Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (4): 1188-1196.doi: 10.13229/j.cnki.jdxbgxb.20230719

Previous Articles Next Articles

Influence factors of preload loss in cable clamp bolt of suspension bridge based on orthogonal experiment method

Yong-jun ZHOU1,2( ),Feng-rui MU2,Cheng CAI3,Fan YANG4

),Feng-rui MU2,Cheng CAI3,Fan YANG4

- 1.Large Structures Highway Safety Engineering Research Center of the Ministry of Education,Chang'an University,Xi'an 710064,China

2.School of Highway,Chang'an University,Xi'an 710064,China

3.Guangxi Xingang Transportation Investment Co. ,Ltd. ,Qinzhou 535000,China

4.Shaanxi Provincial Transport Planning Design and Reaseach Institute Co. ,Ltd. ,Xi'an 710065,China

CLC Number:

- U44

| [1] | 王俊, 李加武, 王峰, 等. 简化U形峡谷风速分布及其对悬索桥抖振响应的影响[J]. 吉林大学学报:工学版, 2023, 53(6): 1658-1668. |

| Wang Jun, Li Jia-wu, Wang Feng, et al. Wind speed distribution in simplified U⁃shaped valley and its effect on buffeting response of long⁃span suspension bridge[J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1658-1668. | |

| [2] | Mayrbaurl R M, Camo S. Guidelines for Inspection and Strength Evaluation of Suspension Bridge Parallel-Wire Cables[M]. USA: Transportation Research Board, 2004. |

| [3] | 中国公路学会桥梁与结构工程学会. 日本本州-四国连络桥上部结构设计标准及解说[M]. 北京: 中国公路学会桥梁与结构工程学会, 1998. |

| [4] | 费卿, 梁锦润. 自锚式悬索桥索夹滑移分析及修复技术[C]∥中国公路学会桥梁和结构工程分会2017年全国桥梁学术会议论文集, 广州, 中国, 2017: 654-659. |

| [5] | Tendo M, Yamada K, Shimura Y. Stress relaxation behavior at high-tension bolted connections of stainless-steel plates[J]. Journal of Engineering Materials & Technology, 2001, 123(2): 198-202. |

| [6] | Alkelani A A, Housari A B, Nassar A S. A proposed model for creep relaxation of soft gaskets in bolted joints at room temperature[J]. Journal of Pressure Vessel Technology(ASME), 2008, 13(1): No.011211-1-6. |

| [7] | 徐浩, 王崴, 马跃. 螺栓联接蠕变松弛有限元分析[J]. 机械设计与制造, 2013, 271(9): 39-41, 45. |

| Xu Hao, Wang Wei, Ma Yue. Finite element analysis of creep relaxation in bolted connections[J]. Mechanical Design and Manufacturing, 2013, 271(9): 39-41, 45. | |

| [8] | 刘海波, 吴嘉锟, 王永青. 地脚螺栓蠕变松弛对大型数控机床几何精度衰退的影响[J]. 西安交通大学学报, 2015, 49(9): 14-17, 140. |

| Liu Hai-bo, Wu Jia-kun, Wang Yong-qing. The effect of creep relaxation of anchor bolts on the geometric accuracy degradation of large CNC machine tools [J]. Journal of Xi'an Jiaotong University, 2015, 49(9): 14-17, 140. | |

| [9] | Xu H, Wang F, Cheng X. Pullout creep properties of grouted soil anchors[J]. Journal of Central South University of Technology, 2007, 14(1): 474-477. |

| [10] | Kim N. Performance of tension and compression anchors in weathered soil[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2003, 129(12): 1138-1150. |

| [11] | 沈锐利, 何恺, 苗如松. 基于多尺度模型的销接式索夹极限抗滑摩阻力分析[J]. 桥梁建设, 2018, 48(5): 16-20. |

| Shen Rui-li, He Kai, Miao Ru-song. Analysis of ultimate sliding friction resistance of pin connected cable clamps based on multi-scale models[J]. Bridge Construction, 2018, 48(5): 16-20. | |

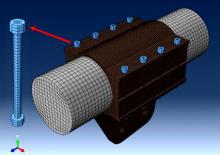

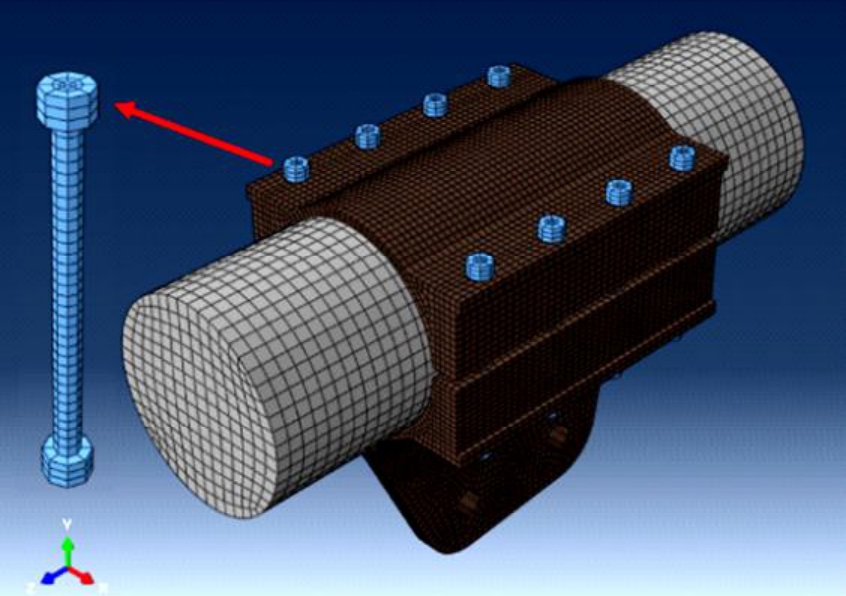

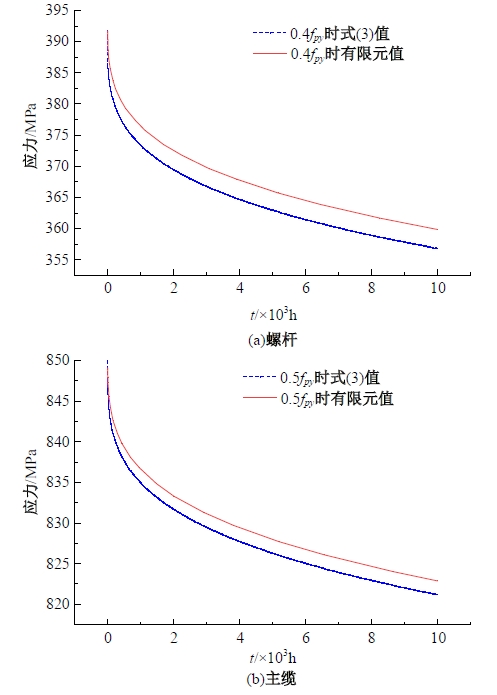

| [12] | 周勇军, 贾利强, 杨帆, 等. 考虑主缆镀锌层蠕变的索夹螺杆紧固力损失预测[J]. 中国公路学报, 2024, 37(7): 157-167. |

| Zhou Yong-jun, Jia Li-qiang, Yang Fan, et al. Research on Preload Loss Prediction of Clamp Bolt Considering Cable Creep of Galvanized Layer[J]. China Journal of Highway and Transport, 2024, 37(7): 157-167. | |

| [13] | 何恺. 铁路悬索桥长索夹下主缆应力及索夹抗滑承载力研究[D]. 成都: 西南交通大学, 2017. |

| He Kai. Research on stress of main cable under long cable clamp and anti sliding bearing capacity of cable clamp of railway suspension bridge[D]. Chengdu: Southwest Jiaotong University, 2017. | |

| [14] | 唐冕, 车天鑫, 宋旭明, 等. 基于蠕变理论的自锚式悬索桥索夹预紧力研究[J]. 华南理工大学学报:自然科学版, 2022, 50(1): 59-68. |

| Tang Mian, Che Tian-xin, Song Xu-ming, et al. Study on pretension force of cable clamp of self anchored suspension bridge based on creep theory[J]. Journal of South China University of Technology (Natural Science Edition), 2022, 50(1): 59-68. | |

| [15] | 梅葵花, 经德良, 黄平明, 等. 悬索桥主缆温度效应的分析研究[C]∥中国公路学会桥梁和结构工程学会2001年桥梁学术研讨会论文集, 重庆,中国,2001. |

| [16] | 吕佳欣, 肖毅. 复合材料螺栓连接预紧力松弛的改进预测模型[J]. 工程力学, 2018, 35(10): 229-237. |

| Jia-xin Lyu, Xiao Yi. Improved approach to modelling preload relaxation in bolted composite joints[J]. Engineering Mechanics, 2018,35 (10): 229-237. | |

| [17] | 陆光闾. 预应力高强钢丝松弛性能研究[J]. 土木工程学报, 1997, 44(6): 41-46. |

| Lu Guang-lyu. Research on relaxation performance of prestressed high strength steel wire[J]. Journal of Civil Engineering, 1997,44(6): 41-46. | |

| [18] | 周勇军, 全伟, 贺拴海. 基于正交试验的连续刚构桥地震响应敏感性参数分析[J]. 地震研究, 2006, 29(2): 176-181, 216. |

| Zhou Yong-jun, Quan Wei, He Shuan-hai. Analysis of seismic response sensitivity parameters of continuous rigid frame bridges based on orthogonal tests[J]. Earthquake Research, 2006, 29(2): 176-181, 216. | |

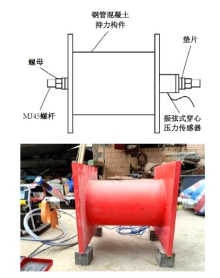

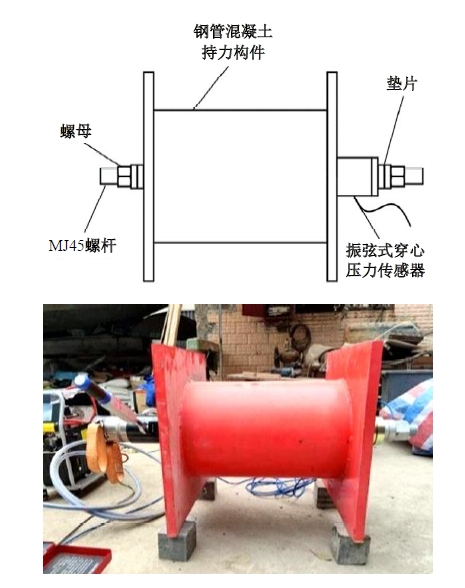

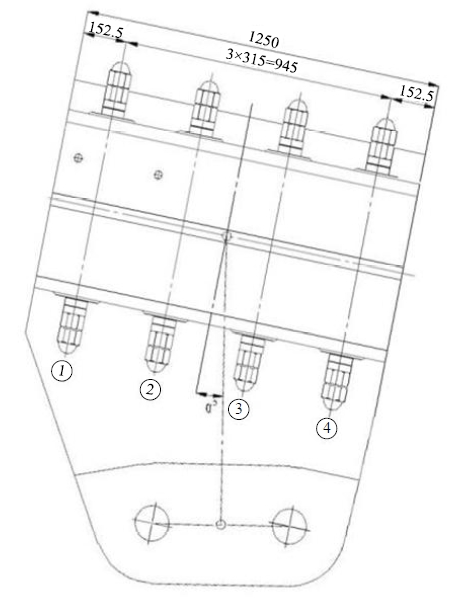

| [19] | 蒋树勤, 周勇军, 曹资源, 等. 基于拉拔法的索夹螺杆紧固力检测试验[J]. 长安大学学报: 自然科学版, 2024, 44(6): 72-80. |

| Jiang Shu-qin, Zhou Yong-jun, Cao Zi-yuan, et al. Experiment on detection of preload force in bolt clamp by pulling method[J]. Journal of Chang'an University(Natural Science Edition), 2024, 44(6): 72-80. | |

| [20] | 黄铁生. 大岛大桥主缆施工[J]. 国外桥梁, 1993, 21(3): 175-180. |

| Huang Tie-sheng. Construction of the main cable of the Oshima Bridge[J]. Foreign Bridges, 1993, 21(3): 175-180. | |

| [21] | 《中国公路学报》编辑部. 中国桥梁工程学术研究综述·2024[J]. 中国公路学报, 2024, 37(12): 1-160. |

| Editorial Department of China Journal of Highway and Transport. Review on China's pavement engineering research:2024[J]. China Journal of Highway and Transport, 2024, 37(12): 1-160. |

| [1] | Yong-xin SUN,Peng-zhen LIN,Zi-jiang YANG,Wei JI. Calculation method for crack width of UHPC beams considering bond slip effect [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2600-2608. |

| [2] | Bao-dong LIU,Fang LI,Xiao-xi WANG,Meng GAO. Flexural stiffness and bearing capacity of corrugated steel plate composite structures reinforced by concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2502-2510. |

| [3] | Yu-xin XUE,Yong-jun ZHOU,Ye-lu WANG,Kai-xiang FAN,Yu ZHAO. Application of dynamic load allowance test method of simply supported girder bridge based on suspension hammer system [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2557-2567. |

| [4] | Xue-lian GUO,Wan-shui HAN,Tao WANG,Kai ZHOU,Xiu-shi ZHANG,Shu-ying ZHANG. Assessment method of resistant overturning stability safety factors of curved bridge under customized transport vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2229-2237. |

| [5] | Lin XIAO,Huan-bo WEI,Xing WEI,Zhi-rui KANG. Numerical analysis on cracking behavior of concrete slab due to corrosion expansion of stud connector in steel-concrete composite beam [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1958-1965. |

| [6] | Chun-lei ZHANG,Chang-yu SHAO,Qing-tian SU,Chang-yuan DAI. Experimental on positive bending behaviour of composite bridge decks with steel-fiber-reinforced concrete and longitudinal bulb-flat ribs [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1634-1642. |

| [7] | Han-hui HUANG,Kang-ming CHEN,Qing-xiong WU. Flexural behavior of composite continuous girders with concrete-filled steel tubular truss chords [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1665-1676. |

| [8] | Guang-bao LI,Dong GAO,Yong LU,Hao PING,Yuan-yuan ZHOU. Internal surface treatment of gas-liquid-solid technology based on improved neural network and Fluent [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1537-1547. |

| [9] | Chang-jiang SHAO,Hao-meng CUI,Qi-ming QI,Wei-lin ZHUANG. Longitudinal seismic mitigation of near⁃fault long⁃span RC soft⁃lighten arch bridge based on viscous damper [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1355-1367. |

| [10] | Qiu ZHAO,Peng CHEN,Yu-wei ZHAO,Ao YU. Overall mechanical performance of jointless bridges with arch structure behind abutment [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 1016-1027. |

| [11] | Hong ZHANG,Zhi-wei ZHU,Tian-yu HU,Yan-feng GONG,Jian-ting ZHOU. Bridge bolt defect identification method based on improved YOLOv5s [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(3): 749-760. |

| [12] | Zhi-qiang HAN,Gang XIE,Ya-juan ZHUO,Zuo-long LUO,Hua-teng LI. Vibration response of continuous girder bridge based on wheel⁃deck coherent excitation [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 436-444. |

| [13] | Guo-jun YANG,Ya-hui QI,Xiu-ming SHI. Review of bridge crack detection based on digital image technology [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 313-332. |

| [14] | Xing WEI,Yong-qi ZHANG,Jun-ming ZHAO,Hui-jun WANG,Lin XIAO. Hot spot stress concentration factor for welded skewed-T joints [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(12): 3478-3485. |

| [15] | Xie-li ZHANG,Chong WU,Qing-tian SU. Experiment on load capacity of profiled steel sheeting-concrete composite bridge decks [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(10): 2870-2883. |

|