Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (1): 178-187.doi: 10.13229/j.cnki.jdxbgxb20210482

Influence of aggregate contact characteristics on shear fatigue life of asphalt mixtures using discrete element method

Yong PENG1( ),Xiu-fang ZHANG1,Ze-yu GUO1,Xue-yuan LU2,Yan-wei LI3,4

),Xiu-fang ZHANG1,Ze-yu GUO1,Xue-yuan LU2,Yan-wei LI3,4

- 1.Institute of Transportation Engineering,Zhejiang University,Hangzhou 310058,China

2.Anhui Transportation Holding Group Co. ,Ltd. ,Hefei 230088,China

3.Hebei Provincial Communications Planning and Design Institute,Shijiazhuang 050011,China

4.Research and Development Center of Transport Industry of Technologies,Materials and Equipments of Highway Construction and Maintenance,Shijiazhuang 050011,China

CLC Number:

- U414

| 1 | 英红,王锦河,张宏,等. 基于图像的AC20型混合料集料接触分布变异性[J]. 同济大学学报:自然科学版,2011,39(3):359-364. |

| Ying Hong, Wang Jin-he, Zhang Hong, et al. Variation of aggregate contacts distribution in AC20 HMA based on digital image processing[J]. Journal of Tongji University (Natural Science), 2011, 39(3): 359-364. | |

| 2 | Coenen A R, Kutay M E, Sefidmazgi N R, et al. Aggregate structure characterisation of asphalt mixtures using two-dimensional image analysis[J]. Road Materials and Pavement Design, 2012, 13(3): 433-454. |

| 3 | 张东,黄晓明,赵永利. 沥青玛蹄脂混合料矿料骨架构成及其接触特性[J]. 吉林大学学报:工学版,2015,45(2):394-399. |

| Zhang Dong, Huang Xiao-ming, Zhao Yong-li. Aggregate skeleton composition of stone mastic asphalt and its contact properties[J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45(2): 394-399. | |

| 4 | 谭忆秋,邢超,任俊达,等. 基于颗粒堆积理论的沥青混合料细观结构特性研究[J]. 中国公路学报,2017,30(7):1-8. |

| Tan Yi-qiu, Xing Chao, Ren Jun-da, et al. Research on mesostructured characteristics of asphalt mixture based on particle packing theory[J]. China Journal of Highway and Transport, 2017, 30(7): 1-8. | |

| 5 | Cai X, Wu K, Huang W. Study on the optimal compaction effort of asphalt mixture based on the distribution of contact points of coarse aggregates[J]. Road Materials and Pavement Design, 2021, 22(7): 1594-1615. |

| 6 | Brahmajaree N, Kanitpong K, Sawangsuriya A. Investigation on internal structural properties of asphalt mixtures subjected to loading using image analysis[J]. International Journal of Pavement Engineering, 2022, 23(1): 107-120. |

| 7 | Samer D, Eyad M, Fouad B. Evaluation of asphalt mix stability using compaction properties and aggregate structure analysis[J]. International Journal of Pavement Engineering, 2003, 4(2): 87-103. |

| 8 | Li P, Su J, Ma S, et al. Effect of aggregate contact condition on skeleton stability in asphalt mixture[J]. International Journal of Pavement Engineering, 2020, 21(2): 196-202. |

| 9 | Sefidmazgi N R, Tashman L, Bahia H. Internal structure characterization of asphalt mixtures for rutting performance using imaging analysis[J]. Road Materials and Pavement Design, 2012, 13(1): 21-37. |

| 10 | Masad E, Muhunthan B, Shashidhar N . et al. Quantifying laboratory compaction effects on the internal structure of asphalt concrete[J]. Transportation Research Record, 1999, 1681(1): 179-185. |

| 11 | 王端宜,黎侃,蔡旭. 基于集料接触特性的沥青混合料抗车辙性能评价[J]. 华南理工大学学报:自然科学版,2012,40(11):121-126, 154. |

| Wang Duan-yi, Li Kan, Cai Xu. Evaluation of rutting resistance of asphalt mixture based on aggregate contact characteristics[J]. Journal of South China University of Technology (Natural Science Edition), 2012, 40(11): 121-126, 154. | |

| 12 | Ling C, Bahia H. Modelling of aggregates' contact mechanics to study roles of binders and aggregates in asphalt mixtures rutting[J]. Road Materials and Pavement Design, 2020, 21(3): 720-736. |

| 13 | Cai X, Wu K H, Huang W K, et al. Study on the correlation between aggregate skeleton characteristics and rutting performance of asphalt mixture[J]. Construction & Building Materials, 2018, 179: 294-301. |

| 14 | 毕玉峰,孙立军. 沥青混合料抗剪试验方法研究[J]. 同济大学学报自:然科学版,2005,33(8):1036-1040. |

| Bi Yu-feng, Sun Li-jun. Research on test method of asphalt mixture's shearing properties[J]. Journal of Tongji University (Natural Science), 2005, 33(8): 1036-1040. | |

| 15 | 邵显智. 沥青混合料抗剪性能影响因素及剪切疲劳试验研究[D]. 上海:同济大学交通运输学院,2005. |

| Shao Xian-zhi. Study on influence factors and fatigue experiment about shear properties of asphalt mixtures[D]. Shanghai: College of Transportation Engineering, Tongji University, 2005. | |

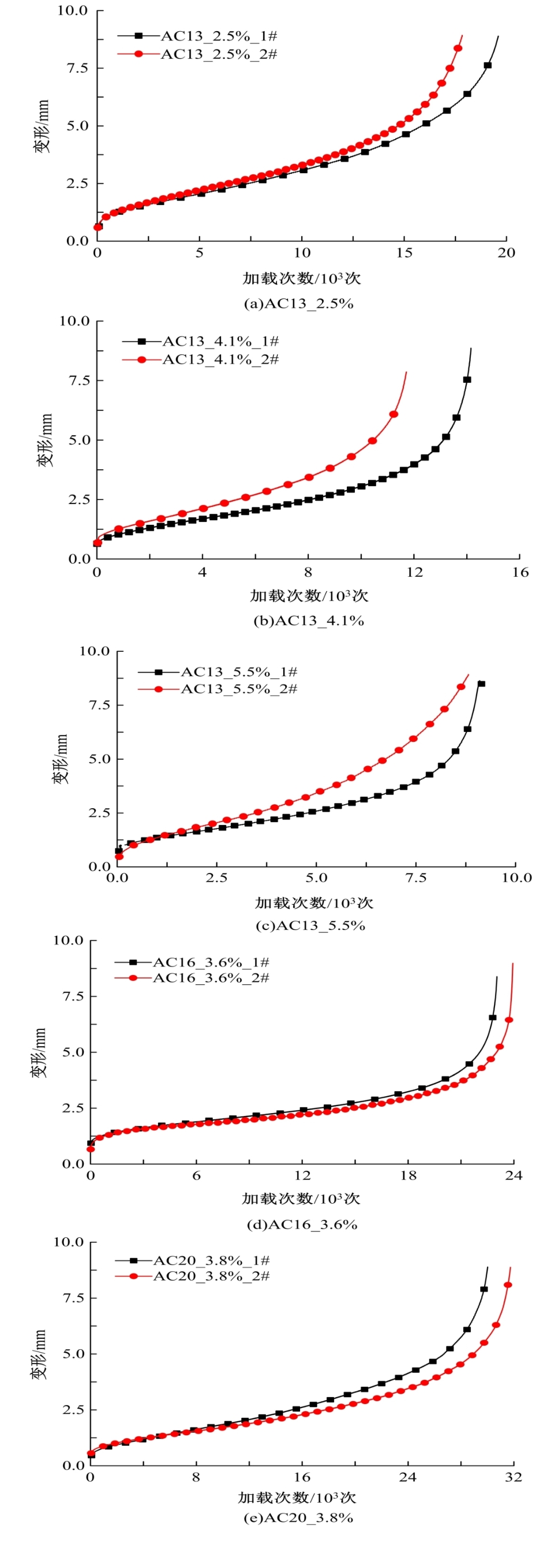

| 16 | Peng Y, Gao H, Lu X, et al. Micromechanical discrete element modeling of asphalt mixture shear fatigue performance[J]. Journal of Materials in Civil Engineering, 2020, 32(7):No.04020183. |

| 17 | 杨宇亮. 沥青混合料细观结构的分析系统[D]. 上海:同济大学交通运输工程学院,2003. |

| Yang Yu-liang. Sub-microstructure analysis system of asphalt concrete (MASAC)[D]. Shanghai: College of Transportation Engineering, Tongji University, 2003. | |

| 18 | 蔡旭,王端宜,黎侃,等. 基于散体力学的沥青混合料剪切模量预估[J]. 中国公路学报,2013,26(6):38-46. |

| Cai Xu, Wang Duan-yi, Li Kan, et al. Prediction of shear modulus of asphalt mixtures based on granular mechanics[J]. China Journal of Highway and Transport, 2013, 26(6): 38-46. | |

| 19 | Itasca Consulting Group. Particle Flow Code in Three-dimensions (PFC3D) Manual (version 3.1)[M].Minneapolis: Itasca Consulting Group, 2004. |

| 20 | Dai Q. Micromechanical modeling of constitutive and damage behavior of heterogeneous asphalt materials[D]. Kingston: University of Rhode Island, 2004. |

| 21 | You Z, Adhikari S, Dai Q. Three-dimensional discrete element models for asphalt mixtures[J]. Journal of Engineering Mechanics, 2008, 134(12):1053-1063. |

| 22 | 张垚. 基于PFC3D的沥青混合料虚拟试验研究[D]. 南京:东南大学交通学院,2015. |

| Zhang Yao. Virtual tests of asphalt mixture based on PFC3D[D]. Nanjing: College of Transportation, Southeast University, 2015. | |

| 23 | 曾梦澜,李洁,黄冰,等. 基于常规试验数据的沥青劲度模量一般公式表达[J]. 中南公路工程,2004(1):45-50, 58. |

| Zeng Meng-lan, Li Jie, Huang Bing, et al. A general formulation for stiffness modulus of asphalt binders using routine test data[J]. Central South Highway Engineering, 2004(1): 45-50, 58. | |

| 24 | 严明星,王金昌. 沥青混合料蠕变柔量与松弛模量的转换关系研究[J]. 公路交通技术,2016,32(5):28-31. |

| Yan Ming-xing, Wang Jin-chang. Study on conversion between creep compliance and relaxation modulus of asphalt mixture[J]. Technology of Highway and Transport, 2016, 32(5): 28-31. |

| [1] | Liu YANG,Chuang-ye WANG,Meng-yan WANG,Yang CHENG. Traffic flow characteristics of six⁃lane freeways with a dedicated lane for automatic cars [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2043-2052. |

| [2] | Zheng-feng ZHOU,Xiao-tao YU,Ya-le TAO,Mao ZHENG,Chuan-qi YAN. High-temperature performance evaluation of resin and elastomer high viscosity asphalt based on grey correlation analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2078-2088. |

| [3] | Tao MA,Yuan MA,Xiao-ming HUANG. Optimal combination of key parameters of intelligent compaction based on multiple nonlinear regression [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2067-2077. |

| [4] | Hai-bin WEI,Shuan-ye HAN,Hai-peng BI,Qiong-hui LIU,Zi-peng MA. Intelligent sensing road active ice and snow removal system and experimental technology [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1411-1417. |

| [5] | Sui-ning ZHENG,Rui HE,Tian-yu LU,Zi-yi XU,Hua-xin CHEN. Preparation and evaluation of RET/rubber composite modified asphalt and asphalt mixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1381-1389. |

| [6] | Bo-wen GUAN,Wen-jin DI,Fa-ping WANG,Jia-yu WU,Shuo-wen ZHANG,Zhi-xun JIA. Damage of concrete subjected to sulfate corrosion under dry⁃wet cycles and alternating loads [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1112-1121. |

| [7] | Fan YANG,Chen-chen LI,Sheng LI,Hai-lun LIU. Numerical simulation of continuously reinforced concrete pavement with double⁃layer reinforcement under effect of temperature shrinkage [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1122-1132. |

| [8] | Hai-bin WEI,Zi-peng MA,Hai-peng BI,Han-tao LIU,Shuan-ye HAN. Conductive rubber composite pavement paving technology based on mechanical response analysis method [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 531-537. |

| [9] | Zhuang-zhuang LIU,You-wei ZHANG,Peng-yu JI,Abshir Ismail Yusuf,Lin LI,Ya-zhen HAO. Study on heat transfer characteristics of electric heating snow melting asphalt pavement [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 523-530. |

| [10] | Qing-lin GUO,Qiang LIU,Chun-li WU,Li-li LI,Yi-ming LI,Fu-chun LIU. Local temperature field and healing level of crack in conductive asphalt and mixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1386-1393. |

| [11] | Cheng-lin SHI,Yong WANG,Chun-li WU,Wen-zhu SONG. Modification of calculation method for active earth pressure on embankment retaining wall [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1394-1403. |

| [12] | Yu-quan YAO,Jian-gang YANG,Jie GAO,Liang SONG. Optimal design on recycled hot⁃mix asphalt mixture based on performance⁃cost model [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 585-595. |

| [13] | Duan-yang GENG,Yan-cheng SUN,Xiao-dong MU,Guo-dong ZHANG,Hui-xin JIANG,Jun-ke ZHU. Simulation test and optimization of grain breakage of silage maize based on differential roller [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 693-702. |

| [14] | Quan-ping XIA,Jiang-ping GAO,Hao-yuan LUO,Qi-gong ZHANG,Zhi-jie LI,Fei YANG. Low⁃temperature performance of composite modified hard asphalt used in high modulus asphalt concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 541-549. |

| [15] | Fen YE,Shi-yuan HU. Mechanical properties of ultra⁃thin overlay considering load transfer capacity of old cement pavement joints [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2636-2643. |

|

||