Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (8): 2520-2529.doi: 10.13229/j.cnki.jdxbgxb.20231187

Previous Articles Next Articles

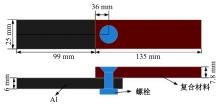

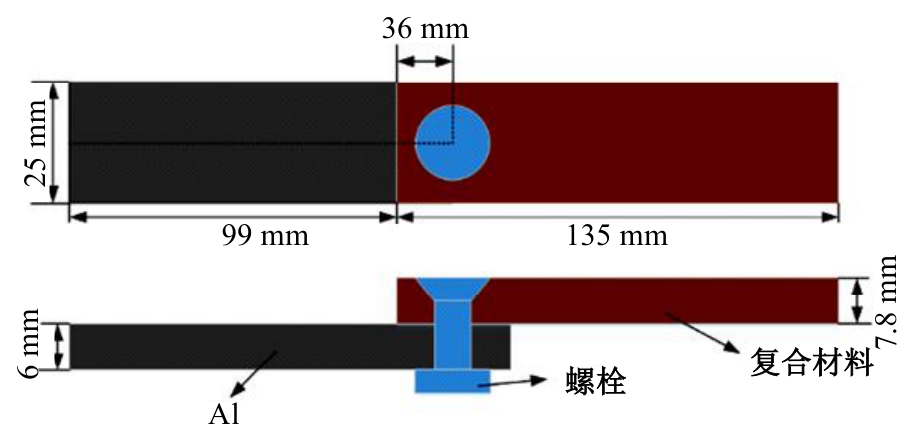

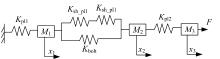

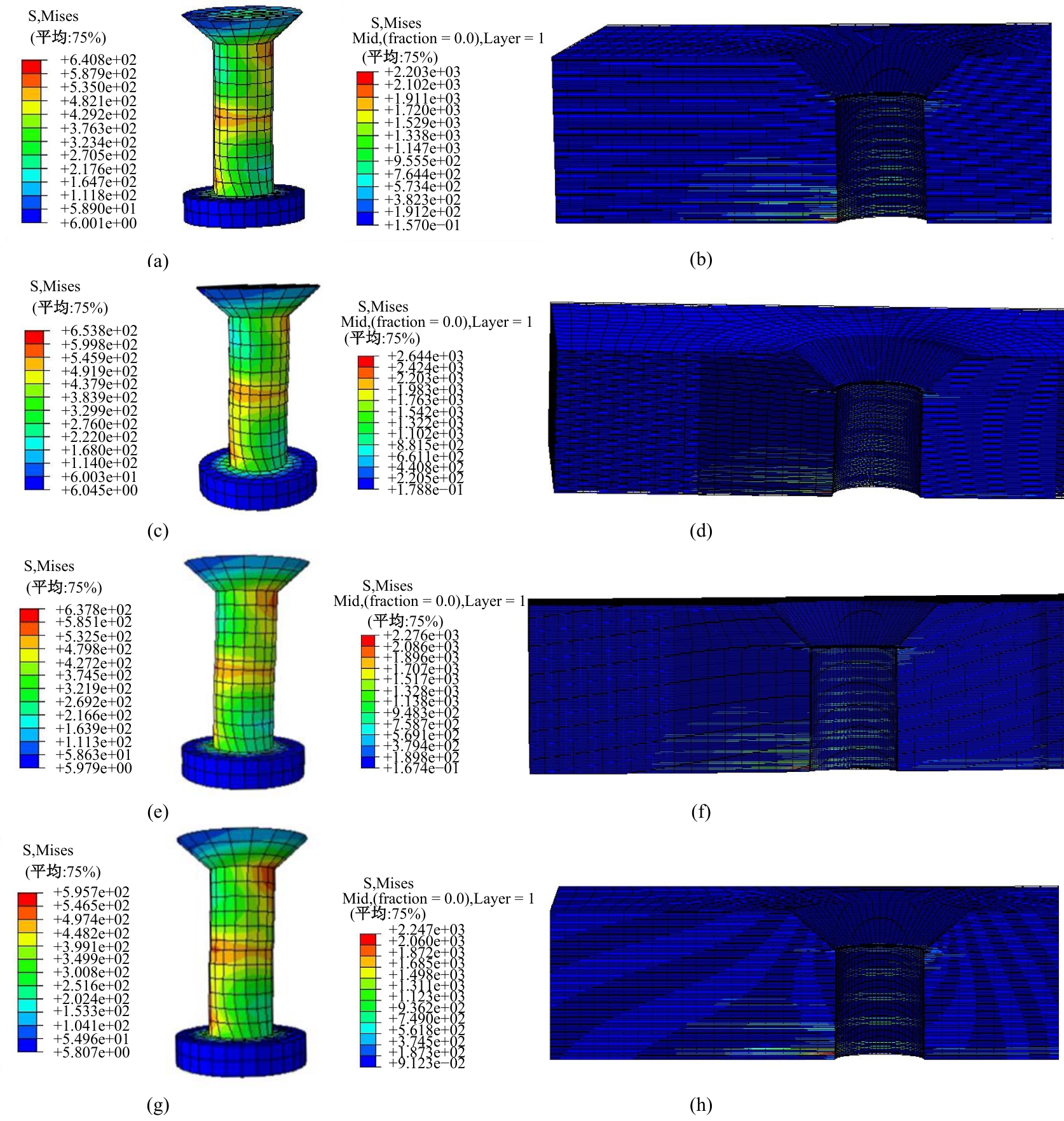

Stiffness characteristics of bolt connection of composite laminates under secondary bending

Ling LI( ),Zhi-wen JIANG,Dong-hao MIAO,Miao-xia XIE(

),Zhi-wen JIANG,Dong-hao MIAO,Miao-xia XIE( ),Fu-an CHENG

),Fu-an CHENG

- School of Mechanical and Electrical Engineering,Xi'an University of Architecture and Technology,Xi'an 710055,China

CLC Number:

- TB332

| [1] | Garg A, Chalak H D. A review on analysis of laminated composite and sandwich structures under hygrothermal conditions[J]. Thin-Walled Structures, 2019, 142: 205-226. |

| [2] | 寇剑锋, 徐绯, 张笑宇, 等. 考虑装配间隙的双搭接螺栓连接剪切刚度的解析求解方法[J]. 复合材料学报, 2018, 35: 1510-1517. |

| Kou Jian-feng, Xu Fei, Zhang Xiao-yu, et al. Analytical method for solving shear stiffness of double lap bolted joint considering assembly gap[J]. Journal of Composite Materials, 2018, 35: 1510-1517. | |

| [3] | 寇剑锋, 徐绯. 螺栓连接层合板孔边挤压应力三维分布[J]. 复合材料学报, 2018, 35:3360-3367. |

| Kou Jian-feng, Xu Fei,et al. Three-dimensional compression stress distribution at hole edge of bolted laminates[J]. Journal of Composite Materials, 2018, 35 : 3360-3367. | |

| [4] | Chishti M, Wang C H, Thomson R S, et al. Numerical analysis of damage progression and strength of countersunk composite joints[J]. Composite Structures, 2012, 94: 643-653. |

| [5] | Tate M B, Rosenfeld S J. Preliminary investigation of the loads carried by individual bolts in bolted joints[J]. NASA Technical Reports Server, 2013, 8: 19930081668. |

| [6] | McCarthy C T, Gray P J. An analytical model for the prediction of load distribution in highly torqued multi-bolt composite joints[J]. Composite Structures, 2011, 93: 287-298. |

| [7] | Liu F R, Zhang J Y, Zhao L B, et al. An analytical joint stiffness model for load transfer analysis in highly torqued multi-bolt composite joints with clearances[J]. Composite Structures, 2015, 131:625-636. |

| [8] | Stocchi C, Robinson P, Pinho S T, et al. A detailed finite element investigation of composite bolted joints with countersunk fasteners[J]. Composites Part A: Applied Science and Manufacturing, 2013, 52:143-150. |

| [9] | Guerrero J M, Sasikumar A, Llobet J, et al. A computationally efficient methodology to simulate hybrid bolted joints including thermal effects[J]. Mechanics of Advanced Materials and Structures, 2021, 30(1): 1-19. |

| [10] | Liu K, Tie Y, Li C. Effects of pre-tightening force and connection mode on the strength and progressive damage of composite laminates with bolted joint[J]. Materials Physics and Mechanics, 2013, 18:18-27. |

| [11] | Tang Y, Zhou Z, Pan S, et al. Mechanical and failure behavior of three-dimensional six-directional braided composites bolted joint[J]. Journal of Reinforced Plastics and Composites, 2017, 36(10): 739-753. |

| [12] | Zhou Y, Nezhad H Y, Hou C, et al. A three dimensional implicit finite element damage model and its application to single-lap multi-bolt composite joints with variable clearance[J]. Composite Structures, 2015, 131:1060-1072. |

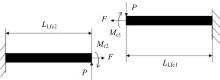

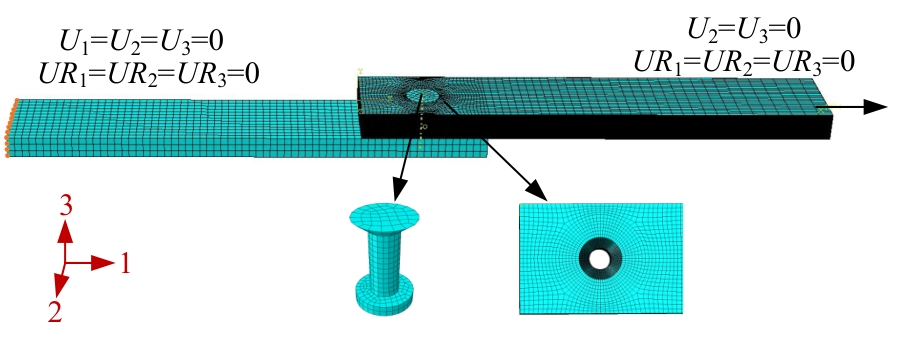

| [13] | Gray P J, Higgins R M, Mccarthy C T. Effect of thickness and laminate taper on the stiffness,strength and secondary bending of single-lap, single-bolt countersunk composite joints[J]. Composite Structures, 2014, 107: 315-324. |

| [14] | Mccarthy M A, Lawlor V P, Stanley W F, et al. Bolt-hole clearance effects and strength criteria in single-bolt, single-lap, composite bolted joints[J]. Composites Science and Technology, 2002, 62: 1415-1431. |

| [15] | Mccarthy M A, Mccarthy C T, Lawlor V P, et al. Three-dimensional finite element analysis of single-bolt, single-lap composite bolted joints: part I—model development and validation[J]. Composite Structures, 2005, 71: 140-158. |

| [16] | Mccarthy C T, Mccarthy M A, Lawlor V P, et al. Progressive damage analysis of multi-bolt composite joints with variable bolt-hole clearances[J]. Composites Part B: Engineering, 2005, 36: 290-305. |

| [17] | Mccarthy C T, Mccarthy M A, et al. Three-dimensional finite element analysis of single-bolt, single-lap composite bolted joints: effects of bolt-hole clearance[J]. Composite Structures, 2005, 71: 159-175. |

| [18] | Mccarthy C T, Mccarthy M A, Stanley W F, et al. Experiences with modeling friction in composite bolted joints[J]. Journal of Composite Materials, 2005, 39: 1881-1908. |

| [19] | 黄河源, 赵美英, 万小朋, 等. 复合材料中厚板沉头连接结构强度与损伤失效[J]. 复合材料学报, 2017,34: 557-563. |

| Huang He-yuan, Zhao Mei-ying, Wan Xiao-peng, et al. Structural strength and damage failure of heavy plate countersunk joint of composite materials[J]. Journal of Composite Materials, 2017, 34:557-563. | |

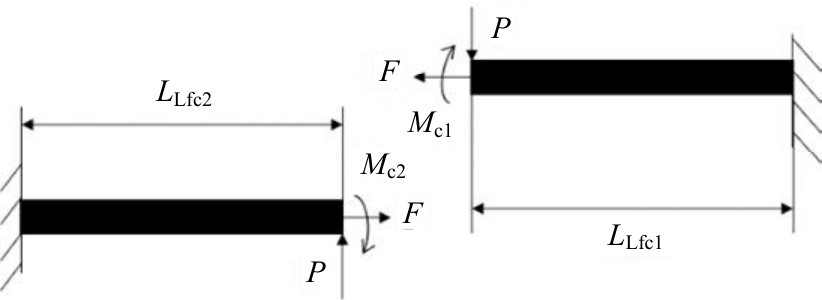

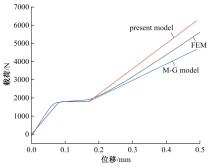

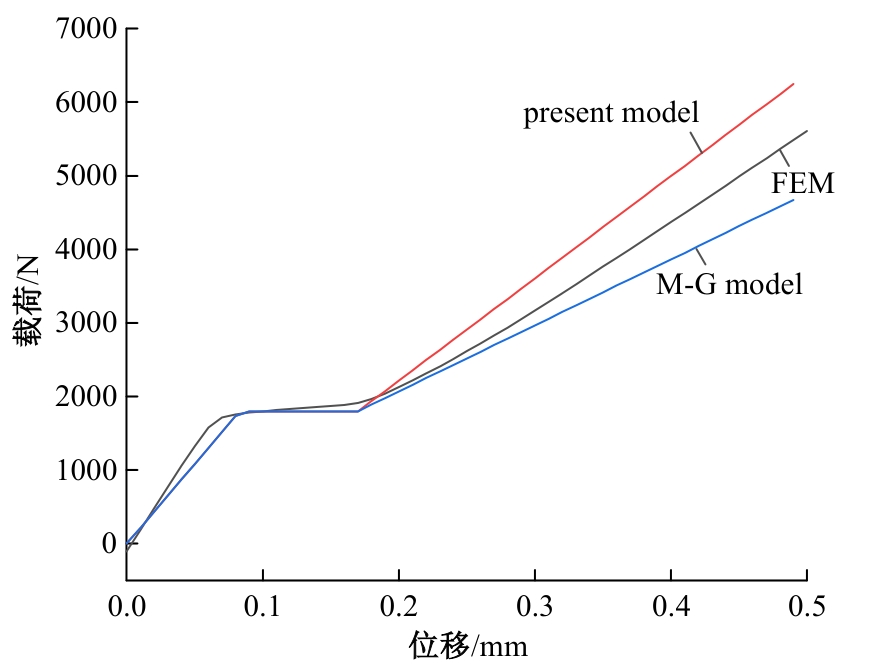

| [20] | 李玲, 张东, 王晶晶, 等. 复合层压板单螺栓连接的刚度建模[J].复合材料学报, 2021,38:2935-2945. |

| Li Ling, Zhang Dong, Wang Jing-jing, et al. Stiffness modeling of single bolted composite laminates[J]. Journal of Composite Materials, 2021, 38:2935-2945. | |

| [21] | 李静雯, 张博明, 孙义亮, 等. 不同铺层方式下连续玻璃纤维/聚丙烯复合材料波纹夹芯板的力学性能[J]. 复合材料学报, 2019, 36: 1074-1082. |

| Li Jing-wen, Zhang Bo-ming, Sun Yi-liang, et al. Mechanical properties of continuous glass fiber/polypropylene composite corrugated sandwich panels under different layering methods[J]. Journal of Composite Materials, 2019, 36: 1074-1082. | |

| [22] | 张建国, 岳金, 宋春生, 等. 碳纤维复合材料螺旋桨铺层角度研究[J]. 武汉理工大学学报: 信息与管理工程版, 2014, 36: 207-210. |

| Zhang Jian-guo, Yue Jin, Song Chun-sheng, et al. Study on layup angle of carbon fiber composite propeller[J]. Journal of Wuhan University of Technology (Information and Management Engineering), 2014,36: 207-210. | |

| [23] | 何柏灵, 葛东云, 莫与明, 等. T800 碳纤维增强复合材料双剪单钉连接的拉伸试验及强度估算[J]. 复合材料学报, 2016, 33: 1540-1552. |

| He Bo-ling, Ge Dong-yun, Mo Yu-ming, et al. Tensile test and strength estimation of T800 carbon fiber reinforced composite with double shear and single nail[J]. Journal of Composite Materials, 2016, 33: 1540-1552. | |

| [24] | Nelson W D, Bunin B L, Hart L J.Critical joints in large composite aircraft structure[J]. NASA Technical Reports Server, 1983, 1: No.19870001540. |

| [25] | 王天宇, 段跃新, 向经伟, 等. 铺层顺序对预成型体搭接复合材料拉伸性能影响的仿真与验证[J]. 复合材料学报, 2018, 35: 2745-2752. |

| Wang Tian-yu, Duan Yue-xin, Xiang Jing-wei, et al. Simulation and verification of effect of lay-up sequence on tensile properties of preformed lapped composites[J]. Journal of Composite Materials, 2018, 35: 2745-2752. |

| [1] | Dao-you ZHENG,Yi-fan YANG,Yu-gang CHENG,Kui ZHAO,Kun WANG,Wen-quan WANG. Microstructures and mechanical properties of composite refined and modified ADC12 Al alloy [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(8): 2570-2578. |

| [2] | Shi-jie JIANG,Shu-guang LI,Zi-zhao XU,Fei WANG. Rheological property of composite filament in metal fused filament fabrication process [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(7): 2180-2192. |

| [3] | Ping YUAN,Ya-fu CAI,Li-zhao DAI,Bi-qin DONG,Lei WANG. Topology search method for structural 3D load paths based on distortion control of corrosion-damaged elements [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(7): 2212-2222. |

| [4] | Wen-yuan XU,Wei LI,Da-yang WANG,Yong-cheng JI. Damage mechanism of FRP reinforced concrete under alkali freezing coupling effect [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(6): 2050-2062. |

| [5] | Wei SHEN,Zi-li BIAN,Yu-wen CHEN,Yu QIU,Shuang-xi XU,Yi-gang WU. Stress field and fatigue assessment method of composite materials with notches [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(5): 1559-1566. |

| [6] | Wei-dong HAO,Jian-qi LI. Deformation characteristics of prestressed steel plate-brick masonry composite wall under support failure [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(4): 1356-1362. |

| [7] | Fang-fang WEI,Li-ping LI,Qing-peng XU,You-zheng ZHAO,Jing-jing YANG. Experiment on seismic behavior of fire-fired composite shear wall with double steel plates and infill concrete after reinforcement [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 230-244. |

| [8] | Hao JIANG,Zheng-wen ZHAO. Experiment on shear performance of RC beams strengthened with basalt fiber grid cement-based composites [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 211-220. |

| [9] | Kai-feng WANG,Xing-yu MA,Jia-xing ZHU,Xiang-yang XU,Hao-cheng FENG,Yu-long LEI. Matching analysis and experimental verification of heavy-duty vehicle torsional shock absorbers [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 36-51. |

| [10] | Wei-song YANG,An ZHANG,Wei-xiao XU,Hai-sheng LI,Ke DU. Seismic performance of stiffness enhanced metal coupling beam damper [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2469-2483. |

| [11] | Bao-dong LIU,Fang LI,Xiao-xi WANG,Meng GAO. Flexural stiffness and bearing capacity of corrugated steel plate composite structures reinforced by concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2502-2510. |

| [12] | Han-hui HUANG,Kang-ming CHEN,Qing-xiong WU. Flexural behavior of composite continuous girders with concrete-filled steel tubular truss chords [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1665-1676. |

| [13] | Chun-lei ZHANG,Chang-yu SHAO,Qing-tian SU,Chang-yuan DAI. Experimental on positive bending behaviour of composite bridge decks with steel-fiber-reinforced concrete and longitudinal bulb-flat ribs [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1634-1642. |

| [14] | Shu-mei LOU,Yi-ming LI,Xin LI,Peng CHEN,Xue-feng BAI,Bao-jia CHENG. Thermal deformation behavior of graphene nanosheets reinforced 7075Al based on BP neural network and Arrhenius constitutive equation [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1237-1245. |

| [15] | Xiao-bo LIU,Miao YANG,De-kun ZHOU. Microstructure and wear resistance of (Mg2Si+Si)/Al composites [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 938-946. |

|

||