Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (8): 2130-2140.doi: 10.13229/j.cnki.jdxbgxb.20230894

Previous Articles Next Articles

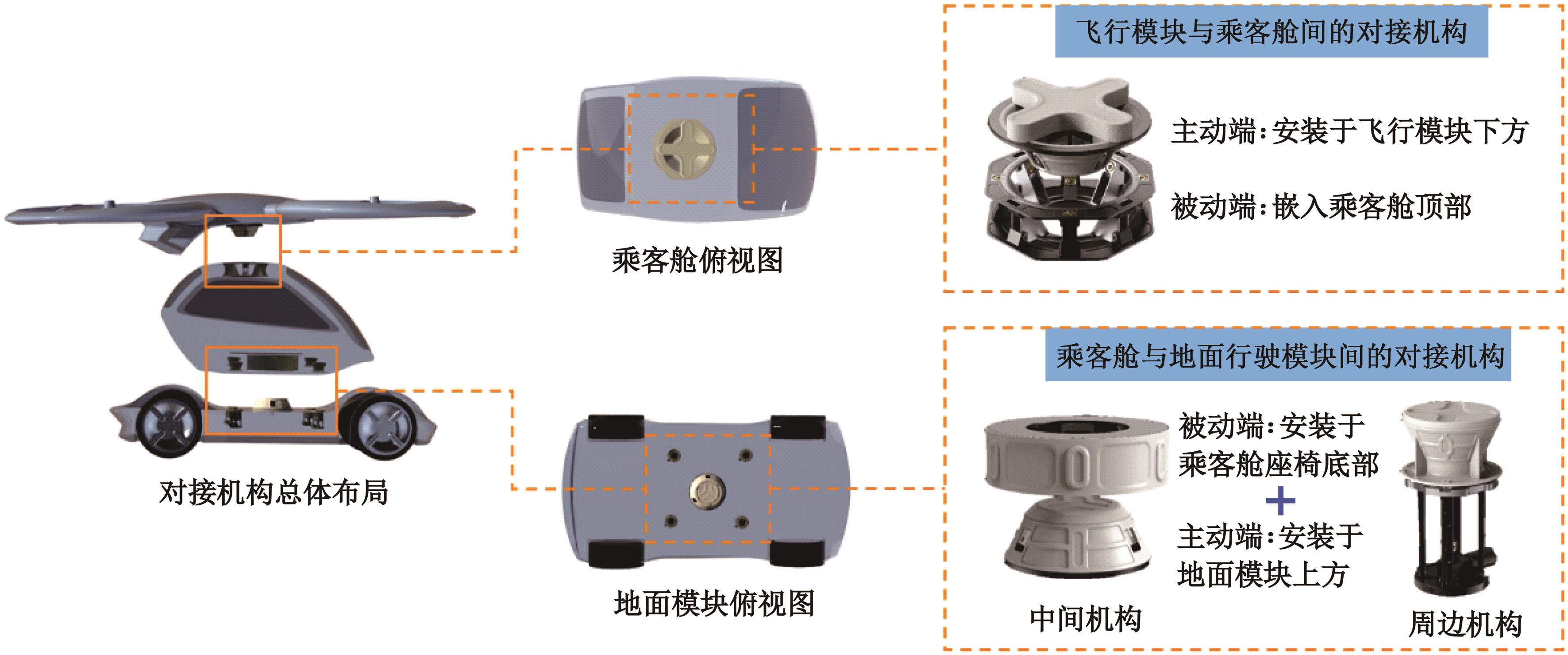

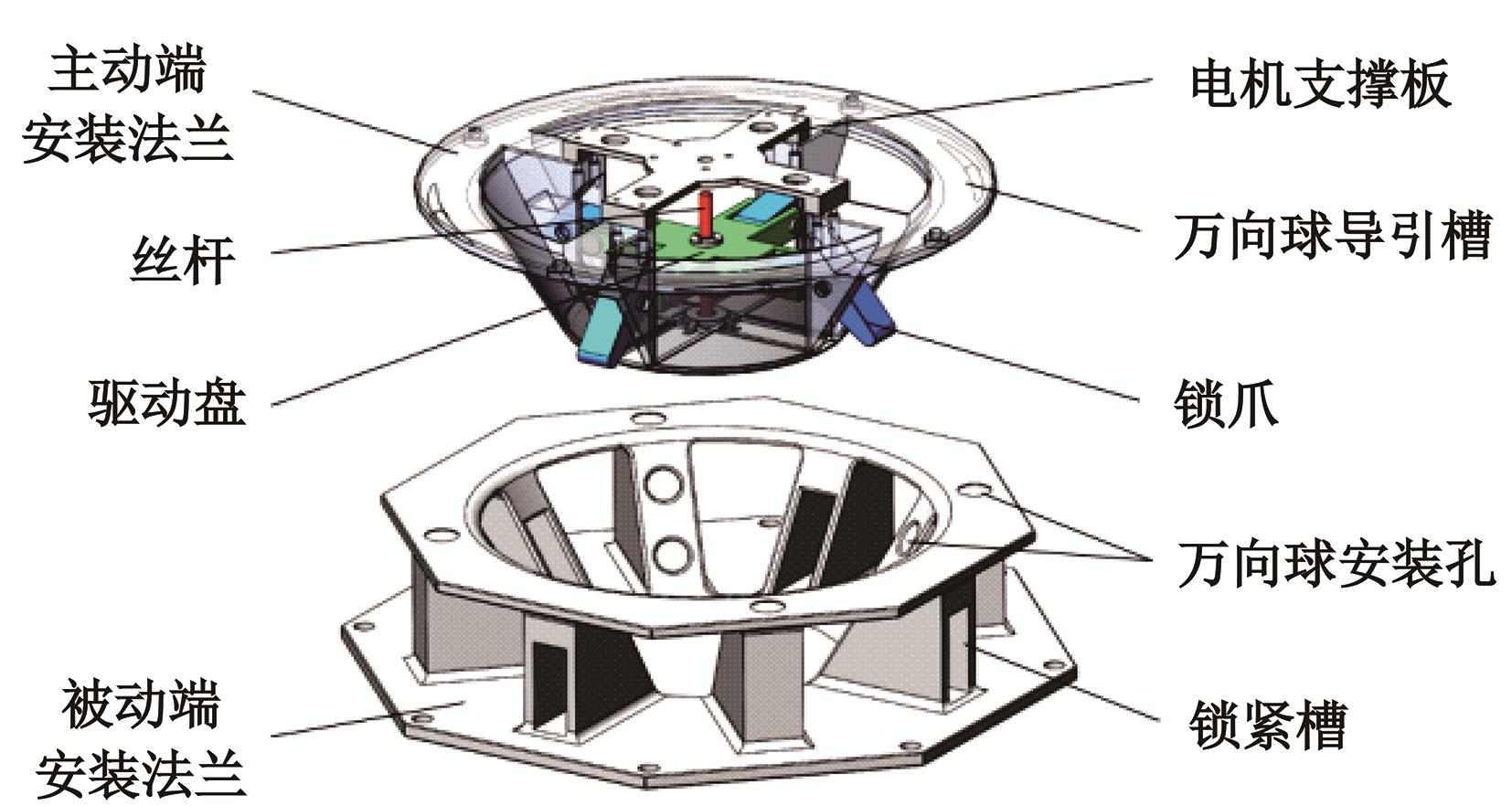

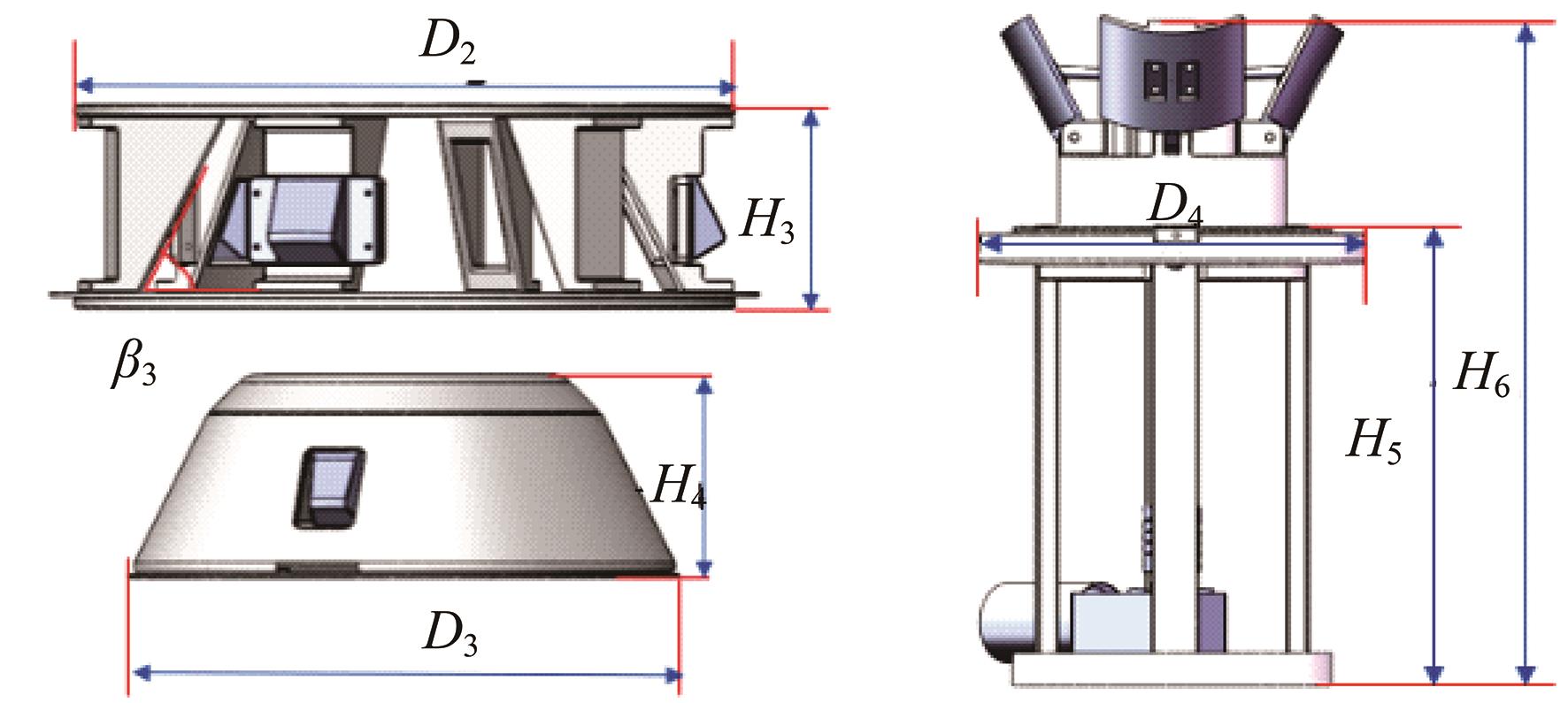

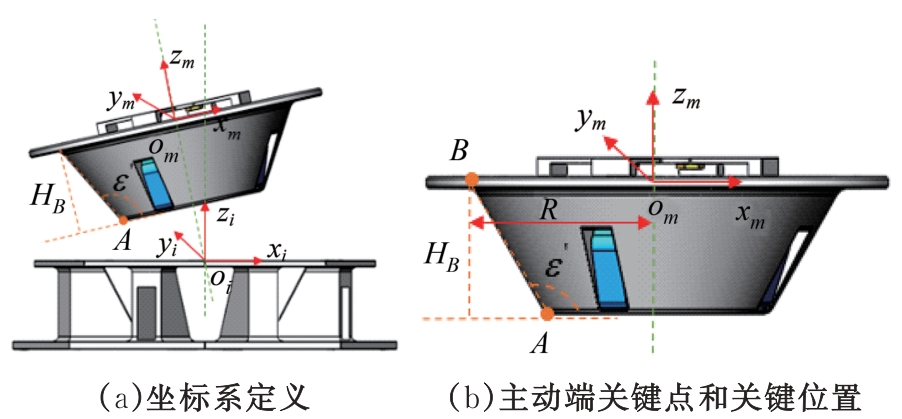

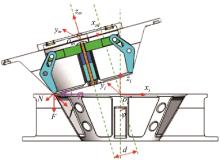

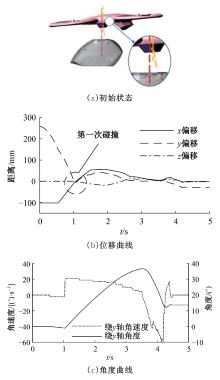

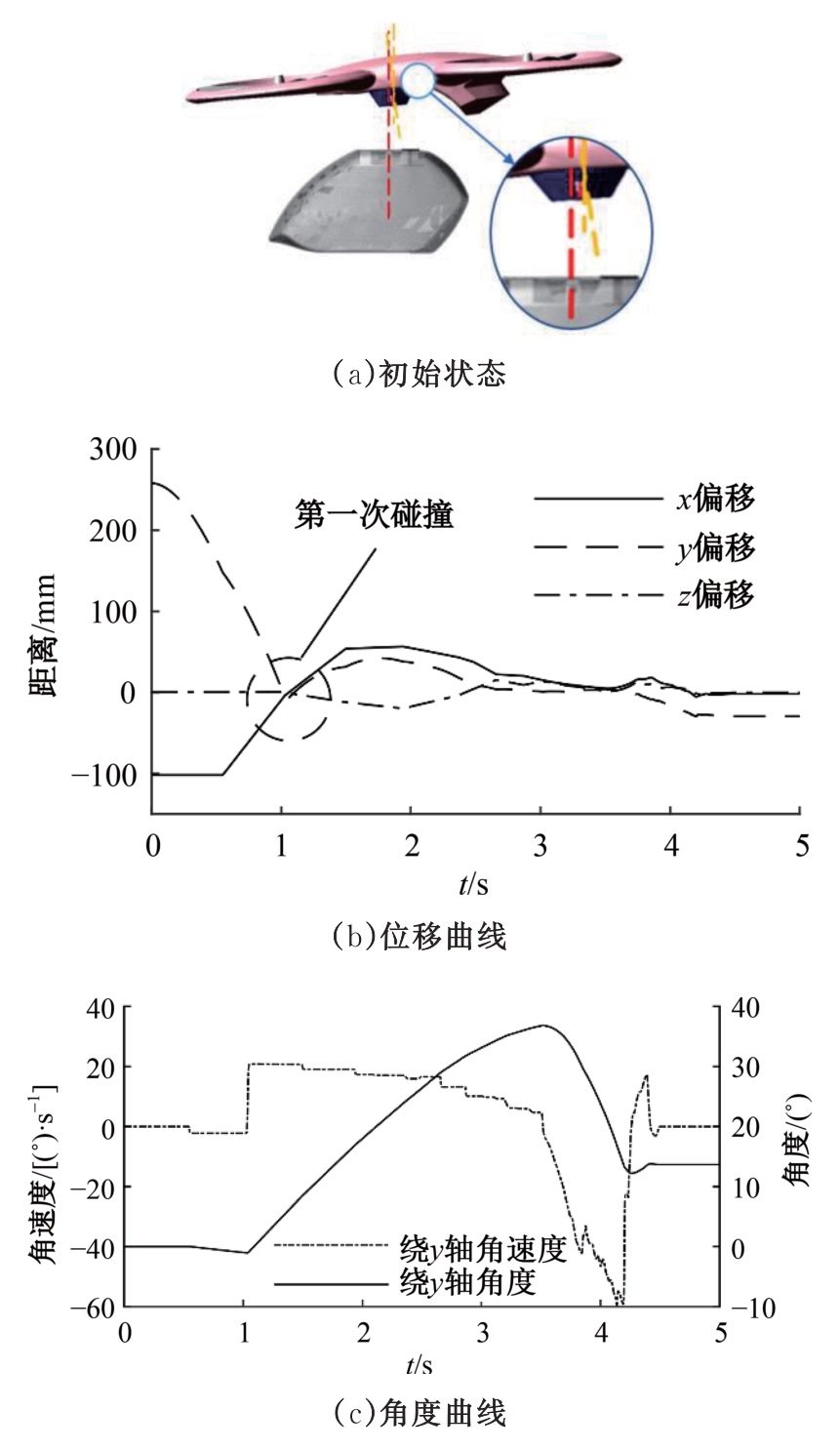

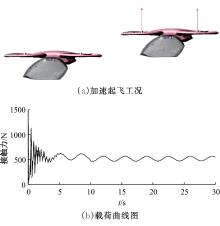

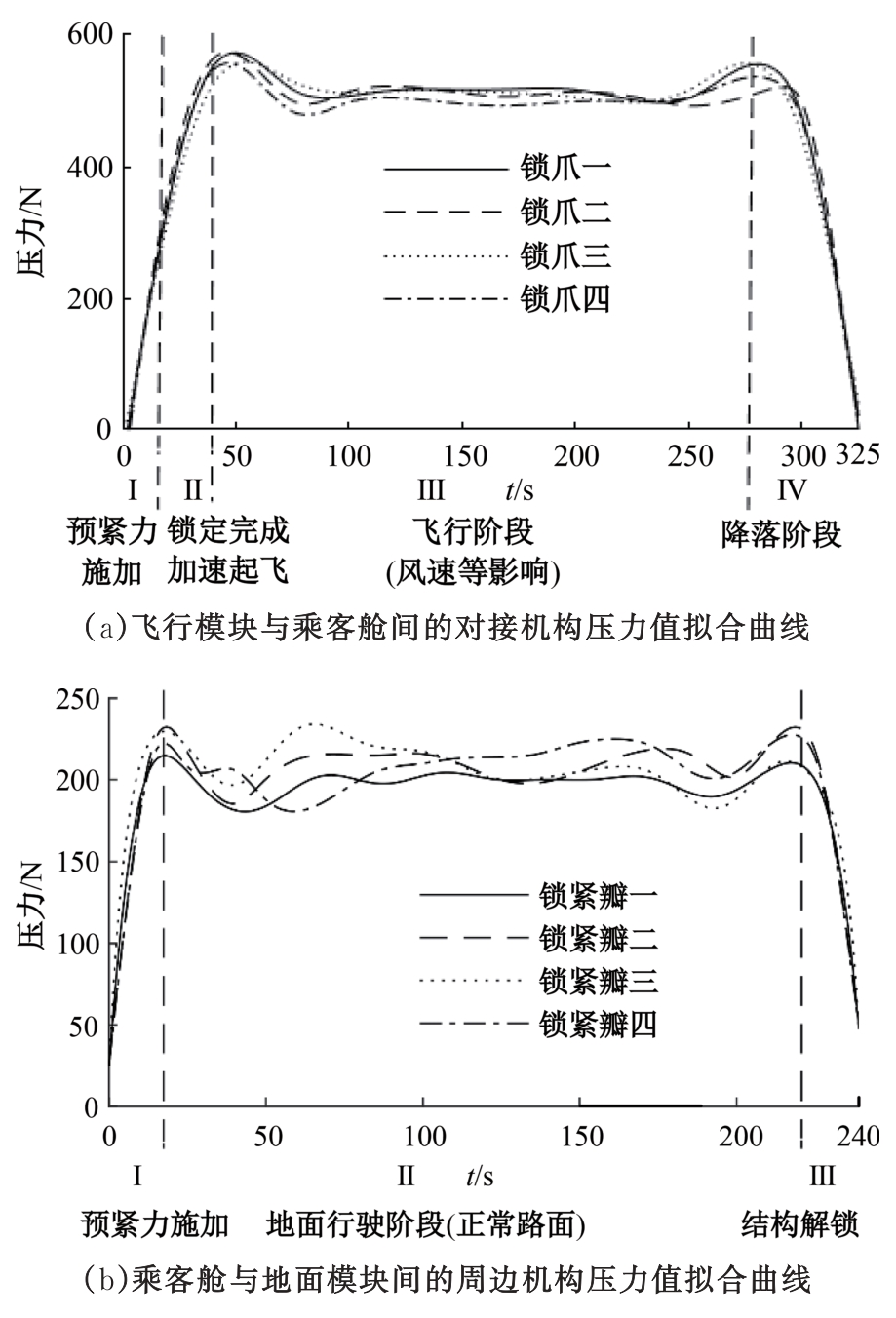

Design and verification of electromechanical system for docking and locking of modular flying vehicle

Chen WANG( ),Te LUO,Qian-qian HUI,Zhong-hao WANG,Fang-fang WANG

),Te LUO,Qian-qian HUI,Zhong-hao WANG,Fang-fang WANG

- School of Construction Machinery,Chang′an University,Xi′an 710064,China

CLC Number:

- TH122

| 1 | 王晓光,管港云,徐嘉铭,等.基于GPS和计算机图像识别的无人机导航系统[J].吉林大学学报:理学版,2022,60(4):955-961. |

| Wang Xiao-guang, Guan Gang-yun, Xu Jia-ming, et al. UAV navigation system based on GPS and computer image recognition[J]. Journal of Jilin University (Science Edition), 2022, 60(4):955-961. | |

| 2 | 满万鑫,李新洪,周思引,等.空间目标在轨捕获方法及关键技术综述[J].空天技术, 2022(6):77-96. |

| Man Wan-xin, Li Xin-hong, Zhou Si-yin, et al. Review of on-orbit capture methods and key technologies of space target[J]. Aerospace Technology, 2022(6):77-96. | |

| 3 | 马常友,高海波,丁亮,等. 机器人末端执行器自更换机构设计及对接策略[J]. 吉林大学学报:工学版, 2019, 49(6): 2027-2037. |

| Ma Chang-you, Gao Hai-bo, Ding Liang, et al. Mechanism design and docking strategy for the end-effectors exchange of the robot[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(6): 2027-2037. | |

| 4 | 郑荣,宋涛,孙庆刚,等. 自主式水下机器人水下对接技术综述[J]. 中国舰船研究, 2018, 13(6): 43-49, 65. |

| Zheng Rong, Song Tao, Sun Qing-gang, et al. Review on underwater docking technology of AUV[J]. Chinese Journal of Ship Research, 2018, 13(6): 43-49, 65. | |

| 5 | 张崇峰,刘志.空间对接机构技术综述[J].上海航天, 2016,33(5):1-11. |

| Zhang Chong-feng, Liu Zhi. Review of space docking mechanism and its technology[J]. Aerospace Shanghai, 2016,33(5):1-11. | |

| 6 | Olivieri L, Francesconi A. Design and test of a semiandrogynous docking mechanism for small satellites[J]. Acta Astronautica, 2016, 122: 219-230. |

| 7 | Pei J, Murchison L, Stewart V, et al. Autonomous rendezvous and docking of two 3u cubesats using a novel permanent-magnet docking mechanism[C]∥54th AIAA Aerospace Sciences Meeting,San Diego, USA, 2016:No.1465. |

| 8 | 李隆球,邵广斌,周德开,等.一种长行程小型化对接机构设计与分析[J].载人航天, 2016,22(6):758-765. |

| Li Long-qiu, Shao Guang-bin, Zhou De-kai, et al. Design and analysis of a long-stroke and miniaturized docking mechanism[J]. Manned Spaceflight, 2016,22(6):758-765. | |

| 9 | 朱超,张文明,胡成威,等.空间站机械臂末端执行器维修系统设计与验证[J].中国空间科学技术,2023,43(5):79-86. |

| Zhu Chao, Zhang Wen-ming, Hu Cheng-wei, et al. Maintenance system design and verification for space station manipulator end-effector[J]. Chinese Space Science and Technology,2023,43(5):79-86. | |

| 10 | 徐升,褚明,孙汉旭.一种空间软对接仿生手腕设计与仿真[J].机械工程学报, 2022,58(13):59-70. |

| Xu Sheng, Chu Ming, Sun Han-xu. Design and simulation of spatially soft-docking bionic wrist[J]. Journal of Mechanical Engineering, 2022,58(13):59-70. | |

| 11 | Wang S, Zhang R, Haggerty D A, et al. A dexterous tip-extending robot with variable-length shape-locking[C]∥ 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 2020:9035-9041. |

| 12 | Yazdani A M, Sammut K, Yakimenko O A,et al. IDVD-based trajectory generator for autonomous underwater docking operations[J]. Robotics and Autonomous Systems,2017,92:12-29. |

| 13 | Page B R, Mahmoudian N. AUV docking and recovery with USV: an experimental study[C]∥OCEANS 2019-Marseille, Marseille, France, 2019: 1-5. |

| 14 | 辛传龙,郑荣,杨博.AUV水下对接系统设计与接驳控制方案研究[J].工程设计学报,2021,28(5):633-645. |

| Xin Chuan-long, Zheng Rong, Yang Bo. Research on the design and connection control scheme of AUV underwater docking system[J]. Chinese Journal of Engineering Design, 2021,28(5):633-645. | |

| 15 | Lu W C, Wang W S. Design of an automatic docking system for quadcopters[C] ∥ 2016 Asia-Pacific Conference on Intelligent Robot Systems (ACIRS),Tokyo, Japan,2016: 199-203. |

| 16 | Lieret M, Wurmer F, Hofmann C, et al. An overhead docking and charging station for autonomous unmanned aircraft[C]∥2021 IEEE 17th International Conference on Automation Science and Engineering (CASE),New York,USA, 2021: 1358-1363. |

| [1] | Yang LIU. Simulation and experiment of elastic roughing for rubber shoe [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2167-2173. |

| [2] | Yang LIU,Tao JIANG. Interference calculation model of Hooke joint of 6-DOF platform considering installation angle [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1519-1527. |

| [3] | Xiao-dan TAN,Yong-peng WANG,Robert Hall,Tian-shuang XU,Qing-xue HUANG. Haul truck dump body optimization for autonomous shovel loading [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1227-1236. |

| [4] | Wei SUN,Jun YANG. Finite element modeling and vibration reduction analysis of cylindrical shell structures with equal⁃angle attachment of piezoelectric shunt patches [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 365-374. |

| [5] | Bin HU,Yi-quan CAI,Xin LUO,Zi-bin MAO,Jun-wei LI,Meng-yu GUO,Jian WANG. Theory and experiment of high⁃speed seed filling in limited gear⁃shaped side space based on seeds group stress [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 574-588. |

| [6] | Yang LIU. Calculation method of anti-backward-tilting buffer force of luffing jib tower crane [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(10): 2785-2794. |

| [7] | Yang ZHAO,Yang XIAO,Hao SUN,Wen-hao HUO,Song FENG,Yong LIAO. Numerical simulation of micro pitting damage characteristics of lubricated contact gears based on contour integral [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 799-810. |

| [8] | Wei ZHENG,Jian-jun SUN,Chen-bo MA,Qiu-ping YU,Yu-yan ZHANG,Tao NIU. Research status and prospect of automobile wheel hub machining fixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 25-36. |

| [9] | Wei CHEN,Yu-long LEI,Xing-zhong LI,Yao FU,Jian-long HU,Li-guo HOU. Calculation of adhesive wear of involute cylindrical spur gear under low⁃speed conditions [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1628-1634. |

| [10] | Zhen GUO,Hong-ying YU,Zhong-xin HUA,Di ZHAO. Kinematic analysis and simulation of folding process for rigid origami mechanisms [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 66-76. |

| [11] | ZHU Wei,WANG Chuan-wei,GU Kai-rong,SHEN Hui-ping,XU Ke,WANG Yuan. Stiffness and dynamics analysis of a new type of tensegrity parallel mechanism [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1777-1786. |

| [12] | WANG Ben, WANG Xiao-li. Key processes of silicon microball bearing [J]. 吉林大学学报(工学版), 2016, 46(3): 824-830. |

|