Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (11): 2746-2755.doi: 10.13229/j.cnki.jdxbgxb20210377

Optimization and experiment of operation parameters of hilly area flax combine harvester

Rui-jie SHI1( ),Fei DAI1,Wu-yun ZHAO1(

),Fei DAI1,Wu-yun ZHAO1( ),Xiao-long LIU1,Jiang-fei QU2,Feng-wei ZHANG1

),Xiao-long LIU1,Jiang-fei QU2,Feng-wei ZHANG1

- 1.College of Mechanical and Electrical Engineering,Gansu Agricultural University,Lanzhou 730070,China

2.Teacher and Cadre Development Center,Lanzhou College of Information Science and Technology,Lanzhou 730300,China

CLC Number:

- S225.31

| 1 | 祁旭升,王兴荣,许军,等.胡麻种质资源成株期抗旱性评价[J].中国农业科学, 2010, 43(15): 3076-3087. |

| Qi Xu-sheng, Wang Xing-rong, Xu Jun . et al. Drought-resistance evaluation of flax germplasm at adult plant stage[J]. Scientia Agricultura Sinica, 2010, 43(15): 3076-3087. | |

| 2 | 罗俊杰, 欧巧明, 叶春雷, 等. 重要胡麻栽培品种的抗旱性综合评价及指标筛选[J]. 作物学报, 2014, 40(7): 1259-1273. |

| Luo Jun-jie, Qiao-ming Ou, Ye Chun-lei, et al. Comprehensive valuation of drought resistance and screening of indices of important flax cultivars[J]. Acta Agronomica Sinica, 2014, 40(7): 1259-1273. | |

| 3 | 史瑞杰, 戴飞, 赵武云, 等. 全喂入式胡麻脱粒机的设计与试验[J]. 中国农业大学学报, 2019, 24(8): 120-132. |

| Shi Rui-jie, Dai Fei, Zhao Wu-yun, et al. Design and test of full-feed flax thresher[J]. Journal of China Agricultural University, 2019, 24(8): 120-132. | |

| 5 | 刘元祥, 戴飞, 赵武云, 等. 手扶式胡麻割晒机的设计与试验[J].中国农机化学报, 2019, 40(12): 26-29. |

| Liu Yuan-xiang, Dai Fei, Zhao Wu-yun, et al. Design and experiment of handheld flax windrower[J]. Journal of Chinese Agricultural Mechanization, 2019, 40(12): 26-29. | |

| 6 | 孙仕明, 孙文峰, 吕海杰. 我国亚麻生产机械化现状及发展建议[J]. 农机化研究, 2004(4): 23-24. |

| Sun Shi-ming, Sun Wen-feng, Lv Hai-jie. The present status and development suggestion on flax production mechanization in our country[J]. Journal of Agricultural Mechanization Research,2004(4): 23-24. | |

| 7 | 屈哲, 余泳昌, 何勋. 我国西南丘陵地区玉米收获机械化的研究探讨[J]. 现代农业装备, 2013(3): 26-29. |

| Qu Zhe, Yu Yong-chang, He Xun. Research and discuss about corn harvest mechanization in southwest hilly area of our country[J]. Modern Agricultural Equipment, 2013(3): 26-29. | |

| 8 | 戴飞, 赵武云, 刘国春, 等. 胡麻脱粒物料分离清选机设计与试验[J]. 农业机械学报, 2019, 50(8): 140-147. |

| Dai Fei, Zhao Wu-yun, Liu Guo-chun, et al. Design and experiment of separating and cleaning machine for flax threshing material[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(8): 140-147. | |

| 9 | 戴飞, 赵武云, 宋学锋, 等. 胡麻脱粒物料分离清选作业机参数优化与试验[J]. 农业机械学报, 2020, 51(7): 100-108. |

| Dai Fei, Zhao Wu-yun, Song Xue-feng, et al. Parameters optimization and experiment on separating and cleaning materia machine for flax threshing material[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(7): 100-108. | |

| 10 | 周刚, 石林榕, 赵武云, 等. 旱地胡麻起垄覆膜播种联合作业机工作参数优化与性能试验[J]. 中国农业大学学报, 2019, 24(6): 147-156. |

| Zhou Gang, Shi Lin-rong, Zhao Wu-yun, et al. Optimization of the working parameters and performance experiment of flax ridging and covering film combined seeder in dry-land[J]. Journal of China Agricultural University, 2019, 24(6): 147-156. | |

| 11 | 石林榕, 马周泰, 赵武云, 等. 胡麻籽粒离散元仿真参数标定与排种试验验证[J]. 农业工程学报, 2019, 35(20): 25-33. |

| Shi Lin-rong, Ma Zhou-tai, Zhao Wu-yun, et al. Calibration of simulation parameters of flaxed seeds using discrete element method and verification of seed-metering test[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(20): 25-33. | |

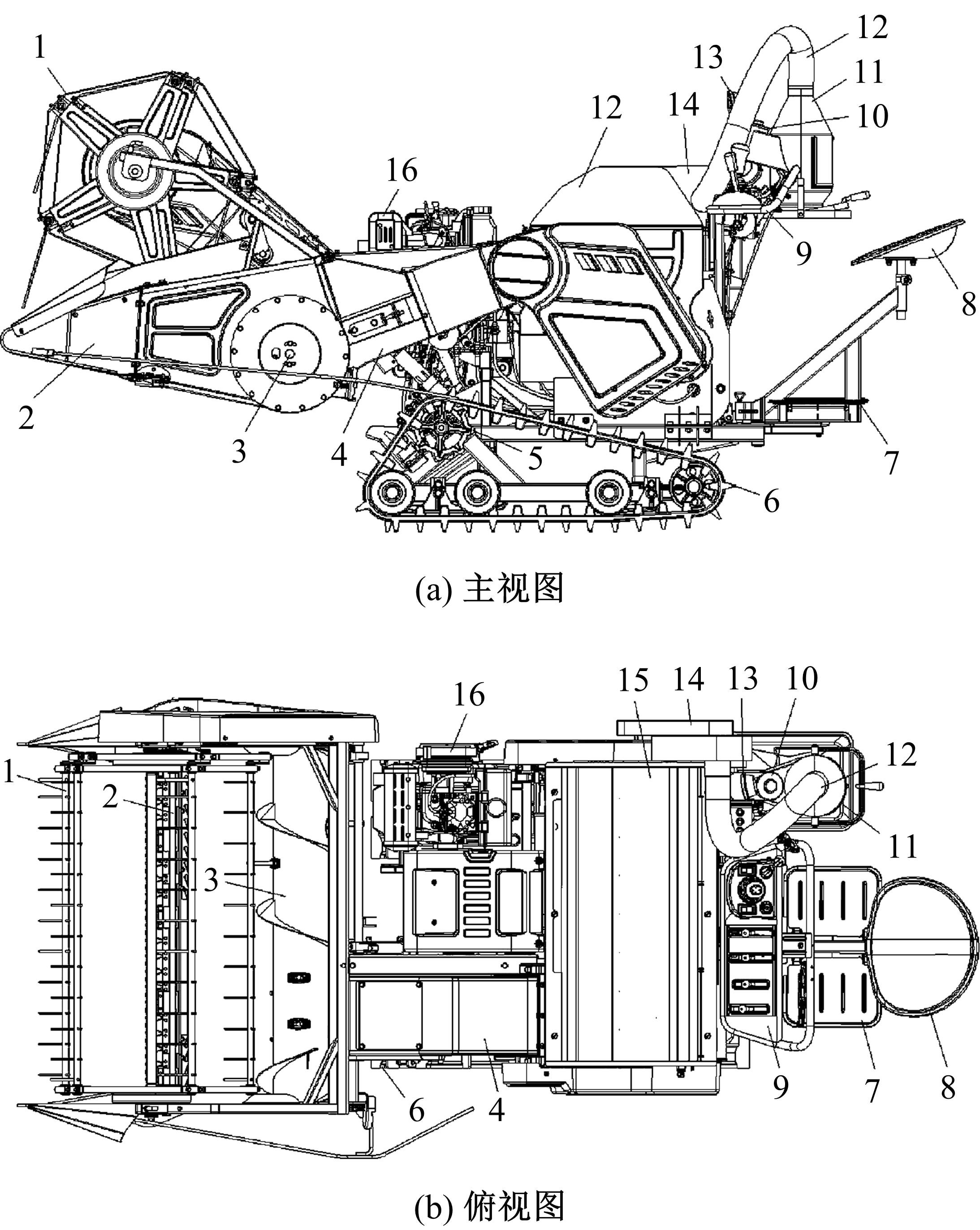

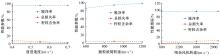

| 12 | 史瑞杰, 戴飞, 刘小龙, 等. 履带式丘陵山地胡麻联合收割机设计与试验[J]. 农业工程学报, 2021, 37(5): 59-67. |

| Shi Rui-jie, Dai Fei, Liu Xiao-long, et al. Design and experiments of crawler-type hilly area flax combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(5): 59-67. | |

| 13 | 史瑞杰, 戴飞, 赵武云, 等. 胡麻茎秆生物力学特性试验[J]. 中国农机化学报, 2018, 39(11): 45-50. |

| Shi Rui-jie, Dai Fei, Zhao Wu-yun, et al. Biomechanical properties test of flax stem[J]. Journal of Chinese Agricultural Mechanization,2018,39(11): 45-50. | |

| 14 | .收获机械 联合收割机 试验方法 [S]. |

| 15 | .脱粒机试验方法 [S]. |

| 16 | .计数抽样检测程序 [S]. |

| 17 | .农业机械试验条件 [S]. |

| 18 | .谷物联合收割机 安全操作规程 [S]. |

| 19 | Shamilah A M, Darius E P, Nor A A J. Actual field speed of rice combine harvester and its influence on grain loss in Malaysian paddy field[J]. Journal of the Saudi Society of Agricultural Sciences, 2020, 19(6): 422-425. |

| 20 | Chai X Y, Zhou Y, Xu L Z, et al. Effect of guide strips on the distribution of threshed outputs and cleaning losses for a tangential-longitudinal flow rice combine harvester[J]. Biosystems Engineering, 2020, 198: 223-234. |

| 21 | 中国农业机械化科学研究院. 农业机械设计手册: 上册[M]. 北京: 中国农业科学技术出版社, 2007. |

| 22 | 戴飞, 赵武云, 马明义, 等. 双垄耕作施肥喷药覆膜机工作参数优化[J]. 农业机械学报, 2016, 47(1):83-90. |

| Dai Fei, Zhao Wu-yun, Ma Ming-yi,et al. Parameters optimization of operation machine for tillage-fertilization and spraying filming on double ridges[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(1): 83-90. | |

| 23 | 张仕林, 赵武云, 戴飞, 等. 全膜双垄沟起垄覆膜机镇压作业过程仿真分析与试验[J]. 农业工程学报, 2020, 36(1): 20-30. |

| Zhang Shi-lin, Zhao Wu-yun, Dai Fei, et al. Simulation analysis and test on suppression operation process of ridging and film covering machine with full-film double-furrow[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(1):20-30. | |

| 24 | 金诚谦, 郭飞扬, 徐金山, 等. 大豆联合收获机作业参数优化[J]. 农业工程学报, 2019, 35(13): 10-22. |

| Jin Cheng-qian, Guo Fei-yang, Xu Jin-shan, et al. Optimization of working parameters of soybean combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(13): 10-22. | |

| 25 | 王伯凯, 胡志超, 曹明珠, 等. 轴流式花生捡拾收获机设计与试验[J]. 农业机械学报, 2021, 52(1): 98, 109-118. |

| Wang Bo-kai, Hu Zhi-chao, Cao Ming-zhu, et al. Design and Test of axial-flow peanut picking and harvesting machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(1): 98, 109-118. | |

| 26 | 黄继承, 沈成, 纪爱敏, 等. 工业大麻收割机切割-输送关键部件作业参数优化[J]. 吉林大学学报: 工学版, 2021, 51(2): 772-780. |

| Huang Ji-cheng, Shen Cheng, Ji Ai-min, et al. Optimization of cutting-conveying key working parameters of hemp harvester[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2):772-780. | |

| 27 | 薛钊, 付君, 陈志, 等. 青饲玉米收获机械切碎装置参数优化试验[J]. 吉林大学学报: 工学版, 2020, 50(2): 739-748. |

| Xue Zhao, Fu Jun, Chen Zhi, et al. Optimization experiment on parameters of chopping device of forage maize harvester[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2):739-748. |

| [1] | Zhi-hui LI,Ya-qian SUN,Peng-fei TAO,Hai-tao LI,Xin LIU. Prediction method of traffic operation risk level after traffic accident [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 127-135. |

| [2] | Duan-yang GENG,Xiao-dong MU,Guo-dong ZHANG,Zong-yuan WANG,Jun-ke ZHU,Hai-gang XU. Analysis and optimization of cleaning mechanism of wheat combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 219-230. |

| [3] | Jia-cheng YUAN,Chang WANG,Kun HE,Xing-yu WAN,Qing-xi LIAO. Effect of components mass ratio under sieve on cleaning system performance for rape combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1897-1907. |

| [4] | Bin ZHANG,Guo-zan CHENG,Hao-cen HONG,Chun-xiao ZHAO,Da-peng BAI,Hua-yong YANG. Structure optimization of triangular groove of valve plate in axial piston pump based on SVR [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1213-1221. |

| [5] | Ji-cheng HUANG,Cheng SHEN,Ai-min JI,Xian-wang LI,Bin ZHANG,Kun-peng TIAN,Hao-lu LIU. Optimization of cutting⁃conveying key working parameters of hemp harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 772-780. |

| [6] | Xue-shen CHEN,Tao CHEN,Tao WU,Xu MA,Ling-chao ZENG,Lin-tao CHEN. Design and experiment on harvester for winter planting potato of straw coverage [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 749-757. |

| [7] | Yuan-li GU, Yuan ZHANG, Xiao-ping RUI, Wen-qi LU, Meng LI, Shuo WANG. Short⁃term traffic flow prediction based on LSSVMoptimized by immune algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1852-1857. |

| [8] | LI Jing, DING Ming-hui, LI Li-gang, CHEN Li-jun. Dynamic characteristics analysis and optimization of air spring based on the piston shape [J]. 吉林大学学报(工学版), 2018, 48(2): 355-363. |

| [9] | MA Kai, GAO Ji-dong, YAN Lei, XU Tao. Dummy material parameter optimization based on calibration experiment of chest pressure in collision [J]. 吉林大学学报(工学版), 2017, 47(5): 1498-1503. |

| [10] | HUANG Xuan, GUO Li-hong, LI Jiang, YU Yang. Target threat assessment based on BP neural network optimized by modified particle swarm optimization [J]. 吉林大学学报(工学版), 2017, 47(3): 996-1002. |

| [11] | WANG Qing-nian, WANG Guang-ping, WANG Peng-yu, HAN Biao, LI Feng. Parameter matching for plug-in hybrid electric vehicle based on cost optimization [J]. 吉林大学学报(工学版), 2016, 46(2): 340-347. |

| [12] | LIU Yun, LIU Fu, HOU Tao, ZHANG Xiao. Kernel-based fuzzy C-means clustering method based on parameter optimization [J]. 吉林大学学报(工学版), 2016, 46(1): 246-251. |

| [13] | SONG Xue-wei, WU Yong-fei, SHEN Chuan-liang, CHEN Shu-ming. Test optimum design in three-way pipe hydroforming load path optimization [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 57-61. |

| [14] | HAN Bao,WU Wen-fu,QUAN Long-zhe. Multi-objective optimization design and simulation on horizontal disk type weeding unit between seedlings [J]. 吉林大学学报(工学版), 2011, 41(03): 692-696. |

| [15] | LIU Shun-An, HU Qing-Yu. IPSO algorithm for optimization of shock absorber [J]. 吉林大学学报(工学版), 2010, 40(02): 341-0345. |

|

||