Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (3): 897-902.doi: 10.13229/j.cnki.jdxbgxb20180926

Previous Articles Next Articles

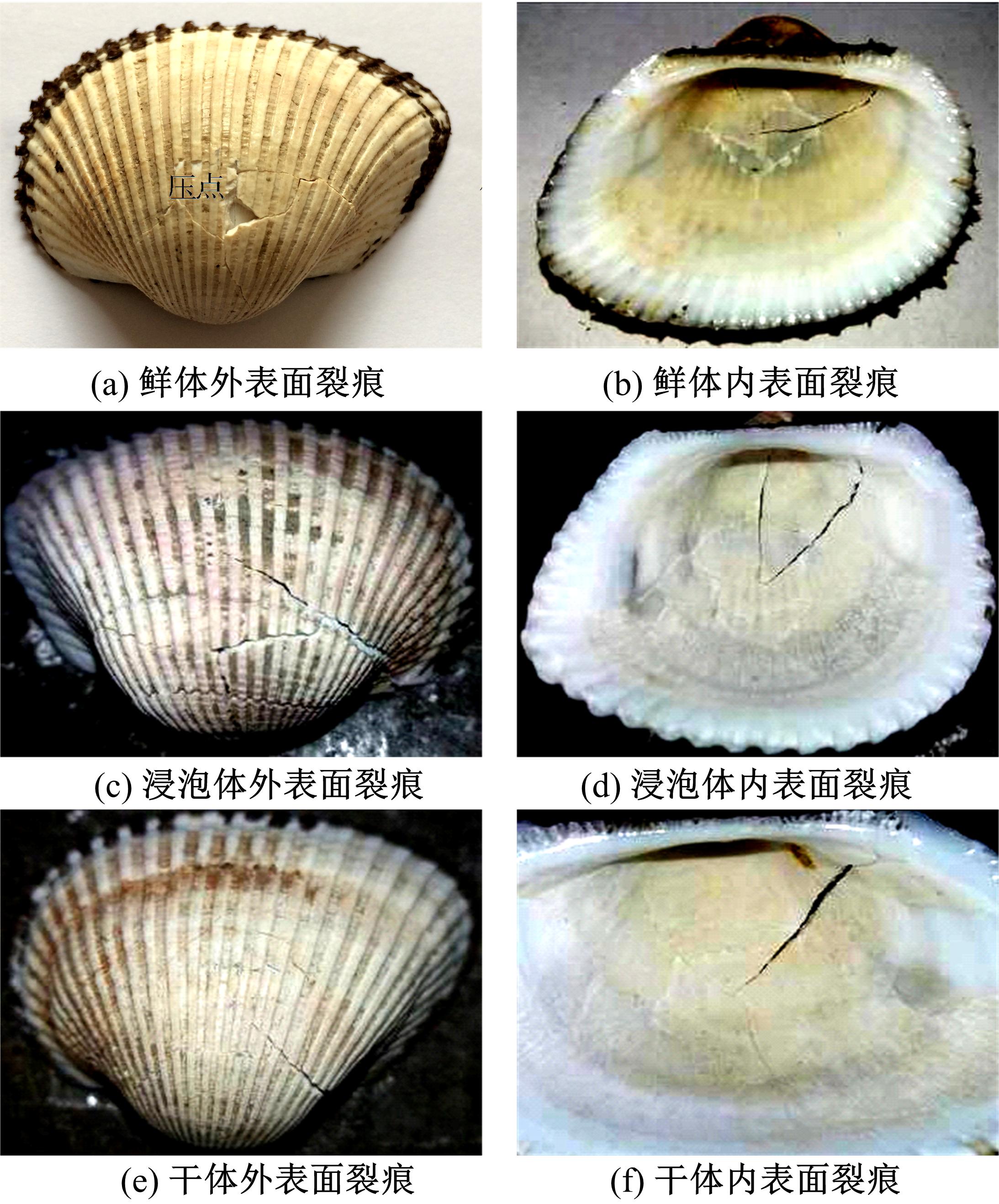

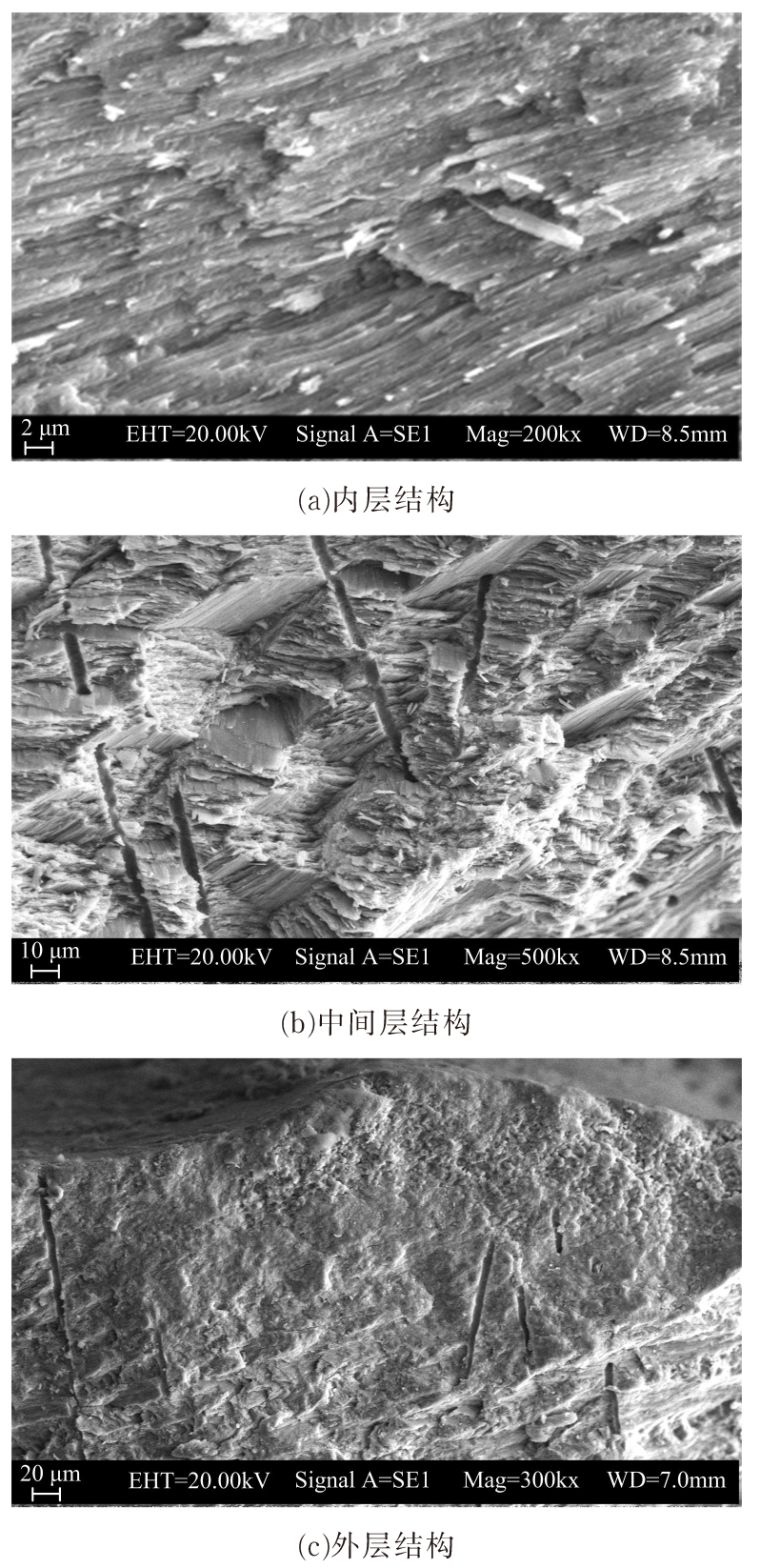

Compression mechanical properties and fracture mechanism of Scapharca Subcrenata shell

Na WU1( ),Jian ZHUANG2,Ke⁃song ZHANG1,Hui⁃xin WANG2,Yun⁃hai MA2(

),Jian ZHUANG2,Ke⁃song ZHANG1,Hui⁃xin WANG2,Yun⁃hai MA2( )

)

- 1. College of Automotive Engineering, ShanDong Jiaotong University, Jinan 250023, China

2. Key Laboratory of Bionic Engineering, Ministry of Education, Jilin University, Changchun 130022, China

CLC Number:

- TB17

| 1 | 马云海,刘玉成,彭杰,等 . 环文蛤角质层与棱柱层结合特性研究[J]. 农业机械学报,2013,44(增刊1):297⁃300. |

| Ma Yun⁃hai , Liu Yu⁃cheng , Peng Jie , et al . Binding characteristics of cuticle and prism Layer of cyclina sinensis[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013,44(Sup.1):297⁃300. | |

| 2 | Bruet B J F , Qi H J , Boyce M C , et al . Nanoscale morphology and indentation of individual nacre tablets from the gastropod mollusc trochus niliticus[J].Journal of Materials Research, 2005,20(9):2400⁃2419. |

| 3 | Sun J Y , Bhushan B . Hierarchical structure and mechanical properties of nacre: a review[J]. RSC Advances,2012,2(20):7617⁃7632. |

| 4 | Tian X M , Han Z W , Li X J , et al . Biological coupling anti⁃wear properties of three typical molluscan shell⁃Scapharca subcrenata, Rapana venosa, Acanthochiton rubrolineatus[J]. Science China Technological Science, 2010,53(11): 2905⁃2913. |

| 5 | Xia S , Wang Z N , Chen H ,et al . Nanoasperity: structure origin of nacre⁃inspired nanocom⁃ posites[J].ACS Nano,2015, 9(2):2167⁃2172. |

| 6 | Zlotnikov Igor , Schoeppler Vanessa .Thermodynamic aspects of molluscan shell ultrastructural morphogenesis[J]. Advanced Functional Material, 2017,27(28):1⁃14. |

| 7 | Suzuki Michio , Nagasawa Hiromichi . Mollusk shell structures and their formation mechanism[J]. Canadian Journal of Zoology⁃Revue Canadienne De Zoologie, 2013,91(6):349⁃366. |

| 8 | Mao L B , Gao H L , Yao H B , et al . Synthetic nacre by predesigned matrix⁃directed mineralization[J]. Science, 2016, 354(6308):107⁃110. |

| 9 | Cheng Q F , Jiang L , Tang Z Y . Bioinspired layered materials with superior mechanical performance[J]. Accounts of Chemical Research, 2014,47(4):1256⁃1266. |

| 10 | Duan J L , Gong S S , Gao Y ,et al . Bioinspired ternary artificial nacre nanocomposites based on reduced graphene oxide and nanofibrillar cellulose[J]. ACS Applied Materials & Interfaces, 2016, 8 (16):10545–10550. |

| 11 | Jackson A P , Vincent J F V , Ihrner R M . The mechanical design of nacre[J]. Proceedings of the Royal Society of London, 1988,234(1277):415⁃440. |

| 12 | Barthelat F , Tang H , Zavattieri P D , et al . On the mechanics of mother⁃of⁃pearl:A key feature in the material hierarchical structure[J]. Journal of the Mechanics & Physics of Solids, 2007,55(2):306⁃337. |

| 13 | Barthelat F , Espinosa H D . Mechanical properties of nacre constituents:an inverse method approach in mechanical properties of bioinspired and biological materials[J]. Materials Research Society Proceedings, 2004, 844: 67⁃78. |

| 14 | 田喜梅 .典型贝类壳体生物耦合特性及其仿生耐磨研究[D]. 长春:吉林大学生物与农业工程学院,2013. |

| Tian Xi⁃mei . Biological coupling and bionic anti⁃wear properties of typical molluscan shells[D]. Changchun: College of Biological and Agricultural Engineering, Jilin University, 2013. | |

| 15 | Albert L , Marc A M . Growth and structure in abalone shell[J]. Material Science and Engineering:A, 2005,390(1/2): 27⁃41. |

| [1] | XI Peng,CONG Qian,WANG Qing-bo,GUO Hua-xi. Wear test and anti-friction mechanism analysis of bionic stripe grinding roll [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1787-1792. |

| [2] | GUO Hao-tian,XU Tao,LIANG Xiao,YU Zheng-lei,LIU Huan,MA Long. Optimization on thermal surface with rib turbulator inspired by turbulence of alopias' gill in simplified gas turbine transition piece [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1793-1798. |

| [3] | JIANG Qiu-yue,YANG Hai-feng,TAN Cai-wang. Strengthening properties of welded joints of 22MnB5 super high strength steel [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1806-1810. |

| [4] | QIAN Zhi-hui, ZHOU Liang, REN Lei, REN Lu-quan. Completely passive walking machine with bionic subtalar joint and matatarsal phalangeal joint [J]. 吉林大学学报(工学版), 2018, 48(1): 205-211. |

| [5] | GE Chang-jiang, YE Hui, HU Xing-jun, YU Zheng-lei. Prediction and control of trailing edge noise on owl wings [J]. 吉林大学学报(工学版), 2016, 46(6): 1981-1986. |

| [6] | LI Meng, SU Yi-nao, SUN You-hong, GAO Ke. High matrix bionic abnormal shape impregnated diamond bit [J]. 吉林大学学报(工学版), 2016, 46(5): 1540-1545. |

| [7] | LIANG Yun-hong, REN Lu-quan. Preliminary study of habitat and its bionics [J]. 吉林大学学报(工学版), 2016, 46(5): 1746-1756. |

| [8] | LIANG Yun-hong, REN Lu-quan. Preliminary study of bionics in human life [J]. 吉林大学学报(工学版), 2016, 46(4): 1373-1384. |

| [9] | QIAN Zhi-hui, MIAO Huai-bin, REN Lei, REN Lu-quan. Lower limb joint angles of German shepherd dog during foot-ground contact in different gait patterns [J]. 吉林大学学报(工学版), 2015, 45(6): 1857-1862. |

| [10] | ZOU Meng, YU Yong-jun, ZHANG Rong-rong, WEI Can-gang, WANG Hui-xia. Simulation analysis of energy-absorption properties of thin-wall tube based on horn structure [J]. 吉林大学学报(工学版), 2015, 45(6): 1863-1868. |

| [11] | YANG Zhuo-juan, WANG Qing-cheng, GAO Ying, MEN Yu-zhuo, YANG Xiao-dong. Effect of different solutions on the wettability of lotus leaves [J]. 吉林大学学报(工学版), 2015, 45(6): 1869-1873. |

| [12] | TIAN Wei-jun, WANG Ji-yue1, LI Ming1, CHEN Si-yuan, LIU Fang-yuan, CONG Qian. Bionic design of the small blade of horizontal axis wind turbines [J]. 吉林大学学报(工学版), 2015, 45(5): 1495-1501. |

| [13] | TIAN Gui-zhong, LIU Zhi-ling, ZHOU Hong-gen, SONG Jiang-chao, ZHU Tao. Quasi-static axial tensile mechanical characteristics of silkworm's anterior silk gland [J]. 吉林大学学报(工学版), 2015, 45(3): 872-877. |

| [14] | DENG Cheng-jiang, HE Xiao-cong, XING Bao-ying, WANG Yu-qi, ZENG Kai, DING Yan-fang. Mechanical properties of self-piercing riveted lap joints in dissimilar metal sheets of aluminum and copper [J]. 吉林大学学报(工学版), 2015, 45(2): 473-480. |

| [15] | DUAN Xing-wang,LIU Jian-sheng. Plasticity at elevated temperature and fracture character of 316LN steel [J]. 吉林大学学报(工学版), 2015, 45(2): 494-500. |

|