Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (2): 422-434.doi: 10.13229/j.cnki.jdxbgxb20200823

Simulation on influence of microstructure of the wall on deep bed filtration of particulate filter

Zhi-jun LI1( ),Hao LIU1,Li-peng ZHANG2(

),Hao LIU1,Li-peng ZHANG2( ),Zhen-guo LI3,Yuan-kai SHAO3,Zhi-yang LI1

),Zhen-guo LI3,Yuan-kai SHAO3,Zhi-yang LI1

- 1.State Key Laboratory of Engines,Tianjin University,Tianjin 300072,China

2.Tianjin Internal Combustion Engine Research Institute,Tianjin 300072,China

3.China Automotive Technology and Research Center Limited Company,Tianjin 300300,China

CLC Number:

- TK411

| 1 | Shanahan C S, Smith S S, Sears B D. A general method for fouling injectors in gasoline direct injection vehicles and the effects of deposits on vehicle performance[J]. SAE International Journal of Fuels and Lubricants, 2017, 10(3): 778-788. |

| 2 | Chan T W, Meloche E, Kubsh J, et al. Evaluation of a gasoline particulate filter to reduce particle emissions from a gasoline direct injection vehicle[J]. SAE International Journal of Fuels and Lubricants, 2012, 5(3): 1277-1290. |

| 3 | Graskow B R, Kittelson D B, Ahmadi M R, et al. Exhaust particulate emissions from a direct injection spark ignition engine[J]. SAE Transactions, 1999(1): 602-609. |

| 4 | 胡志远, 赵心语, 夏孝程, 等. 国Ⅵ GDI汽油车颗粒物排放特性与微观形貌特征[J]. 同济大学学报: 自然科学版, 2020, 48(2): 241-248. |

| Hu Zhi-yuan, Zhao Xin-yu, Xia Xiao-cheng, et al. Emission characteristics and microscopic morphology of particles from a gasoline direct injection vehicle based on china Ⅵ emission regulation[J]. Journal of Tongji University(Natural Science), 2020, 48(2): 241-248. | |

| 5 | Hiroshi O, Preechar K, Katsunori H. Visualization of oxidation of soot nanoparticles trapped on a diesel particulate membrane filter[J]. SAE International Journal of Engines, 2011, 4(1): 515-526. |

| 6 | Park K, Cao F, Kittelson D B, et al. Relationship between particle mass and mobility for diesel exhaust particles[J]. Environmental Science & Technology, 2003, 37(3): 577-583. |

| 7 | Zelenyuk A, Wilson J, Imre D, et al. Detailed characterization of particulate matter emitted by lean-burn gasoline direct injection engine[J]. International Journal of Engine Research, 2016, 18(5/6): 560-572. |

| 8 | Zervas E, Dorlhène P, Daviau R, et al. Repeatability of fine particle measurement of diesel and gasoline vehicles exhaust gas[J]. SAE Technical Papers, 2004-01-1983. |

| 9 | Montajir R M, Kawai T, Goto Y, et al. Thermal conditioning of exhaust gas: potential for stabilizing diesel nano-particles[C]∥SAE 2005 World Congress & Exhibition, Japan, 2005-01-0187. |

| 10 | 潘锁柱. 缸内直喷汽油机排气微粒物理化学特征的研究[D]. 天津: 天津大学机械工程学院,2012. |

| Pan Suo-zhu. Study on the physicochemical characteristics of exhaust particulates from gasoline direct injection engine[D]. Tianjin: School of Mechanical Engineering, Tianjin University, 2012. | |

| 11 | Kittelson D B. Engines and nanoparticles: a review[J]. Journal of Aerosol Science, 1998, 29(5/6):575-588. |

| 12 | Raatz T, Mueller E. Examination of particle size distribution of homogeneous and conventional diesel combustion[C]∥ SAE Technical Paper, 2001-01-3576. |

| 13 | Schneider J, Hock N, Weimer S, et al. Nucleation particles in diesel exhaust: composition inferred from in situ mass spectrometric analysis[J]. Environmental Science & Technology, 2005, 39(16): 6153-6161. |

| 14 | Sementa P, Maria V B, Catapano F. Thermodynamic and optical characterizations of a high performance GDI engine operating in homogeneous and stratified charge mixture conditions fueled with gasoline and bioethanol[J]. Fuel, 2011, 90(7): 204-219. |

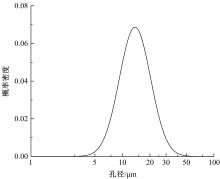

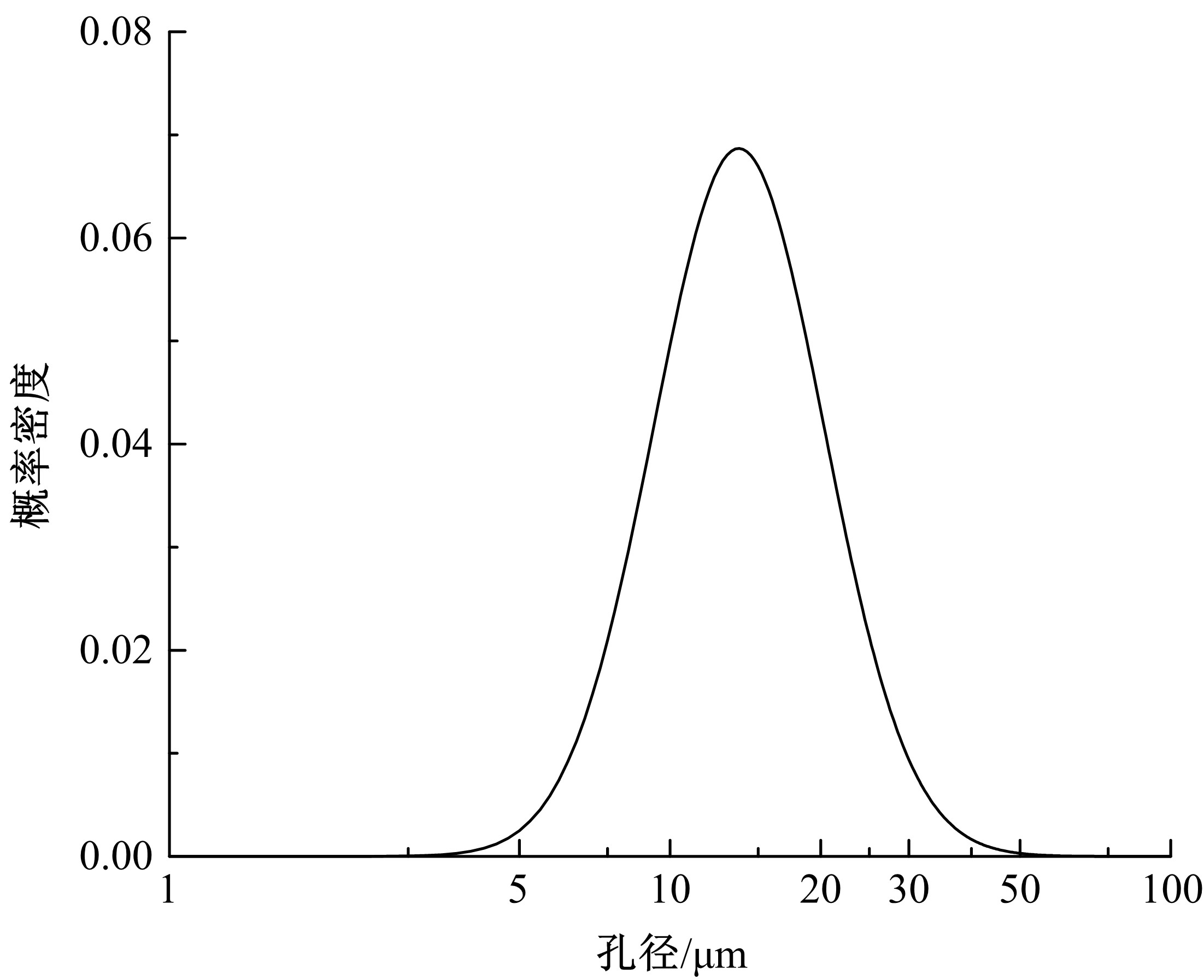

| 15 | Gong J, Stewart M L, Zelenyuk A, et al. Importance of filter's microstructure in dynamic filtration modeling of gasoline particulate filters (GPFs): inhomogeneous porosity and pore size distribution[J]. Journal of Chemical Engineering, 2018, 338: 15-26. |

| 16 | Cho H K, Park C G, Shin H J, et al. Comparison of the in vitro toxicological activity of various particulate matter[J]. Toxicology and Industrial Health, 2018, 34(2): 99-109. |

| 17 | 鲍晓峰, 吕猛, 朱仁成. 中国轻型汽车排放控制标准的进展[J]. 汽车安全与节能学报, 2017, 8(3): 213-225. |

| Bao Xiao-feng, Lv Meng, Zhu Ren-cheng. Progress of emission control standards for light-duty vehicles in China [J]. Journal of Automotive Safety and Energy, 2017, 8(3): 213-225. | |

| 18 | Swanson J, Watts W, Kittelson D, et al. Filtration efficiency and pressure drop of miniature diesel particulate filters[J]. Aerosol Science and Technology, 2013, 47(4): 452-461. |

| 19 | Ohno K, Taoka N, Furuta T, et al. Characterization of high porosity SiC-DPF[C]∥SAE Technical Paper, 2002-01-0325. |

| 20 | Konstandopoulos A G, Skaperdas E, Masoudi M. Microstructural properties of soot deposits in diesel particulate traps[C]∥SAE Technical Paper, 2002-01-1015. |

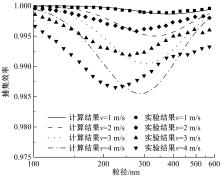

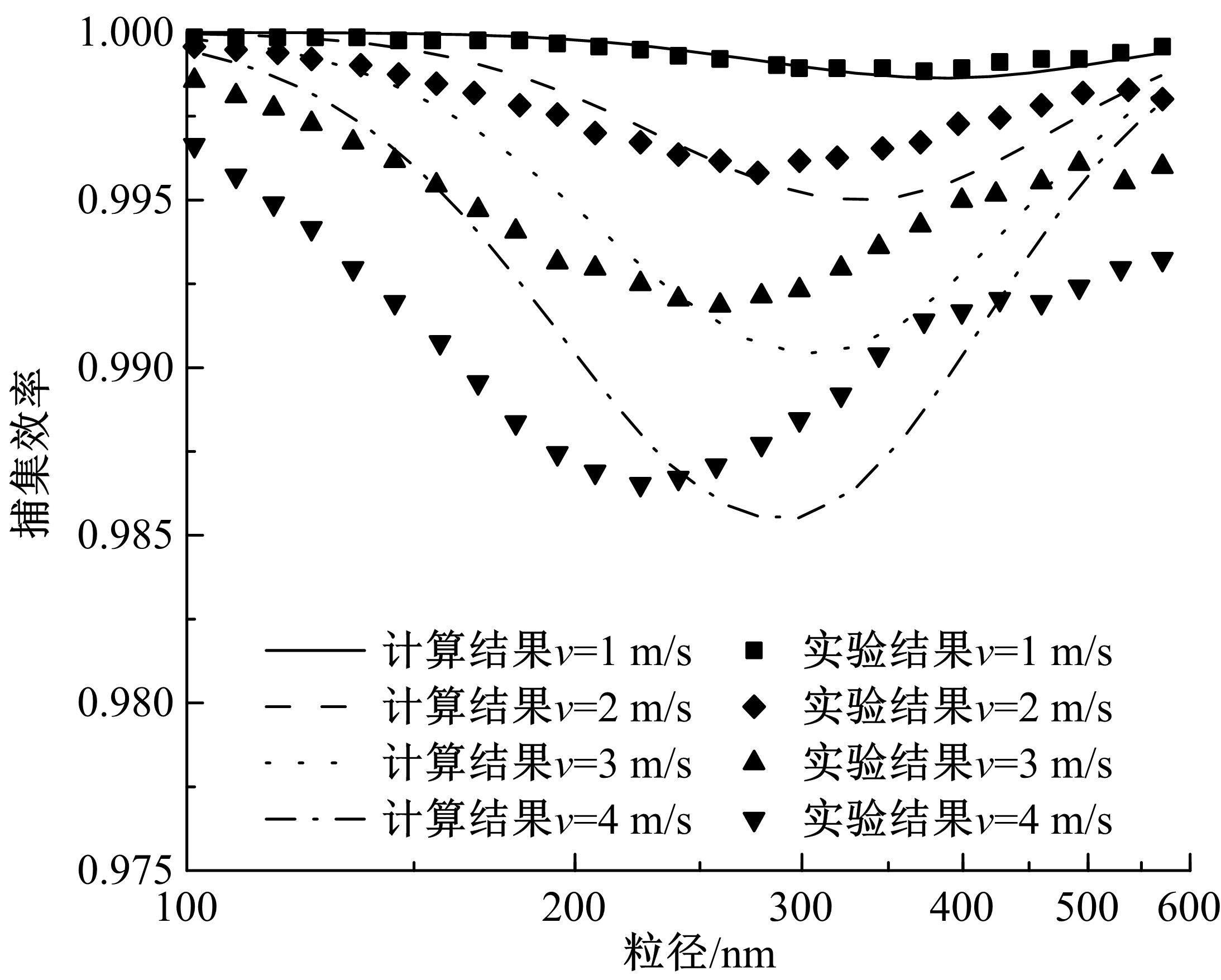

| 21 | Viswanathan S, Rothamer D, Sakai S, et al. Effect of particle size distribution on the deep-bed capture efficiency of an exhaust particulate filter[J]. Journal of Engineering for Gas Turbines and Power, 2015, 137(10): 101504. |

| 22 | Adam F, Olfert J, Wong K F, et al. Effect of engine-out soot emissions and the frequency of regeneration on gasoline particulate filter ef-ficiency[C]∥SAE Technical Paper, 2020-01-1431. |

| 23 | Liu X, Chanko T, Lambert C, et al. Gasoline particulate filter efficiency and backpressure at very low mileage[C]∥SAE Technical Paper, 2018-01-1259. |

| 24 | Joshi A, Johnson T V. Gasoline particulate filters—a review[J]. Emission Control Science and Technology, 2018, 4(4): 219-239. |

| 25 | Li X, Dallmann T R, May A A, et al. Size distribution of vehicle emitted primary particles measured in a traffic tunnel[J]. Atmospheric Environment, 2018, 191: 9-18. |

| 26 | Merkel G A, Beall D M, Hickman D L, et al. Effects of microstructure and cell geometry on performance of cordierite diesel particulate filters[C]∥SAE Technical Paper, 2001-01-0193. |

| 27 | Gong J, Rutland C J. PDF-based heterogeneous multiscale filtration model[J]. Environmental Science & Technology, 2015, 49(8): 4963-4970. |

| 28 | Václavík M, Plachá M, Kočí P, et al. Structure characterisation of catalytic particulate filters for automotive exhaust gas aftertreatment[J]. Materials Characterization, 2017, 134: 311-318. |

| 29 | Gong J, Viswanathan S, Rothamer D A, et al. Dynamic heterogeneous multiscale filtration model: probing microand macroscopic filtration characteristics of gasoline particulate filters[J]. Environ Sci Technol, 2017, 51(19): 11196-11204. |

| 30 | Karin P, Cui L, Rubio P, et al. Microscopic visualization of PM trapping and regeneration in micro-structural pores of a DPF wall[J]. SAE International Journal of Fuels and Lubricants, 2009, 2(1): 661-669. |

| 31 | Konstandopoulos A G, Skaperdas K, Evangelos M, et al. Fundamental studies of diesel particulate filters transient loading regeneration and aging[C]∥SAE Technical Paper, 2000-01-1016. |

| 32 | Serrano J R, Climent H, Piqueras P, et al. Filtration modelling in wall-flow particulate filters of low soot penetration thickness[J]. Energy, 2016, 112: 883-898. |

| 33 | Serrano J R, Arnau F J, Piqueras P, et al. Packed bed of spherical particles approach for pressure drop prediction in wall-flow DPFs (diesel particulate filters) under soot loading conditions[J]. Energy, 2013, 58: 644-654. |

| 34 | Marre S, Palmeri J, Larbot A, et al. Modeling of submicrometer aerosol penetration through sintered granular membrane filters[J]. Journal of Colloid & Interface Science, 2004, 274(1): 167-182. |

| 35 | Saito C, Nakatani T, Miyairi Y, et al. New particulate filter concept to reduce particle number emissions[C]∥SAE Technical Paper, 2011-01-0814. |

| [1] | Wen-biao GONG,Rui ZHU,Xin-zhe QIE,Heng CUI,Ming-yue GONG. Microstructure and properties of 6082 aluminum alloyultra⁃thick plate preparated by friction stir weld [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 512-519. |

| [2] | Jian WANG,Xin XU,Han GU,Duo-jun ZHANG,Sheng-ji LIU. Heating characteristics of DOC based on exhaust thermal management of diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 408-416. |

| [3] | Chang-qing SONG,Wen-miao CHEN,Jun LI,Da-wei QU,Hao CUI. Effects of single and dual ignition on combustion characteristics of natural gas under different equivalence ratios [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1929-1935. |

| [4] | Yi-xiao ZHU,Xiao-min HE,Yi JIN. Effects of radial strut width on flow structure ofsingle⁃cavity trapped vortex combustor [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1936-1944. |

| [5] | Chang-cheng LIU,Zhong-chang LIU,Jing TIAN,Yun XU,Ze-yu YANG. In⁃cylinder exergy destruction during combustion process ofheavy⁃duty turbocharged diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1911-1919. |

| [6] | Qiao WANG,Wan-chen SUN,Liang GUO,Peng CHENG,Lu-yan FAN,Guo-liang LI. Effects of butanol/diesel blends on combustion and particulate emission characteristics of compression ignition engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1920-1928. |

| [7] | Xiao-yu HU,Guo-xiang LI,Shu-zhan BAI,Ke SUN,Si-yuan LI. Modified boiling heat transfer model considering roughness and material of heating surface [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1945-1950. |

| [8] | Xin TONG,Ya-jiao ZHANG,Yu-shan HUANG,Zheng-zheng HU,Qing WANG,Zhi-hui ZHANG. Microstructure and mechanical properties of 304L stainless steel processed by selective laser melting [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1615-1621. |

| [9] | De⁃jun WANG,Zhi⁃chao LYU,Qi⁃ming WANG,Jian⁃rui ZHANG,Jian⁃nan DING. Cylinder pressure identification based on EKF and frequency⁃amplitude modulation Fourier series [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1174-1185. |

| [10] | Jin⁃zhong LU,Wan⁃ting ZHOU,Sheng⁃yang ZHANG,Yi⁃kai SHAO,Chang⁃yu WANG,Kai⁃yu LUO. Effect of coverage layer on corrosion resistance of 6061⁃T6 aluminum alloy subjected to laser shock peening [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 842-849. |

| [11] | Peng⁃fei ZANG,Zhe WANG,Yang GAO,Chen⁃le SUN. Investigation of integrated control strategy for stable operation of linear generator/engine system [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 798-804. |

| [12] | JIANG Tao,LIN Xue-dong,LI De-gang,YANG Miao,TANG Xue-lin. Effect of control parameters on heat release rate with ANN method [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1747-1754. |

| [13] | JIANG Qiu-yue,YANG Hai-feng,TAN Cai-wang. Strengthening properties of welded joints of 22MnB5 super high strength steel [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1806-1810. |

| [14] | QIN Jing, XU He, PEI Yi-qiang, ZUO Zi-nong, LU Li-li. Influence of initial temperature and initial pressure on premixed laminar burning characteristics of methane-dissociated methanol flames [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1475-1482. |

| [15] | LIN Xue-dong, JIANG Tao, XU Tao, LI De-gang, GUO Liang. Control strategy of high pressure pump in starting condition of high pressure common rail diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1436-1443. |

|

||