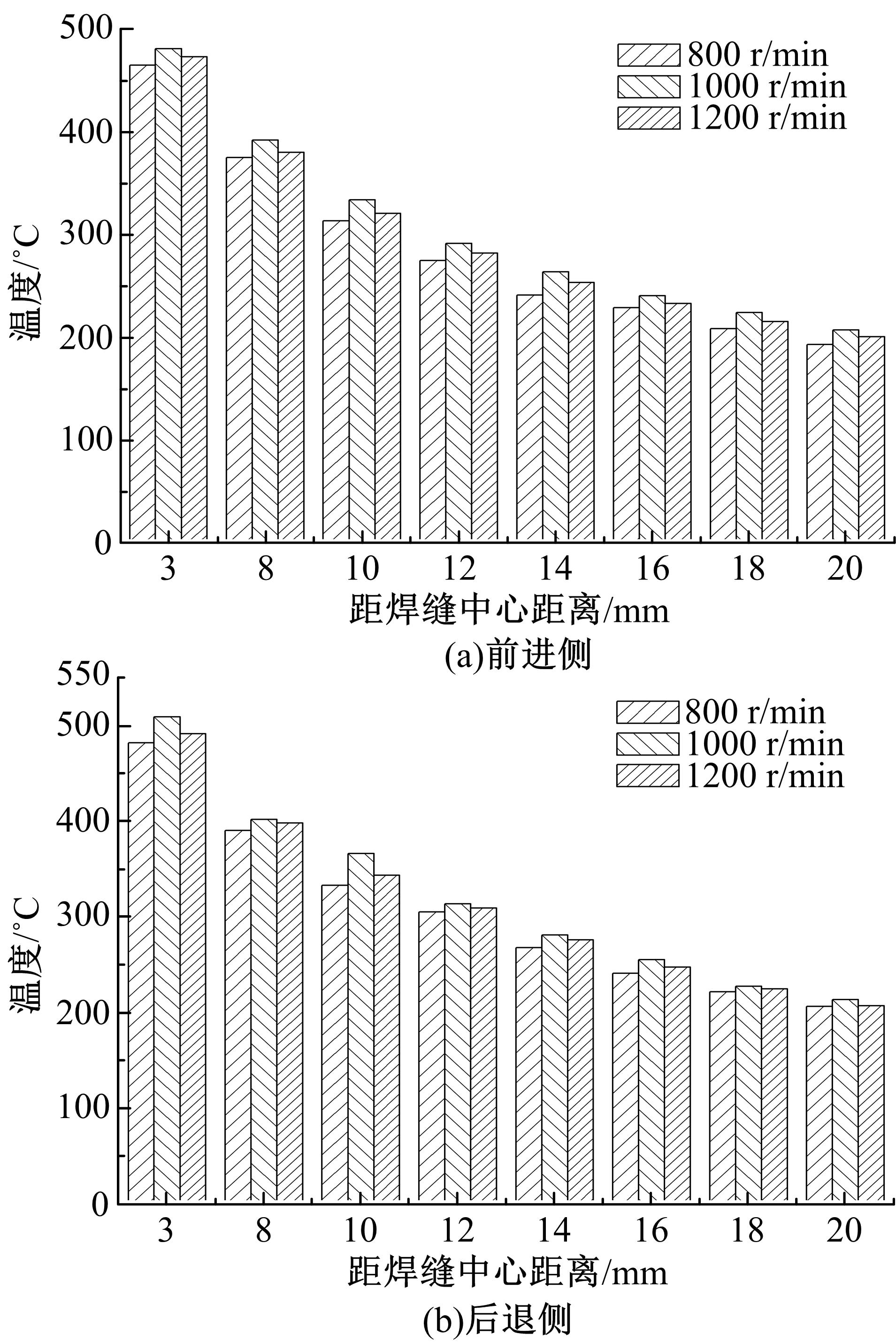

| 15 | 李敬勇,周小平,董春林,等. 6082铝合金双轴肩搅拌摩擦焊试板温度场研究[J].航空材料学报,2013,33(5):36⁃40. |

| LiJing⁃yong,ZhouXiao⁃ping,DongChun⁃lin,et al. Temperature fields in 6082 Aluminum alloy samples bobbin⁃tool friction stir welded[J]. Journal of Aeronautical Materials,2013,33(5):36⁃40. | |

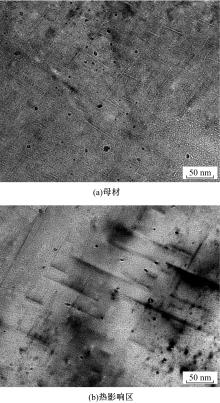

| 16 | 王冰. 6082⁃T6铝合金搅拌摩擦焊接头微观组织及力学性能的研究[D]. 长春: 吉林大学材料科学与工程学院,2015. |

| WangBing. Study on microstructures and mechanical properties of friction stir welding joints of 6082⁃T6 aluminum alloy[D]. Changchun: College of Materials Science and Engineering, Jilin University,2015. | |

| 17 | AndersenS J, ZandbergenH W, JansenJ, et al. The crystal structure of the β'' phase in Al⁃Mg⁃Si alloys[J]. Acta Materialia,1998,46(2):3238⁃3298. |

| 18 | EdwardsG A, StillerK, DunlopG L, et al. The precipitation sequence in Al⁃Mg⁃Si alloys[J]. Acta Materialia,1998,46(11):3893⁃3904. |

| [1] | LIU Zhi-feng, ZHAO Dai-hong, WANG Yu-mo, HUN Lian-ming, ZHAO Yong-sheng, DONG Xiang-min. Relationship between bearing capacity of heavy machine hydrostatic rotary table and temperature field distribution of oil pad [J]. 吉林大学学报(工学版), 2018, 48(3): 773-780. |

| [2] | ZHAO Yu-guang, YANG Xue-hui, XU Xiao-feng, ZHANG Yang-yang, NING Yu-heng. Effects of Al-10Sr modifiers with different states, modification temperature and holding time on microstructure of ZL114A alloy [J]. 吉林大学学报(工学版), 2018, 48(1): 212-220. |

| [3] | TANG Hua-guo, MA Xian-feng, ZHAO Wei, LIU Jian-wei, ZHAO Zhen-ye. Synthesis microstructure and thermal properties of high performance bulk Al [J]. 吉林大学学报(工学版), 2017, 47(5): 1542-1547. |

| [4] | WANG Guo-lin, SUN Yan-tian, LIANG Chen, YANG Jian, ZHOU Hai-chao. Contour design of radial tire based on full stress theory [J]. 吉林大学学报(工学版), 2017, 47(2): 365-372. |

| [5] | SHAO Qing, XU Tao, XU Cong-zhan, GUO Hao-tian, GUO Gui-kai, ZHANG Hai-bo. Simulation of angular contact ball bearing characteristics with PEEK cage [J]. 吉林大学学报(工学版), 2017, 47(1): 163-168. |

| [6] | LIU Xiao-bo, ZHOU De-kun, ZHAO Yu-guang. Microstructure and mechanical property of Mg2Si/Al composites fabricated by semi-solid extrusion under different isothermal heat treatments [J]. 吉林大学学报(工学版), 2016, 46(5): 1577-1582. |

| [7] | LI Chun-ling, FAN Ding, WANG Bin, YU Shu-rong. 5A06 aluminum alloy and galvanized steel butt welding-brazing by laser with preset filler powder [J]. 吉林大学学报(工学版), 2016, 46(2): 516-521. |

| [8] | ZHANG Jia-tao, ZHAO Yu-guang, TAN Juan. Effect of starting microstructure on refining potency of electro-pulsing on reverse austenite grain [J]. 吉林大学学报(工学版), 2016, 46(1): 193-198. |

| [9] | GUAN Qing-feng, LI Yan, HOU Xiu-li, YANG Sheng-zhi, WANG Xiao-tong. Modification of solid solution Mg-Gd-Y-Nd alloy irradiated by high current pulsed electron beam [J]. 吉林大学学报(工学版), 2015, 45(4): 1200-1205. |

| [10] | MA Yun-hai, SHANG Wen-bo, FAN Xue-ying, GAO Zhi-hui, TONG Jin, YAN Zhi-feng, CHANG Zhi-yong. Preparation and degradation of porous β-tricalcium phosphate bioceramic for bone imitaion [J]. 吉林大学学报(工学版), 2015, 45(4): 1367-1374. |

| [11] | GAO Song, LIANG Ji-cai, CHEN Guang-yi, WEI Zhi-yong, TENG Fei. Rapid adjusting of fundamental units in process of flexible 3D stretch-bending [J]. 吉林大学学报(工学版), 2014, 44(6): 1723-1728. |

| [12] | CHEN Yan-hong, WU Wei-jing, LIU Hong-wei, SHEN Shuai, LI Ce-yuan, GENG Huan-liang. Thermal characteristics of battery for pure electric vehicles [J]. 吉林大学学报(工学版), 2014, 44(4): 925-932. |

| [13] | SHI Dong-yong, YING Liang, HU Ping, SHEN Guo-zhe, WU Wen-hua, JIANG Da-xin. Numerical simulation of 3D temperature field in hot forming of high strength steel [J]. 吉林大学学报(工学版), 2014, 44(4): 946-952. |

| [14] | JIANG Feng-guo, ZHAO Jing-lu, ZHENG Zhong-yuan. Reliability analysis of steel columns exposed to fire by load and resistance factor design [J]. 吉林大学学报(工学版), 2014, 44(4): 978-984. |

| [15] | HUANG Jian-kang, HE Cui-cui, SHI Yu, FAN Ding. Thermodynamic analysis of Al-Fe intermetallic compounds formed by dissimilar joining of aluminum and galvanized steel [J]. 吉林大学学报(工学版), 2014, 44(4): 1037-1041. |

|

||