Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (12): 2778-2787.doi: 10.13229/j.cnki.jdxbgxb20210465

Previous Articles Next Articles

Internal thermodynamic characteristics and performance test of new oil⁃free scroll compressor

Jian SUN( ),Bin PENG(

),Bin PENG( ),Bing-guo ZHU

),Bing-guo ZHU

- School of Electrical and Mechanical Engineering,Lanzhou University of Technology,Lanzhou 730050,China

CLC Number:

- TH455

| 1 | 刘振全, 王君. 涡旋式流体机械与涡旋压缩机[M]. 北京: 机械工业出版社, 2009. |

| 2 | 李敏霞, 王派, 马一太, 等. 转子压缩机与涡旋压缩机的对比与发展[J]. 制冷学报, 2019, 40(1): 25-31, 81. |

| Li Min-xia, Wang Pai, Ma Yi-tai, et al. Comparison and development of rotary and scroll compressor[J]. Journal of Refrigeration, 2019, 40(1): 25-31, 81. | |

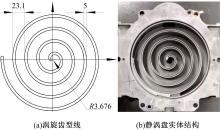

| 3 | 侯才生, 刘涛, 郭李先. 一种新型变壁厚涡旋型线的构建理论[J]. 吉林大学学报:工学版, 2020, 50(5): 1627-1634. |

| Hou Cai-sheng, Liu Tao, Guo Li-xian. Construction theories of a new type of variable wall thickness scroll profile[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1627-1634. | |

| 4 | 张朋成, 彭斌, 张宇波. 基于圆渐开线建立变截面涡旋齿的方法与理论[J]. 吉林大学学报:工学版, 2022, 52(4): 789-798. |

| Zhang Peng-cheng, Peng Bin, Zhang Yu-bo. Method and theory of establishing variable thickness scrolls based on circle involute[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(4): 789-798. | |

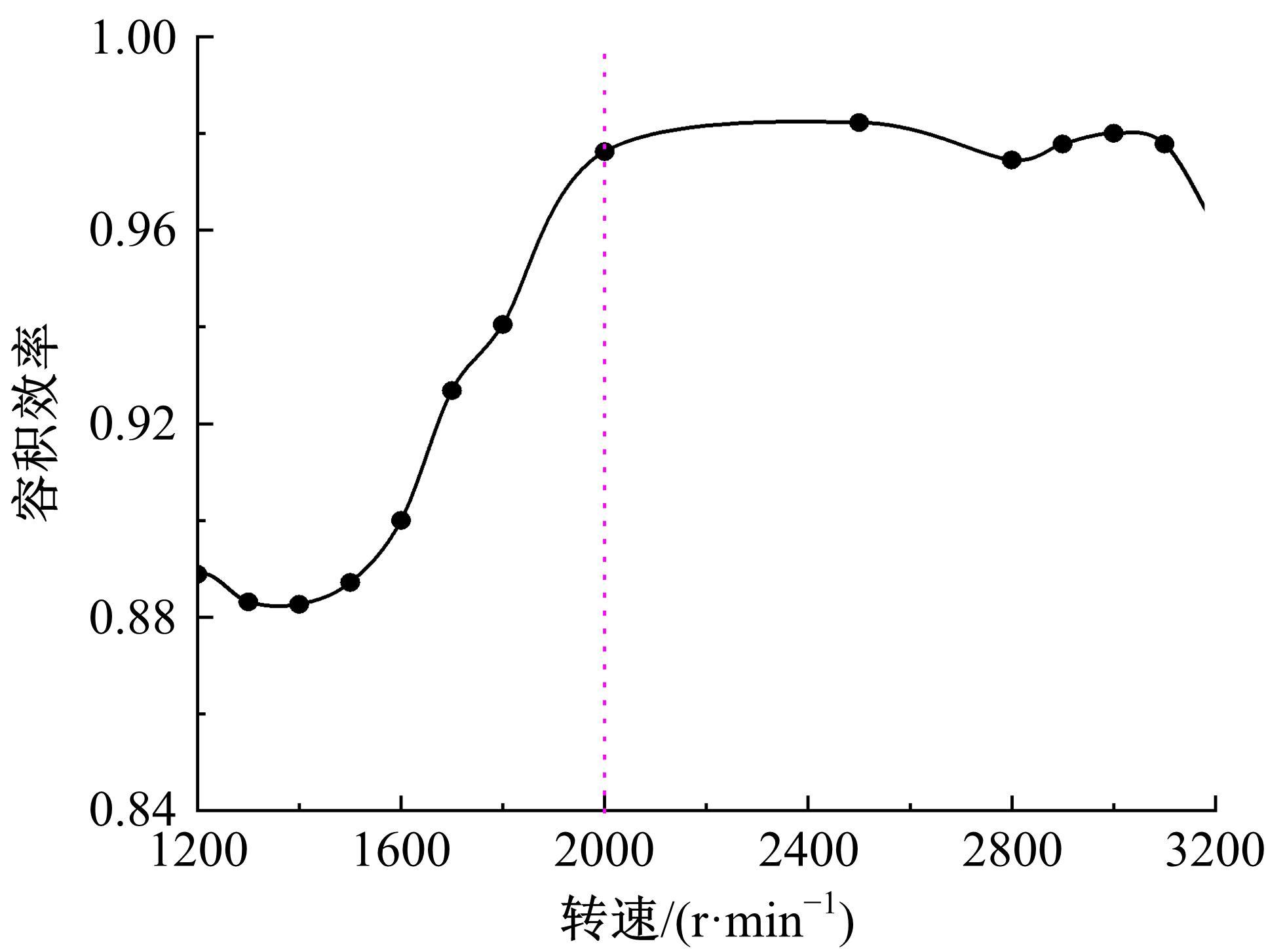

| 5 | 彭斌, 赵生显, 李要红. 新型无油涡旋压缩机性能[J]. 中国机械工程, 2018, 29(24): 2917-2924. |

| Peng Bin, Zhao Sheng-xian, Li Yao-hong. Performances of new oil-free scroll compressors[J]. China Mechanical Engineering, 2018, 29(24): 2917-2924. | |

| 6 | Peng B, Vincent L, Arnaud L, et al. Variable thickness scroll compressor performance analysis—Part I: geometric and thermodynamic modeling[J]. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2016, 231(4): 633-640. |

| 7 | Pereira E L L, Deschamps C J. Numerical analysis and correlations for radial and tangential leakage of gas in scroll compressors[J]. International Journal of Refrigeration, 2020, 110: 239-247. |

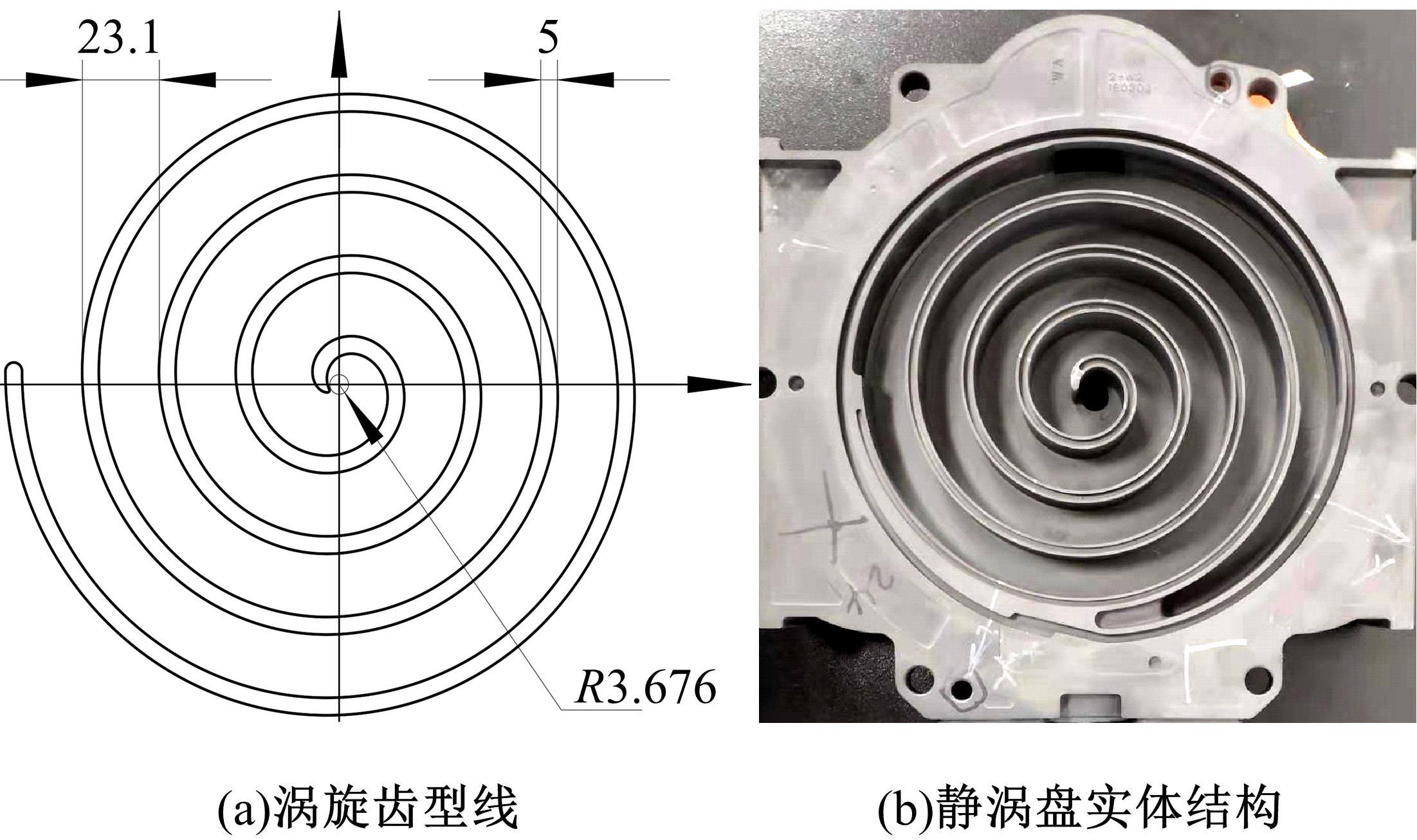

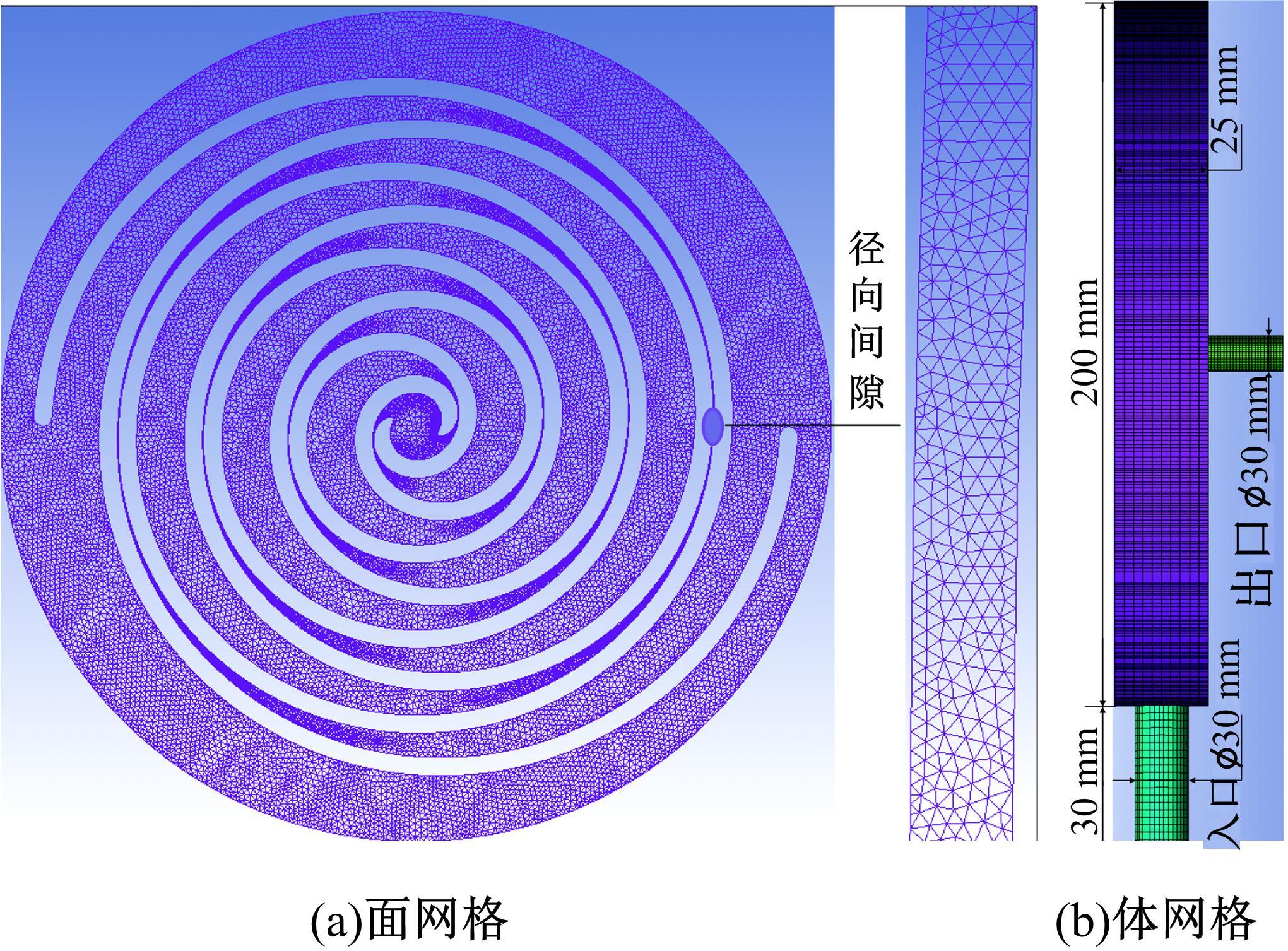

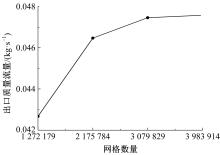

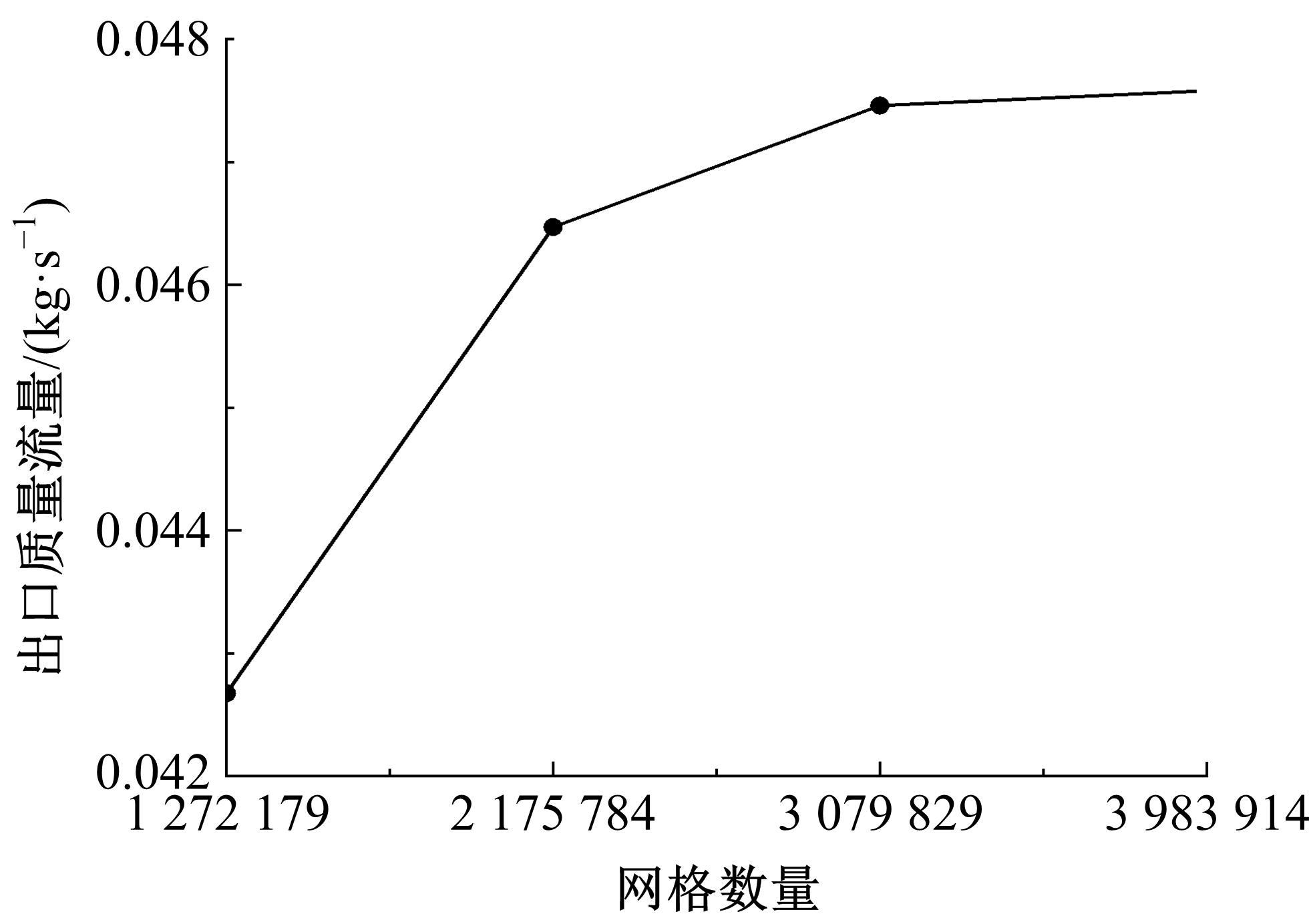

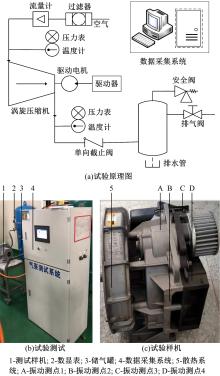

| 8 | Sun J, Peng B, Zhu B G. Numerical simulation and experimental research of oil-free scroll air compressor based on CFD[J]. Recent Patents on Mechanical Engineering, 2022, 15(3): 328-339. |

| 9 | 孙健, 彭斌, 朱兵国. 无油双涡圈空气涡旋压缩机的数值模拟及试验研究[J]. 上海交通大学学报, 2022, 56(5): 611-621. |

| Sun Jian, Peng Bin, Zhu Bing-guo. Numerical simulation and experimental study of oil-free double-warp air scroll compressor[J]. Journal of Shanghai Jiao Tong University, 2022, 56(5): 611-621. | |

| 10 | 李超, 杨紫娟, 丁凯, 等. 涡旋压缩腔径向泄漏对内部流场影响的分析[J]. 流体机械, 2016, 44(1): 22-26. |

| Li Chao, Yang Zi-juan, Ding Kai, et al. Analysis of radial leakage impact on flow field for scroll compressor compression chamber[J]. Fluid Machinery, 2016, 44(1): 22-26. | |

| 11 | 王君, 宋永兴, 姜营, 等. 基于结构化动网格的涡旋压缩机内部流场模拟[J]. 工程热物理学报, 2016, 37(2): 309-313. |

| Wang Jun, Song Yong-xing, Jiang Ying, et al. Numerical simulations of internal flow fields for scroll compressors based on structured dynamic meshes[J]. Journal of Engineering Thermophysics, 2016, 37(2): 309-313. | |

| 12 | 王君, 宋永兴, 查海滨, 等. 涡旋压缩机三维数值模拟及排气过程研究[J]. 工程热物理学报, 2016, 37(4): 766-769. |

| Wang Jun, Song Yong-xing, Zha Hai-bin, et al. 3D numerical simulation and study of discharge proccess for scroll compressors[J]. Journal of Engineering Thermophysics, 2016, 37(4): 766-769. | |

| 13 | Wang J, Song Y X, Li Q, et al. Novel structured dynamic mesh generation for CFD analysis of scroll compressors[J]. Proceedings of the Institution of Mechanical Engineers Part A:Journal of Power and Energy, 2015, 229(8): 1007-1018. |

| 14 | 查海滨, 张晓慧, 王君, 等. 涡旋压缩机非定常流动的三维数值模拟[J]. 流体机械, 2016, 44(2): 17-23. |

| Zha Hai-bin, Zhang Xiao-hui, Wang Jun, et al. Numerical simulation of three-dimensional unsteady flow in the scroll compressor[J]. Fluid Machinery, 2016, 44(2): 17-23. | |

| 15 | Sun S H, Wu K, Guo P C, et al. Analysis of the three-dimensional transient flow in a scroll refrigeration compressor[J]. Applied Thermal Engineering, 2017, 127: 1086-1094. |

| 16 | Cavazzini G, Giacomel F, Ardizzon G, et al. CFD-based optimization of scroll compressor design and uncertainty quantification of the performance under geometrical variations[J]. Energy, 2020, 209: No. 118382. |

| 17 | Zhao R C, Li W H, Zhuge W L. Unsteady characteristic and flow mechanism of a scroll compressor with novel discharge port for electric vehicle air conditioning[J]. International Journal of Refrigeration, 2020, 118: 403-414. |

| 18 | 彭斌, 董灏, 李要红, 等. 基于CFD动网格的无油涡旋压缩机性能研究[J]. 机床与液压, 2020, 48(4): 126-130. |

| Peng Bin, Dong Hao, Li Yao-hong, et al. Research on performance of oil-free scroll compressor based on CFD dynamic mesh[J]. Machine Tool & Hydraulics, 2020, 48(4): 126-130. | |

| 19 | Sun J, Peng B, Zhu B G. Performance analysis and test research of pemfc oil-free positive displacement compressor for vehicle[J]. Energies, 2021, 14 (21): No. 7329. |

| 20 | 桂伟兵, 李海生, 武涛, 等. 涡旋压缩机振动测试的试验研究[J]. 流体机械, 2016, 44(11): 1-5, 66. |

| Gui Wei-bing, Li Hai-sheng, Wu Tao, et al. Experimental study on the vibration testing of scroll compressor[J]. Fluid Machinery, 2016, 44(11): 1-5, 66. |

| [1] | Zhuang-zhuang LIU,You-wei ZHANG,Peng-yu JI,Abshir Ismail Yusuf,Lin LI,Ya-zhen HAO. Study on heat transfer characteristics of electric heating snow melting asphalt pavement [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 523-530. |

| [2] | Chen HUA,Run-xin NIU,Biao YU. Methods and applications of ground vehicle mobility evaluation [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1229-1244. |

| [3] | Zhi ZHENG,Bo GENG,Fu-min WANG,Jun-hong DONG,Si-si WEI. Improvement of protective ability for existing low⁃grade concrete guardrail [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1362-1374. |

| [4] | Peng-cheng ZHANG,Bin PENG,Yu-bo ZHANG. Method and theory of establishing variable thickness scrolls based on circle involute [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 789-798. |

| [5] | Yan-feng JIA,Da-yi QU,Lu LIN,Rong-han YAO,Xiao-long MA. Coordinated speed control of connected mixed traffic flow based on trajectory [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2051-2060. |

| [6] | Xing-jun HU,Jing-long ZHANG,Yu-fei LUO,Li XIN,Sheng LI,Jin-rui HU,Wei LAN. Influence investigation of cooling tube structure and airflow direction on thermal⁃hydraulic performance of air⁃cooled charge air cooler [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1933-1942. |

| [7] | Yong-hui SHANG,Lin-rong XU,Wei-zheng LIU,Yu CAI. Dynamic features of transition section between improved soil and A⁃filled of heavy⁃haul railway [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2128-2136. |

| [8] | Zong-wei YAO,Xu-dong GAO,Gang LIU,Qiu-shi BI. Research on working performance of vertical screw stirring mill based on numerical simulations [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1642-1650. |

| [9] | Xing-jun HU,Jing-long ZHANG,Li XIN,Yu-fei LUO,Jing-yu WANG,Tian-ming YU. Investigation on influence of cooling tube structure and airflow speed on cold side performance of air⁃cooled charge air cooler [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1557-1564. |

| [10] | Zheng-lei YU,Li-xin CHEN,Ze-zhou XU,Ren-long XIN,Long MA,Jing-fu JIN,Zhi-hui ZHANG,Shan JIANG. Analysis of mechanical characteristics and recovery characteristics of bionic protective structures based on additive manufacturing [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1540-1547. |

| [11] | Zheng-lei YU,Ren-long XIN,Li-xin CHEN,Yi-ning ZHU,Zhi-hui ZHANG,Qing CAO,Jing-fu JIN,Jie-liang ZHAO. Load bearing characteristics of honeycomb protection structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 1140-1145. |

| [12] | Bin ZHANG,Guo-zan CHENG,Hao-cen HONG,Chun-Xiao ZHAO,Hua-yong YANG. Cavitation mechanism of double⁃acting vane pump based on computational fluid dynamics simulation method [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 831-839. |

| [13] | Ya-feng GONG,Yun-ze PANG,Bo WANG,Guo-jin TAN,Hai-peng BI. Mechanical properties of new prefabricated box culvert structure based on road conditions in Jilin Province [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 917-924. |

| [14] | Chang SU,Ying HAN,Ying-chao ZHANG,Zhen-hua MIAO. Influence performance with wheel spoke design parameters of vehicle aerodynamic [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 107-113. |

| [15] | Cai-sheng HOU,Tao LIU,Li-xian GUO. Construction theories of a new type of variable wall thickness scroll profile [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1627-1634. |

|