Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (7): 2136-2142.doi: 10.13229/j.cnki.jdxbgxb.20220313

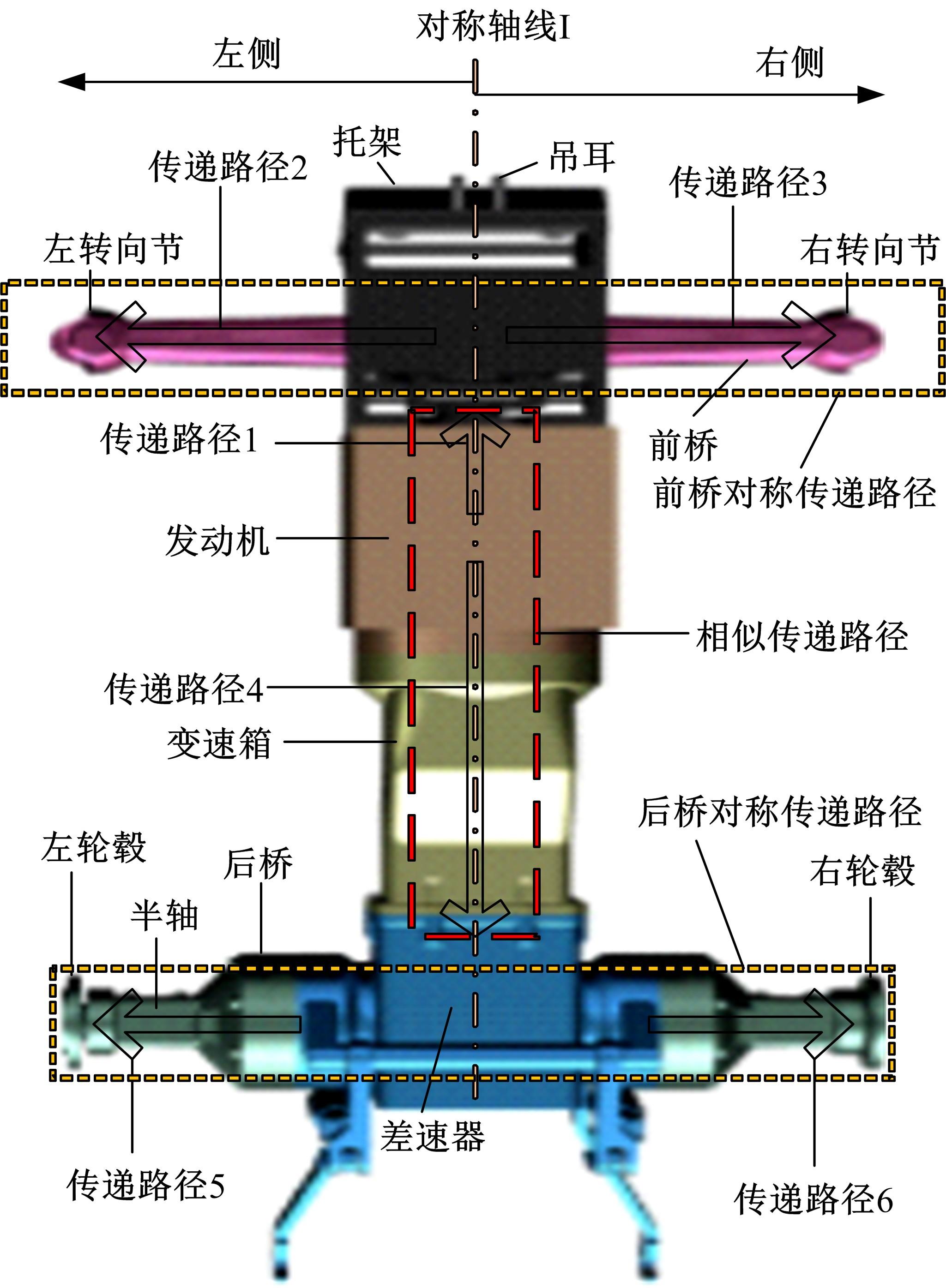

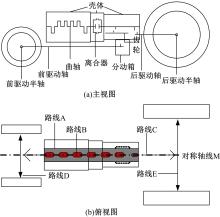

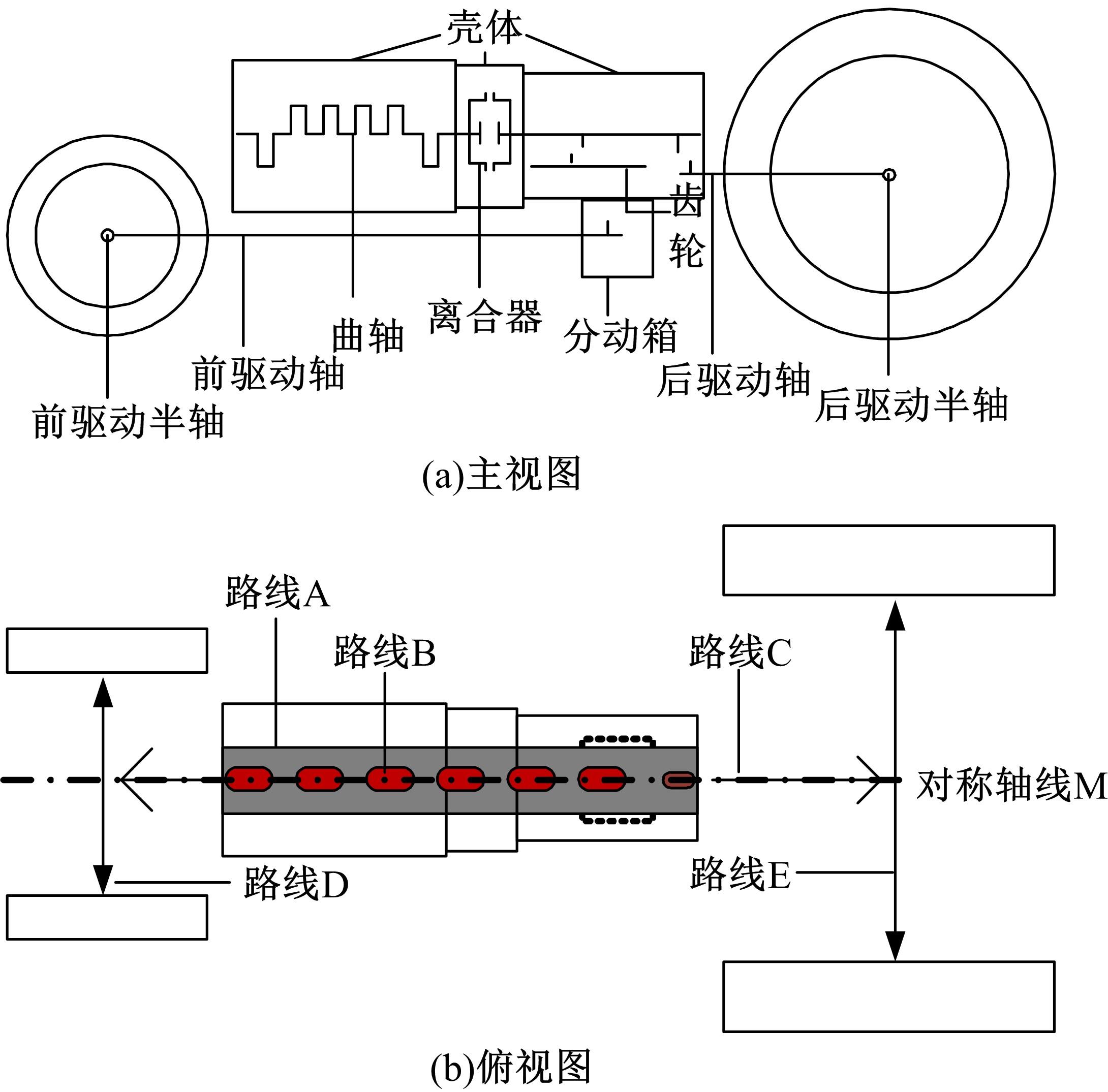

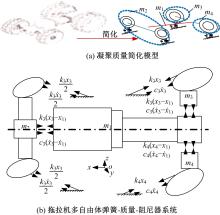

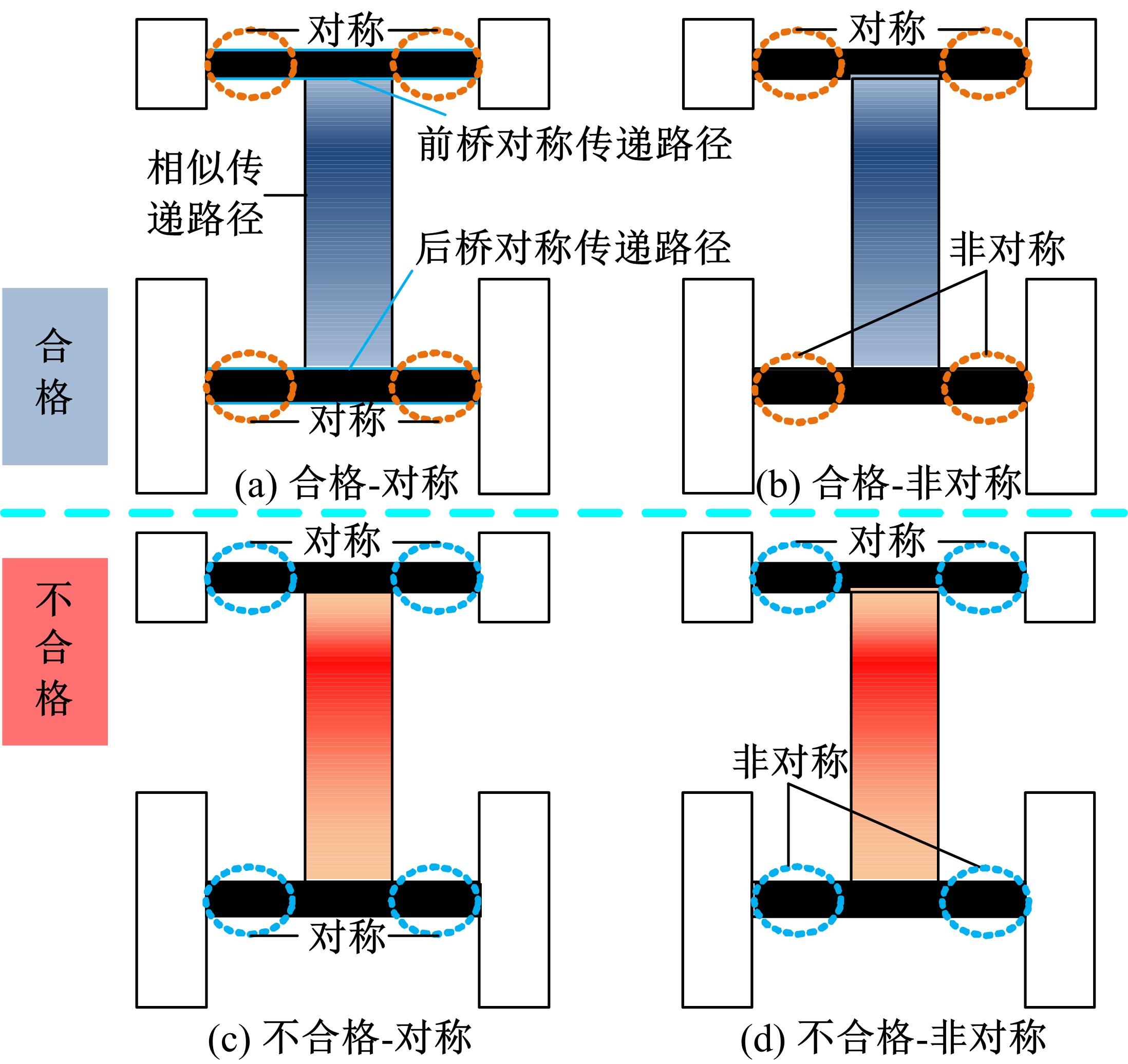

Vibration symmetry characteristics of wheeled tractor structure

Mao-jian ZHANG( ),Jing-fu JIN,Yi-ying CHEN,Ting-kun CHEN(

),Jing-fu JIN,Yi-ying CHEN,Ting-kun CHEN( )

)

- College of Biological and Agricultural Engineering,Jilin University,Changchun 130022,China

CLC Number:

- S219.1

| 1 | Li J Y, Li X Q, Li Y D, et al. A new method of tractor engine state identification based on vibration characteristics[J]. Processes, 2023, 11(2):No.303. |

| 2 | Qi Bei-bei. Intelligent fault monitoring system of new energy tractor engine for big data[J]. INMATEH―Agricultural Engineering, 2021, 64(2): 205-214. |

| 3 | 李耀明,庞靖,徐立章,等. 基于振动激励溯源的谷物联合收获机清选筛制造缺陷定位[J]. 农业工程学报,2019,35(5):10-17. |

| Li Yao-ming, Pang Jing, Xu Li-zhang, et al. Manufacturing defect location of cleaning screen of grain combine harvester based on vibration excitation tracing[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(5): 10-17. | |

| 4 | 丁翰韬,陈树人,周巍伟,等. 喂入量扰动下联合收获机振动特性机理研究[J]. 农业机械学报,2022,53():20-27, 51. |

| Ding Han-tao, Chen Shu-ren, Zhou Wei-wei, et al. Mechanism analysis of combine harvester's vibration characteristics under feeding interference[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(Sup.2): 20-27, 51. | |

| 5 | 柳剑,王世友,李巧菲. 基于任务多样性的农机装备维修策略研究[J]. 农业机械学报,2022,53():69-74, 218. |

| Liu Jian, Wang Shi-you, Li Qiao-fei. Maintenance strategy of agricultural machinery equipment based on task variety[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(Sup.2): 69-74, 218. | |

| 6 | Xue Li-jun, Jiang Hong-hua, Zhao Ye-hui, et al. Fault diagnosis of wet clutch control system of tractor hydrostatic power split continuously variable transmission[J]. Computers & Electronics in Agriculture, 2022, 194: No.106778. |

| 7 | Mandal S K, Shekh M I, Kumar S, et al. Failure analysis of PTO shaft of an agricultural tractor[J]. Materials Today: Proceedings, 2022,66:3924-3929. |

| 8 | Qi Bei-bei. Intelligent fault monitoring system of new energy tractor engine for big data[J]. INMATEH―Agricultural Engineering, 2021, 64(2): 205-214. |

| 9 | .Mechanical vibration-measurement and evaluation of machine vibration—part 1: general guidelines [S]. |

| 10 | .机械振动:在非旋转部件上测量评价机器的振动 [S]. |

| 11 | 樊新海,李胜利,安钢,等. 装甲车辆传动装置振动烈度监测与评估[J]. 兵工学报,2009,30(3):272-275. |

| Fan Xin-hai, Li Sheng-li, An Gang, et al. Vibration severity monitoring and evaluation for armored vehicle transmission[J]. Acta Armamentarii,2009,30(3):272-275. | |

| 12 | 吉林大学. 一种拖拉机整机装配质量评价方法和检测装置[P].中国:CN111174999A,2020-05-19. |

| 13 | 王连冰,薛静远,韩丽曼,等. 无线三轴振动测试系统的设计[J]. 吉林大学学报:信息科学版,2020,38(2):206-212. |

| Wang Lian-bing, Xue Jing-yuan, Han Li-man, et al. Design of wireless triaxial vibration test system[J]. Journal of Jilin University(Information Science Edition), 2020,38(2):206-212. | |

| 14 | 李贤哲,刘孟楠,徐立友,等. 拖拉机串联式液力机械复合传动系统设计与试验[J]. 农业机械学报,2022,53(1):406-413. |

| Li Xian-zhe, Liu Meng-nan, Xu Li-you, et al. Design and test of tractor serial hydraulic and mechanical hybrid transmission system[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(1): 406-413. | |

| 15 | 史丽晨,李坤,王海涛,等. 拖拉机行星齿轮箱故障响应特性动力学仿真及验证[J]. 农业工程学报,2018,34(7):66-74. |

| Shi Li-chen, Li Kun, Wang Hai-tao, et al. Fault response characteristics of tractor planetary gearbox based on dynamical simulation and its validation[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(7): 66-74. | |

| 16 | 方增强,李 娜,史洪涛,等. 拖拉机方向盘振动异常的分析与改进[J]. 机械制造,2022,60(3):79-83. |

| Fang Zeng-qiang, Li Na, Shi Hong-tao, et al. Analysis and improvement of abnormal vibration of steering wheel of tractor[J]. Machinery, 2022, 60(3): 79-83. |

| [1] | Guang-qiang ZHU,Tian-yu LI,Fu-jun ZHOU,Wen-ming WANG. Design and experiment of bionic ear picking device for fresh corn [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1231-1244. |

| [2] | Shan ZENG,Deng-pan HUANG,Wen-wu YANG,Wei-jian LIU,Zhi-qiang WEN,Li ZENG. Design and test of the chassis of triangular crawler reclaiming rice harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1943-1950. |

| [3] | Guo-liang WEI,Qing-song ZHANG,Biao WANG,Kun HE,Qing-xi LIAO. Analysis and experiment on parameters of plough body of rapeseed direct seeder [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1709-1718. |

| [4] | Chang-kai WEN,Bin XIE,Zheng-he SONG,Jian-gang HAN,Qian-wen YANG. Design method of tractor durability accelerated structure test [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 703-715. |

| [5] | Jia-jie LIU,Lan MA,Wei XIANG,Bo YAN,Qing-hua WEN,Jiang-nan LYU. Design of 4QM⁃4.0 fibre crops green fodder combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(12): 3039-3048. |

| [6] | Bai-gong ZENG,Kui-liang LI,Jin YE,Li-li REN,Jaloliddin Rashidov,Ming ZHANG. Design and experiment of harvesting device for industrialized production line of Shanghaiqing [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2756-2764. |

| [7] | Xing-yu WAN,Qing-xi LIAO,Ya-jun JIANG,Yi-yin SHAN,Yu ZHOU,Yi-tao LIAO. Discrete element simulation and experiment of mechanized harve- sting and chopping process for fodder rape crop harvest [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2735-2745. |

| [8] | Guang-qiang ZHU,Tian-yu LI,Fu-jun ZHOU. Design and experiment of flexible clamping and conveying device for bionic ear picking of fresh corn [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2486-2500. |

| [9] | Rong-qing LIANG,Bo ZHONG,He-wei MENG,Zhi-min SUN,Za KAN. Design of 4QJ⁃3 type pickup header of silage oat [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1887-1896. |

| [10] | Jia-cheng YUAN,Chang WANG,Kun HE,Xing-yu WAN,Qing-xi LIAO. Effect of components mass ratio under sieve on cleaning system performance for rape combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1897-1907. |

| [11] | Xiao-long ZHU,Zhong XIE. Automatic construction of knowledge graph based on massive text data [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1358-1363. |

| [12] | Yao-rong CHENG,Qian YANG,Guo-hua ZHENG. Tractor scheduling optimization of drop and pull transport in large⁃scale manufacturing enterprises considering carbon emission [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 893-899. |

| [13] | Qian CONG,Jin XU,Bo-shuai MA,Xiao-chao ZHANG,Ting-kun CHEN. Design and test of tractor hydraulic suspension system testing device based on virtual simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 754-760. |

| [14] | Dao WU,Li-bin ZHANG,Yun-xiang ZHANG,Hong-ying SHAN,Hong-mei SHAN. Visual detection method for vehicle braking time sequence based on slip rate identification [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 206-216. |

| [15] | Jun FU,Yi-chen ZHANG,Chao CHENG,Zhi CHEN,Xin-long TANG,Lu-quan REN. Design and experiment of bow tooth of rigid flexible coupling for wheat threshing [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 730-738. |

|

||