Journal of Jilin University(Engineering and Technology Edition) ›› 2020, Vol. 50 ›› Issue (2): 512-519.doi: 10.13229/j.cnki.jdxbgxb20190241

Microstructure and properties of 6082 aluminum alloyultra⁃thick plate preparated by friction stir weld

Wen-biao GONG1( ),Rui ZHU1,Xin-zhe QIE1,Heng CUI2,Ming-yue GONG2

),Rui ZHU1,Xin-zhe QIE1,Heng CUI2,Ming-yue GONG2

- 1.Key Laboratory of Advanced Structural Materials, Ministry of Education, Changchun University of Technology, Changchun 130012, China

2.Changchun Railway Vehicles Co. Ltd. , Changchun 130062, China

CLC Number:

- TG456.9

| 1 | 牛得田. 铝合金车体在轨道车辆上的应用及展望[J]. 机车车辆工艺, 2003(3): 1-2. |

| Niu De-tian. Application of Al alloy carbody to railway vehicles and its prospects[J]. Locomotive & Rolling Stock Technology, 2003(3): 1-2. | |

| 2 | 盛建辉, 彭家仁, 李光, 等. 搅拌摩擦焊工艺及其在地铁铝合金车体上的应用[J]. 电力机车与城轨车辆, 2009, 32(3): 28-31. |

| Sheng Jian-hui,Peng Jia-ren, Li Guang, et al. Friction stir welding technology and its application on metro aluminum alloy car body[J]. Electric Locomotive and the Urban Rail Vehicles, 2009, 32(3): 28-31. | |

| 3 | 杨悦, 周磊磊. 微弧氧化对铝合金搅拌摩擦焊缝耐蚀性能的影响[J]. 吉林大学学报: 工学版, 2016, 46(2): 511-515. |

| Yang Yue,Zhou Lei-lei. Effect of micro-arc oxidation treatment on corrosion resistance of aluminum friction stir welding welds[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(2): 511-515. | |

| 4 | 黎俊初, 周德生, 刘大海, 等. 2A12铝合金筋板件T型搅拌摩擦焊工艺及焊后热处理[J]. 材料科学与工艺, 2011, 19(2): 80-85, 91. |

| Li Jun-chun, Zhou De-sheng, Liu Da-hai, et al. Friction stir welding and successive heat treatment of T-shaped rib-web parts of 2A12 aluminium alloy[J]. Materials Science &Technology, 2011, 19(2): 80-85, 91. | |

| 5 | 杨模聪, 孙中刚, 马锐, 等. 2060搅拌摩擦焊对接接头显微组织与析出相分析[J]. 材料科学与工艺, 2014, 22(5): 119-123. |

| Yang Mo-cong, Sun Zhong-gang, Ma Rui, et al. Analysis for microstricture and precipitation phase evolution of friction stir welding 2060 butt jiont[J]. Materials Science and Technology, 2014, 22(5): 119-123. | |

| 6 | 张秋征, 宫文彪, 刘杰. 6005A-T6铝合金厚板单面与双面搅拌摩擦焊的性能比较[J]. 材料热处理学报, 2014, 35(6): 75-79. |

| Zhang Qiu-zheng, Gong Wen-biao, Liu Jie. Property comparison of aluminum alloy 6005A-T6 thick plate by single-sided and double-sided processes of friction stir welding[J]. Transactions of Materials and Heat Treatment, 2014, 35(6): 75-79. | |

| 7 | 罗维, 贺地求, 邬红光, 等. 22 mm 6061-T6铝合金板的搅拌摩擦焊接[J]. 金属铸锻焊技术, 2010, 39(15): 130-132. |

| Luo Wei, He Di-qiu, Wu Hong-guang, et al. Friction stir welding of 22 mm plate of 6061-T6 aluminum alloy plate[J]. Casting Forging Welding, 2010, 39(15): 130-132. | |

| 8 | Ma Z, Chen D, Liu H, et al. Microstructure and properties of welding joints of 30 mm thickness 7A52 aluminum alloy plate by friction stir welding[J]. Ordnance Material Science & Engineering, 2014, 37(2): 63-65. |

| 9 | He D, Luo W, Wu H. Microstructure and mechanical property analysis on double-sided friction stir welding joints of 60 mm 6061-T6 aluminum alloy plate[J]. Journal of Materials Engineering, 2011, 1(9): 20-24. |

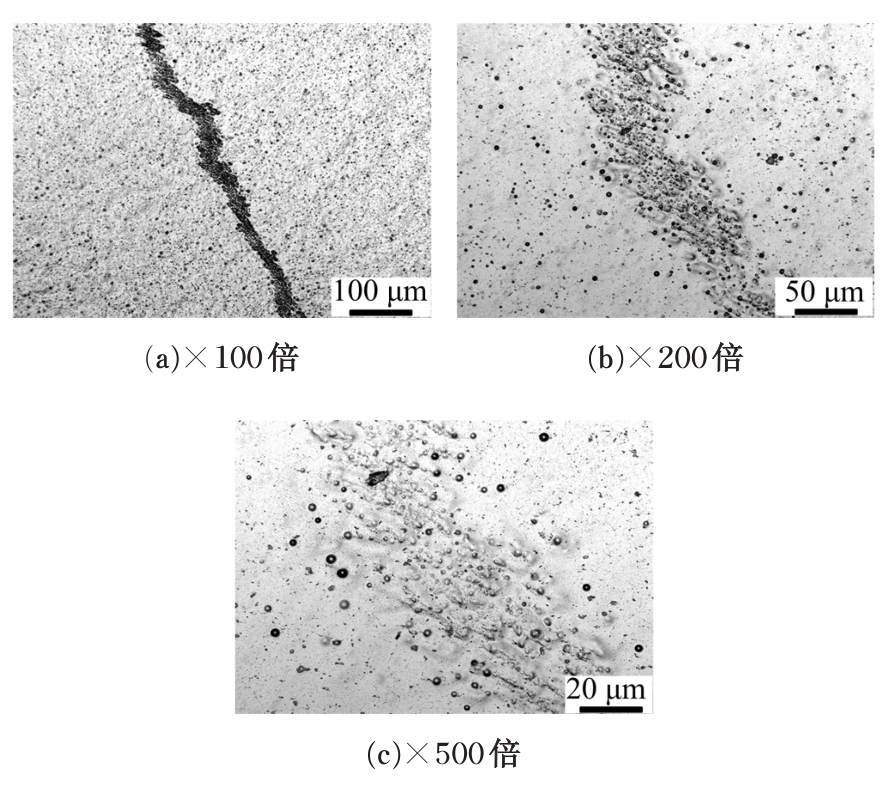

| 10 | Zhang Z, Xiao B L, Ma Z Y. Effect of segregation of secondary phase particles and “S” line on tensile fracture behavior of friction stir-welded 2024Al-T351 joints[J]. Metallurgical & Materials Transactions A, 2013, 44(9): 4081-4097. |

| 11 | Di S, Yang X, Fang D, et al. The influence of zigzag-curve defect on the fatigue properties of friction stir welds in 7075-T6 Al alloy[J]. Materials Chemistry & Physics, 2007, 104(2/3): 244-248. |

| 12 | Okamura H, Aota K, Sakamoto M, et al. Behavior of oxides during friction stir welding of aluminum alloy and their effect on its mechanical properties[J]. Welding International, 2002, 16(4): 266-275. |

| 13 | Scialpi A, Filippis L A C D, Cavaliere P. Influence of shoulder geometry on microstructure and mechanical properties of friction stir welded 6082 aluminum alloy[J]. Material & Design, 2007, 28(4): 1124-1129. |

| 14 | Adamowski J, Szkodo M. Friction stir welds(FSW) of aluminum alloy AW6082-T6[J]. Journal of Achievements in Materials and Manufacturing Engineering, 2007, 20(1/2): 403-406. |

| 15 | Xu W F, Liu J H. Microstructure evolution along thickness in double-side friction stir welded 7085 Al alloy[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(10): 3212-3222. |

| 16 | Yadav D, Bauri R. Effect of friction stir processing on microstructure and mechanical properties of aluminium[J]. Materials Science & Engineering A, 2012, 539: 85-92. |

| 17 | Denquin A, Allehaux D, Campagnac M H, et al. Relationship between microstructural variations and properties of a friction stir welded 6056 aluminum alloy[J]. Welding in the World, 2002, 46(11/12): 14-19. |

| 18 | 李于朋, 孙大千, 宫文彪. 6082-T6铝合金薄板双轴肩搅拌摩擦焊温度场[J]. 吉林大学学报: 工学版, 2019, 49(3): 836-841. |

| Li Yu-peng, Sun Da-qian, Gong Wen-biao. Temperature fields in bobbin-tool friction stir welding for 6082-t6 aluminum alloy sheet[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(3): 836-841. | |

| 19 | Andersen S J, Zandbergen H W, Jansen J, et al. The crystal structure of the β'' phase in Al-Mg-Si alloys[J]. Acta Materialia, 2007, 46(9): 3283-3298. |

| 20 | 王冰. 6082-T6铝合金搅拌摩擦焊接头微观组织及力学性能的研究[D]. 长春: 吉林大学材料科学与工程学院, 2015. |

| Wang Bing. Study on microstructures and mechanical properties of friction stir welding joints of 6082-T6 aluminum alloy[D]. Changchun: College of Materials Science and Engineering, Jilin University, 2015. | |

| 21 | Murayama M, Hono K. Pre-precipitate clusters and precipitation processes in Al-Mg-Si alloys[J]. Acta Materialia, 1999, 47(5): 1537-1548. |

| 22 | 王希靖, 魏学玲, 张亮亮. 6082-T6铝合金搅拌摩擦焊组织演变与力学性能[J]. 焊接学报, 2018, 39(3): 1-5. |

| Wang Xi-jing, Wei Xue-ling, Zhang Liang-liang. Microstructure evolution and mechanical properties of 6082-T6 Al alloy friction stir welding[J]. Transactions of the China Welding Institution, 2018, 39(3): 1-5. |

| [1] | Jin-guo WANG,Shuai REN,Rui-fang YAN,Kai HUANG,Zhi-qiang WANG. Effect of TiC particles on microstructure and mechanical properties of as cast ductile iron [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 2010-2018. |

| [2] | De-lei YANG,Le-wei TONG. Calculation formula of SCF for CHS⁃CFSHS welded T⁃joints with brace under axial tension [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1891-1899. |

| [3] | Ming LI,Hao-ran WANG,Wei-jian ZHAO. Mechanical properties of laminated slab with shear keys [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1509-1520. |

| [4] | Xin TONG,Ya-jiao ZHANG,Yu-shan HUANG,Zheng-zheng HU,Qing WANG,Zhi-hui ZHANG. Microstructure and mechanical properties of 304L stainless steel processed by selective laser melting [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1615-1621. |

| [5] | Jin⁃zhong LU,Wan⁃ting ZHOU,Sheng⁃yang ZHANG,Yi⁃kai SHAO,Chang⁃yu WANG,Kai⁃yu LUO. Effect of coverage layer on corrosion resistance of 6061⁃T6 aluminum alloy subjected to laser shock peening [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 842-849. |

| [6] | Na WU,Jian ZHUANG,Ke⁃song ZHANG,Hui⁃xin WANG,Yun⁃hai MA. Compression mechanical properties and fracture mechanism of Scapharca Subcrenata shell [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 897-902. |

| [7] | Yu⁃peng LI,Da⁃qian SUN,Wen⁃biao GONG. Temperature fields in bobbin⁃tool friction stir welding for 6082⁃T6 aluminum alloy sheet [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 836-841. |

| [8] | JIANG Qiu-yue,YANG Hai-feng,TAN Cai-wang. Strengthening properties of welded joints of 22MnB5 super high strength steel [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1806-1810. |

| [9] | ZHENG Xiao-yi, SUN Da-qian, LI Xin, DU Gui-gang, XIN Wei-da, REN Zhen-an. Microstructure and properties of cladded Al-Nb layers reinforced by NbAl3 [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1531-1536. |

| [10] | ZHAO Yu-guang, YANG Xue-hui, XU Xiao-feng, ZHANG Yang-yang, NING Yu-heng. Effects of Al-10Sr modifiers with different states, modification temperature and holding time on microstructure of ZL114A alloy [J]. 吉林大学学报(工学版), 2018, 48(1): 212-220. |

| [11] | ZHANG Zhi-qiang, LIU Cong-hao, HE Dong-ye, LI Xiang-ji, LI Ji-xuan. Effect of hot stamping process of boron steel on shape precision based on performance gradient distribution [J]. 吉林大学学报(工学版), 2017, 47(6): 1829-1833. |

| [12] | TANG Hua-guo, MA Xian-feng, ZHAO Wei, LIU Jian-wei, ZHAO Zhen-ye. Synthesis microstructure and thermal properties of high performance bulk Al [J]. 吉林大学学报(工学版), 2017, 47(5): 1542-1547. |

| [13] | CUI Ya-nan, HAN Ji-wei, FENG Lei, LI Jia-di, WANG Le. Microstructure of asphalt under salt freezing cycles [J]. 吉林大学学报(工学版), 2017, 47(2): 452-458. |

| [14] | GUAN Qing-feng, HUANG Wei, LI Huai-fu, GONG Xiao-hua, ZHANG Cong-lin, LYU Peng. Diffusion alloying of Cu-C induced by high current pulsed electron beam [J]. 吉林大学学报(工学版), 2016, 46(6): 1967-1973. |

| [15] | ZHOU Feng-dao, WANG Shuang, HAN Si-yu, XU Fei, LIAN Shi-bo, SUN Cai-tang. Improved quadrature detection algorithm for controlled source electromagnetic detection [J]. 吉林大学学报(工学版), 2016, 46(6): 2128-2136. |

|

||