Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (9): 2697-2707.doi: 10.13229/j.cnki.jdxbgxb.20221420

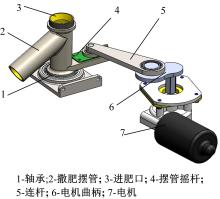

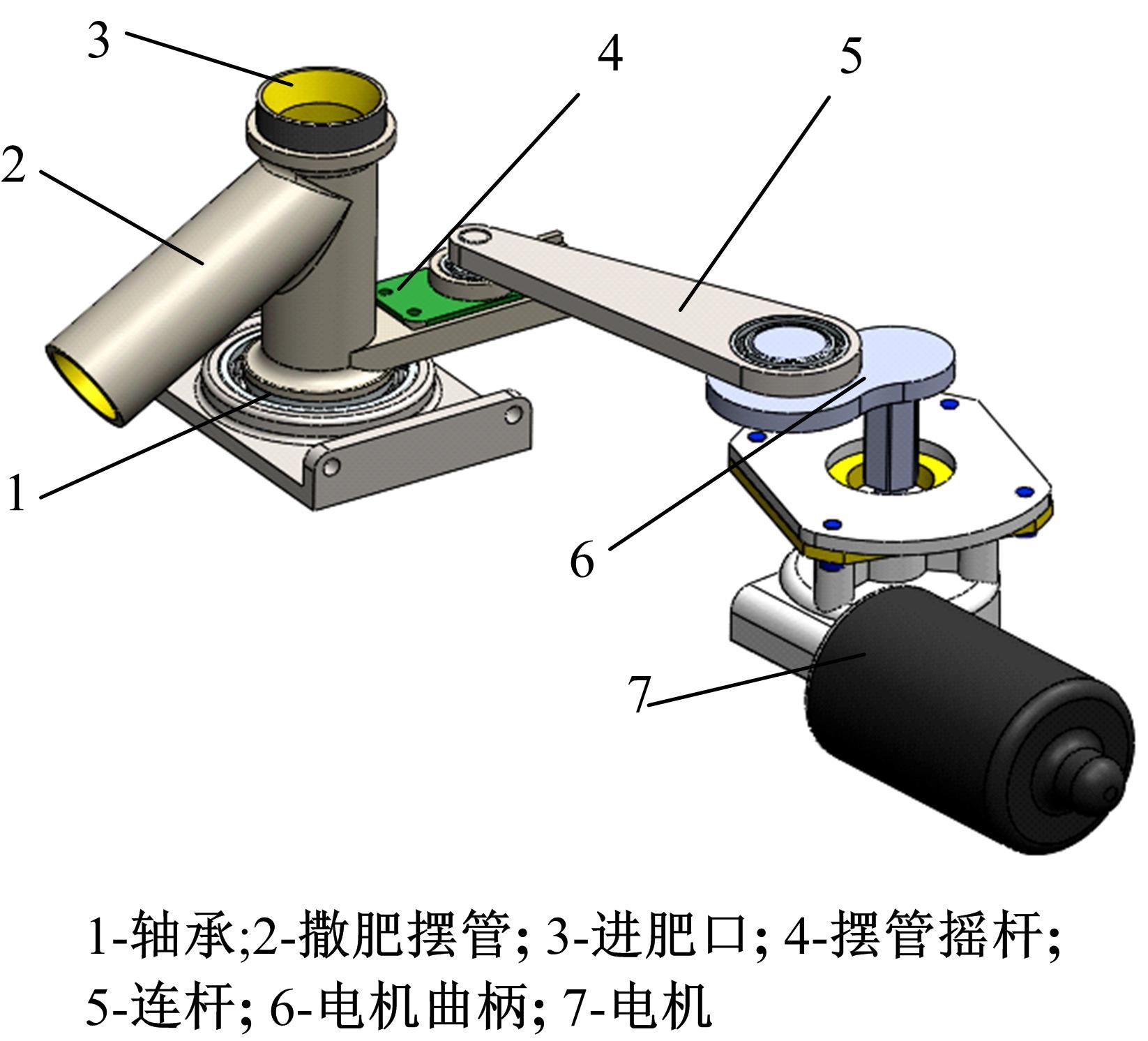

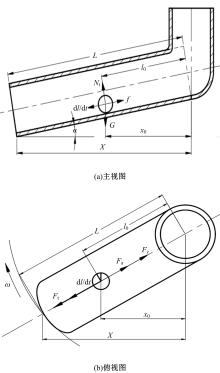

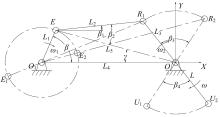

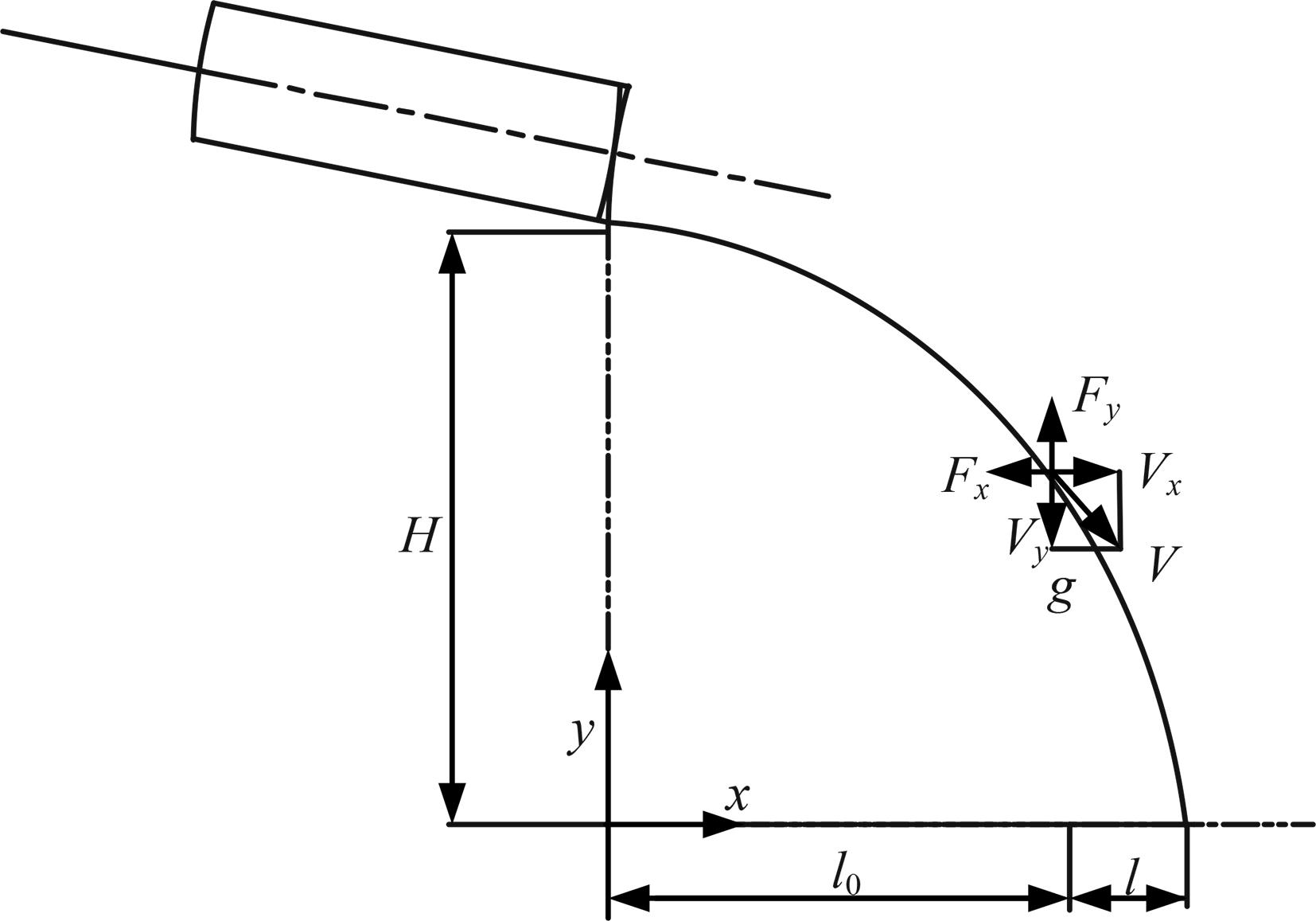

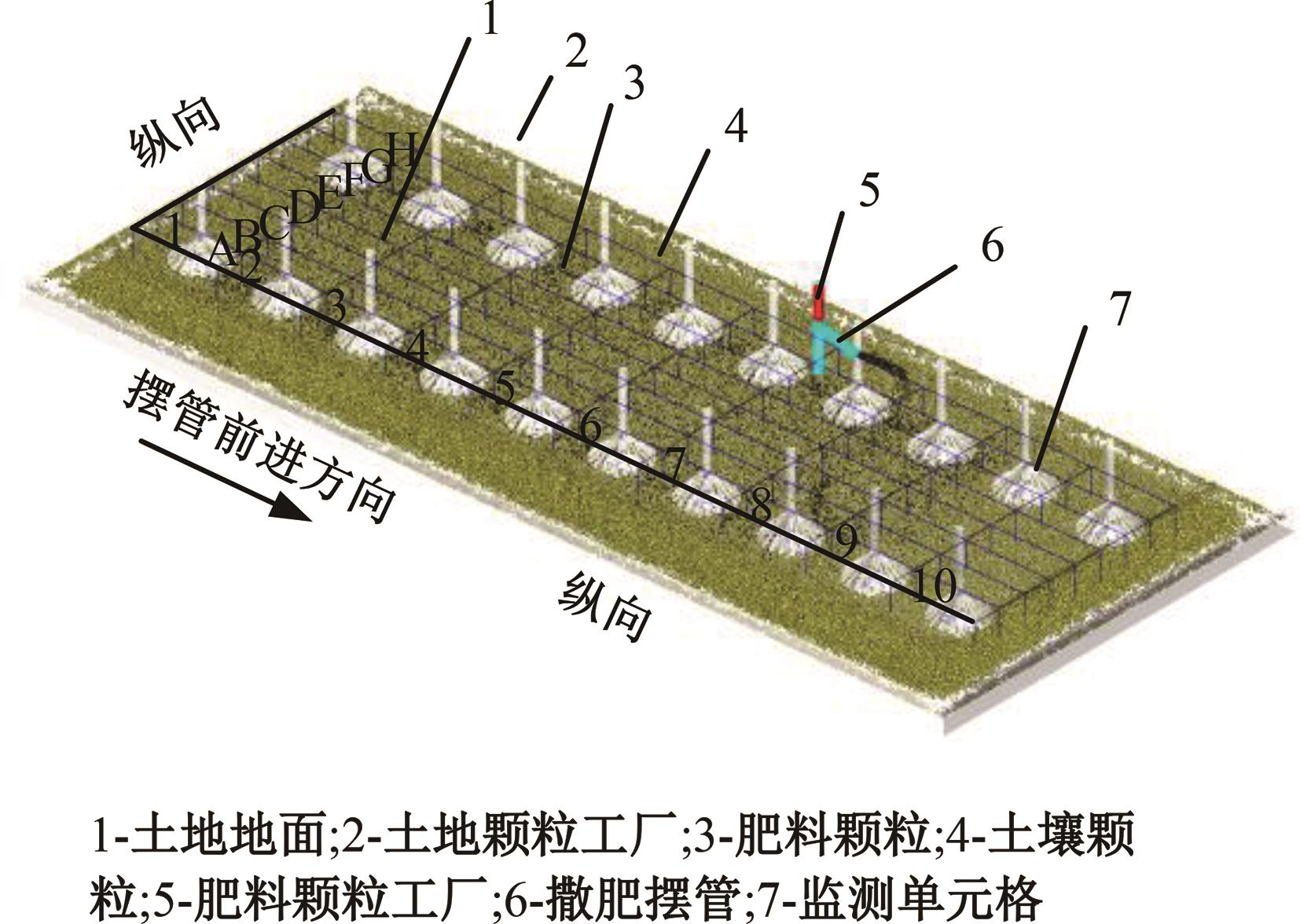

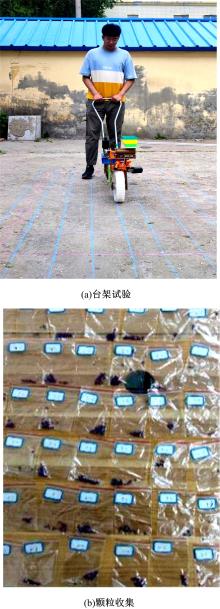

Design and experiment of corn strip swing tube fertilizer spreader

Guo-qiang DUN1,2( ),Xing-peng WU2,Xin-xin JI1,2,Fu-li ZHANG1,Wen-yi JI3,Li-gui ZHU1

),Xing-peng WU2,Xin-xin JI1,2,Fu-li ZHANG1,Wen-yi JI3,Li-gui ZHU1

- 1.Intelligent Agricultural Machinery Equipment Engineering Laboratory,Harbin Cambridge University,Harbin 150069,China

2.College of Mechanical and Electrical Engineering,Northeast Forestry University,Harbin 150040,China

3.College of Engineering,Northeast Agricultural University,Harbin 150030,China

CLC Number:

- S224.2

| 1 | 张东超, 汤智辉, 何义川, 等.基于EDEM离散元法的分层施肥靴仿真与试验[J]. 农机化研究, 2020,42(2): 146-151. |

| Zhang Dong-chao, Tang Zhi-hui, He Yi-chuan, et al. Simulation and experimen of layered fertilizing boots based on EDEM discrete element method[J]. Journal of Agricultural Mechanization Research, 2020, 42(2): 146-151. | |

| 2 | 杨文武, 方龙羽, 罗锡文, 等.螺旋排肥器排肥口参数对排肥性能影响的试验研究[J].农业工程学报,2020, 36(17): 1-8. |

| Yang Wen-wu, Fang Long-yu, Luo Xi-wen, et al. Experimental study of the effects of discharge port parameters on the fertilizing performance for fertilizer distribution apparatus with screw[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(17): 1-8. | |

| 3 | 薛忠, 赵亮, 王凤花, 等.基于EDEM的螺旋式排肥器排肥性能研究[J].农机化研究, 2020, 42(6): 87-95. |

| Xue Zhong, Zhao Liang, Wang Feng-hua, et al. Study on the performance of spiral fertilizer distributor based on EDEM[J]. Journal of Agricultural Mechanization Research, 2020, 42(6):87-95. | |

| 4 | 顿国强, 于春玲, 郭艳玲, 等.叠片式啮合圆弧齿轮排肥器设计与仿真试验[J]. 中国农业科技导报,2020, 22(5): 78-85. |

| Guo-qiang Dun, Yu Chun-ling, Guo Yan-ling, et al. Design and simulation test of laminated-type meshing arc gear fertilizer device [J]. Journal of Agricultural Science and Technology,2020,22(5):78-85. | |

| 5 | 施印炎, 陈满, 汪小旵, 等.稻麦精准变量施肥机排肥性能分析与试验[J]. 农业机械学报, 2017, 48(7):97-103. |

| Shi Yin-yan, Chen Man, Wang Xiao-chan, et al. Analysis and experiment of fertilizing performance for precision fertilizer applicator in rice and wheat fields[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(7): 97-103. | |

| 6 | Coetzee C J, Lombard S G. Discrete element method modelling of a centrifugal fertilizer spreader[J].Biosystems Engineering, 2011, 109(7): 308-325. |

| 7 | 刘宏新, 王佳兴, 苏航, 等.倾斜对置圆盘侧抛式有机肥撒播机设计及关键部件研究[J].东北农业大学学报,2018, 49(8): 83-90, 98. |

| Liu Hong-xin, Wang Jia-xing, Su Hang, et al. Design on side type discharge organic fertilizer spreader with inclined opposite discs and research on its key components[J]. Journal of Northeast Agricultural University, 2018, 49(8): 83-90, 98. | |

| 8 | 张李娴, 吕新民.摆管式撒肥机的研究设计[J].西北农业学报,2009,18(4):372-374. |

| Zhang Li-xian, Lv Xin-min. Research and design on fertilizer spreading machines of swing tube type[J]. Acta Agriculturae Boreali-occidentalis Sinica, 2009,18(4): 372-374. | |

| 9 | 张李娴. 摆管式撒肥机的研究与设计[D]. 杨凌: 西北农林科技大学机械与电子工程学院, 2009. |

| Zhang Li-xian. Research and design on fertilizer spreading machines of swing tube type[D]. Yangling: College of Mechanical and Electronic Engineering,Northwest A&F University, 2009. | |

| 10 | 苟于江,李华英,王大明,等.基于EDEM的小型变量撒肥机设计与仿真优化[J].农机化研究,2022,44(11):65-71, 76. |

| Gou Yu-jiang, Li Hua-ying, Wang Da-ming, et al. Design and simulation parameter optimization of small intelligent variable fertilizer spreader based on EDEM[J]. Journal of Agricultural Mechanization Research, 2022, 44(11): 65-71, 76. | |

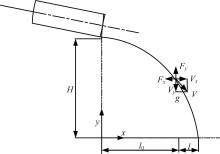

| 11 | 李鹏. 摆管式撒肥机机理与试验研究[D].武汉:华中农业大学,2013. |

| Li Peng. Theoretical and experimental study on fertilizer spreading machines of swing tube type[D]. Wuhan: Huazhong Agricultural University, 2013. | |

| 12 | 何亚凯,赵学观,李翠玲,等.玉米追肥机械施肥技术研究现状与分析[J].农机化研究,2021,43(7):1-9. |

| He Ya-kai, Zhao Xue-guan, Li Cui-ling, et al. Research status and analysis on fertilization technology of corn topdressing machinery[J]. Journal of Agricultural Mechanization Research, 2021,43(7):1-9. | |

| 13 | 顿国强, 于春玲, 郭艳玲, 等. 间隙啮合渐开线齿轮排肥器的结构优化仿真及试验[J]. 华中农业大学学报, 2020, 39(1): 171-179. |

| Guo-qiang Dun, Yu Chun-ling, Guo Yan-ling, et al. Optimization simulation and experiment of structure of interval meshing involute meshing involute gear fertilizer apparatus[J]. Journal of Huazhong Agricultural University, 2020,39(1): 171-179. | |

| 14 | 祝清震, 武广伟, 陈立平, 等. 槽轮结构参数对直槽轮式排肥器排肥性能的影响[J]. 农业工程学报, 2018, 34(18): 12-20. |

| Zhu Qing-zhen, Wu Guang-wei, Chen Li-ping, et al.Influences of structure parameters of straight flute wheel on fertilizing performance of fertilizer apparatus[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(18): 12-20. | |

| 15 | Liu C L, Wang Y L, Song J N, et al. Experimental determination and numerical simulation of granular material restitution coefficient[J]. International Agricultural Engineering Journal, 2016, 25(4): 48-56. |

| 16 | 顿国强, 于春玲, 郭艳玲, 等.双齿轮式排肥器设计与试验[J].农业机械学报,2020,51(3):87-96. |

| Guo-qiang Dun, Yu Chun-ling, Guo Yan-ling, et al. Design and experiment of double-gear type fertilizer apparatus[J]. Transactions of the Chinese Society for Agricultural Machinery,2020,51(3):87-96. | |

| 17 | 顿国强, 刘文辉, 吴星澎, 等. 螺旋挤压式精量排肥器的仿真优化设计及试验[J].吉林大学学报: 工学版, 2023, 53(10): 3026-3037. |

| Guo-qiang Dun, Liu Wen-hui, Wu Xing-peng, et al. Simulation optimization design and experiment of screw extrusion precision fertilizer ejector[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(10): 3026-3037. | |

| 18 | 刘宏新, 杜春利, 尹林伟, 等. 倾斜对置圆盘有机肥侧抛射流形态与控制研究[J]. 农业机械学报,2022, 53(1): 168-177. |

| Liu Hong-xin, Du Chun-li, Yin Lin-wei, et al. Shooting flow shape and control of organic fertilizer side throwing on inclined opposite discs[J]. Transactions of the Chinese Society for Agricultural Machinery,2022, 53(1): 168-177. | |

| 19 | 吕金庆, 王泽明, 孙雪松, 等.马铃薯螺旋推进式排肥器研究与试验[J].农机化研究, 2015, 37(6): 194-196, 200. |

| Lv Jin-qing, Wang Ze-ming, Sun Xue-song, et al. Design and experimental study of fFeed screw potato planter propulsion[J]. Journal of Agricultural Mechanization Research, 2015, 37(6): 194-196, 200. | |

| 20 | 刘宇轩, 高志勇, 顿国强, 等. 手扶式三岔条带中耕施肥机的设计与仿真[J].农业装备与车辆工程, 2021, 59(6): 29-32. |

| Liu Yu-xuan, Gao Zhi-yong, Guo-qiang Dun, et al. Design and simulation of walk-behind three-chamber strip cultivating fertilizer applicator[J]. Agricultural Equipment & Vehicle Engineering, 2021, 59(6): 29-32. | |

| 21 | 张睿, 王秀, 赵春江, 等. 链条输送式变量施肥抛撒机的设计与试验[J].农业工程学报, 2012, 28(6): 20-25. |

| Zhang Rui, Wang Xiu, Zhao Chun-jiang, et al. Design and experiment of variable rate fertilizer spreader with conveyor chain[J]. Transactions of the Chinese Society of Agricultural Engineerin,2012,28(6):20-25. | |

| 22 | 刘彩玲, 黎艳妮, 宋建农, 等.基于EDEM的离心甩盘撒肥器性能分析与试验[J].农业工程学报, 2017,33(14): 32-39. |

| Liu Cai-ling, Li Yan-ni, Song Jian-nong, et al. Performance analysis and experiment on fertilizer spreader with centrifugal swing disk based on EDEM[J]. Transactions of the Chinese Society of Agricultural Engineerin,2017,33(14):32-39. | |

| 23 | .Equipment for distributing fertilizers-Test methods-part 2: fertilizer distributors in lines [S]. |

| 24 | Garía-Ramos FJ, Boné A, Vidal M, et al. Application of a 3-D laser scanner for characterizing centrifugal fertiliser spreaders[J]. Biosystems Engineering, 2012, 113(1): 33-41. |

| 25 | 吕金庆,尚琴琴,杨颖,等.锥盘式撒肥装置的性能分析与试验[J].农业工程学报,2016,32(11):16-24. |

| Jin-qing Lyu, Shang Qin-qin, Yang Ying, et al. Performance analysis and experiment on granular fertilizer spreader with cone disc[J]. Transactions of the Chinese Society of Agricultural Engineerin, 2016,32(11): 16-24. |

| [1] | Ling LI,Xu-yang DU,Jing-jing WANG,Xiao-guang RUAN,An-jiang CAI. Analysis of bolt load uniformity under convex flange connection [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2451-2459. |

| [2] | Guang-he ZHU,Zhi-qiang ZHU,Yi-ping YUAN. Device fault ceiling evaluation algorithm based on timing model and deep learning [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2348-2354. |

| [3] | Guo-zhong ZHANG,Kai-quan DING,Zheng-bo LI,Long CHEN,Nan-rui TANG,Wan-ru LIU,Hai-dong HUANG,Yong ZHOU,Hong-chang WANG. Design and experiment of biomimetic sliding plate for rice direct seeding machine based on loach body surface [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1482-1492. |

| [4] | Xiao-kang ZHAO,Zhe HU,Zhen-xing NIU,Jiu-peng ZHANG,Jian-zhong PEI,Yong WEN. Meso-cracking behavior of cement-stabilized macadam materials based on heterogeneous model [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1258-1266. |

| [5] | Fang-yun LI,Rong XIA,Yi-xin ZHANG. Hybrid electric vehicle hybrid power supply cooperative control considering battery state of charge [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 1114-1119. |

| [6] | Fu ZHANG,Li-min LOU,Dan QIAN,Shi-qiang WANG,Chun-ling FENG,Yi-rong ZHAO. Optimum design and test of compression mechanism of big square baler [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 1166-1174. |

| [7] | Peng-fei ZHOU,Xue-geng CHEN,He-wei MENG,Rong-qing LIANG,Bing-cheng ZHANG,Za KAN. Design and experiment of trommel with function of separating soil from residual film mixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2718-2731. |

| [8] | Wei-jian LIU,Xi-wen LUO,Shan ZENG,Zhi-qiang WEN,Li ZENG. Field turning mechanism and performance test of crawler reclaimed rice harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2695-2705. |

| [9] | Mao-jian ZHANG,Jing-fu JIN,Yi-ying CHEN,Ting-kun CHEN. Vibration symmetry characteristics of wheeled tractor structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2136-2142. |

| [10] | Chun-di SI,Ya-ning CUI,Zhong-yin XU,Tao-tao FAN. Meso⁃mechanical behavior analysis of asphalt bridge deck pavement after interlayer bonding failure [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1719-1728. |

| [11] | Guang-qiang ZHU,Tian-yu LI,Fu-jun ZHOU,Wen-ming WANG. Design and experiment of bionic ear picking device for fresh corn [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1231-1244. |

| [12] | Guo-qiang DUN,Wen-hui LIU,Xing-peng WU,Ning MAO,Wen-yi JI,Hong-yan MA. Simulation optimization and experiment of screw extrusion precision fertilizer ejector [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(10): 3026-3037. |

| [13] | Guo-qiang DUN,Wen-hui LIU,Ning MAO,Xing-peng WU,Wen-yi JI,Hong-yan MA. Optimization design and experiment of alternate post changing seed metering device for soybean plot breeding [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 285-296. |

| [14] | Yong PENG,Xiu-fang ZHANG,Ze-yu GUO,Xue-yuan LU,Yan-wei LI. Influence of aggregate contact characteristics on shear fatigue life of asphalt mixtures using discrete element method [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 178-187. |

| [15] | Shan ZENG,Deng-pan HUANG,Wen-wu YANG,Wei-jian LIU,Zhi-qiang WEN,Li ZENG. Design and test of the chassis of triangular crawler reclaiming rice harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1943-1950. |

|

||