Journal of Jilin University(Engineering and Technology Edition) ›› 2018, Vol. 48 ›› Issue (6): 1787-1792.doi: 10.13229/j.cnki.jdxbgxb20170955

Previous Articles Next Articles

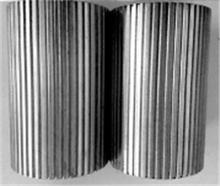

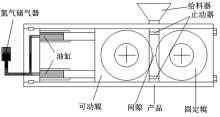

Wear test and anti-friction mechanism analysis of bionic stripe grinding roll

XI Peng( ),CONG Qian(

),CONG Qian( ),WANG Qing-bo,GUO Hua-xi

),WANG Qing-bo,GUO Hua-xi

- Key Laboratory of Bionic Engineering, Ministry of Education, Jilin University, Changchun 130022,China

CLC Number:

- TH69

| [1] |

鲍崇高 . 磨辊表层的材料与耐磨性[J]. 现代面粉工业, 2010,24(4):16-19.

doi: 10.3969/j.issn.1674-5280.2010.04.007 |

|

Bao Chong-gao . The material and wear resistance of the grinding roller surface[J]. Modern Flour Milling Industry, 2010,24(4):16-19.

doi: 10.3969/j.issn.1674-5280.2010.04.007 |

|

| [2] | 明亮 . 德国KHD公司三工位转台式振动成型机[J]. 设备管理与维修, 2010(7):71-72. |

| Ming Liang . Three station turntable type vibration forming machine of German KHD company[J]. Plant Maintenance Engineering, 2010(7):71-72. | |

| [3] |

张莉, 张茂花 . CDG型辊压机的结构特点[J]. 新世纪水泥导报, 2010,16(2):25-27.

doi: 10.3969/j.issn.1008-0473.2010.02.006 |

|

Zhang Li, Zhang Mao-hua . Structural features of CDG roller press[J]. Cement Guide for New Epoch, 2010,16(2):25-27.

doi: 10.3969/j.issn.1008-0473.2010.02.006 |

|

| [4] |

Matthijs G, Rymen D, Beatriz M , et al. Approaches to homozygosity mapping and exome sequencing for the identification of novel types of CDG[J]. Glycoconjugate Journal, 2013,30(1):67-76.

doi: 10.1007/s10719-012-9445-7 |

| [5] |

Jaeken J, Hennet T, Matthijs G , et al. CDG nomenclature: time for a change![J]. Biochim Biophys Acta, 2009,1792(9):825-826.

doi: 10.1016/j.bbadis.2009.08.005 pmid: 3917312 |

| [6] |

Coorg R, Lotze T E . Child neurology: a case of PMM2-CDG (CDG 1a) presenting with unusual eye movements[J]. Neurology, 2012,79(15):131-133.

doi: 10.1212/WNL.0b013e31826e2617 pmid: 23045520 |

| [7] |

Fernández I, Belzunce F J . Wear and oxidation behavior of high chromium white cast irons[J]. Materials Characterization, 2008,59(6):669-674.

doi: 10.1016/j.matchar.2007.05.021 |

| [8] | Lv Hai-feng, Cao Hai-ning, Xu Zhong-zhou . Efficient energy-saving roller press[P]. China Patent:CN 202762472 U, 2012-09-04. |

| [9] |

张维果, 王学成 . 浅谈煤矿机械磨料磨损机理[J]. 煤炭工程, 2010(6):76-78.

doi: 10.3969/j.issn.1671-0959.2010.06.030 |

|

Zhang Wei-guo, Wang Xue-cheng . Abrasive wear mechanism of coal mine machinery[J]. Coal Engineering, 2010(6):76-78.

doi: 10.3969/j.issn.1671-0959.2010.06.030 |

|

| [10] |

孙艺文, 汝绍锋, 丛茜 . 仿生凹坑形钻井泥浆泵活塞磨损寿命试验[J]. 石油学报, 2017,38(2):234-240.

doi: 10.7623/syxb201702011 |

|

Sun Yi-wen, Ru Shao-feng, Cong Qian . Wear-life experiment of drilling mud pump piston with dimple-shaped bionic surface[J]. Acta Petrolei Sinica, 2017,38(2):234-240.

doi: 10.7623/syxb201702011 |

|

| [11] |

Harsha A P, Jha S K . Erosive wear studies of epoxy-based composites at normal incidence[J]. Wear, 2008,265(7/8):1129-1135.

doi: 10.1016/j.wear.2008.03.003 |

| [12] | Li Yan-bin, Gao You-hua. Finite element analysis for platform of 3 DOF spacecraft simulator based on the theory of deformable body mechanics [C]//2010 International Conference on Mechanic Automation and Control Engineering(MACE),Wuhan,China, 2010: 709-712. |

| [13] | 黄胜 . 高压辊磨机粉碎行为研究[D]. 长沙:中南大学机电工程学院, 2012. |

| Huang Sheng . Research on crush behavior of high pressure grinding rolls[D]. Changsha: College of Mechanical and Electrical Engineering, Central South University, 2012. | |

| [14] | 金向明, 高德平, 蔡显新 , 等. 航空发动机静不定转子支撑载荷的有限元分析[J]. 航空动力学报, 2008,23(7):1323-1327. |

| Jin Xiang-ming, Gao De-ping, Cai Xian-xin , et al. Finite element analysis of inertial load of the statically indeterminate rotor stay bearing[J]. Journal of Aerospace Power, 2008,23(7):1323-1327. | |

| [15] | 刘超 . 高压辊磨机振动特征提取与分析[D]. 长沙:中南大学机电工程学院, 2012. |

| Liu Chao . Vibration feature extraction and analysis of high pressure grinding roll[D]. Changsha:College of Mechanical and Electrical Engineering, Central South University, 2012. | |

| [16] |

Cimilli S, Nergis F B U, Candan C . Modeling of heat transfer measurement unit for cotton plain knitted fabric using a finite element method[J]. Textile Research Journal, 2008,78(1):53-59.

doi: 10.1177/0040517507082186 |

| [17] |

Zuo Xiao-ming, Xu Zhao-mei . Thermal analysis and optimization of plant-fiber and starch dishware mould based on ANSYS[J]. Advanced Materials Research, 2010, 102-104:125-129.

doi: 10.4028/www.scientific.net/AMR.102-104.125 |

| [18] |

Qin Xian-yun, Zhang Jian-ming, Li Guang-yao , et al. An element implementation of the boundary face method for 3D potential problems[J]. Engineering Analysis with Boundary Elements, 2010,34(11):934-943.

doi: 10.1016/j.enganabound.2010.04.009 |

| [1] | Na WU,Jian ZHUANG,Ke⁃song ZHANG,Hui⁃xin WANG,Yun⁃hai MA. Compression mechanical properties and fracture mechanism of Scapharca Subcrenata shell [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 897-902. |

| [2] | GUO Hao-tian,XU Tao,LIANG Xiao,YU Zheng-lei,LIU Huan,MA Long. Optimization on thermal surface with rib turbulator inspired by turbulence of alopias' gill in simplified gas turbine transition piece [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1793-1798. |

| [3] | ZHENG Xiao-yi, SUN Da-qian, LI Xin, DU Gui-gang, XIN Wei-da, REN Zhen-an. Microstructure and properties of cladded Al-Nb layers reinforced by NbAl3 [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1531-1536. |

| [4] | QIAN Zhi-hui, ZHOU Liang, REN Lei, REN Lu-quan. Completely passive walking machine with bionic subtalar joint and matatarsal phalangeal joint [J]. 吉林大学学报(工学版), 2018, 48(1): 205-211. |

| [5] | GE Chang-jiang, YE Hui, HU Xing-jun, YU Zheng-lei. Prediction and control of trailing edge noise on owl wings [J]. 吉林大学学报(工学版), 2016, 46(6): 1981-1986. |

| [6] | LI Meng, SU Yi-nao, SUN You-hong, GAO Ke. High matrix bionic abnormal shape impregnated diamond bit [J]. 吉林大学学报(工学版), 2016, 46(5): 1540-1545. |

| [7] | LIANG Yun-hong, REN Lu-quan. Preliminary study of habitat and its bionics [J]. 吉林大学学报(工学版), 2016, 46(5): 1746-1756. |

| [8] | LIANG Yun-hong, REN Lu-quan. Preliminary study of bionics in human life [J]. 吉林大学学报(工学版), 2016, 46(4): 1373-1384. |

| [9] | QIAN Zhi-hui, MIAO Huai-bin, REN Lei, REN Lu-quan. Lower limb joint angles of German shepherd dog during foot-ground contact in different gait patterns [J]. 吉林大学学报(工学版), 2015, 45(6): 1857-1862. |

| [10] | ZOU Meng, YU Yong-jun, ZHANG Rong-rong, WEI Can-gang, WANG Hui-xia. Simulation analysis of energy-absorption properties of thin-wall tube based on horn structure [J]. 吉林大学学报(工学版), 2015, 45(6): 1863-1868. |

| [11] | YANG Zhuo-juan, WANG Qing-cheng, GAO Ying, MEN Yu-zhuo, YANG Xiao-dong. Effect of different solutions on the wettability of lotus leaves [J]. 吉林大学学报(工学版), 2015, 45(6): 1869-1873. |

| [12] | TIAN Wei-jun, WANG Ji-yue1, LI Ming1, CHEN Si-yuan, LIU Fang-yuan, CONG Qian. Bionic design of the small blade of horizontal axis wind turbines [J]. 吉林大学学报(工学版), 2015, 45(5): 1495-1501. |

| [13] | TIAN Gui-zhong, LIU Zhi-ling, ZHOU Hong-gen, SONG Jiang-chao, ZHU Tao. Quasi-static axial tensile mechanical characteristics of silkworm's anterior silk gland [J]. 吉林大学学报(工学版), 2015, 45(3): 872-877. |

| [14] | QIAN Zhi-hui, MIAO Huai-bin, Shang Zhen, REN Lu-quan. Foot-ground contact analysis of German shepherd dog in walking, trotting and jumping gaits [J]. 吉林大学学报(工学版), 2014, 44(6): 1692-1697. |

| [15] | LI Fang, ZHAO Gang, LIU Wei-xin, SUN Zhuang-zhi. Numerical simulation of drag reduction characteristics of a bionic jet surface with multiple holes [J]. 吉林大学学报(工学版), 2014, 44(6): 1698-1703. |

|